Patents

Literature

43results about How to "Affect flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

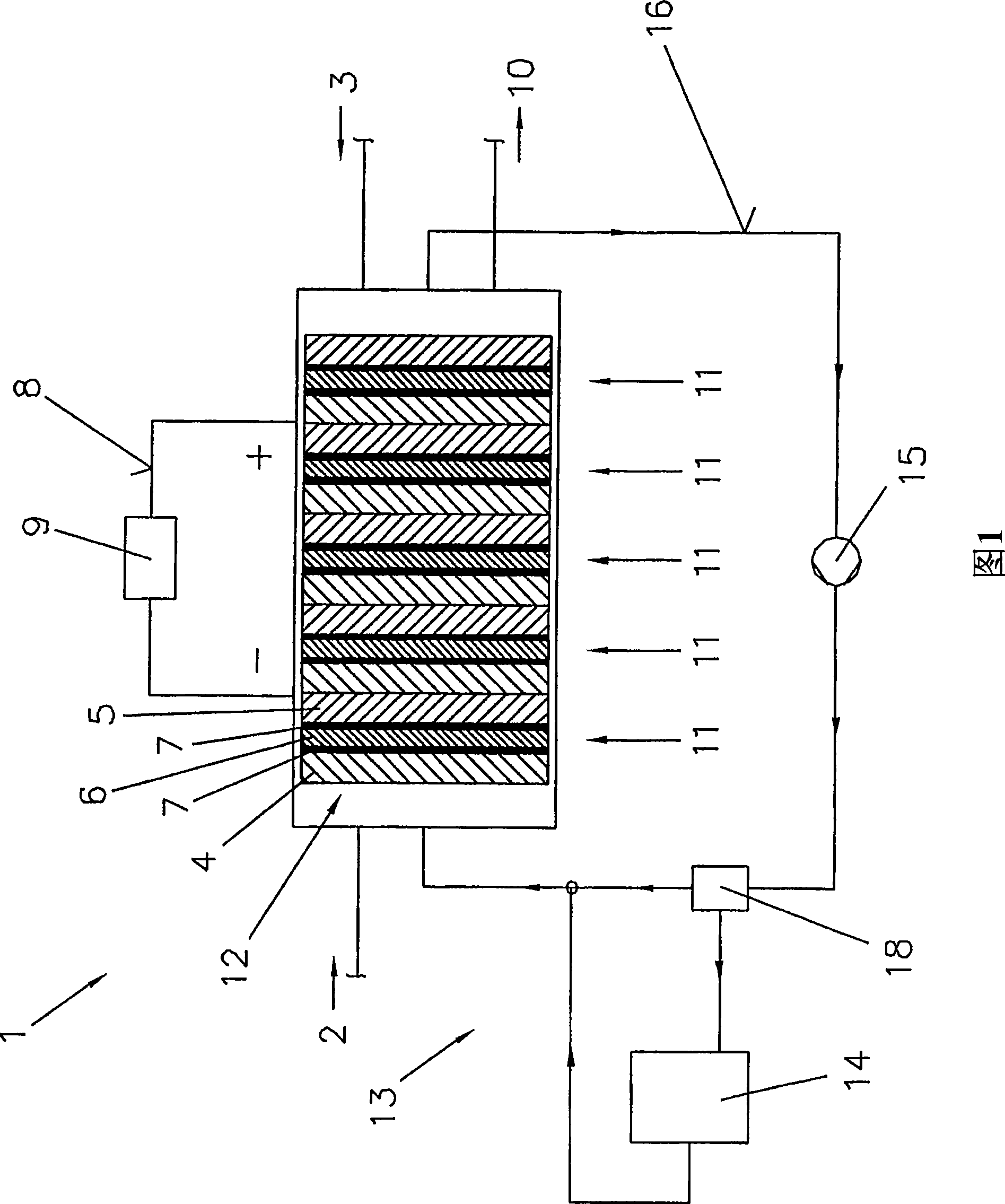

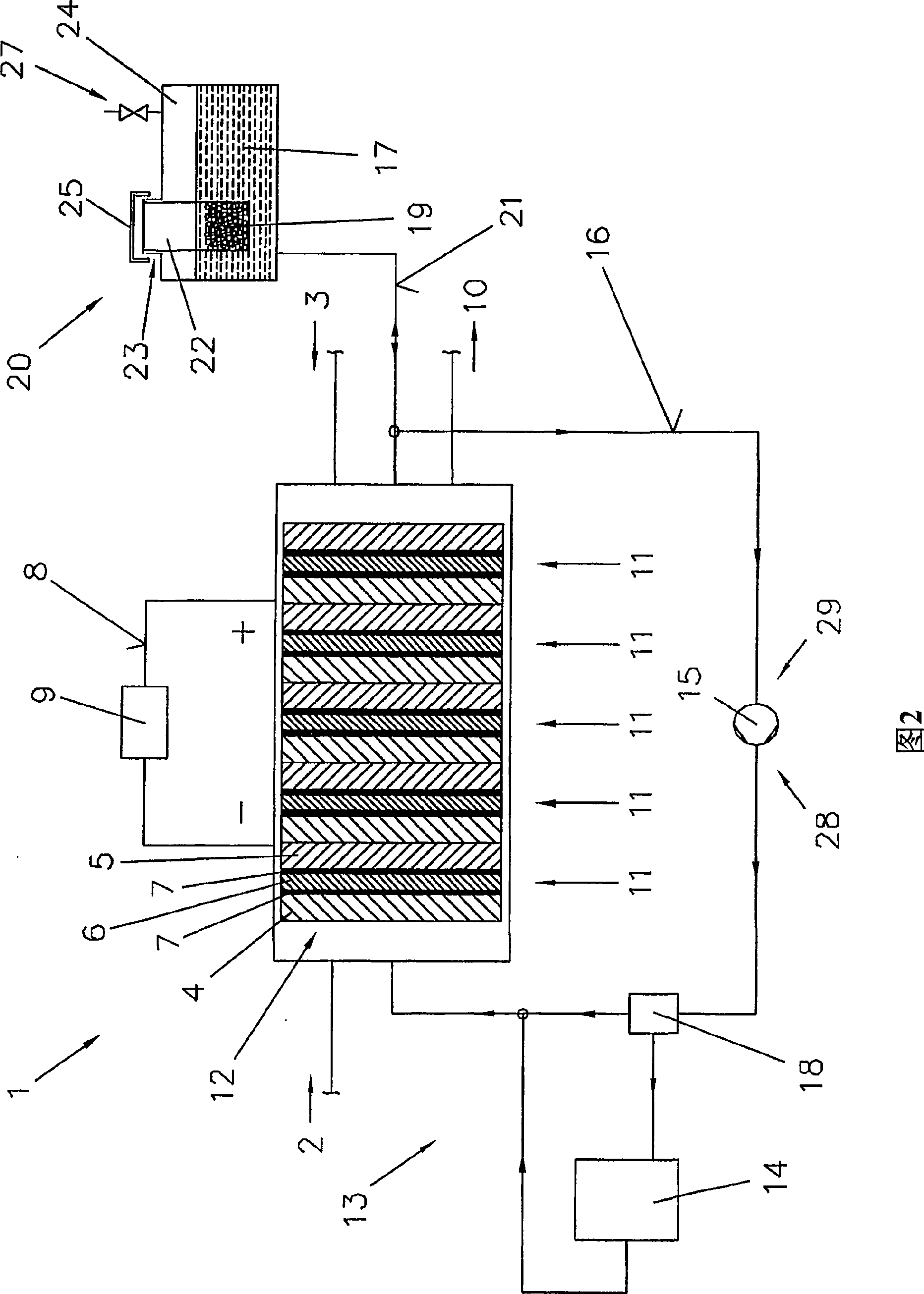

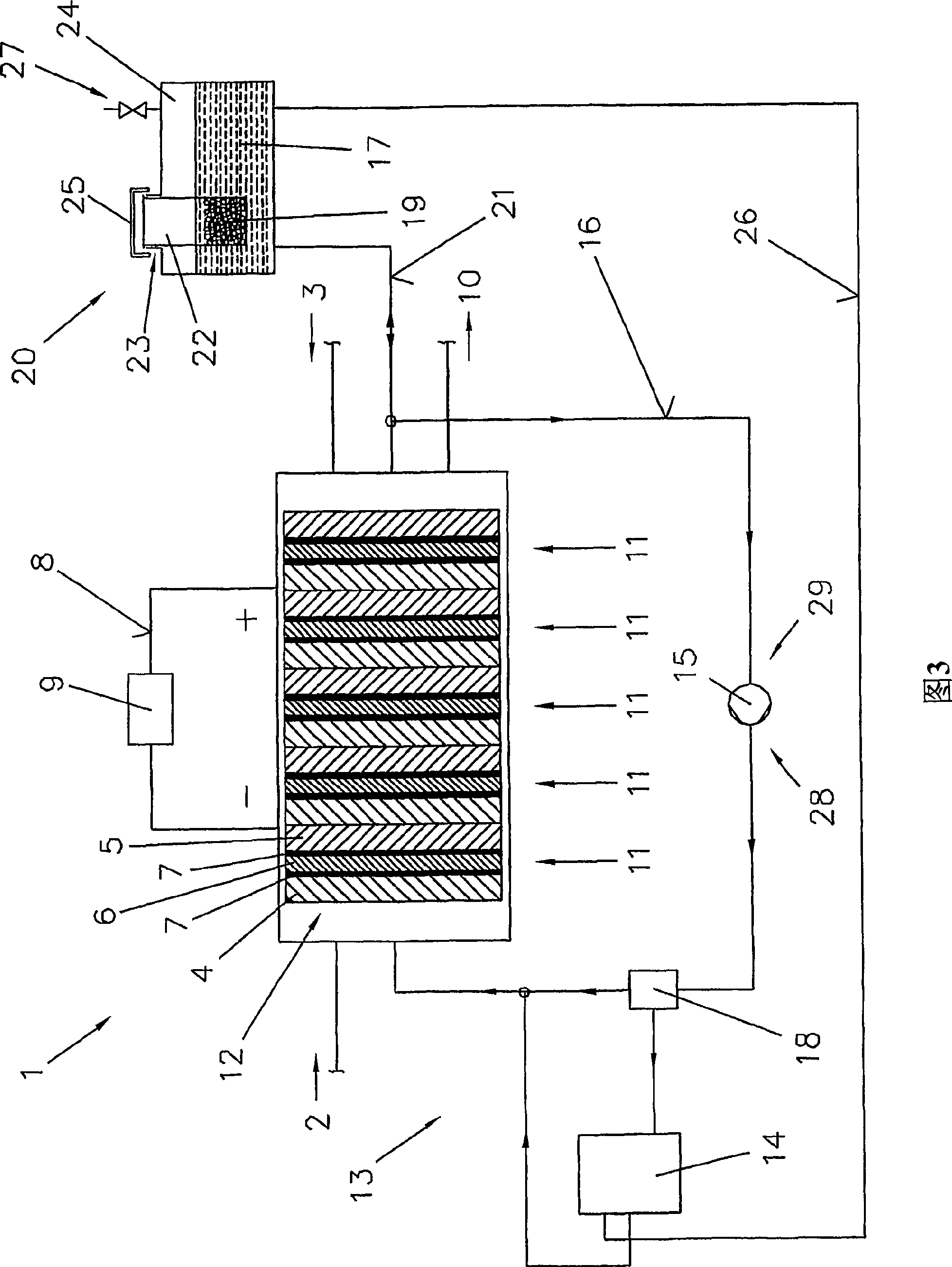

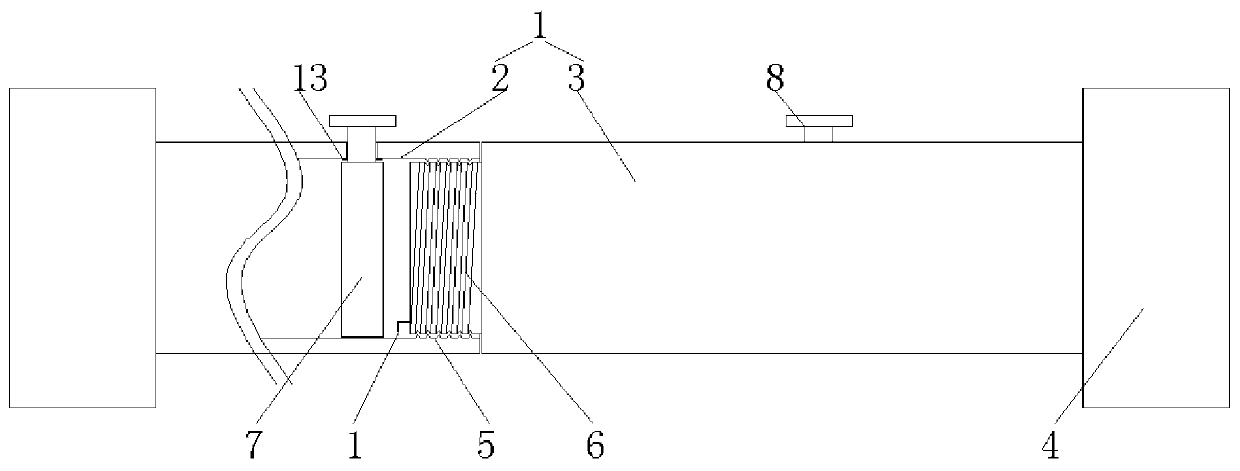

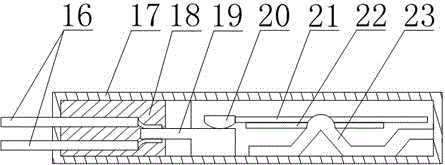

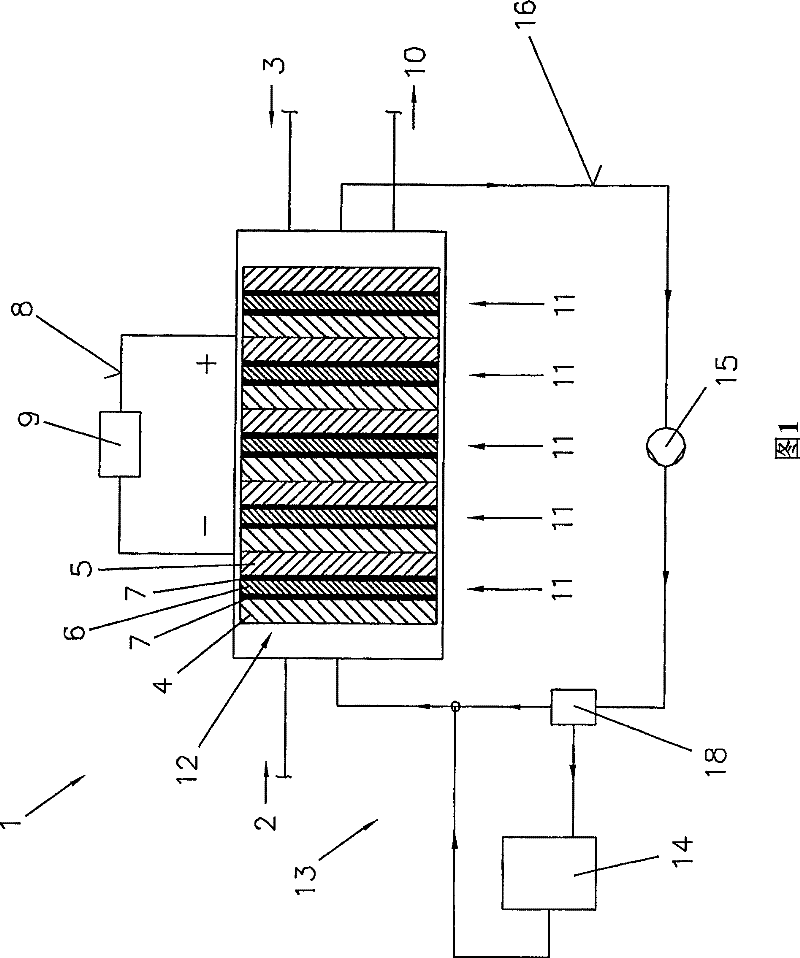

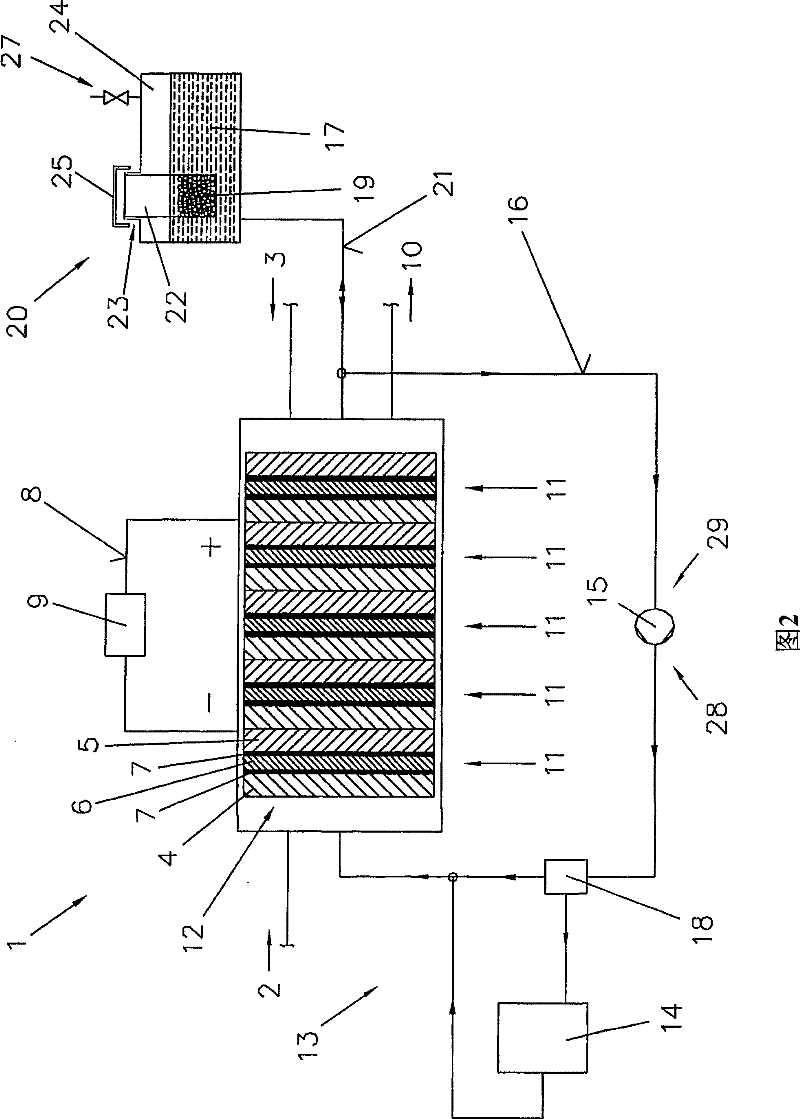

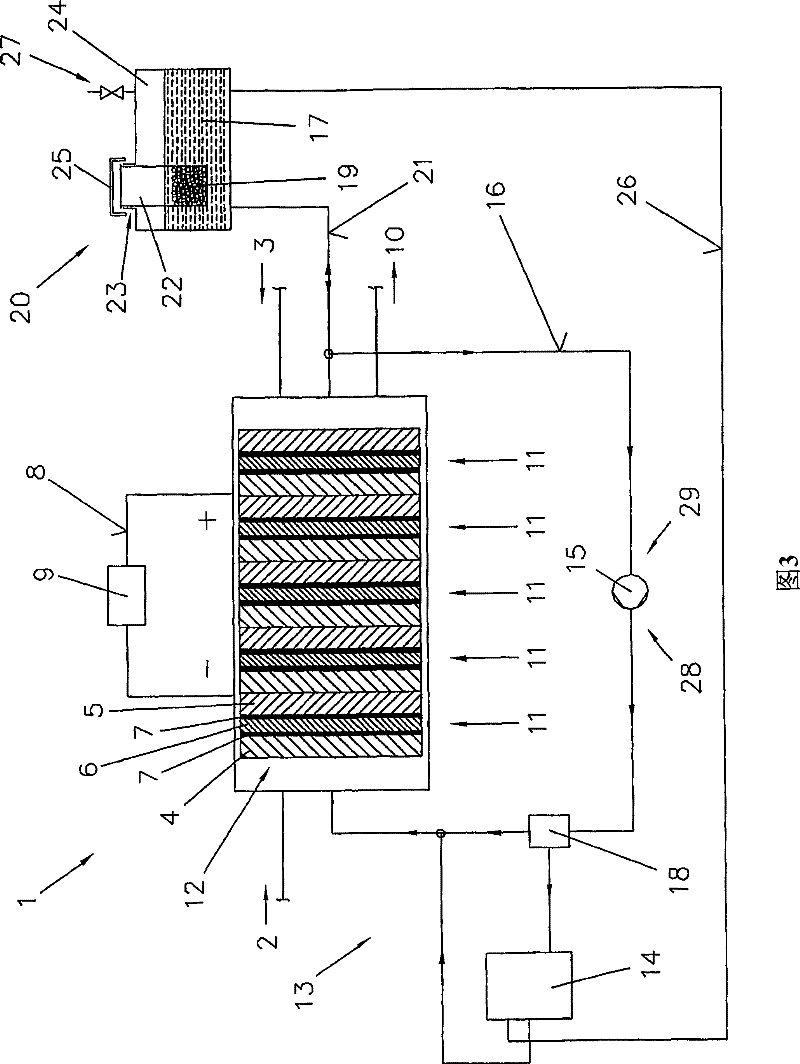

Cooling system for a fuel cell

The invention relates to a cooling system (13) for a fuel cell (1) having at least one cooler (14), a thermostat (18), a pump (15) for delivering a coolant (17) in a cooling cycle (16), and having an equalization container (20), wherein a deionizing resin (19), which is arranged in the equalization container (20), is provided for reducing the electrical conductivity of the coolant (17), and wherein the equalization container (20) is connected to the cooling cycle (16) via at least one line (21). In order to provide such a cooling system (13), in which the electrical conductivity of the coolant (17) can be kept continuously low in a simple and cost-effective manner, provision is made for the deionizing resin (19) to be arranged in a container (22) in an interior (24) of the equalization container (20) such that the deionizing resin (19) enters at least partially into the coolant (17) and the line (21), which connects the equalization container (20) and the cooling cycle (16), is freely accessible.

Owner:FRONIUS INTERNATIONAL GMBH

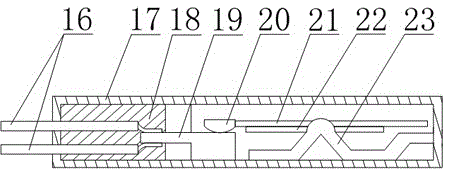

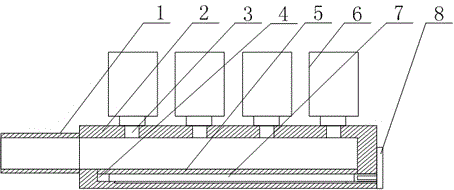

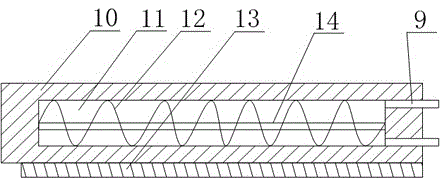

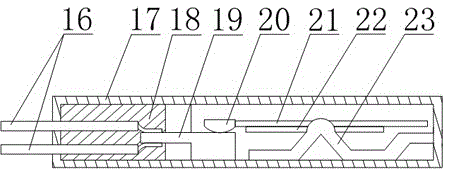

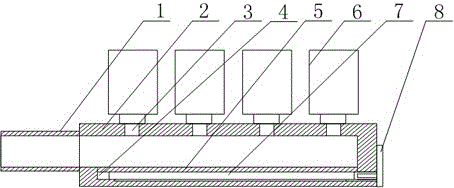

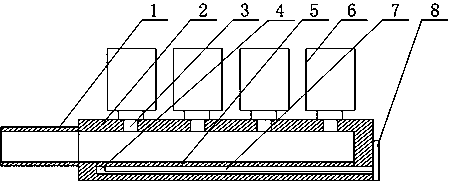

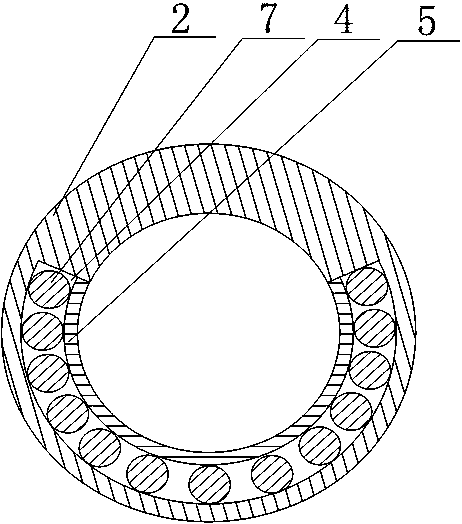

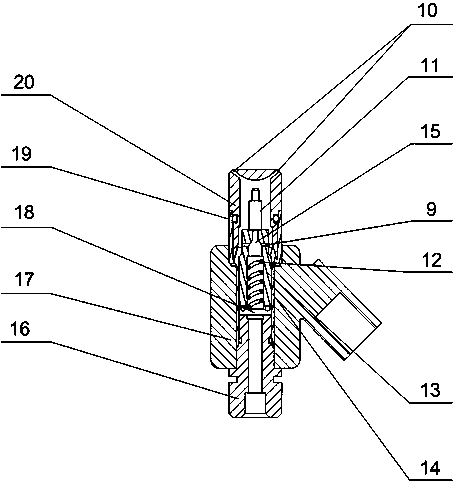

Gas injection device for automobile

InactiveCN105604743AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityHeat conducting

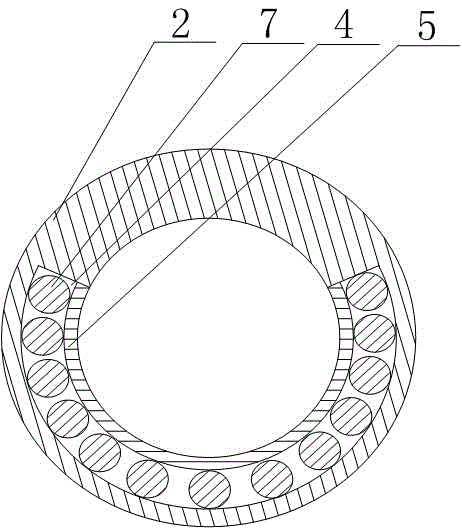

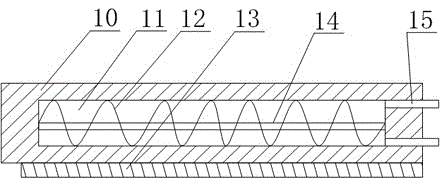

The invention discloses a gas injection device for an automobile. The gas injection device comprises a gas inlet pipe and a hollow pipe, wherein a groove of which the section is a major arc is formed in the inner wall of the hollow pipe; injection holes are just opposite to the arc bottom of the groove; a plurality of electric heating tubes are arranged in the groove; a guide block is arranged at the bottoms of the electric heating tubes; a guide groove matched with the guide block is formed in the bottom of the groove; each electric heating tube comprises a tube body, an insulated material filling the inside of the tube body and an electric heating wire arranged inside the tube body; a binding post is connected to the tail end of each electric heating wire, penetrates through a small hole and is connected with a wiring plug board; a heat conducting board covers the opening end of the groove. The plurality of electric heating tubes are arranged in the arc groove; the side end of the groove is sealed by the wiring plug board, so that the heat dissipation can be reduced; meanwhile, the electric hating tubes are favorably taken and placed, i.e., a user can determine the number of the electric heating tubes in real time according to the supply amount of gas, so that stable operation for gas output flow is finished at the minimum heating cost.

Owner:CHENGDU DUJIA ELECTRICAL

Anti-deformation process for hot-melting socket welding of thin-wall plastic pipe

The invention discloses an anti-deformation process for hot-melting socket welding of a thin-wall plastic pipe. The anti-deformation process comprises the following step of: step 1: conducting preparatory work; and step 2, hot-melting socket: simultaneously heating and melting the outer surface of the end part of an inner pipe and the inner surface of the end part of an outer pipe by using a heating tool, and mutually inserting the end parts of the inner pipe and the outer pipe after the surfaces are melted, and then a flattening mechanism is pushed to the outside of the outer pipe connectingend to flatten the end of the outer pipe, the fusion end of the inner pipe and the fusion end of the outer pipe can be solidified after 15-20 seconds, and pipeline connection is completed. The invention relates to the technical field of pipeline installation. According to the anti-deformation process for hot-melting socket welding of the thin-wall plastic pipe, a hard lining is arranged to supportthe inner wall of the inner pipe, so that inward collapse of the pipe during hot-melting welding can be avoided, the whole lining is made of a water-soluble material, and the lining can be graduallydispersed by water and dissolved in water during later used. The inner diameter of the inner pipe is not reduced due to the thickness of the inner pipe, the flow speed of water flow is not affected, the supporting effect is good, the lining does not need to be taken out, and using is convenient.

Owner:严金金

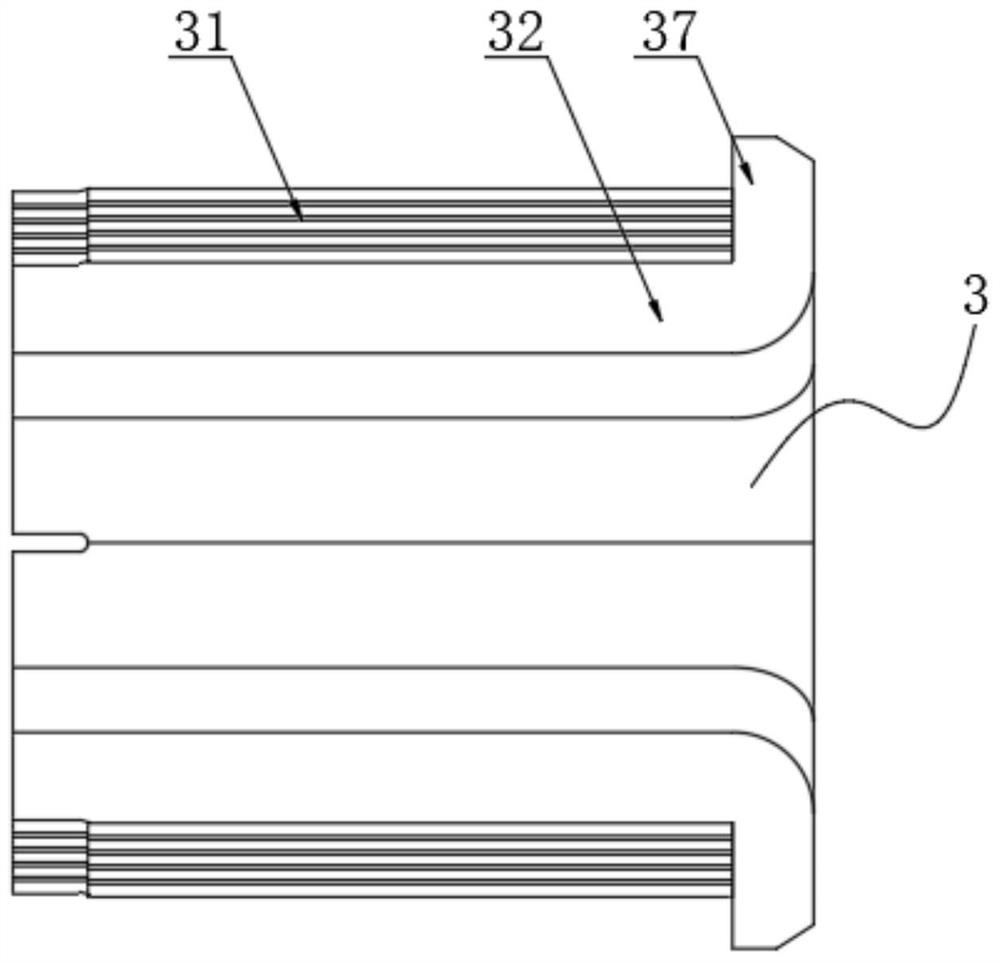

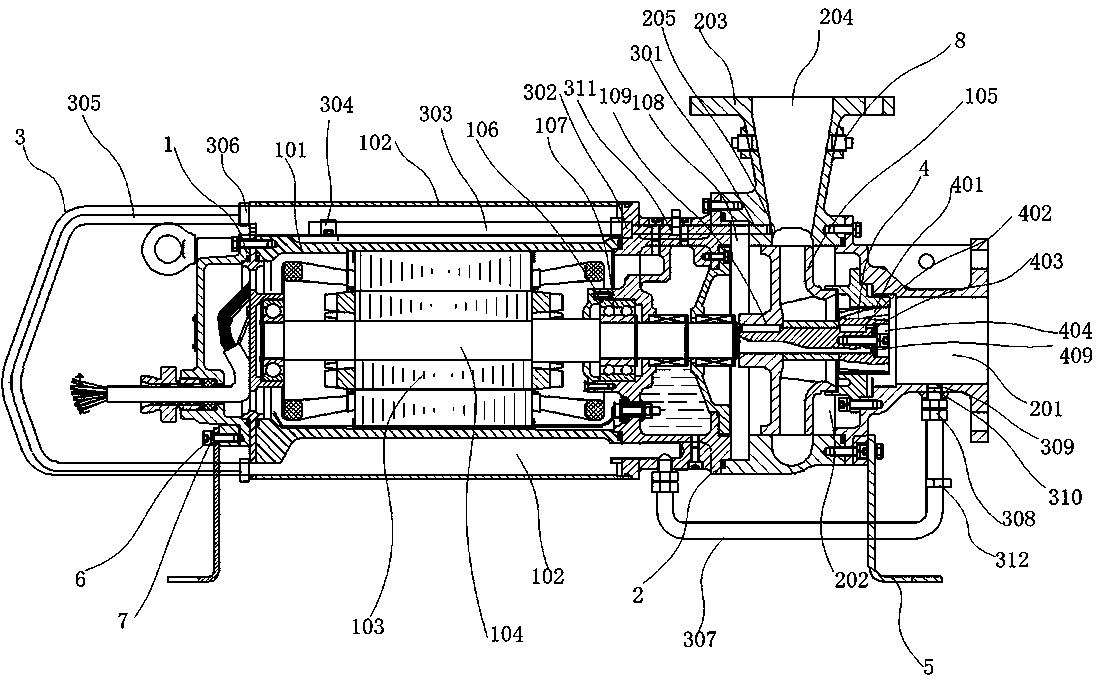

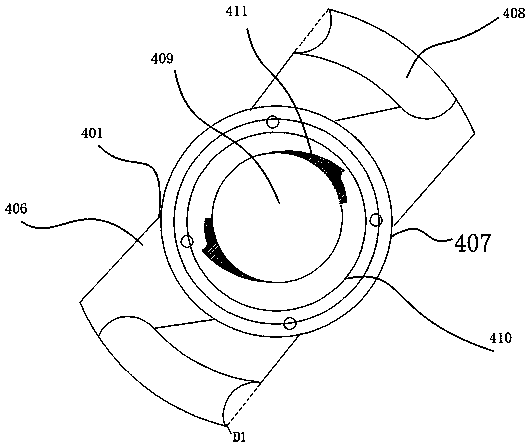

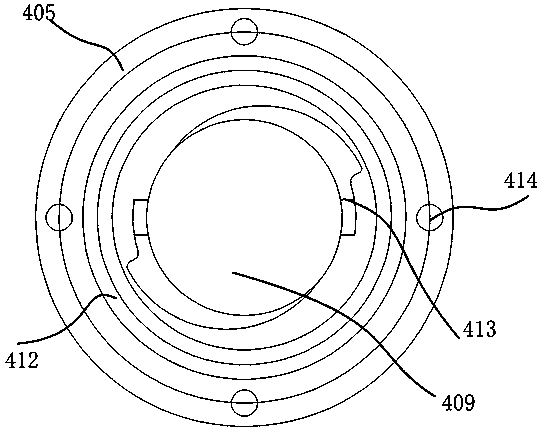

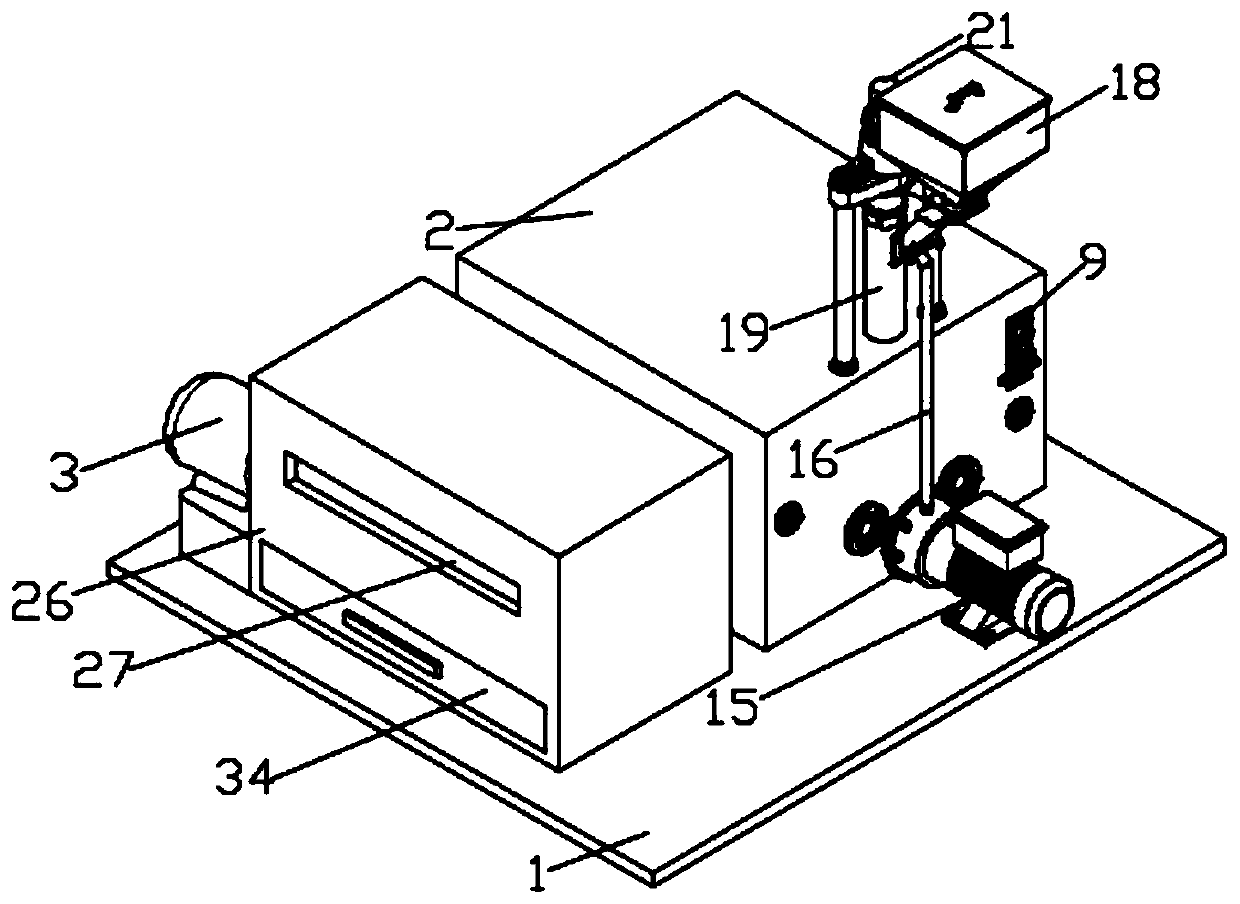

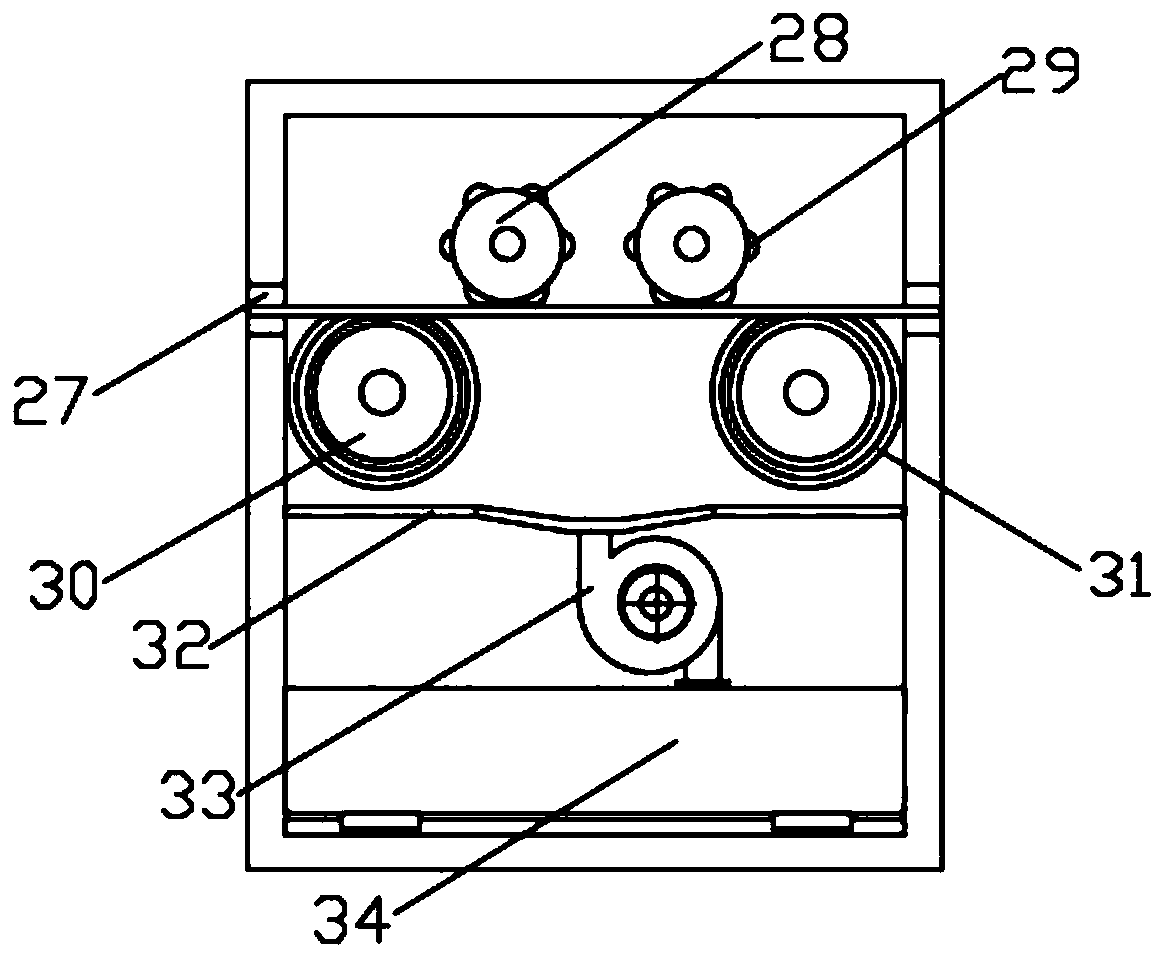

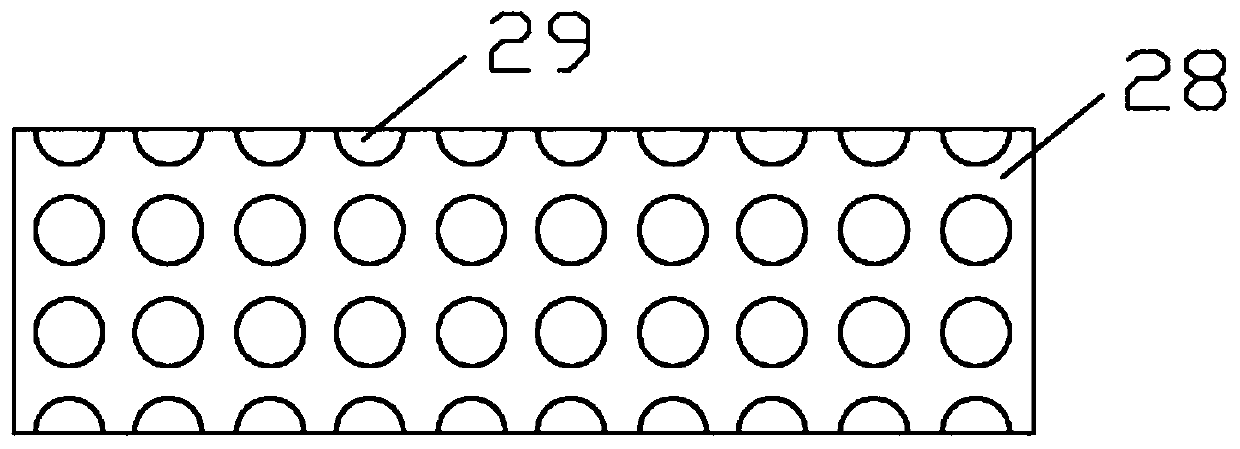

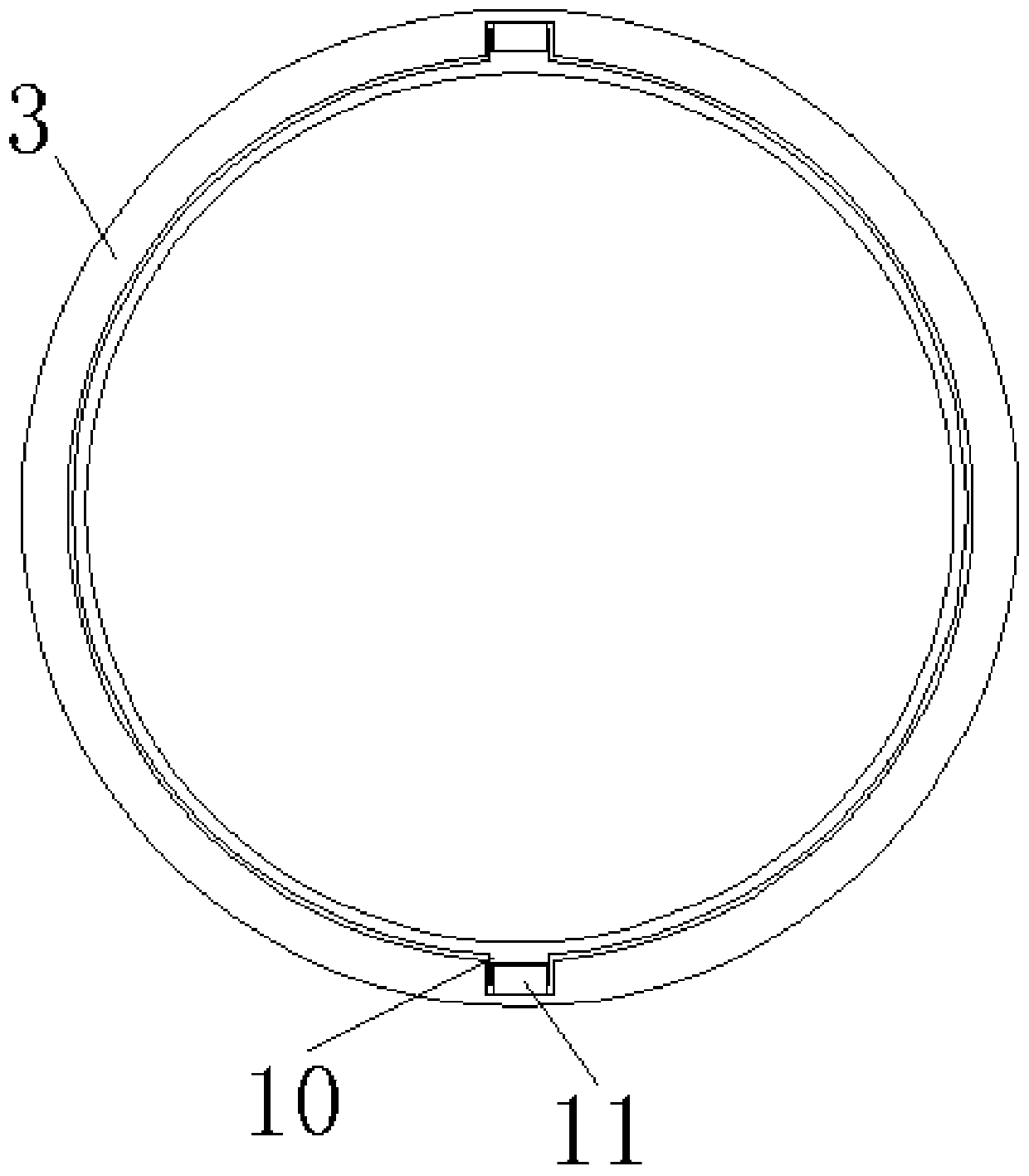

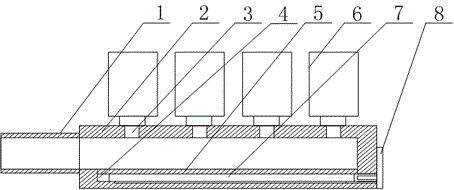

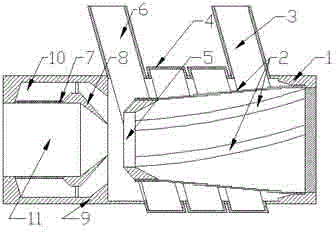

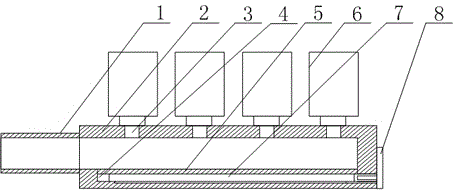

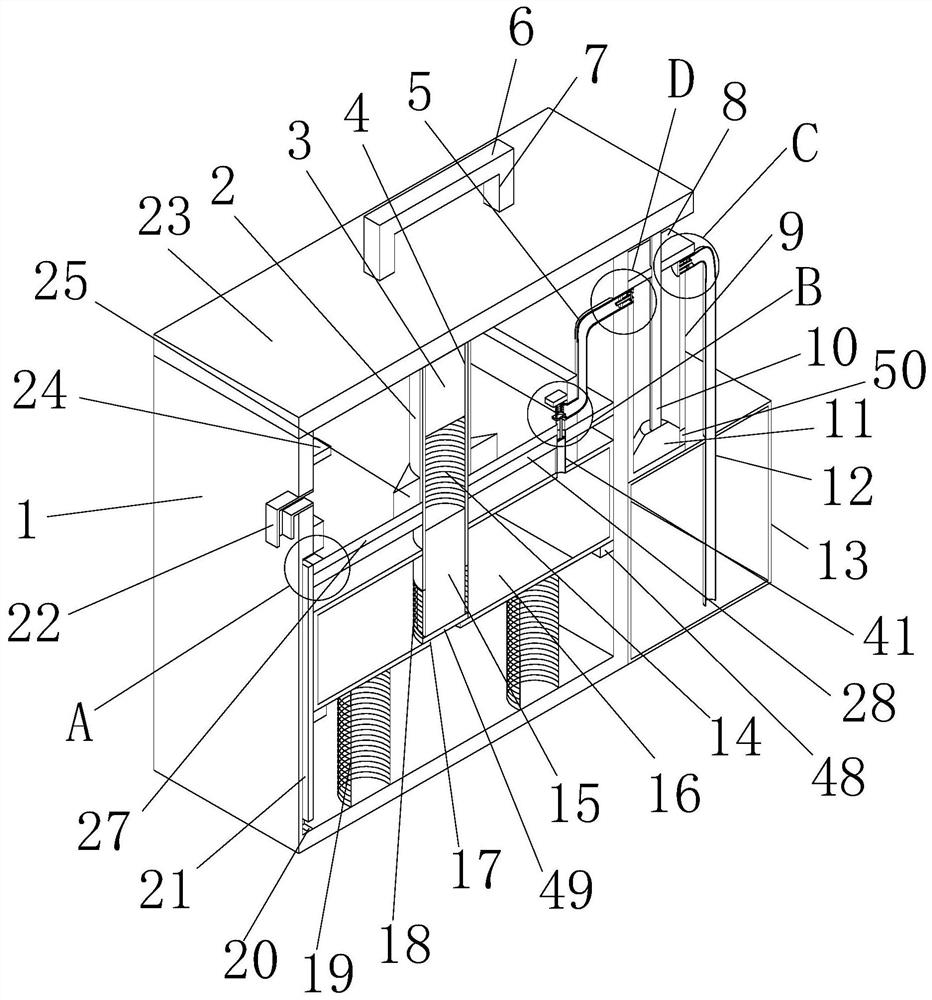

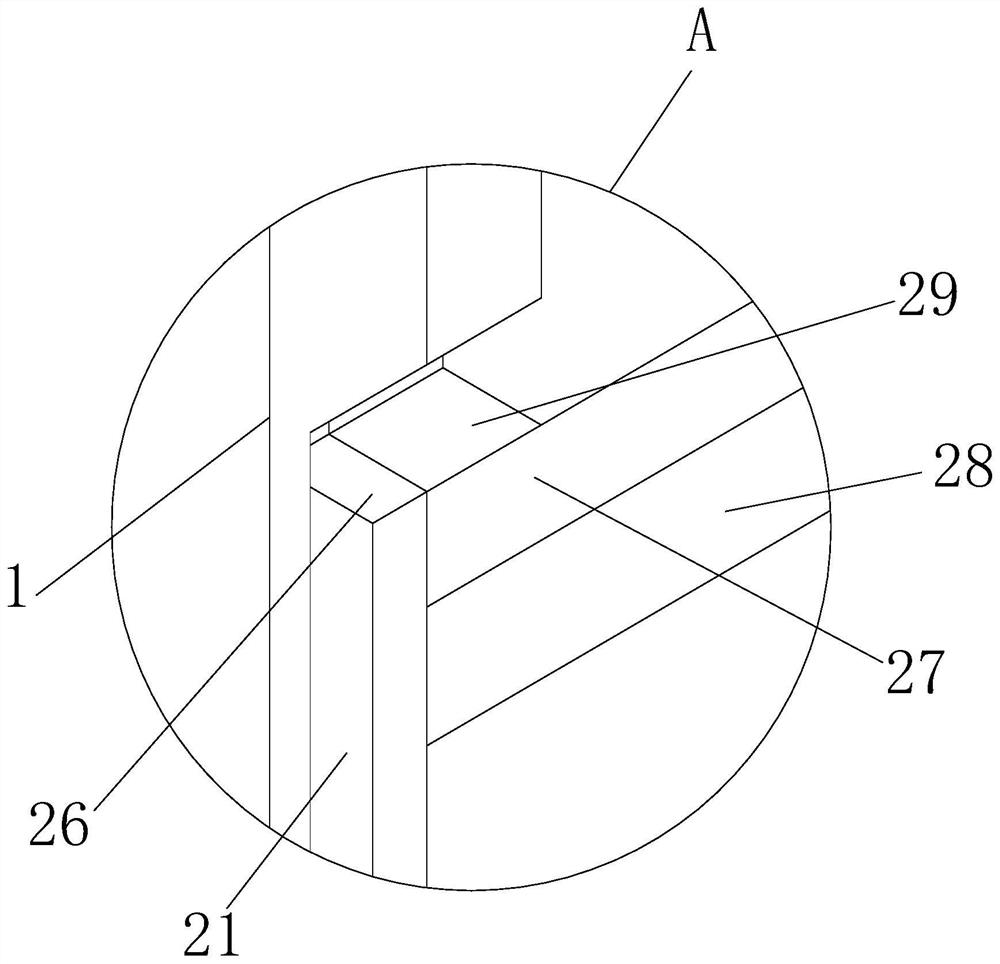

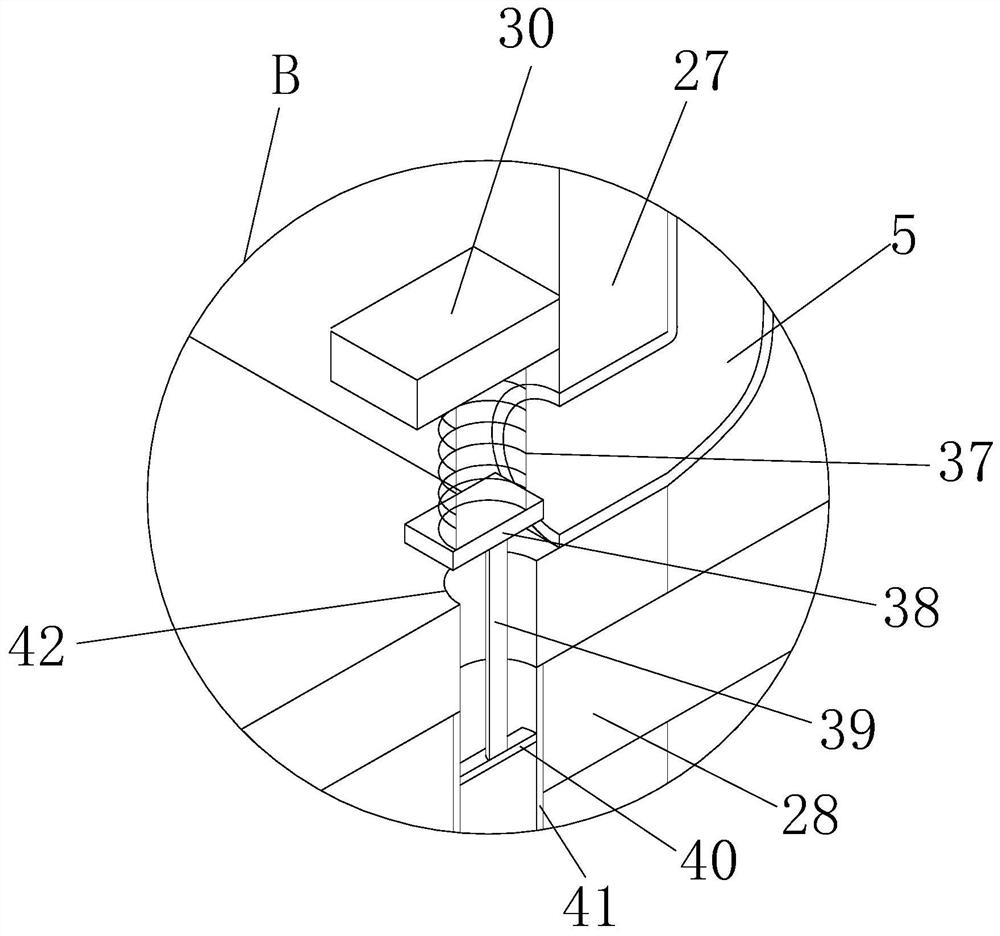

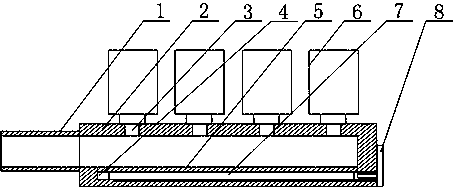

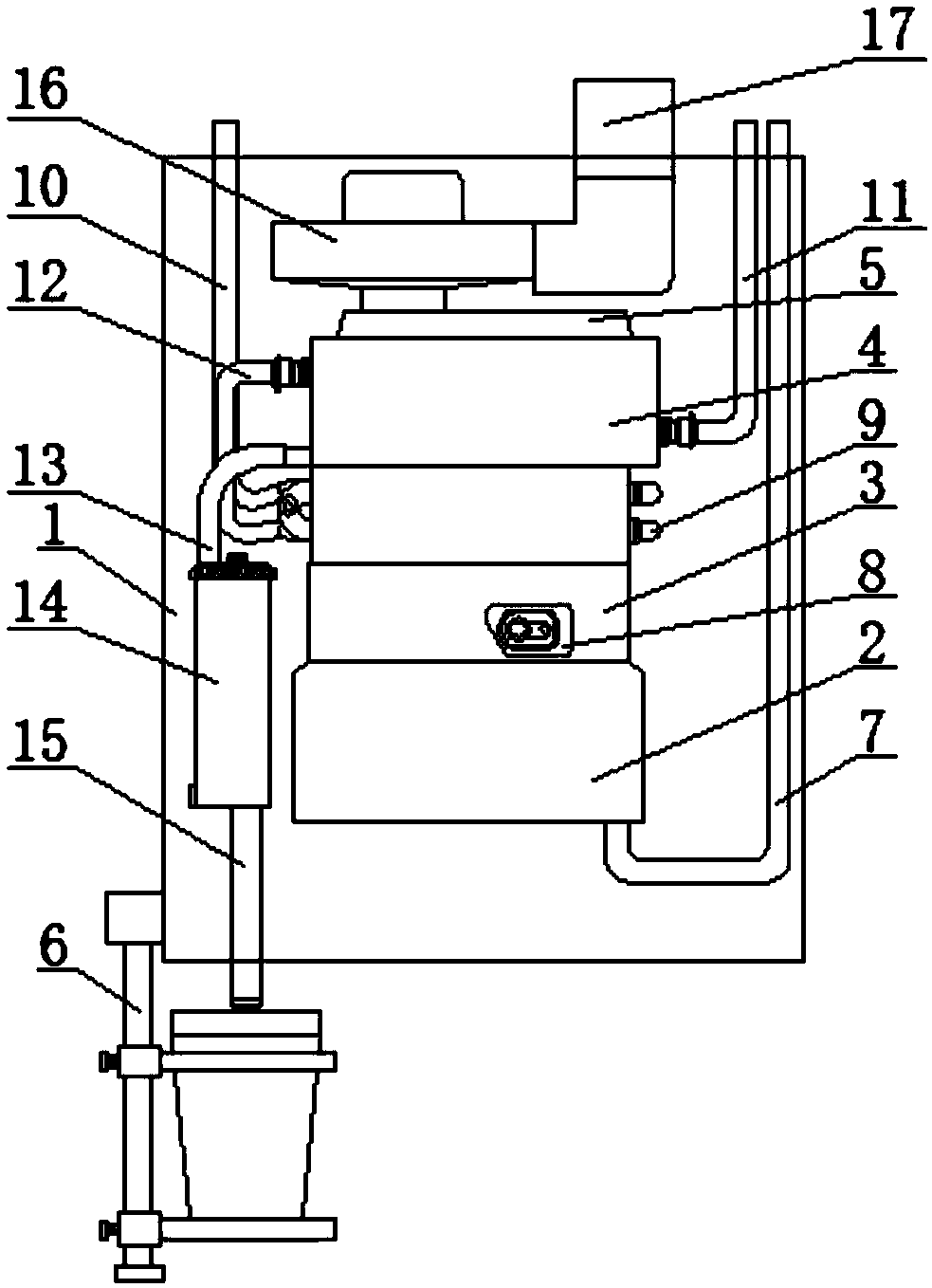

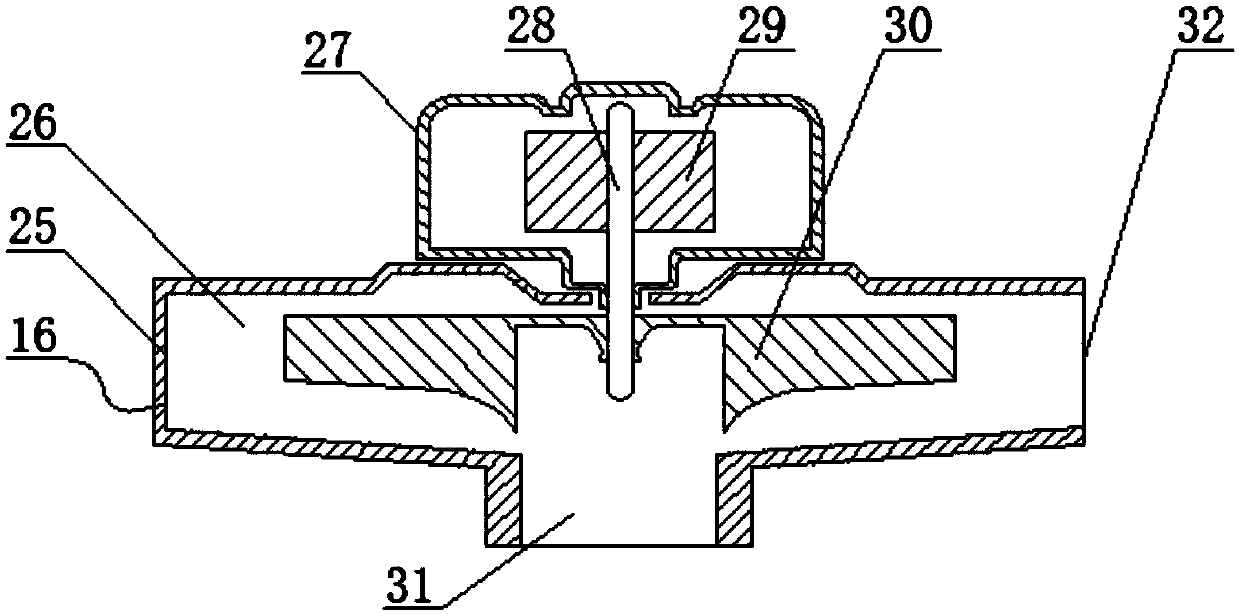

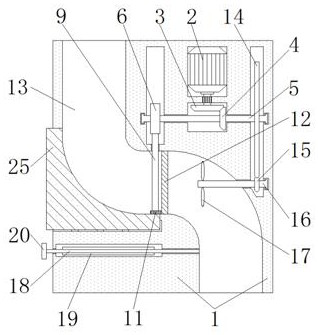

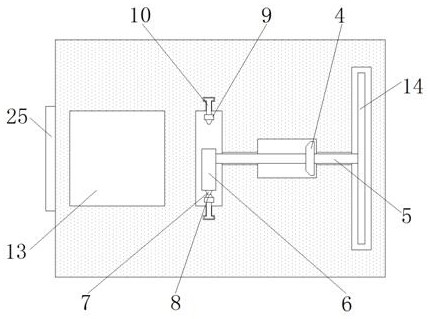

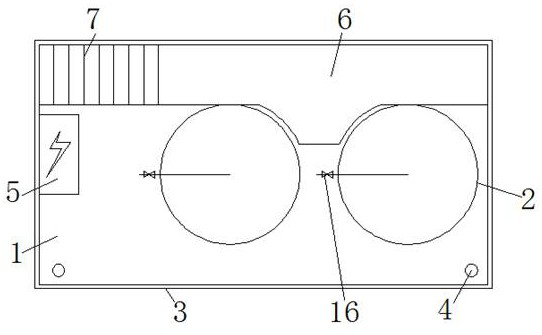

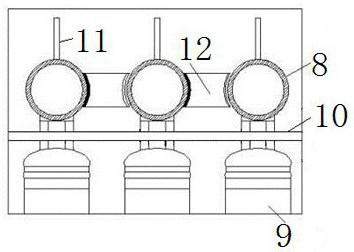

Bedroom cold water pump

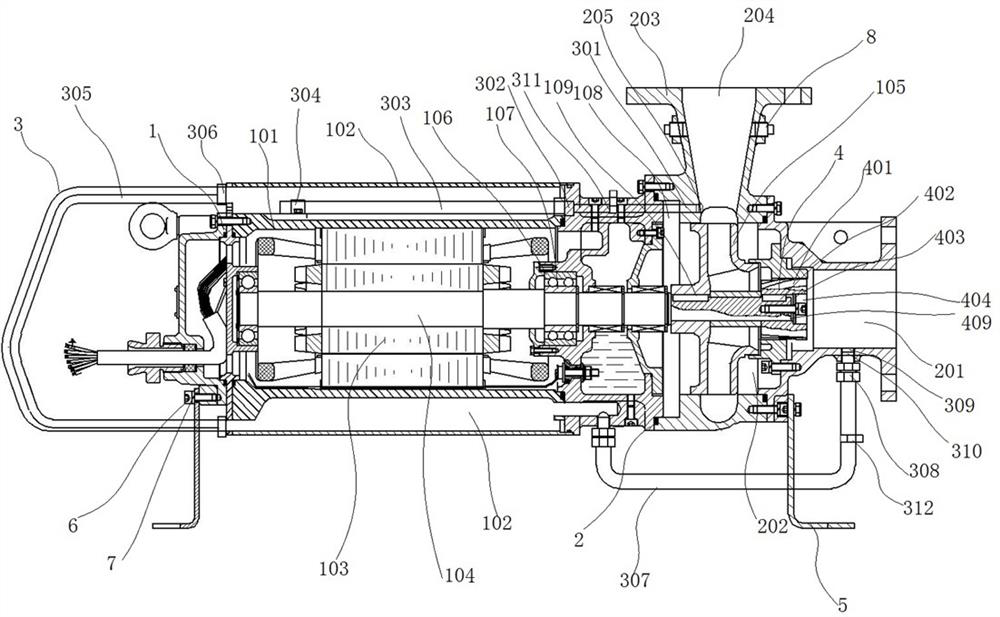

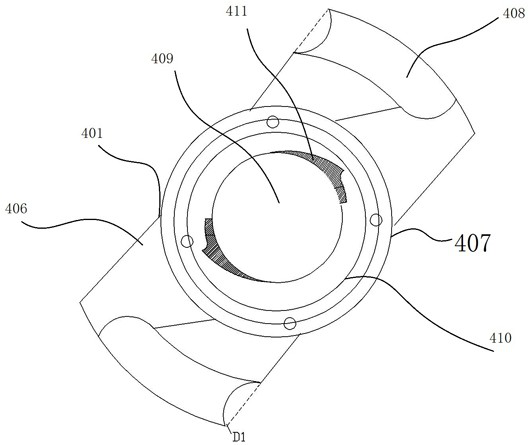

ActiveCN109812422ARapid coolingAvoid failureSpecific fluid pumpsPump componentsClamp connectionEngineering

The invention discloses a bedroom cold water pump comprising a motor part assembly, a volute assembly, a circulating cooling filter assembly and a cutting assembly. One part of water of a sewage outlet of a water outlet base of the volute assembly is introduced into a cooling sealing cavity in the motor part assembly through the circulating cooling filter assembly, sewage is used for circularly cooling a motor in a motor sealing cavity, energy utilization of resources is achieved, and the motor can be rapidly cooled. The cutting assembly is arranged in the volute assembly, arc tool slots are arranged on the two sides of the bottom end of a cutting tool bit in a mirror image mode, the rotary cutting efficiency of the two ends of the cutting tool bit can be improved through the arc tool slots, hard impurities can be rapidly cut, and the cutting effect is good. A thread protruding ring is in clamped connection with the interior of a ring-hook-shaped avoiding groove and is fixed through aconnection bolt, and connection firmness between the cutting tool bit and a cutting port ring part can be effectively ensured. By means of up-down matching arrangement of the cutting tool bit and thecutting port ring part, impurities are not likely to be clamped in the cutting assembly to caused faults and damage.

Owner:TAIZHOU TAIFENG PUMP IND

Antibacterial and disinfectant ultra-soft floor wet wipe and preparation method thereof

The invention discloses an antibacterial and disinfectant ultra-soft floor wet wipe and a preparation method thereof. Antibacterial and disinfectant liquid prepared by uniformly mixing cetyl pyridinium chloride, phenoxyethanol, glycerol, benzalkonium chloride, chamomile extracting solution, olive oil, citric acid and deionized water has god sterilization and disinfection effects; meanwhile, a carding fiber net, a modified hot melt fiber net, a hot rolled fiber net absorption layer and a water absorption fiber layer are subjected to spunlace reinforcement so that the winding of the whole is firm; no layering phenomenon occurs; and a prepared semi-finished product wet wipe has good permeability and softness. The antibacterial and disinfectant liquid at the bottom of a dip dyeing box is pumped by a water pump and is discharged to a connecting pipe through a liquid extraction pipe; the antibacterial and disinfectant liquid enters a liquid discharging pipe through the connecting pipe; an output shaft of a second motor drives a driving shaft to rotate; the driving shaft drives a shaft sleeve arranged on the surface to rotate; the shaft sleeve drives a stirring rod to stir the antibacterial and disinfectant liquid; and meanwhile, a scale removal pad is driven to remove scales on the inner wall of the liquid discharging pipe.

Owner:铜陵麟安生物科技有限公司

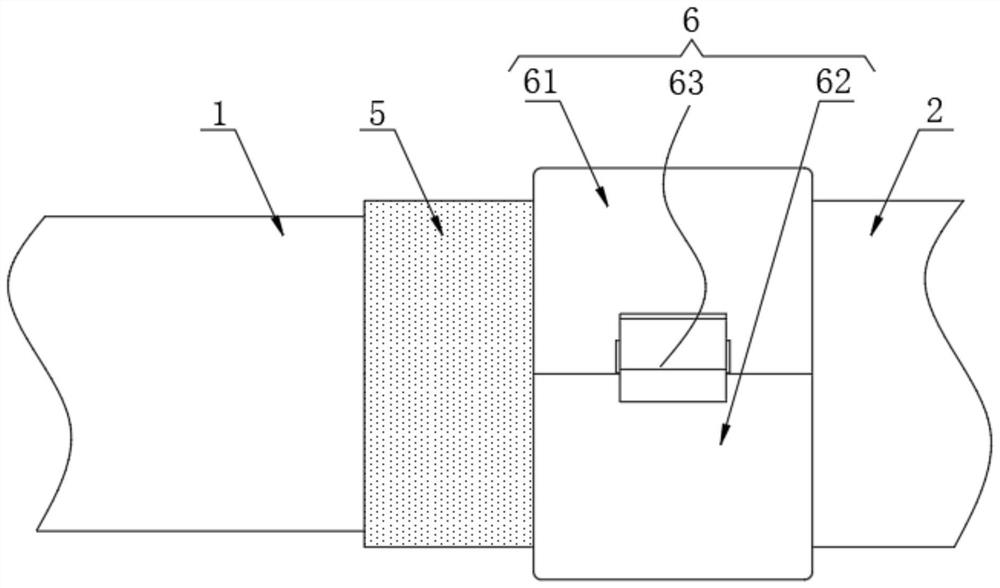

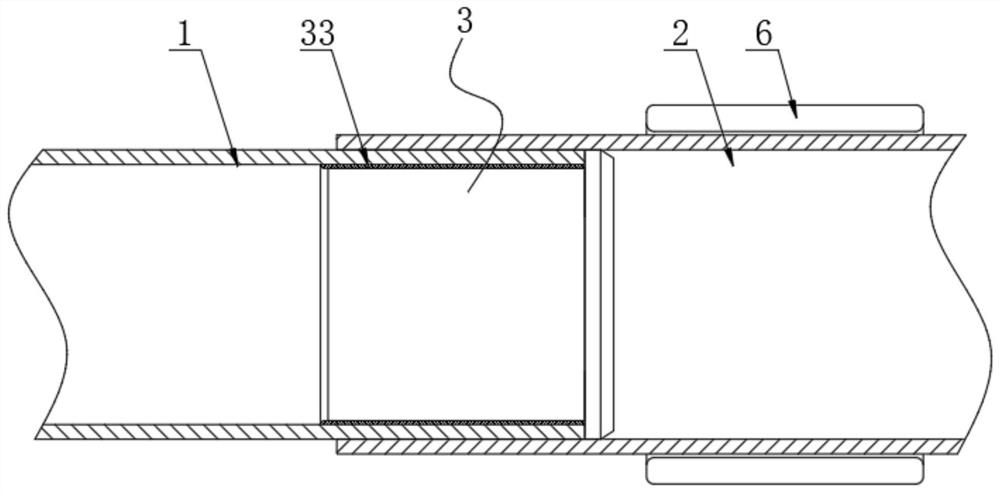

Multifunctional double-flange pipeline

InactiveCN111043414AEasy to fixEasy to separatePipe elementsPipe protection against damage/wearEngineeringStructural engineering

The invention relates to the technical field of pipelines, and discloses a multifunctional double-flange pipeline. The multifunctional double-flange pipeline comprises a pipeline body, wherein the pipeline body comprises a first pipeline body and a second pipeline body, the first pipeline body is in threaded connection with the second pipeline body, and flange plates are fixedly connected to one end of the first pipeline body and one end of the second pipeline body correspondingly; and the other ends of the inner cavities of the first pipeline body and the second pipeline body are movably connected with valve bodies. According to the multifunctional double-flange pipeline, the first pipeline body and the second pipeline body can be connected together through clamping between internal threads and external threads, and the internal threads are separated from the external threads, so that the first pipeline body and the second pipeline body are separated; the first pipeline body and the second pipeline body are in threaded connection, so that the first pipeline body and the second pipeline body are conveniently separated, a user can conveniently clean impurities collected in a storagebag as well as clean the storage bag, the filtering effect of the storage bag is kept, and the situation that the flowing speed of medium fluid is affected due to the fact that the storage bag is blocked by the impurities can be prevented; and the flange plates are arranged at the two ends of the pipeline body, so that the pipeline body is conveniently fixed.

Owner:阮健宁

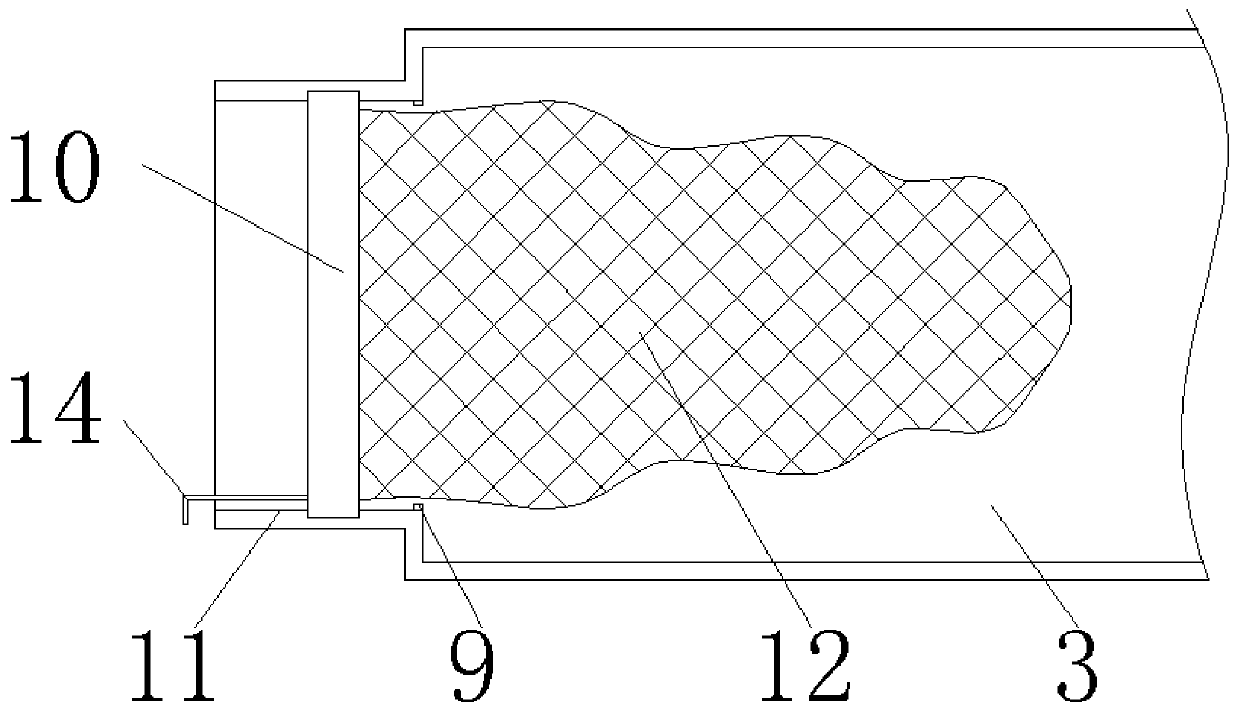

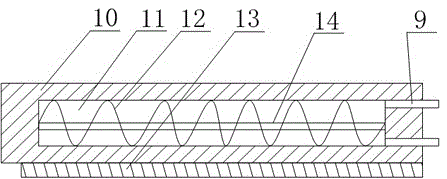

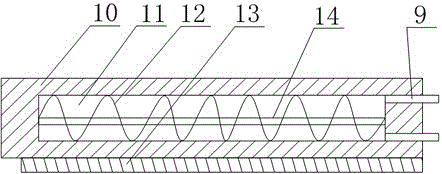

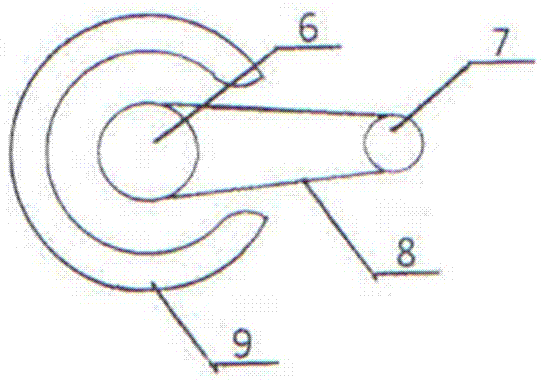

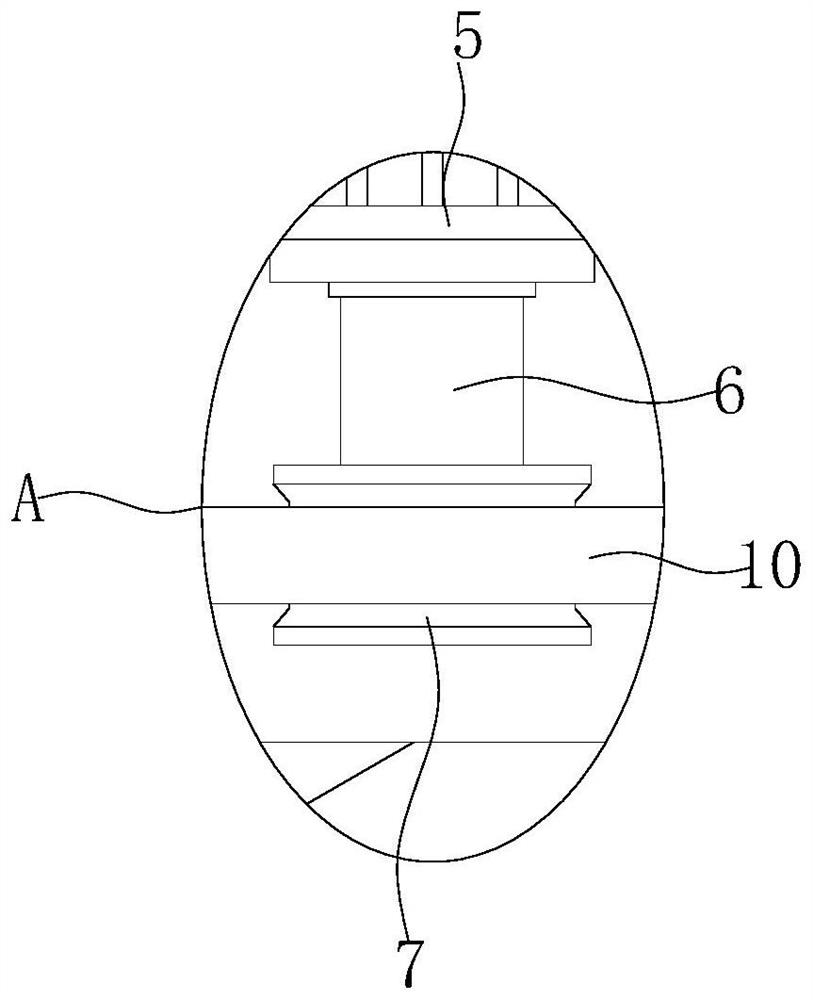

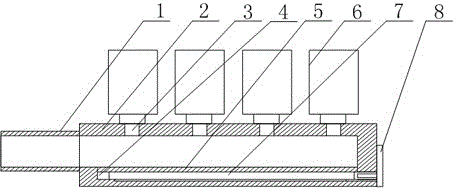

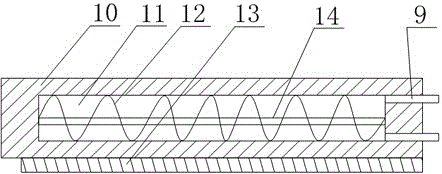

CNG (Compressed Natural Gas) injection system for automobile

InactiveCN105604740AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityCompressed natural gas

The invention discloses a CNG (Compressed Natural Gas) injection system for an automobile. The CNG injection system comprises a gas inlet pipe and a hollow pipe, wherein a plurality of injection holes are formed in the upper end of the hollow pipe; electromagnetic valves are correspondingly arranged on the injection holes; a groove is formed in the inner wall of the hollow pipe; the injection holes are just opposite to the groove; a plurality of electric heating tubes are arranged in the groove side by side; a guiding block is arranged at the bottom of each electric heating tube; a guiding groove matched with the guiding blocks is formed in the bottom of the groove; each electric heating tube comprises a tube body, an insulated material filling the inside of each tube body and an electric heating wire arranged inside each tube body; a binding post is connected to the tail end of each electric heating wire; a small hole communicating with the outside is formed in one end, away from the air inlet pipe, of the groove; each binding post penetrates through the corresponding small hole and is connected with a wiring plug board; a heat conducting plate covers an open end of the groove. The guiding block is arranged at the lower part of the tube bodies of the electric heating tubes and is matched with the guiding groove, so that the placement of the tube bodies is more stable, i.e., the electric heating tubes can be fastened without adding a new fixing structure, and further the aim of optimizing an internal structure of an injection rail is achieved.

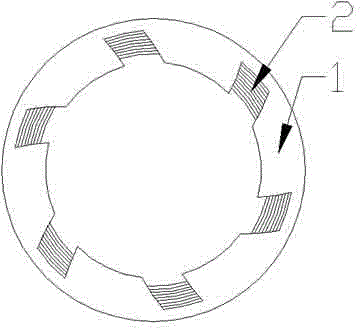

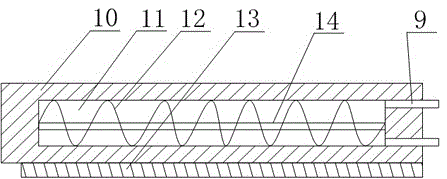

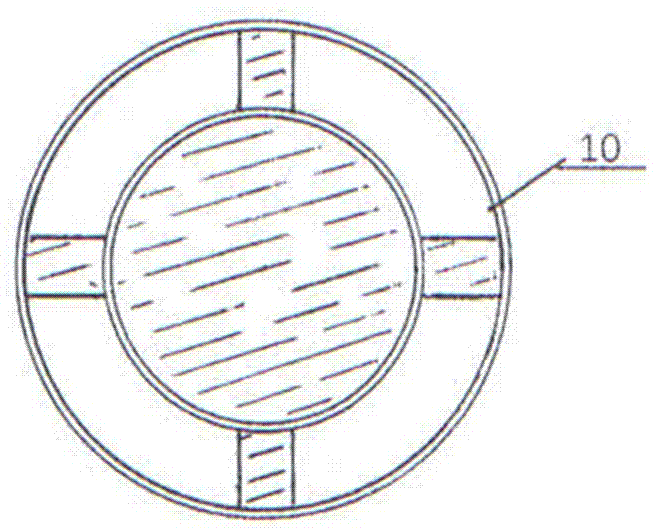

Screw type liquid filter

InactiveCN104399312AImprove filtering effectImprove securityFiltration circuitsEngineeringFiltration

A related screw type liquid filter comprises a swirling separation part, a conflux separation part and a spiral inflow pipe; the spiral inflow pipe wraps the outer wall of the swirling separation part; the swirling separation part rotates a fluid mainly through a main body provided with a spiral swirling tank, so that impurities with different mass are separated; and the fluid is subjected to secondary separation filtration in a separation assembly with a gradually divergent opening in the conflux separation part. Therefore, secondary separation is performed on the fluid through a simple structure. The screw type liquid filter is convenient to mount and low in cost.

Owner:WUXI EPIC TECH

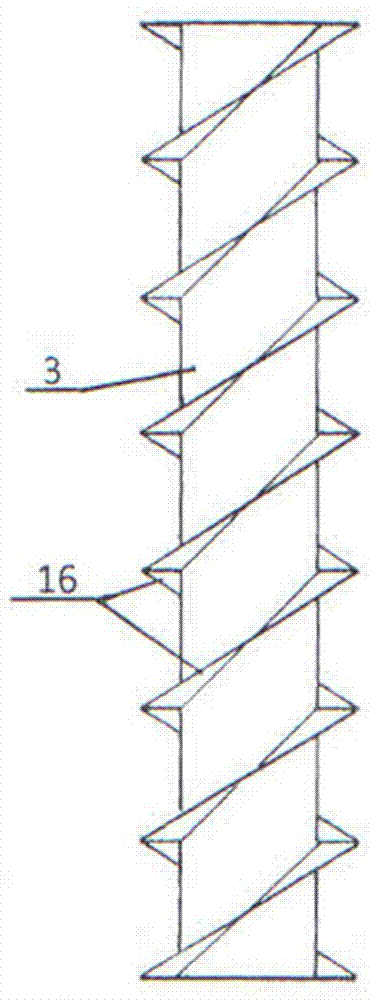

Combustible gas injection system for dual-fuel locomotive

InactiveCN105604742AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityHeat conducting

The invention discloses a combustible gas injection system for a dual fuel locomotive. The combustible gas injection system comprises a gas inlet pipe and a hollow pipe, wherein the upper end of the hollow pipe is provided with a plurality of injection holes which are correspondingly provided with solenoid valves; the inner wall of the hollow pipe is provided with grooves; the injection holes are over against the grooves; a plurality of electric heating tubes are arranged in the grooves side by side; the bottom of each electric heating tube is provided with a guide block; the bottom of each groove is provided with a guide groove matched with the guide block; each electric heating tube comprises a tube body, an electric insulating material filled in the tube body and an electric heating wire arranged inside the tube body; the tail end of the electric heating wire is connected with a wiring terminal; one end of the groove far from the gas inlet pipe is provided with a pinhole communicating with the outside; the wiring terminal penetrates through the pinhole and is connected with a wiring plugboard; and a heat conducting board is covered on the open end of each groove. The lower part of the tube body of each electric heating tube is provided with the guide block which is matched with the guide groove, so that the tube body can be mounted more stably; and thus, the electric heating tubes can be fastened without adding any new fixing structure, thereby achieving the goal of optimizing the injection rail internal structure.

Owner:CHENGDU KELIFU SCI & TECH

Automotive fuel gas supply device

The invention discloses an automotive fuel gas supply device which comprises a gas inlet pipe and a hollow pipe. A plurality of spray holes are formed in the upper end of the hollow pipe. Electromagnetic valves are correspondingly mounted on the spray holes. A groove is formed in the inner wall of the hollow pipe, and the spray holes exactly face the groove. A plurality of electric heating pipes are arranged in the groove side by side. A guide block is mounted at the bottom of each electric heating pipe. Guide grooves matched with the guide blocks are formed in the bottom of the groove. Each electric heating pipe comprises a pipe body, an insulation material with which the pipe body is filled and an electric heating wire arranged in the pipe body. The tail ends of the electric heating wires are connected with binding posts. Small holes communicating with the outside are formed in the end, far away from the gas inlet pipe, of the groove. The binding posts penetrate the small holes to be connected with a wiring plug board. The open end of the groove is covered with a heat conduction plate. The guide blocks are mounted on the lower portions of the pipe bodies of the electric heating pipes and matched with the guide grooves, and therefore the pipe bodies can be mounted more stably, in other words, the electric heating pipes can be fastened without additionally arranging a new fixing structure, and the aim of optimizing an internal structure of a spray rail is achieved.

Owner:四川省诚德蓝天环保科技有限公司

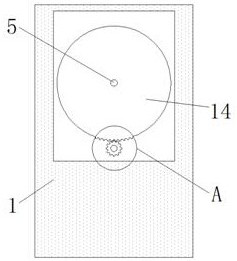

Anti-freezing CNG air feeder

InactiveCN105626314AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusAnti freezingHeat conducting

The invention discloses an anti-freezing CNG air feeder. The anti-freezing CNG air feeder comprises an air inlet pipe and a hollow pipe. A plurality of injection holes are formed in the upper end of the hollow pipe. An electromagnetic valve is correspondingly installed at each injection hole. A groove is formed in the inner wall of the hollow pipe. The injection holes right face the groove. A plurality of electric heat pipes are arranged inside the groove side by side. Guide blocks are installed at the bottom of each electric heat pipe. A guide groove matched with each guide block is formed in the bottom of the groove. Each electric heat pipe comprises a pipe body, an insulating material and an electric heat wire, wherein each insulating material is filled in the corresponding pipe body, and each electric heat wire is arranged in the corresponding pipe body. Wiring posts are connected to the tail end of each electric heat wire. A small hole communicating with the outside is formed in the end, away from the air inlet pipe, of the groove. The wiring posts penetrate through the small hole and are connected with a wiring plug board. The open end of the groove is covered with a heat-conducting plate. The guide blocks are installed on the lower portion of the pipe body of each electric heat pipe, each guide block is matched with the corresponding guide groove, placing of the pipe bodies is made to be more stable, and the electric heat pipes can be fastened without adding new fixing structures, so that the purpose of optimizing the internal structure of an injection rail is achieved.

Owner:CHENGDU DUJIA ELECTRICAL

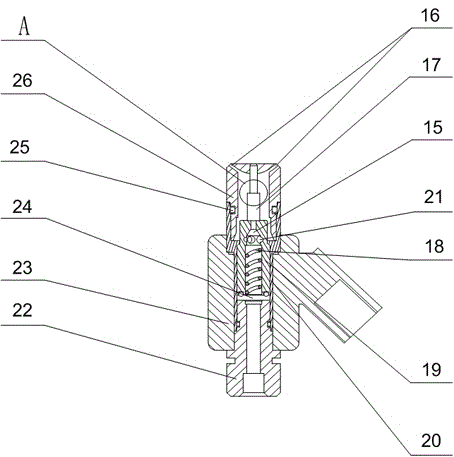

Liquid atomization device

PendingCN112547338AIncrease flow rateImprove atomization finenessLiquid spraying apparatusAir pumpEngineering

The invention relates to the technical field of liquid atomization, in particular to a liquid atomization device. The liquid atomization device comprises a shell, an air pump, an atomizing core, a liquid storage cover and a liquid storage bottle, wherein the air pump, the atomizing core, the liquid storage cover and the liquid storage bottle are arranged in the shell. One end of the atomizing coreis connected with the air pump; the other end of the atomizing core is connected with a straw which is arranged in the liquid storage bottle; a first air channel running through the atomizing core isformed in the atomizing core; the first air channel is of a multi-level structure; the inner diameter of the first air channel is gradually reduced from the end connected with the air pump to the endconnected with the straw; and the liquid storage bottle is covered with the bottom of the liquid storage cover. The end, connected with the straw, of the atomizing core is arranged in the liquid storage cover; a second air channel is formed in the upper portion of the liquid storage cover; a flow blocking structure is arranged in the second air channel; the flow blocking structure is used for reducing the flow speed of air and liquid; and a first air outlet is formed in the top of the liquid storage cover. By means of the liquid atomization device, the atomizing fineness can be improved; andthe liquid is prevented from flowing outwards after dumping.

Owner:威斯巴特科技(宁波)有限公司

Water pumping energy storage power generation device

InactiveCN107201983AAffect trafficAffect flow rateHydro energy generationMachines/enginesWater turbineEngineering

The invention discloses a water pumping energy storage power generation device. The water pumping energy storage power generation device aims at improving drainage power generation efficiency and enabling the drainage power generation capacity to be equal to or larger than water pumping power consumption. According to the technical scheme, the water pumping energy storage power generation device is characterized in that a pipeline from top to bottom (or from bottom to top) is changed from one way to three or more back-and-forth ways, in other words, the pipeline is turned downwards, upwards and then downwards repeatedly, the pipeline is provided with an inlet and an outlet no matter how many times the pipeline is turned back and forth, and the pipeline is provided with one, two or more water turbines; and with one water turbine as the unit, the certain distance is reserved between one part of the internal center of the cross section of the corresponding portion of the pipeline and small-angle circumference of the periphery for enabling a main shaft provided with no spiral pipe or blade to stretch out of the pipeline, the upper and lower portions or front and back portions of the exposed section are each sleeved with a bearing and a bearing pedestal, the isolated portions, between the two bearing pedestals, of the main shaft are additionally provided with transmission wheels for outputting or inputting power, and therefore the longer the pipeline is and the larger the number of water turbines is, the larger the power generation capacity is.

Owner:刘运武

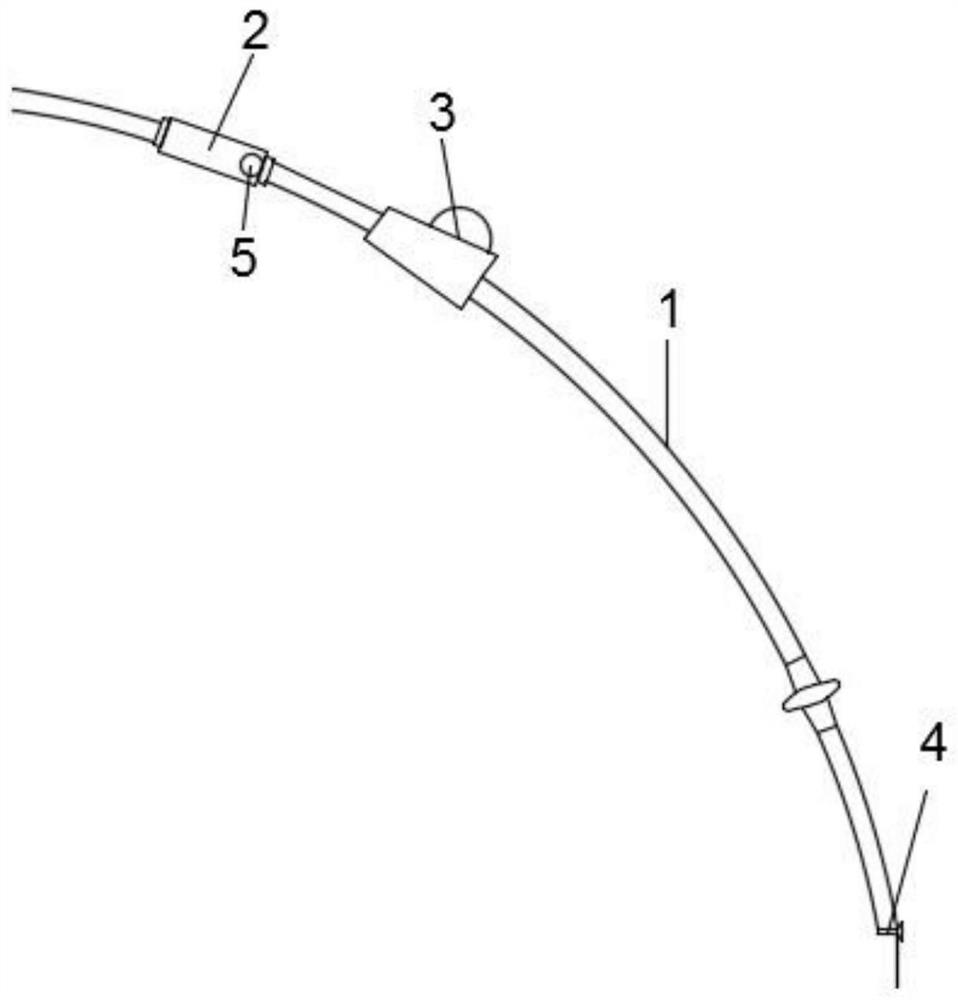

Novel Murphy's dropper

The invention relates to the technical field of medical auxiliary equipment, in particular to a novel Murphy's dropper. The novel Murphy's dropper comprises an infusion tube body, wherein an air-stopping Murphy's dropper, a drip speed controller and an infusion needle are sequentially connected to the infusion tube body in series; an air-stopping ball is arranged in the air-stopping Murphy's dropper; an air-stopping ball traction mechanism is arranged at an outlet in the lower end of an inner cavity of the air-stopping Murphy's dropper; and damping fluff is arranged in the drip speed controller. According to the novel Murphy's dropper, the air-stopping ball is placed in the air-stopping Murphy's dropper; when liquid medicine exists in the air-stopping Murphy's dropper, the air-stopping ball is suspended on the liquid medicine; when the liquid medicine drips completely, the air-stopping ball comes to the bottom of the air-stopping Murphy's dropper to block the connecting end of a tube opening of the infusion tube body and the bottom of the inner cavity of the air-stopping Murphy's dropper, so that the problem of blood flowback caused by flowback of air in the body is prevented; andmeanwhile, the damping fluff is arranged on the wall of a sliding groove in the drip speed controller, so that the sliding resistance of an idler wheel on the drip speed controller is improved, and the influence on the flow speed of the liquid medicine due to the fact that the self weight of the idler wheel drives a body of the idler wheel to slide downwards to press the infusion tube body is prevented.

Owner:南京市江宁医院

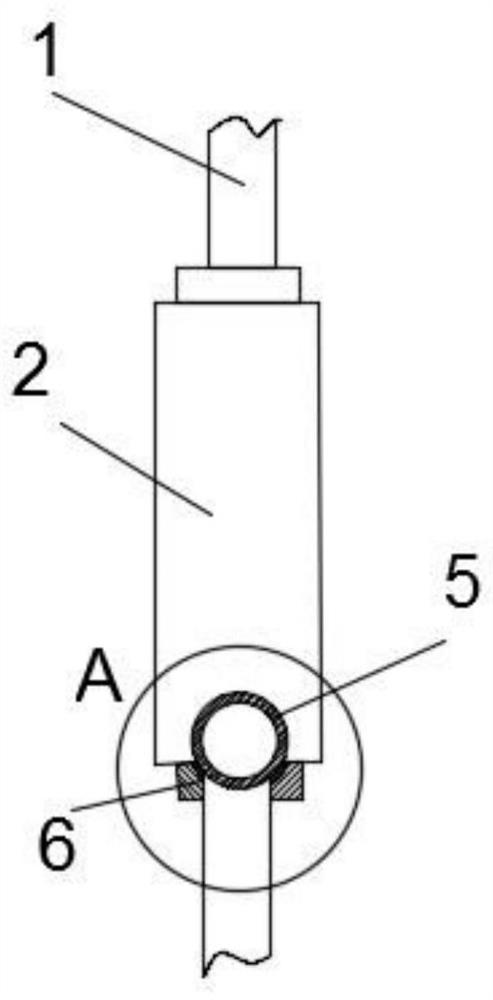

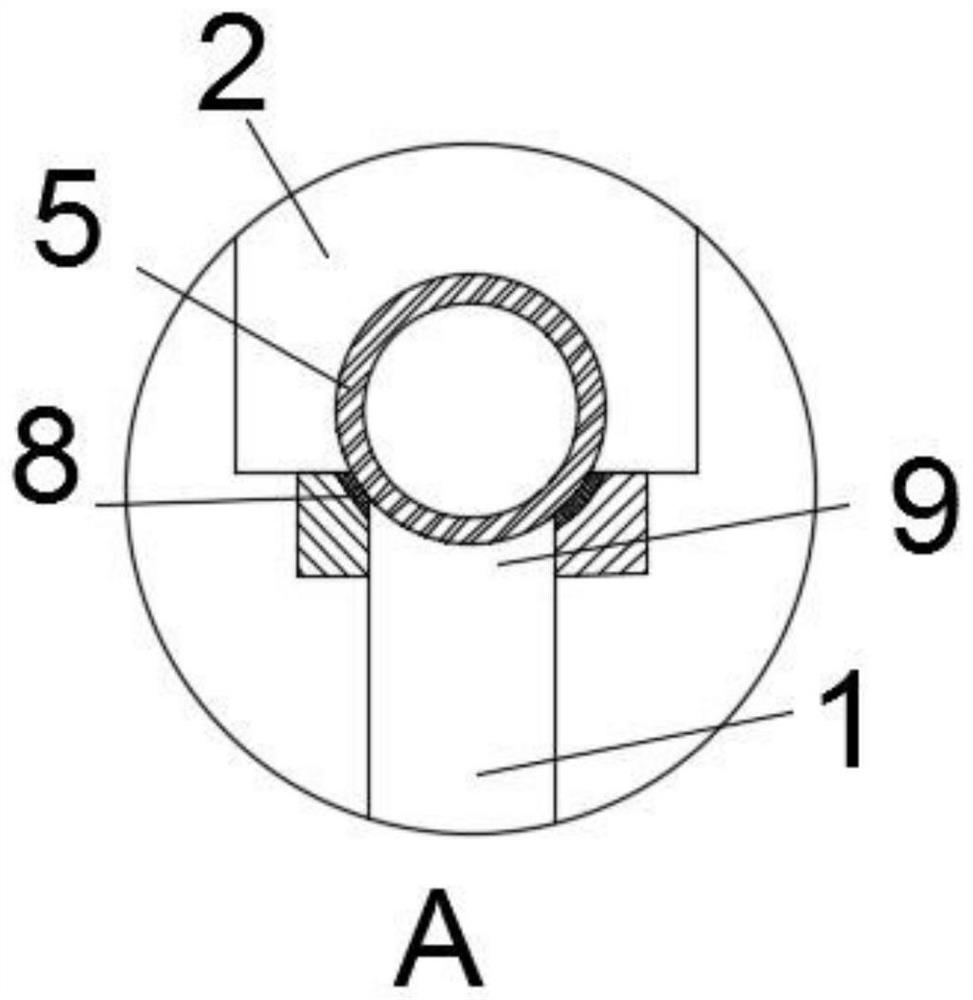

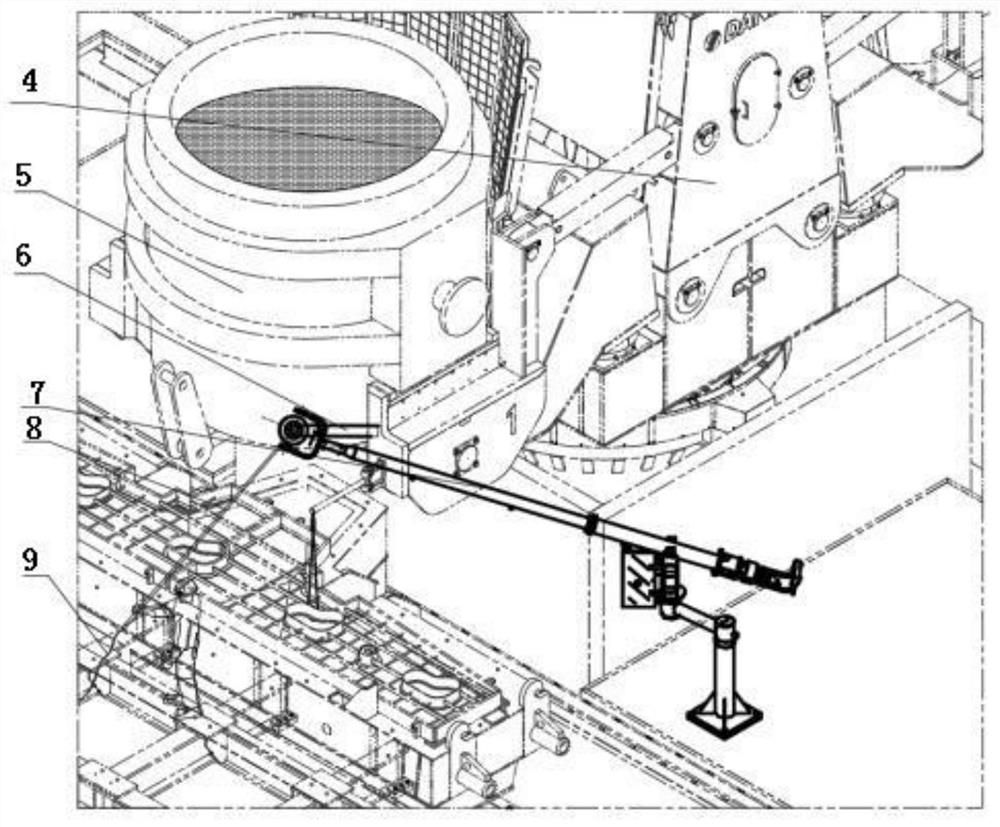

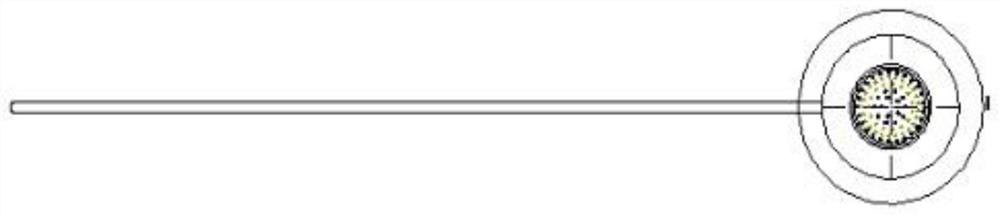

Continuous casting ladle long nozzle residual steel cleaning equipment and using method thereof

The invention discloses continuous casting ladle long nozzle residual steel cleaning equipment and a using method thereof, and relates to the technical field of metallurgical continuous casting machines. The continuous casting ladle long nozzle residual steel cleaning equipment comprises a connecting pipe, a pressing plate is arranged at the right end of the connecting pipe, a purging spray head is arranged on the pressing plate, the connecting pipe is a stainless steel seamless steel pipe, and the inlet end of the connecting pipe is connected with an argon gas source on site. The continuous casting bale long nozzle residual steel cleaning equipment is installed on a casting platform of a continuous casting machine, one end of the continuous casting bale long nozzle residual steel cleaning equipment is connected with argon, the other end of the continuous casting bale long nozzle residual steel cleaning equipment is aligned with the inlet end of a long nozzle, residual steel in the long nozzle can be conveniently and rapidly blown and swept, timely cleaning of the long nozzle residual steel is achieved, the service life of the nozzle is prolonged, and excessive molten steel residual steel attached to the nozzle is prevented, influence to the flow speed of molten steel is avoided, and potential influence factors (blowing is not uniform and residual steel cleaning is not thorough due to the fact that argon is introduced into a common steel pipe for cleaning before) which influence the fluctuation of the liquid level of the intermediate tank are eliminated.

Owner:MAANSHAN IRON & STEEL CO LTD

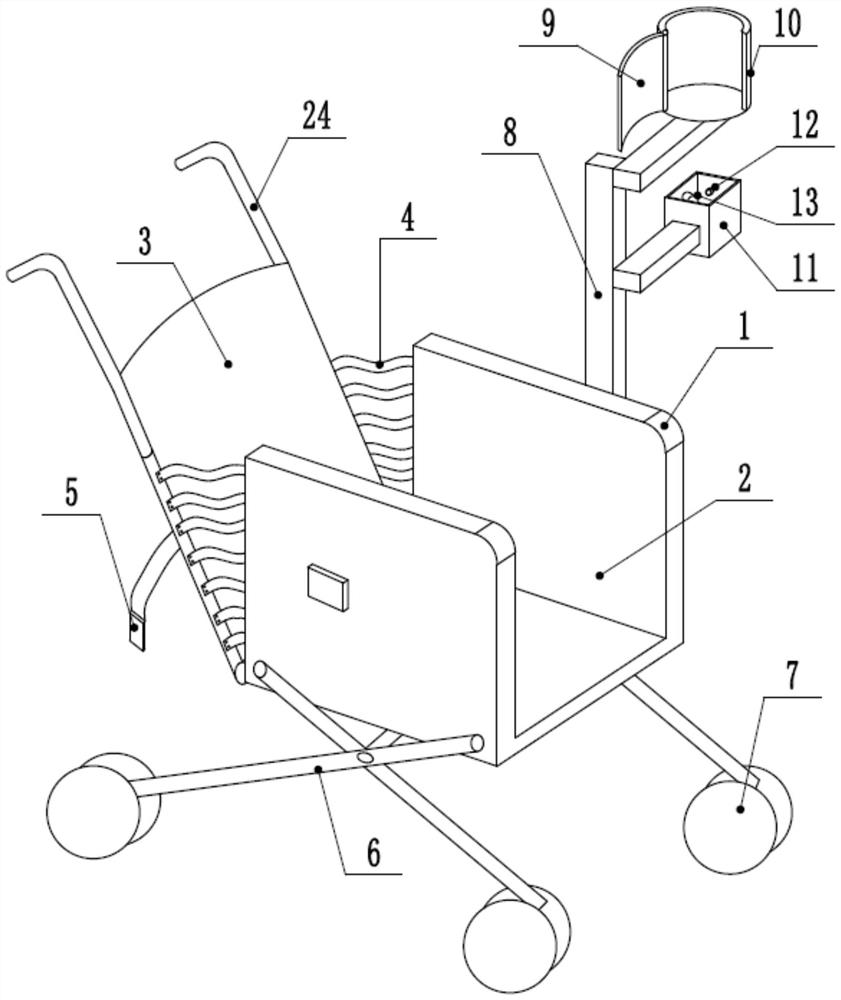

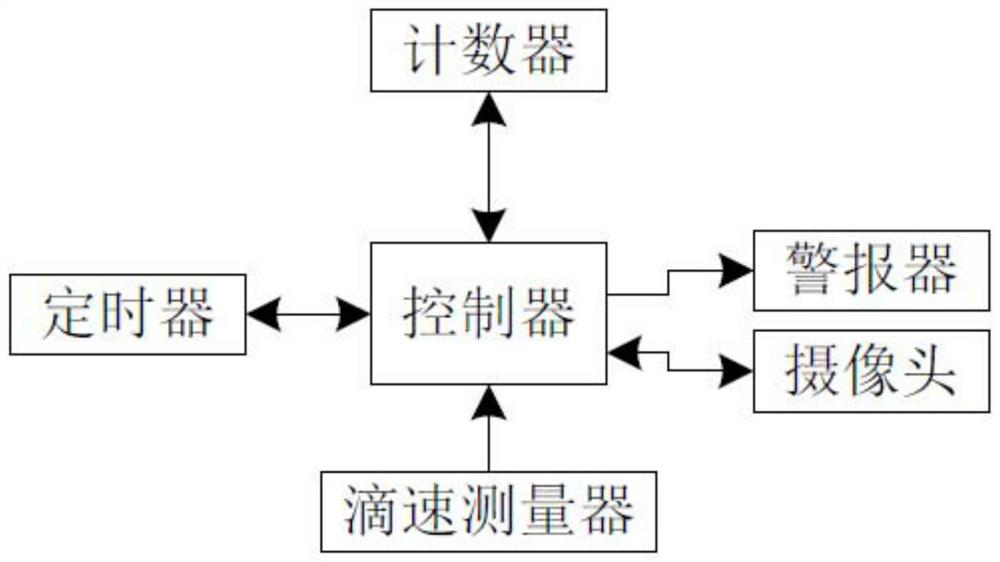

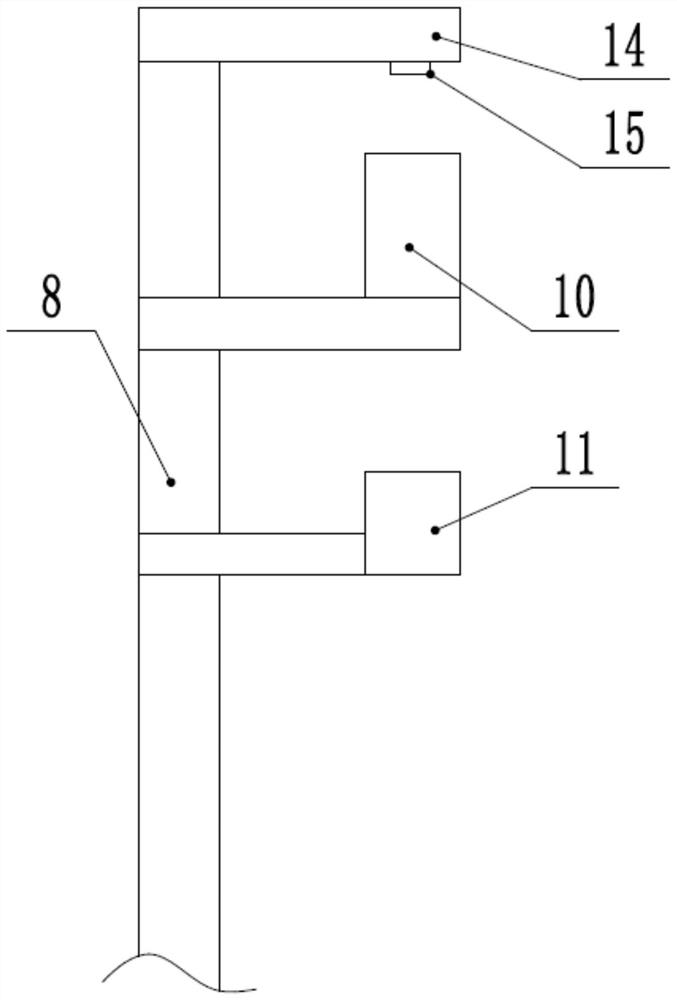

Multifunctional Children's Infusion Cart

ActiveCN110743060BPrevent backflowReduce the effect of infusionWheelchairs/patient conveyanceMedical devicesComputer scienceInfusion solution

The invention relates to the field of infusion auxiliary equipment, in particular to a multifunctional children's infusion vehicle, which includes a vehicle body, an accommodating tank is provided on the vehicle body, an infusion rod is arranged on the vehicle body, and an infusion device is provided at the free end of the infusion rod, and the infusion device includes a frame, detector and recognizer, the placement frame is in the shape of a cylinder; the detector includes a detection box, contrast backplane, light source and camera, and the recognizer includes a controller, counter, timer and alarm. The present invention gives an alarm when the dripped water drops are few enough to meet the requirements, timely discovers the stagnant situation in the infusion dropper, detects air in the infusion dropper in advance, and avoids blood backflow caused by the infusion droplet entering air.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Disinfection device for gynecological medical care products

InactiveCN111569117BLow costIncrease pressureLavatory sanitoryCleaning using liquidsNursing careWater flow

The invention relates to the technical field of medical equipment, and discloses a gynecological medical care product disinfection device, and then put the medical care products to be sterilized into the disinfection box, and move the pressing plate downward to drive the disinfection box to move downward through the movable tube, and connect the The outlet can be connected with the water tank, and at the same time, it drives the pressure column to move downward through the pressure spring recovery box, so that the disinfectant water can be squeezed into the water inlet tank, and then enter the disinfection box through the connection port. After the disinfectant water passes through the items, it will flow into the recovery box through the water outlet. After the pressure of the pressure spring is released, release the pressing plate, and the rebound of the elastic rope will drive the disinfection box to move upwards, and the sterilized items can be picked up and pulled. The rebound of the spring will drive the baffle to move upwards, and the disinfectant water in the recovery box will flow into the bottom of the shell through the recovery port, and the rebound of the pressure spring a will drive the recovery box to move upwards, so that the device can be sterilized again with disinfectant water, thereby saving costs .

Owner:湖南省妇幼保健院

Vehicle liquefied gas continuous supply system

InactiveCN107762675AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricitySolenoid valve

The invention discloses a vehicle liquefied gas continuous supply system. The vehicle liquefied gas continuous supply system comprises a gas inlet pipe and a hollow pipe. The upper end of the hollow pipe is provided with a plurality of injection holes. Solenoid valves are mounted on the corresponding injection holes. The inner wall of the hollow pipe is provided with a groove. The injection holesface the groove. A plurality of electric heating pipes are arranged in the groove side by side. The bottoms of the electric heating pipes are provided with guide blocks. The bottom of the groove is provided with guide grooves matched with the guide blocks. Each electric heating pipe comprises a pipe body, an insulating material filled up in the pipe body and an electric heating wire arranged in the pipe body. The tail end of each electric heating wire is connected with binding posts. Small holes communicating with the outside are formed in the end, far from the gas inlet pipe, of the groove. The bonding posts penetrate through the small holes and are connected with a wiring plug board. The open end of the groove is covered with a heat conductive plate. The lower portions of the pipe bodiesof the electric heating pipes are provided with the guide blocks which are matched with the guide grooves, so that the pipe bodies are placed more stably, that is, the electric heating pipes can be fastened without adding a new fixing structure, and the purpose of optimizing the internal structure of an injection rail is achieved.

Owner:邱晓霞

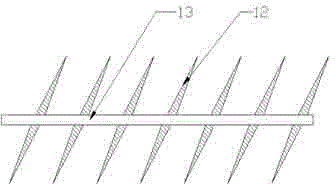

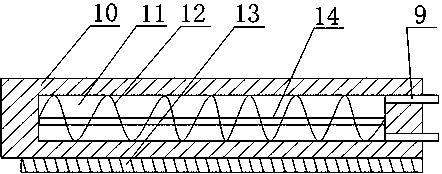

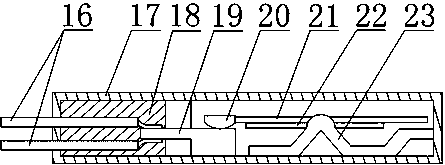

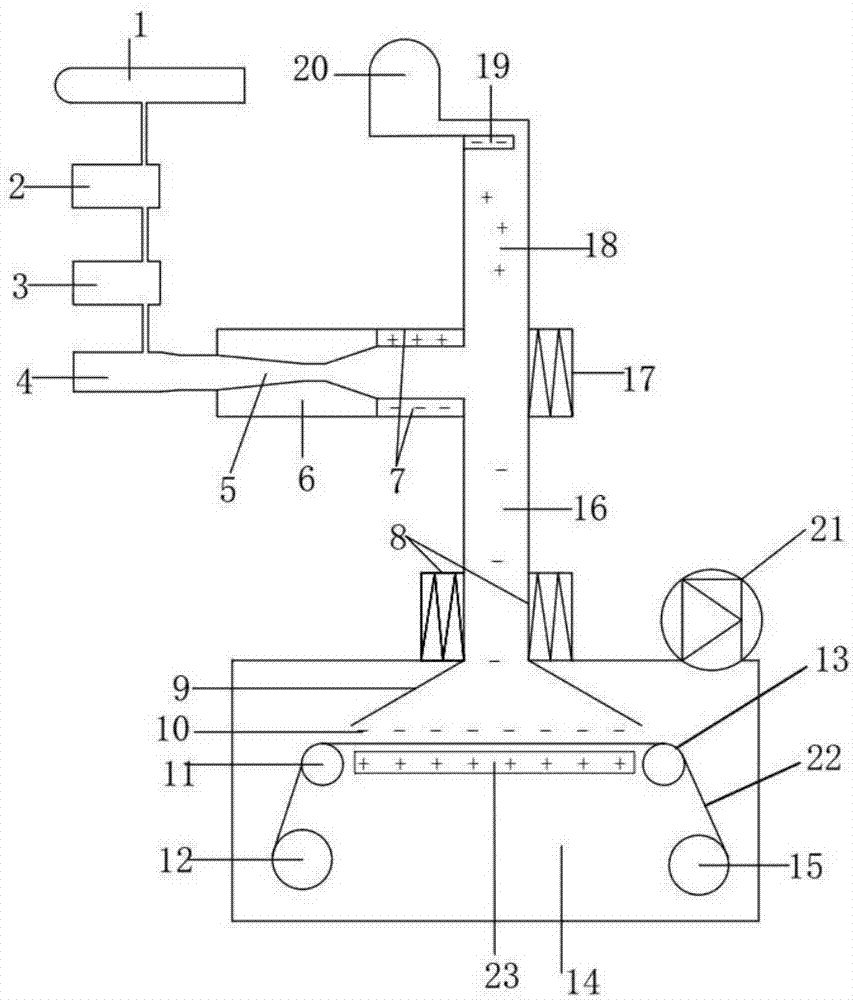

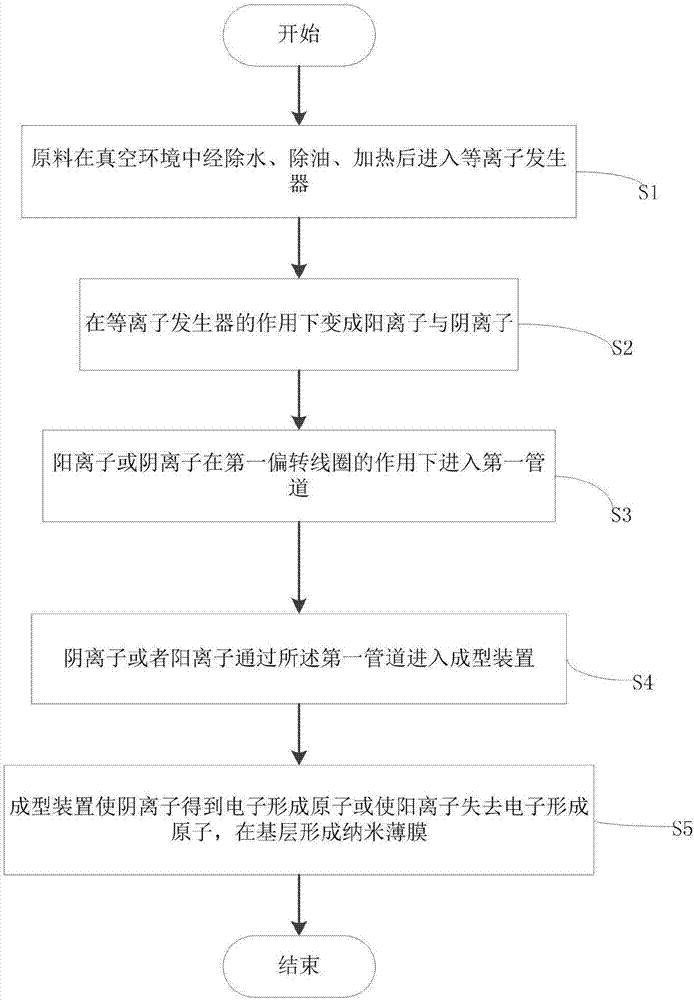

System and method for preparing nano film

InactiveCN107267918AHigh chemical activityIncrease flow rateVacuum evaporation coatingSputtering coatingIonElectromagnetic coil

The invention discloses a system and method for preparing a nano film. The system for preparing the nano film comprises a processing device, a plasma generator, a deflection device and a forming device. The deflection device comprises a first pipeline and a first electromagnetic coil. The forming device is provided with a base layer. The plasma generator ionizes raw materials preparing the nano film into negative ions and positive ions. Through the first electromagnetic coil, the negative ions or the positive ions are deflected into the first pipeline and enter the forming device through the first pipeline, the negative ions get electrons to become atoms through the forming device or the negative ions lose electrons to become atoms through the forming device, and the nano film is formed on the base layer. According to the system and method for preparing the nano film, the quality of the nano film is greatly improved.

Owner:深圳市航盛新材料技术有限公司

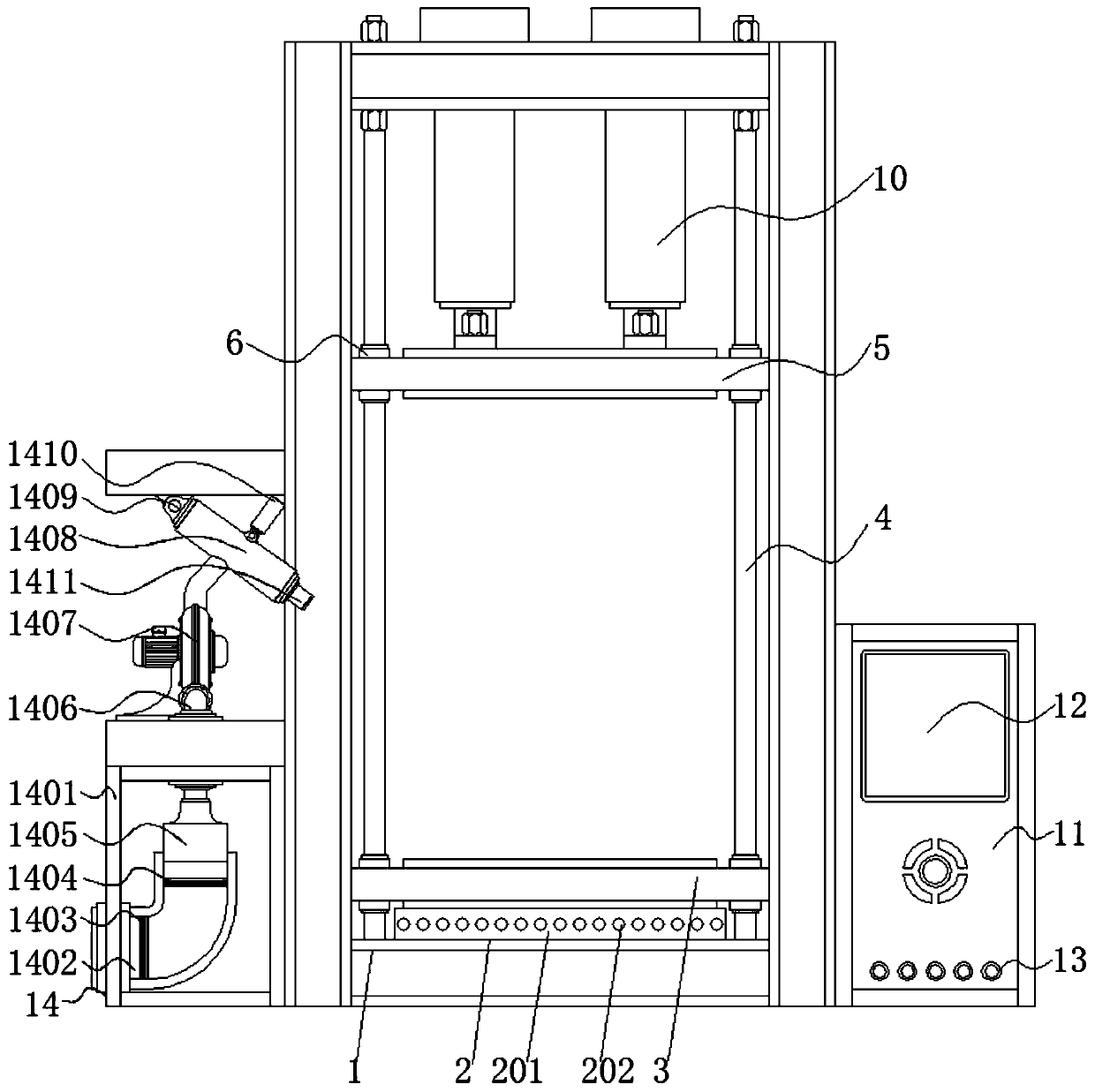

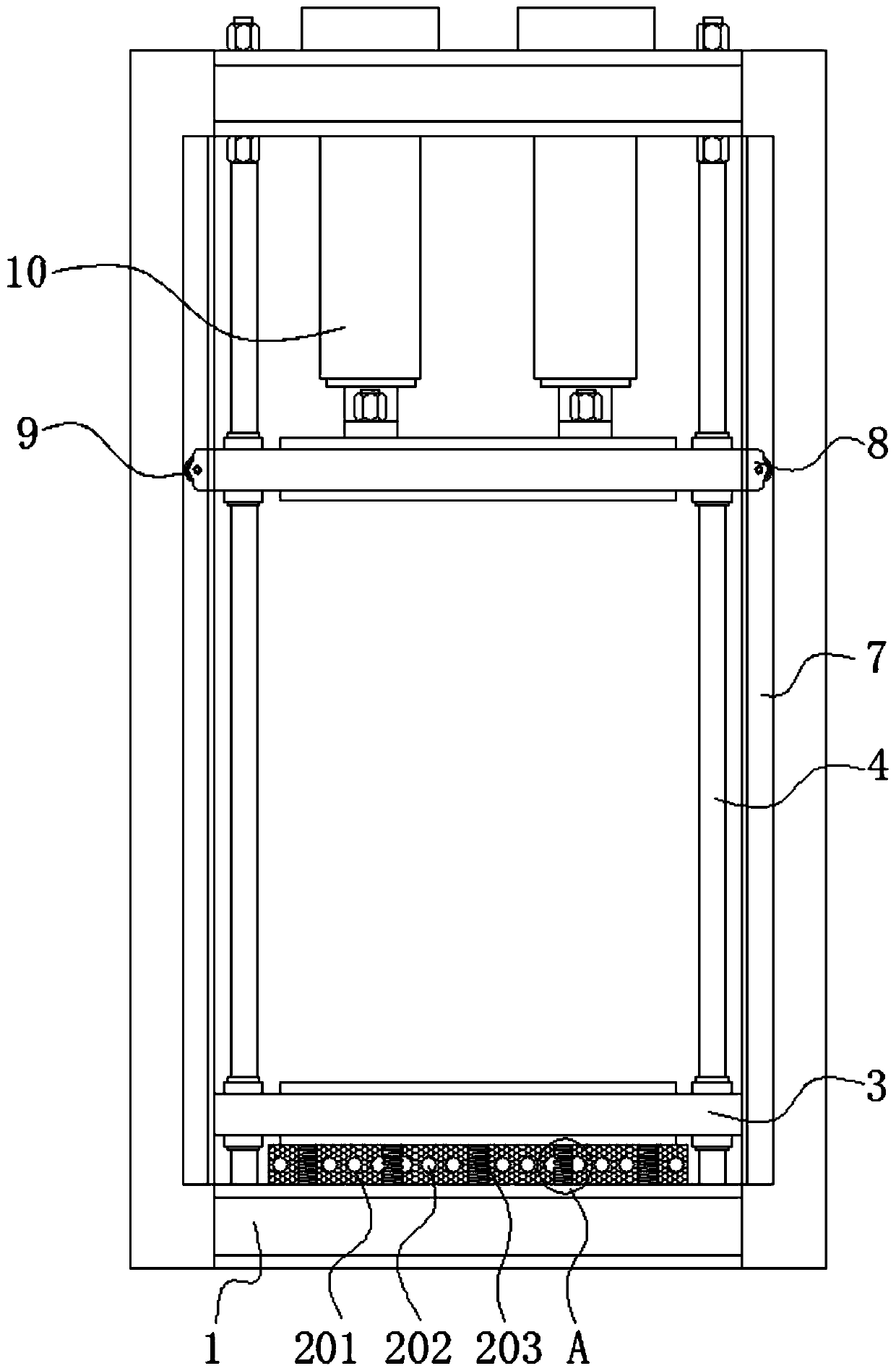

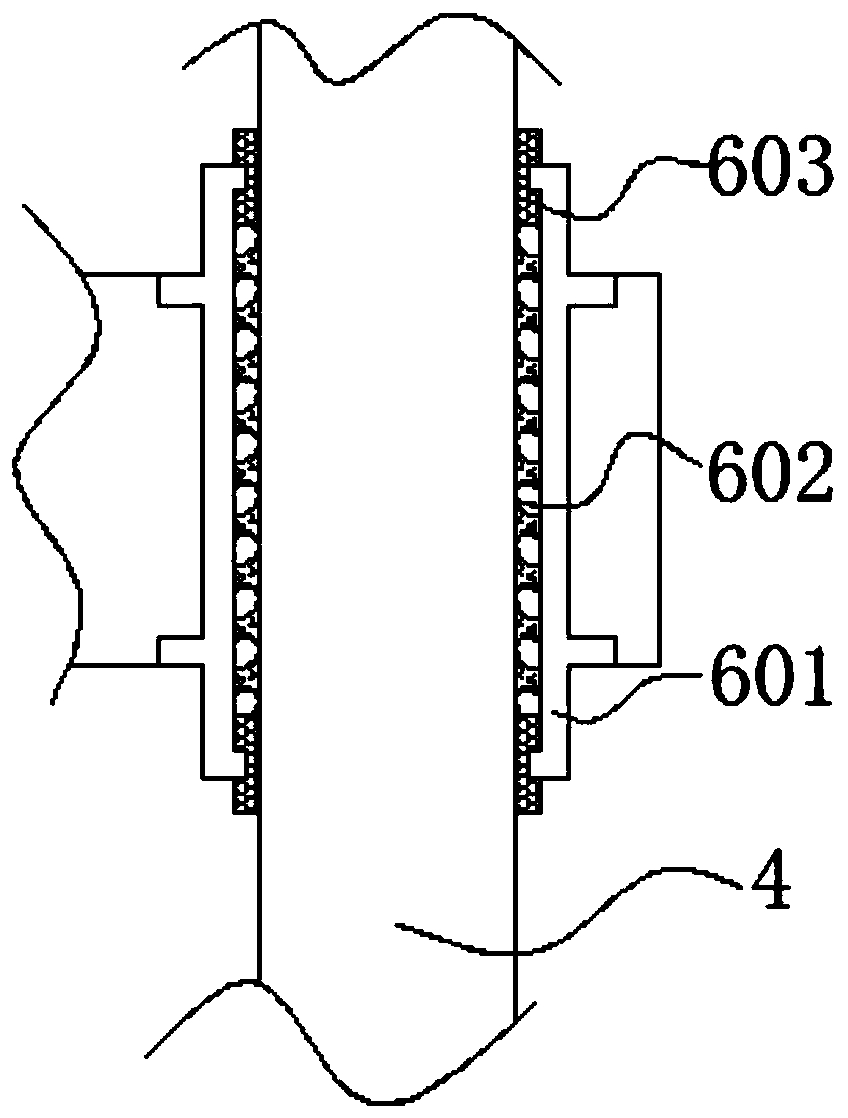

Safe framework type hydraulic press

InactiveCN111452418AReduce forceMake up for deformationDispersed particle filtrationTransportation and packagingHydraulic ramEngineering

The invention discloses a safe framework type hydraulic press, and relates to the technical field of hydraulic presses. The safe framework type hydraulic press comprises a framework and a cleaning mechanism. A buffering mechanism is disposed in the framework, a bottom plate is installed on the upper portion of the buffering mechanism, lubricating mechanisms penetrate through the left and right sides of the bottom plate, sliding rods penetrate through the lubricating mechanisms, a pressing plate is installed above the bottom plate, and sliding grooves are formed in the left and right sides of the pressing plate. Ejector blocks are arranged in the sliding grooves, rollers are disposed in the ejector blocks, a pushing hydraulic oil cylinder is installed on the upper portion of the pressing plate, a control box is installed on one side of the framework, a screen is installed at the front end of the control box, a rubber spacer is installed below the screen, and the cleaning mechanism is located on the other side of the framework. The safe framework type hydraulic press is provided with the sliding rods, and symmetric distribution of the sliding rods can effectively prevent the pressingplate from deviating, so that the position of the pressing plate can be stably adjusted.

Owner:太田机械江苏有限公司

Cooling system for a fuel cell

The invention relates to a cooling system (13) for a fuel cell (1) having at least one cooler (14), a thermostat (18), a pump (15) for delivering a coolant (17) in a cooling cycle (16), and having an equalization container (20), wherein a deionizing resin (19), which is arranged in the equalization container (20), is provided for reducing the electrical conductivity of the coolant (17), and wherein the equalization container (20) is connected to the cooling cycle (16) via at least one line (21). In order to provide such a cooling system (13), in which the electrical conductivity of the coolant (17) can be kept continuously low in a simple and cost-effective manner, provision is made for the deionizing resin (19) to be arranged in a container (22) in an interior (24) of the equalization container (20) such that the deionizing resin (19) enters at least partially into the coolant (17) and the line (21), which connects the equalization container (20) and the cooling cycle (16), is freelyaccessible.

Owner:FRONIUS INTERNATIONAL GMBH

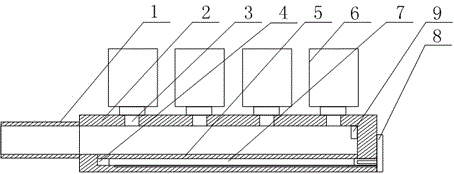

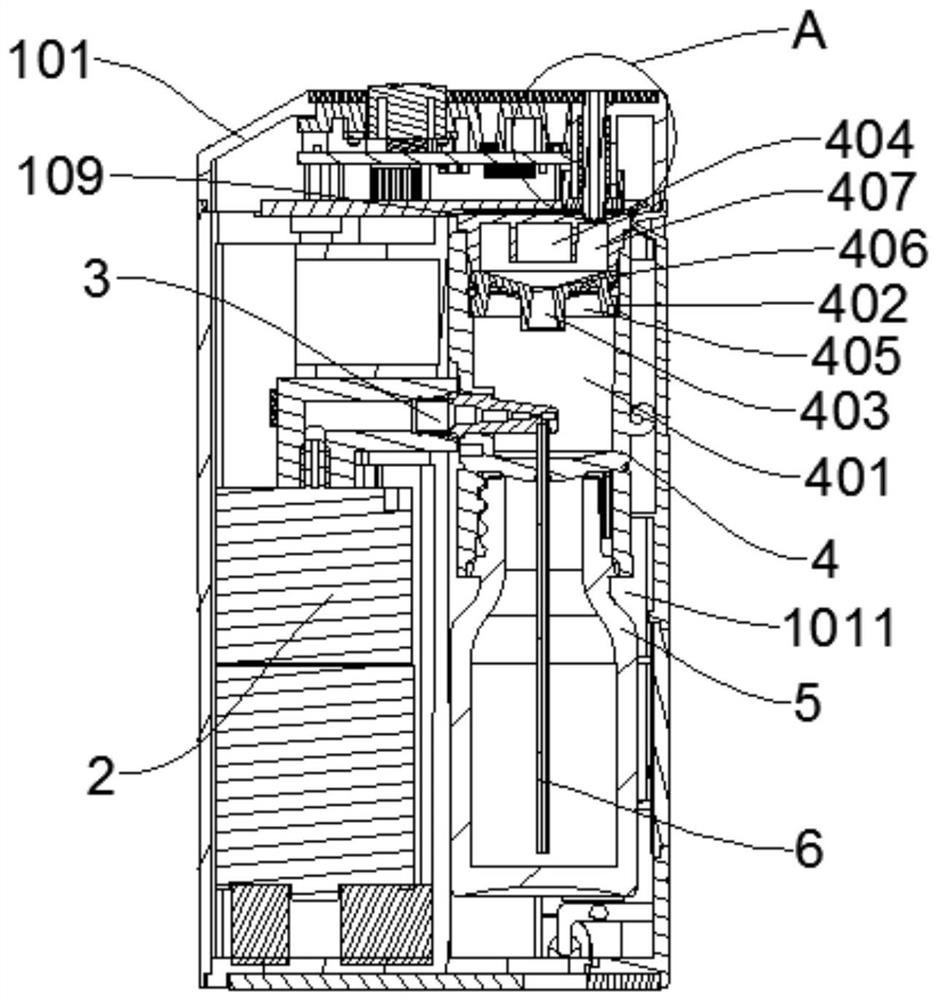

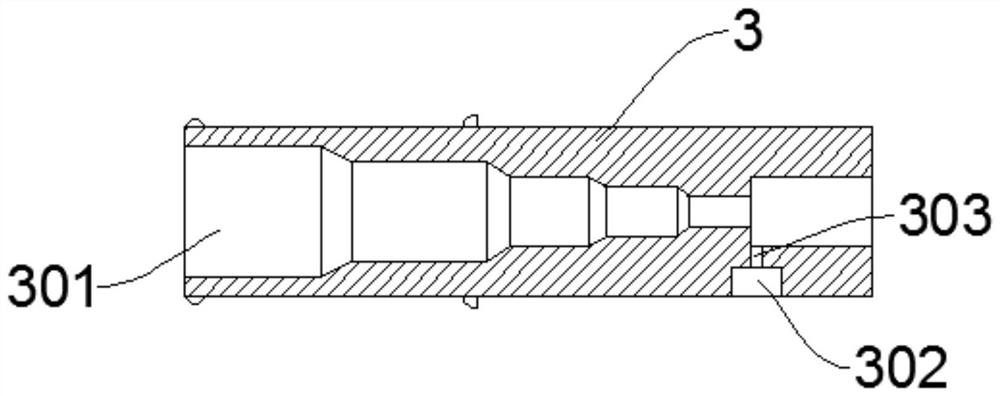

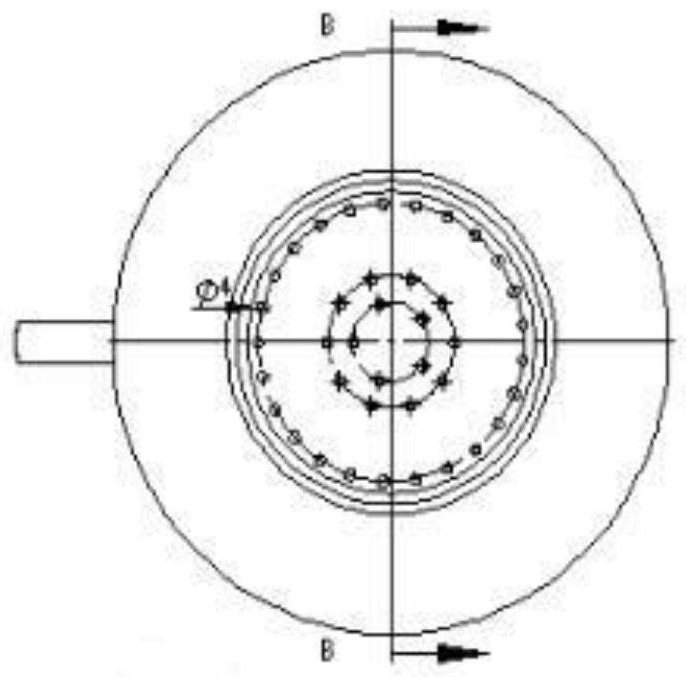

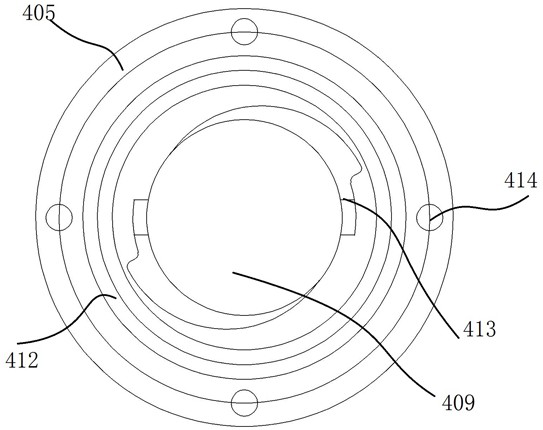

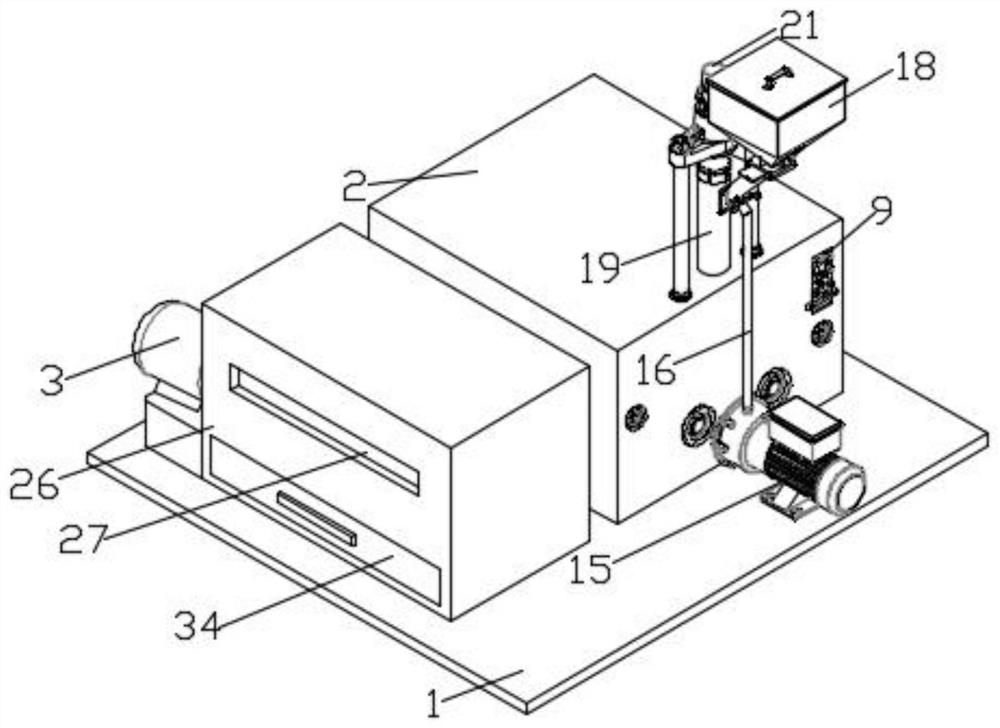

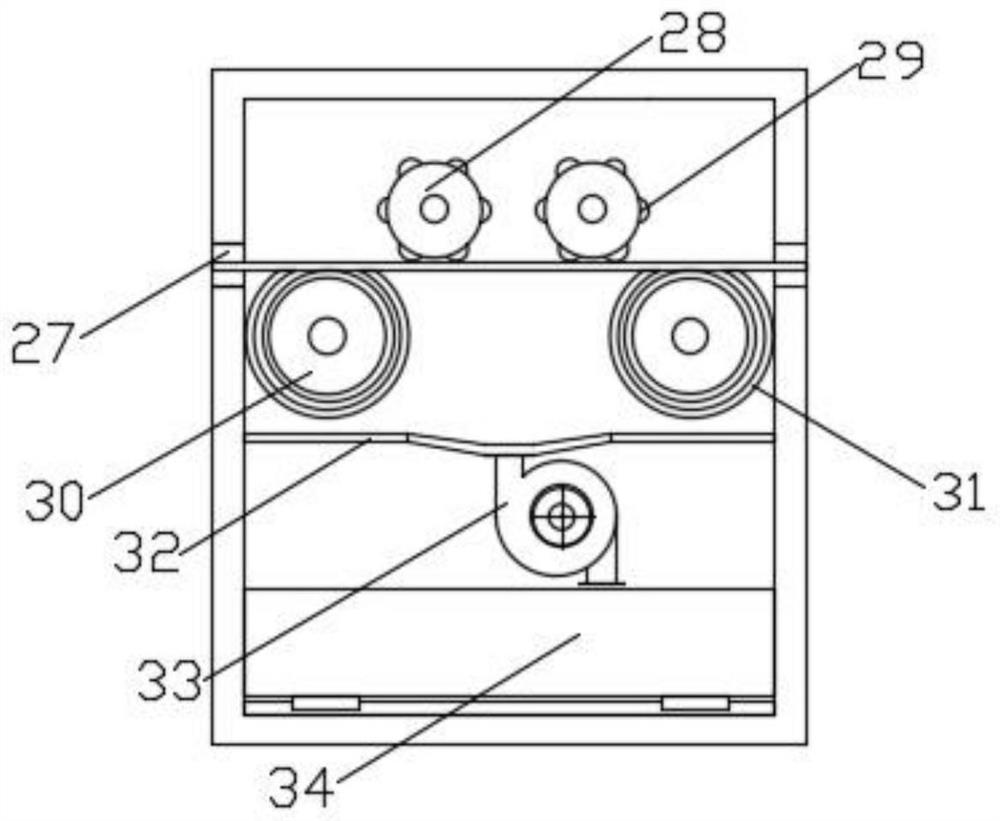

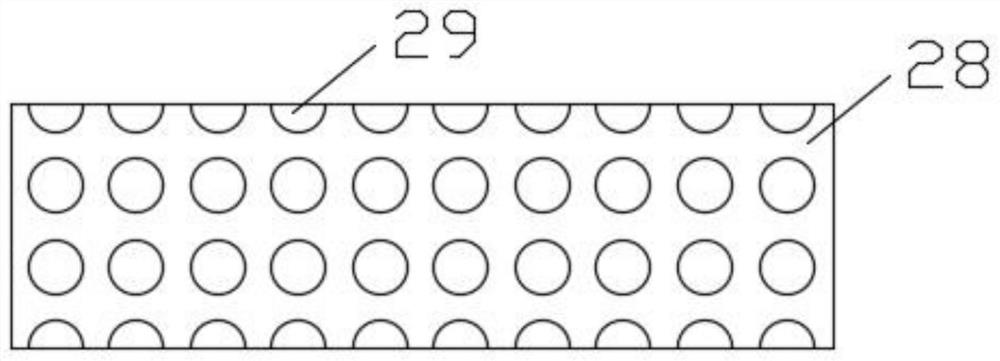

A horizontal cold water pump

ActiveCN109812422BRapid coolingAvoid failureSpecific fluid pumpsPump componentsElectric machineEngineering

The invention discloses a bedroom cold water pump comprising a motor part assembly, a volute assembly, a circulating cooling filter assembly and a cutting assembly. One part of water of a sewage outlet of a water outlet base of the volute assembly is introduced into a cooling sealing cavity in the motor part assembly through the circulating cooling filter assembly, sewage is used for circularly cooling a motor in a motor sealing cavity, energy utilization of resources is achieved, and the motor can be rapidly cooled. The cutting assembly is arranged in the volute assembly, arc tool slots are arranged on the two sides of the bottom end of a cutting tool bit in a mirror image mode, the rotary cutting efficiency of the two ends of the cutting tool bit can be improved through the arc tool slots, hard impurities can be rapidly cut, and the cutting effect is good. A thread protruding ring is in clamped connection with the interior of a ring-hook-shaped avoiding groove and is fixed through aconnection bolt, and connection firmness between the cutting tool bit and a cutting port ring part can be effectively ensured. By means of up-down matching arrangement of the cutting tool bit and thecutting port ring part, impurities are not likely to be clamped in the cutting assembly to caused faults and damage.

Owner:TAIZHOU TAIFENG PUMP IND

Antibacterial and antivirus super soft floor wet wipe and preparation method thereof

ActiveCN110840312BLow toxicityImprove anti-corrosion performanceBiocideFungicidesBenzalkonium chlorideGlycerol

Owner:铜陵麟安生物科技股份有限公司

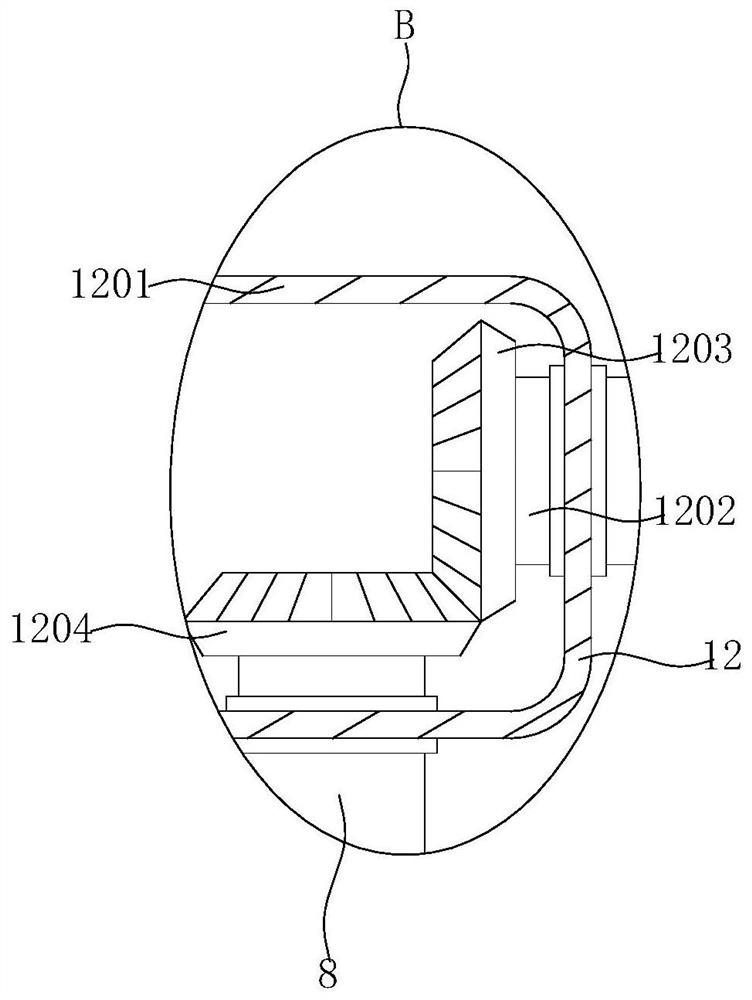

Liquefied gas stable jetting subsection transporting structure for cars

InactiveCN107762680AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricitySolenoid valve

The invention discloses a liquefied gas stable jetting subsection transporting structure for cars. The liquefied gas stable jetting subsection transporting structure comprises a gas inlet pipe and a hollow pipe, a plurality of jetting holes are formed in the upper end of the hollow pipe, solenoid valves are correspondingly installed on the jetting holes, grooves with major arc cross sections are formed in the inner wall of the hollow pipe, the jetting holes right face the arc bottoms of the grooves, a plurality of electric heating pipes are arranged in the grooves, one end of each electric heating pipe penetrates the end of the hollow pipe to be connected with a connection line insertion plate, a heat conduction plate covers the open end of each groove, and the interiors of the grooves areseparated from the interior of the hollow pipe through the heat conduction plates. Compared with a hydrothermal manner, the adopted electric heating manner avoids the liquid leakage risk, and meanwhile, the heating efficiency is greatly improved; and the multiple electric heating pipes are placed in the arc grooves, the side ends of the grooves are sealed through the connection line insertion plate, heat losing can be reduced, meanwhile, the electric heating pipes can be conveniently taken and placed, in other words, a user can determine the number of the electric heating pipes in real time according to the supply amount of gas, and it is guaranteed that stable operation on gas output flow is achieved with smallest cost.

Owner:邱晓霞

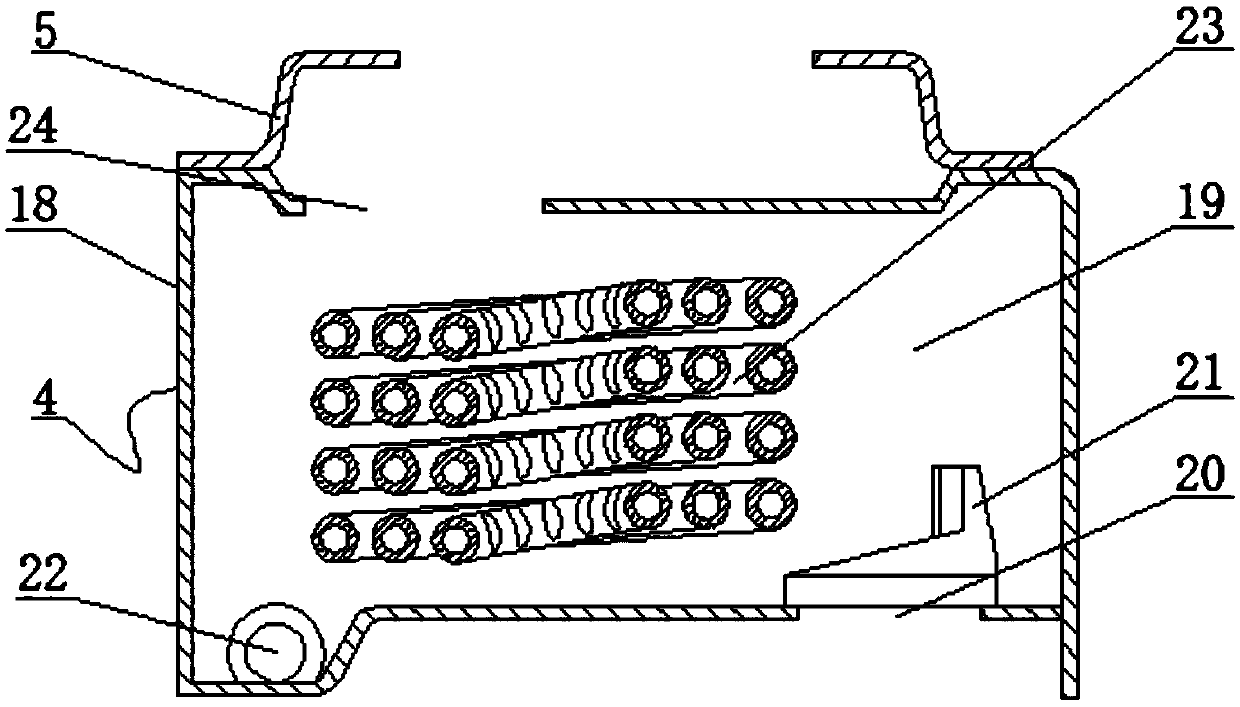

Latent heat recovery type water heater

InactiveCN109579306ACausing leakageEasy to pourAir heatersSustainable buildingsEngineeringLatent heat

The invention discloses a latent heat recovery type water heater. The latent heat recovery type water heater comprises a water heater shell and a burner, the burner is fixedly mounted at the lower endposition of the interior of the water heater shell, and a sensible heat exchanger is fixedly mounted at the upper end position of the burner. A latent heat exchanger is fixedly mounted at the upper end position of the sensible heat exchanger, and an exhaust box is fixedly mounted at the upper end position of the latent heat exchanger. A condensate water collecting device is fixedly mounted at thebottom end position of the outer end surface of the left side wall of the water heater shell, and a gas supply pipe is fixedly mounted at the bottom end position of the right side of the burner. Condensate water can be collected by the condensate water collecting device, and the situation of the leakage of the condensate water caused by the rupture of a hose is effectively avoided; and through anarranged collecting cup fixing device, a condensate water collecting cup arranged in the condensate water collecting device can be clamped and fixed conveniently and effectively.

Owner:SIYUAN ELECTRIC APPLIANCES

A Preliminary Filter for Photochemical Sewage Treatment

ActiveCN111729366BReduce cloggingAffect flow rateWater/sewage treatment by irradiationSpecific water treatment objectivesGear wheelElectric machinery

Owner:DAQING HUALI MECHANICAL MFG

Antifreezing liquefied gas spraying device

InactiveCN107762666AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusElectricityLiquid gas

The invention discloses an antifreezing liquefied gas spraying device. The antifreezing liquefied gas spraying device comprises a gas inlet pipe and a hollow pipe. The upper end of the hollow pipe isprovided with a plurality of spraying holes. The spraying holes are correspondingly provided with electromagnetic valves. A groove is formed in the inner wall of the hollow pipe. The spraying holes are dead against the groove. The groove is internally provided with a plurality of electrical heating pipes side by side. The bottoms of the electrical heating pipes are provided with a guide block. Thebottom of the groove is provided with a guide groove coordinating with the guide block. Each electrical heating pipe comprises a pipe body, an insulating material filling the pipe body and a heatingwire arranged in the pipe body, wherein the tail end of the heating wire is connected with wiring terminals, the end, far away from the gas inlet pipe, of the groove is provided with small holes communicating with the outside, and the wiring terminals pass through the small holes and are connected with a wiring board. The open end of the groove is covered by a heat conduction plate. The lower portions of the pipe bodies of the electrical heating pipes are provided with the guide block which coordinates with the guide groove, and therefore the pipe bodies can be put more stably, the fastening of the electrical heating pipes can be achieved without additionally arranging a new fixing structure, and the purpose of optimizing the internal structure of a spray rail is achieved.

Owner:彭建明

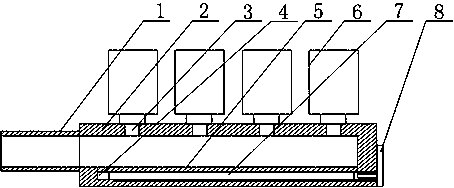

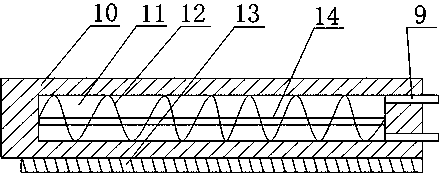

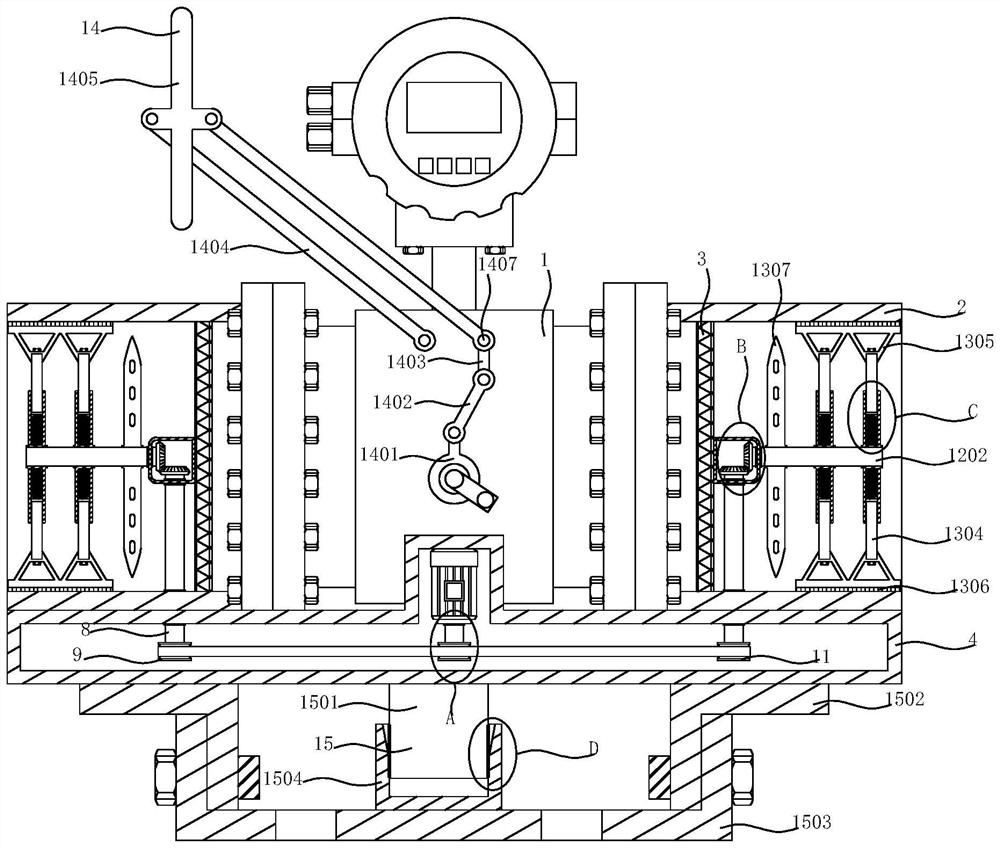

Flow meter for preventing impurities from blocking pipeline for sewage conveying

InactiveCN113155223AImprove cleaning efficiencyReduce manufacturing costVolume meteringCouplingElectric machinery

The invention discloses a flow meter for preventing impurities from blocking a pipeline for sewage conveying, and relates to the technical field of sewage treatment. The flow meter for preventing impurities from blocking a pipeline for sewage conveying comprises a flow meter body, anti-blocking pipelines are fixedly installed at the two ends of the flow meter body through bolts, filter screens are fixedly connected to the inner walls of the two anti-blocking pipelines, T-shaped plates are fixedly installed on the outer walls of the two anti-blocking pipelines, motors are fixedly installed at the tops of the inner sides of the T-shaped plates, an output shaft of the motor is fixedly connected with a short rotating rod through a coupling, and one end of the short rotating rod is fixedly connected with a first chain wheel. According to the flow meter for preventing impurities from blocking a pipeline for sewage conveying, through cooperative use of the sleeve, the telescopic spring, the movable block, the connecting rod, the connecting frame, a brush and a crushing blade, the inner wall of the pipeline can be effectively cleaned, the impurities on the inner wall of the pipeline are effectively prevented from being coagulated into blocks, the situation that the flow speed of sewage is affected by the impurities is avoided, and the flowing smoothness of the sewage is improved.

Owner:成都百思图科技有限公司

Fuel gas injection method for dual-fuel vehicle

InactiveCN105822461AAffect flow rateGuaranteed circulationInternal combustion piston enginesFuel supply apparatusHeat conductingEngineering

The invention discloses a fuel gas injection method for a dual-fuel vehicle. The fuel gas injection method comprises a gas intake pipe and a hollow pipe. A plurality of injection holes are formed in the upper end of the hollow pipe, and the injection holes are correspondingly provided with electromagnetic valves. A groove is formed in the inner wall of the hollow pipe. The injection holes directly face the groove. A plurality of electrical heated tubes are arranged in the groove side by side. Guide blocks are installed at the bottoms of the electrical heated tubes. Guide grooves matched with the guide blocks are formed in the bottom of the groove. Each electrical heated tube comprises a tube body, an insulating material filled inside the tube body, and a heating wire arranged inside the tube body. The tail end of each heating wire is connected with a binding post. A small hole communicating with the outside is formed in the end, far away from the gas intake pipe, of the groove. Each binding post penetrates through the small hole to be connected with a wiring board. The open end of the groove is covered with a heat conducting plate. The guide blocks are installed on the lower portions of the tube bodies of the electrical heated tubes, the guide blocks are matched with the guide grooves, and thus the tube bodies can be placed more stably. The electrical heated tubes can be fastened without adding new fixing structures, and accordingly the purpose of optimizing the inner structure of an injection rail is achieved.

Owner:CHENGDU KELIFU SCI & TECH

Improved multi-tube filter

PendingCN114100241AExtended service lifeAvoid bending deformationStationary filtering element filtersEngineeringMechanical engineering

The invention relates to an improved multi-tube filter which comprises a base, a plurality of filter cylinders are arranged on the base, water baffles are arranged on the periphery of the upper portion of the base, a plurality of liquid collecting tubes and a plurality of filter elements in threaded connection with the liquid collecting tubes are arranged in the filter cylinders, and clamping structures are arranged at the threaded connection positions of the filter elements and the liquid collecting tubes. Vertical supporting plates are arranged on the upper portions of the liquid collecting pipes, transverse partition blocks are arranged between the adjacent liquid collecting pipes, and a filter valve is arranged at an inlet of the filter cylinder. It can be guaranteed that the screwed filter element is not prone to falling off, the liquid collecting pipe is not prone to bending deformation, the connecting portion of the liquid collecting pipe and the wall of the filter cylinder is not prone to damage, impurities in fluid can be filtered out, the impurities are prevented from being attached to the interior of the valve body, and the phenomenon of pipe explosion caused by pressure increase is avoided.

Owner:WUXI XINGSHENG ENVIRONMENTAL PROTECTION EQUIPCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com