Patents

Literature

89results about How to "Easy to purge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

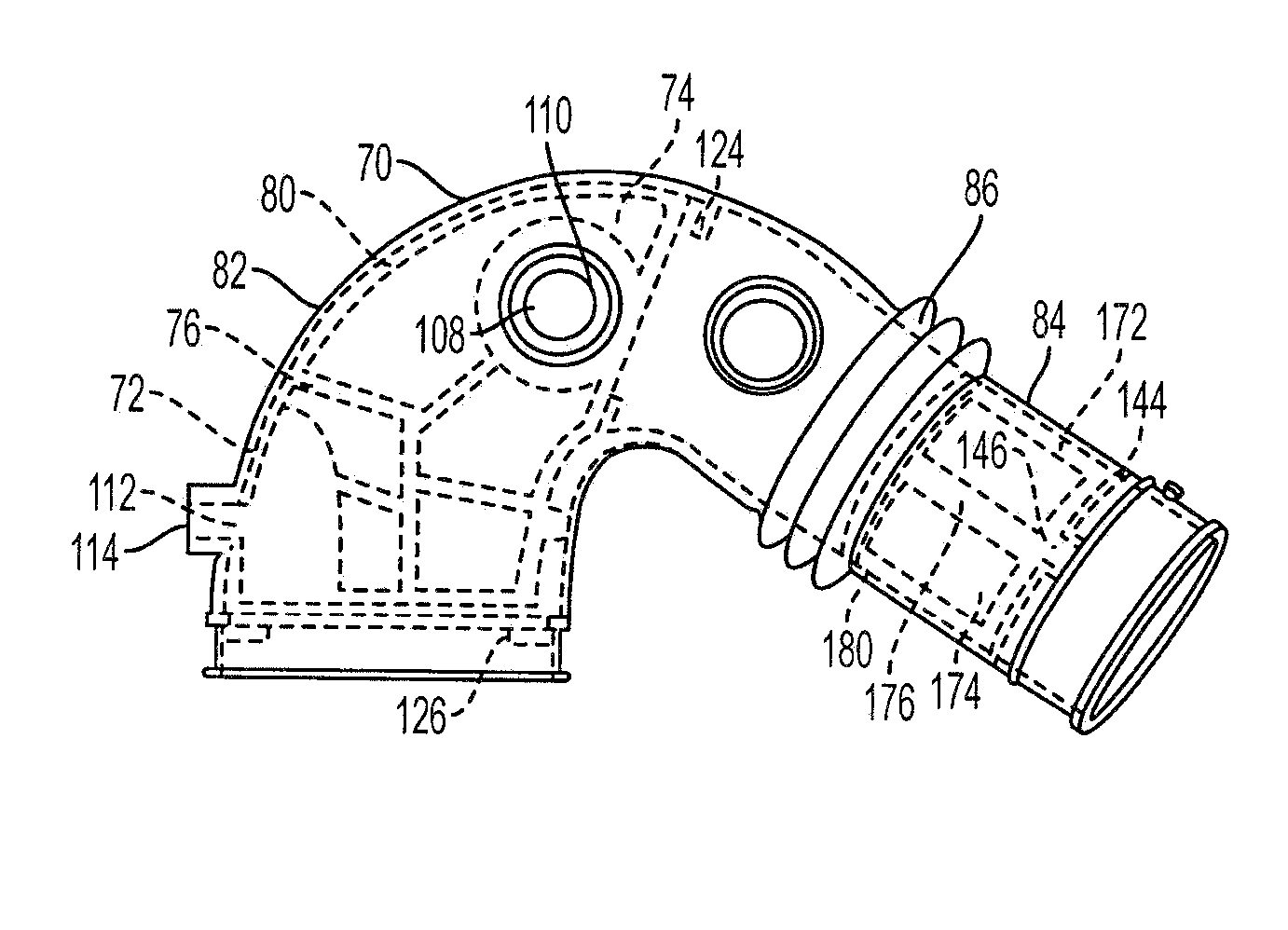

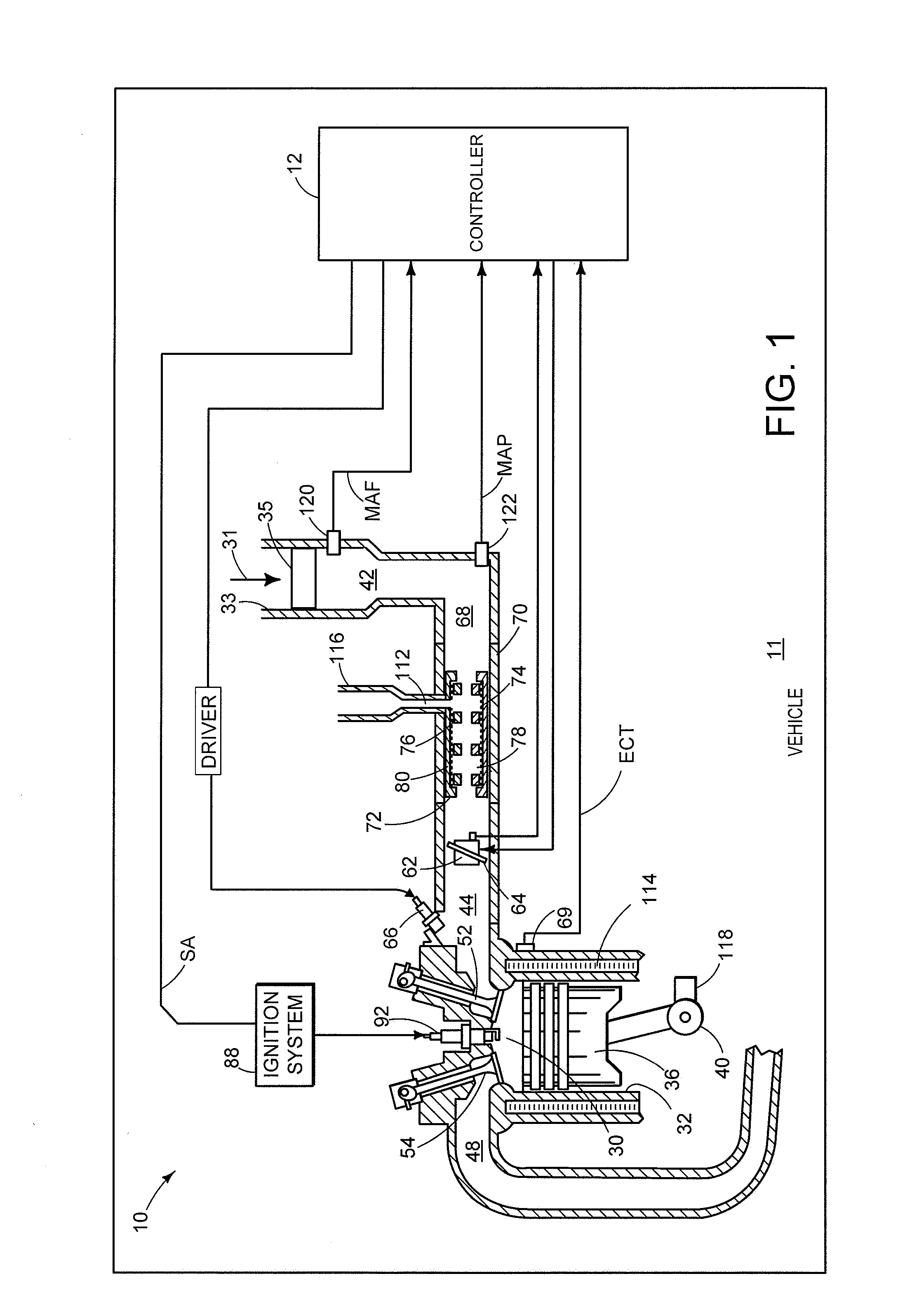

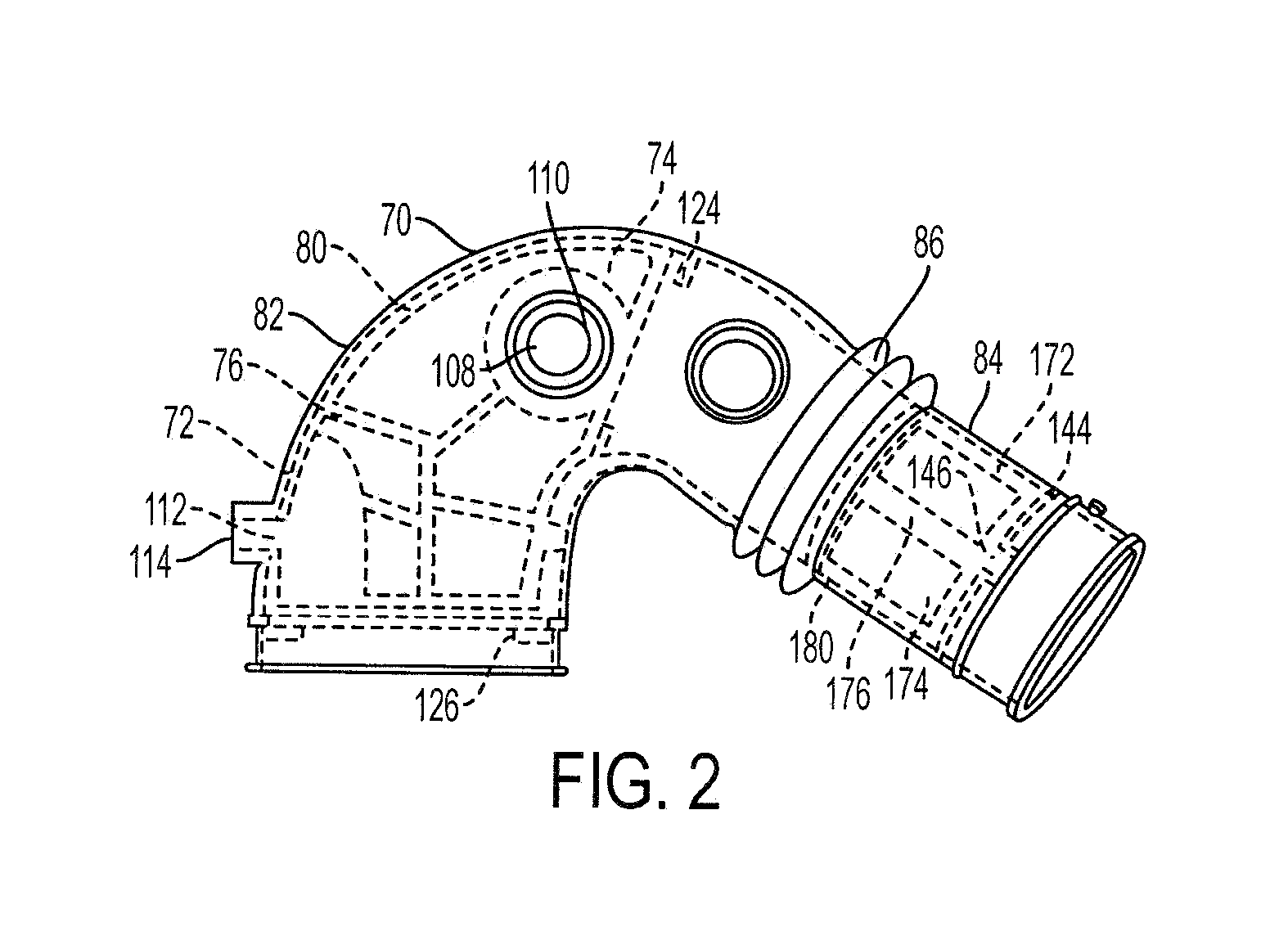

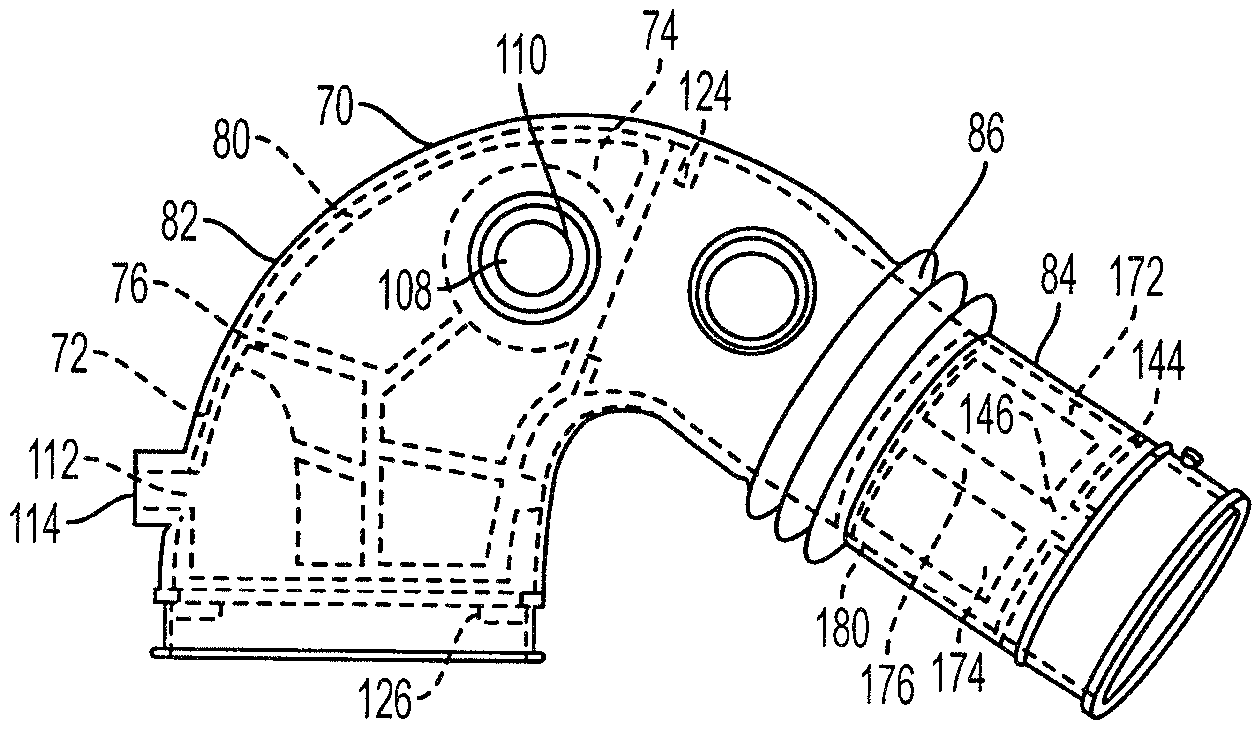

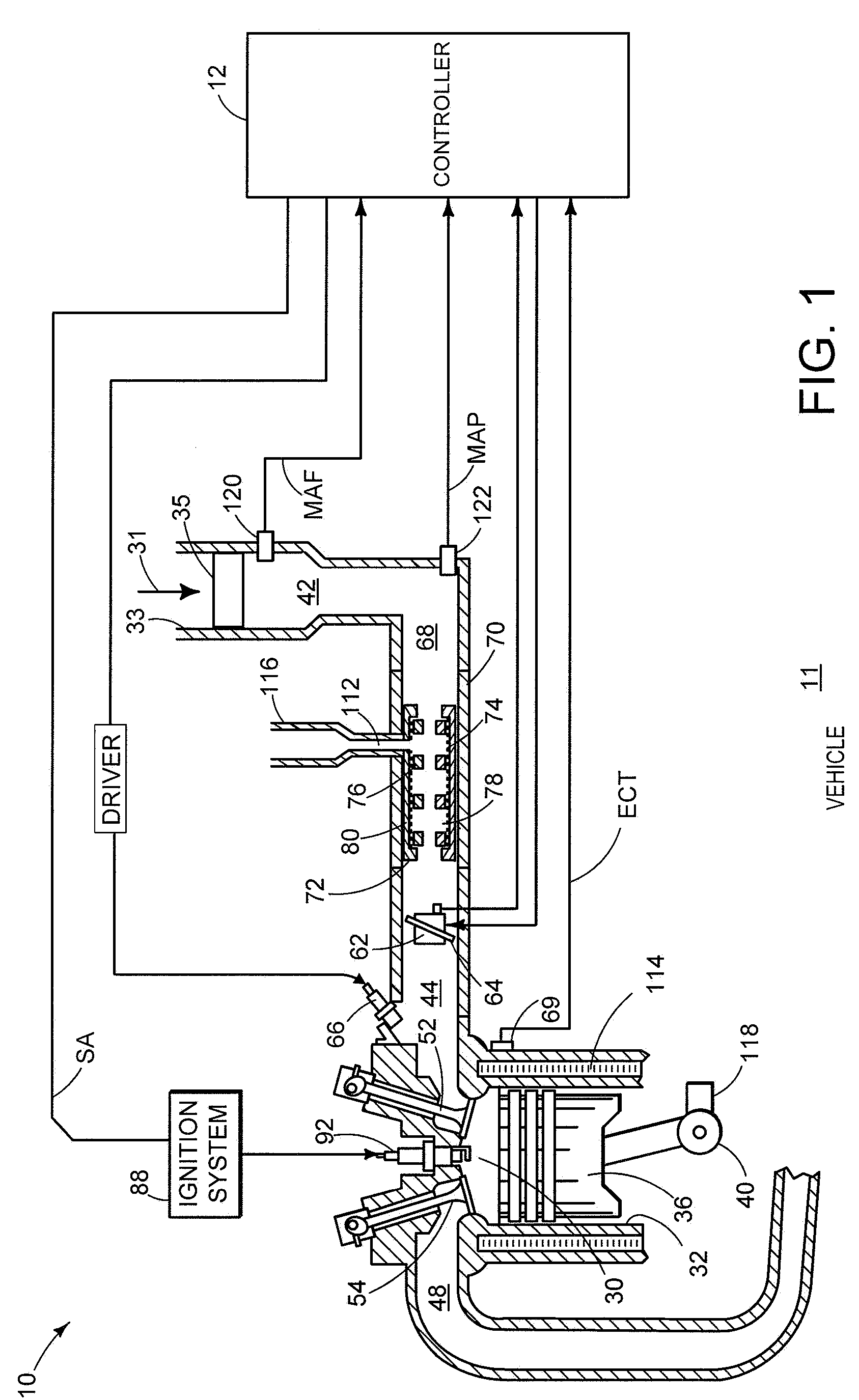

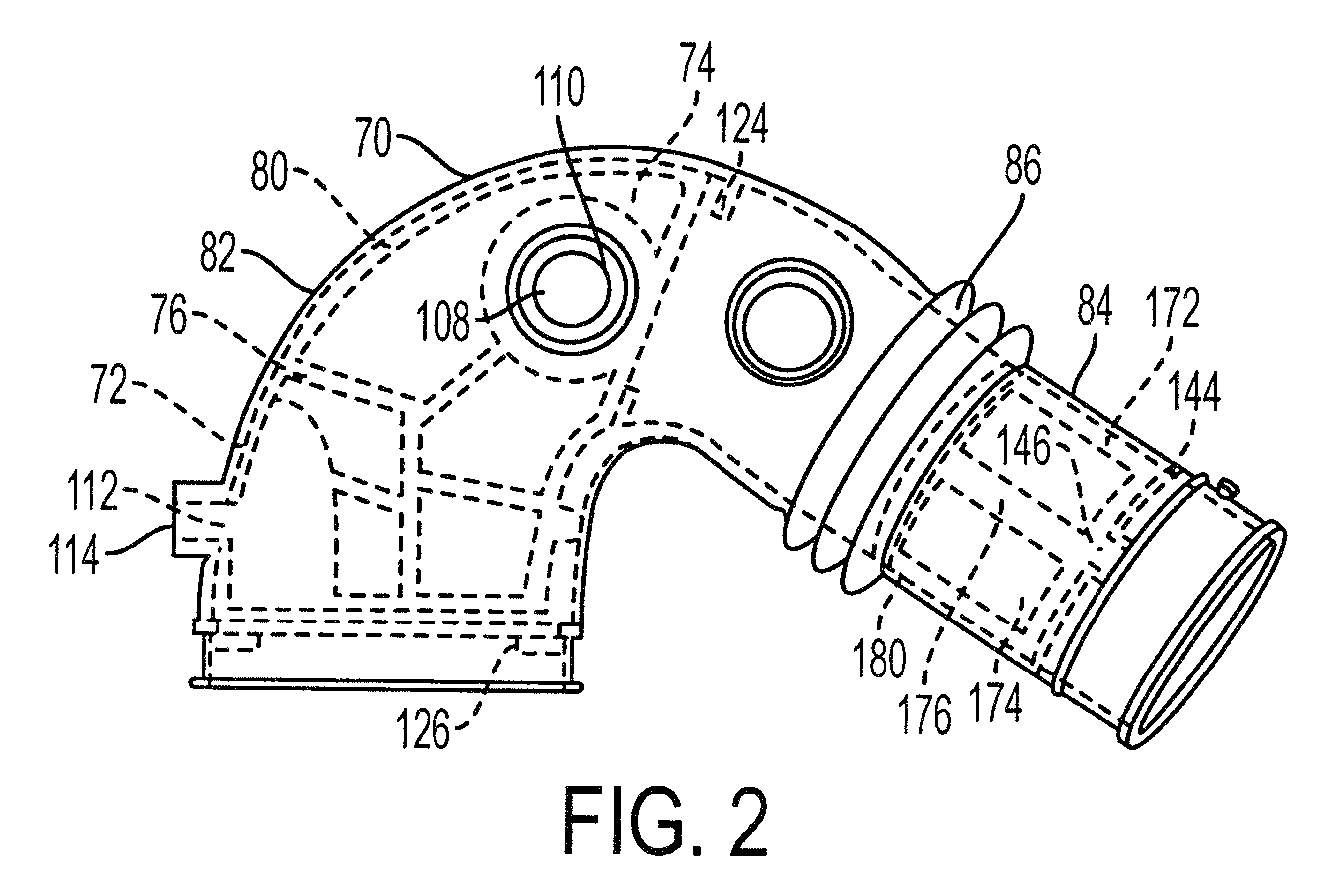

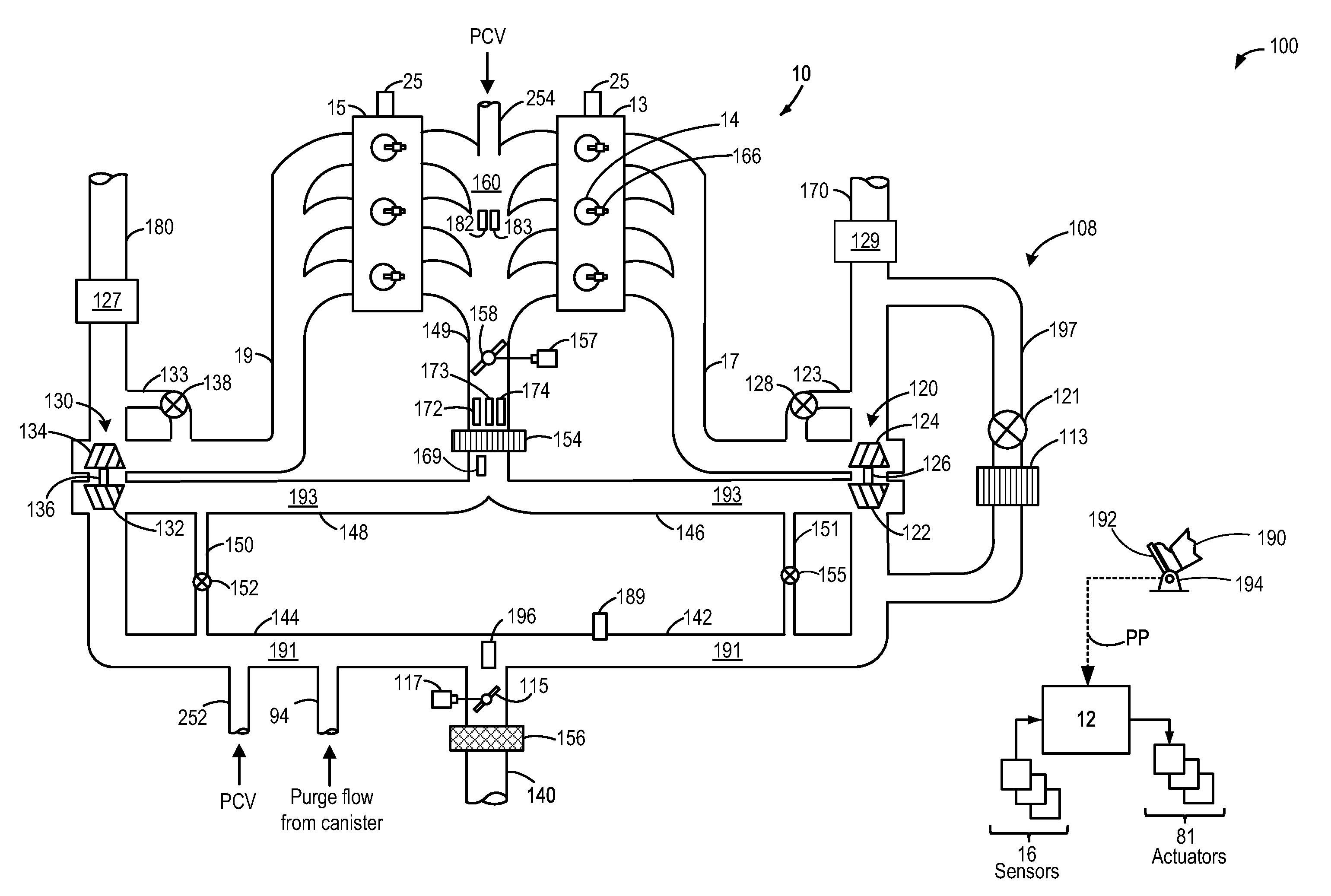

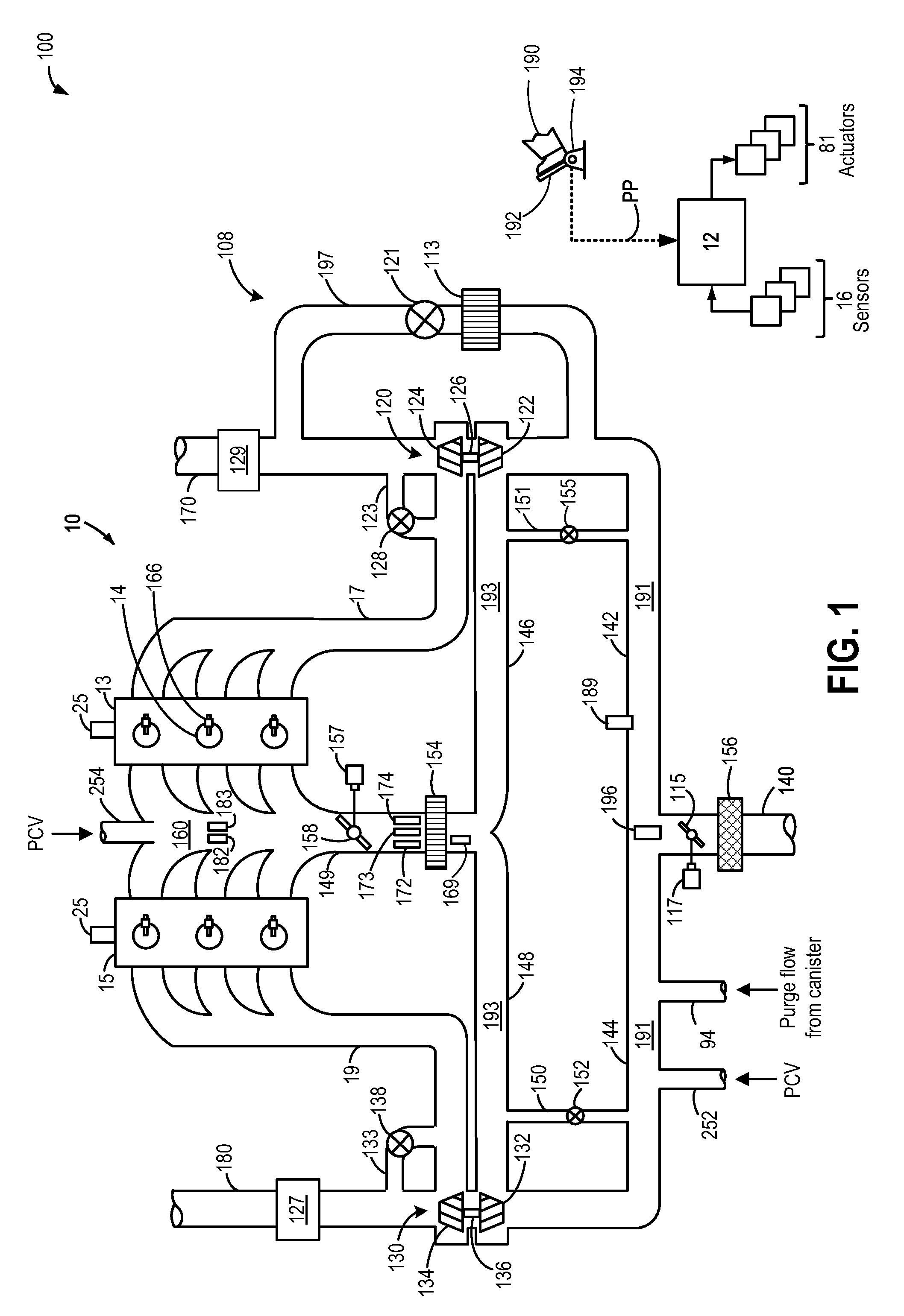

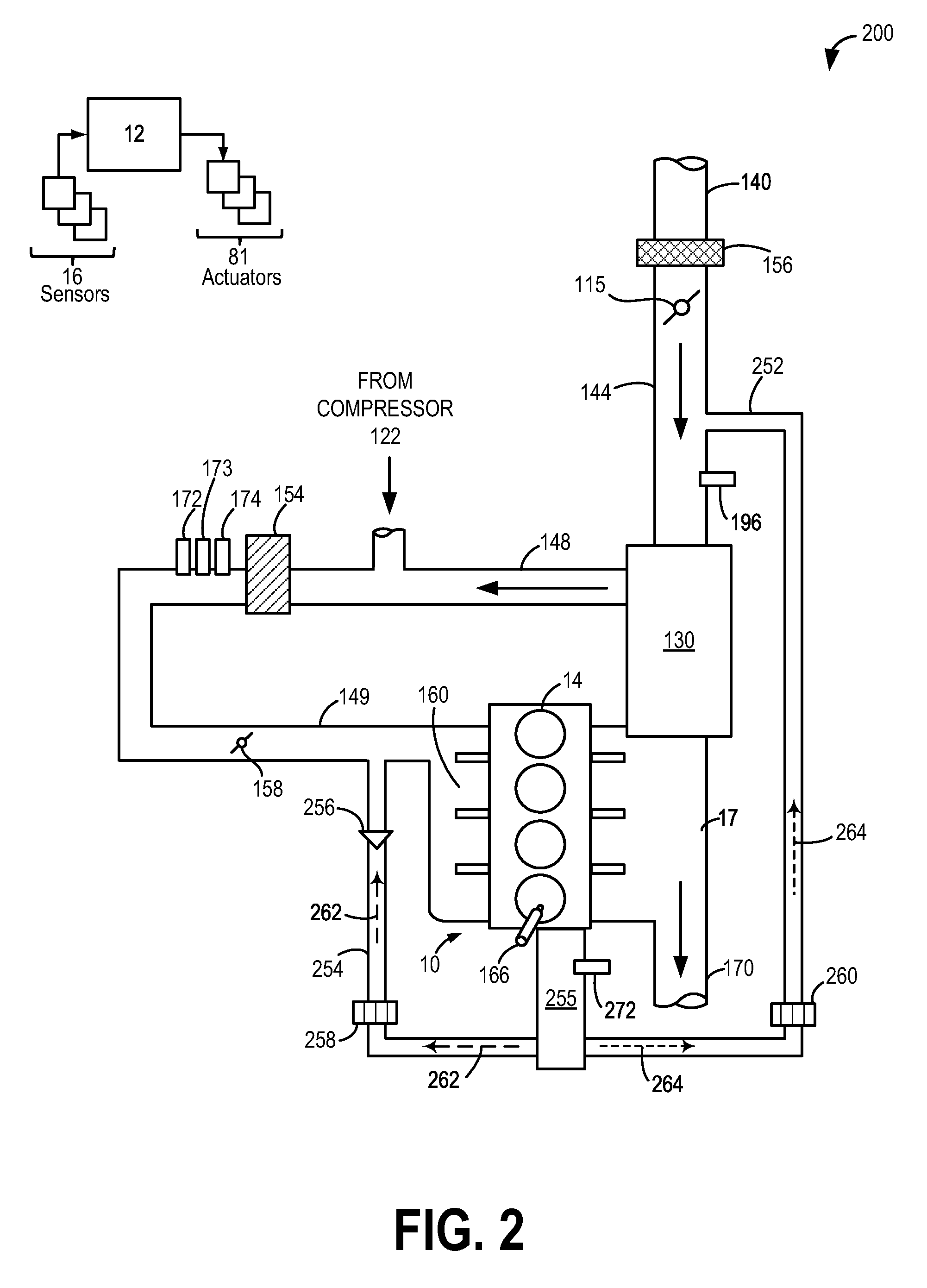

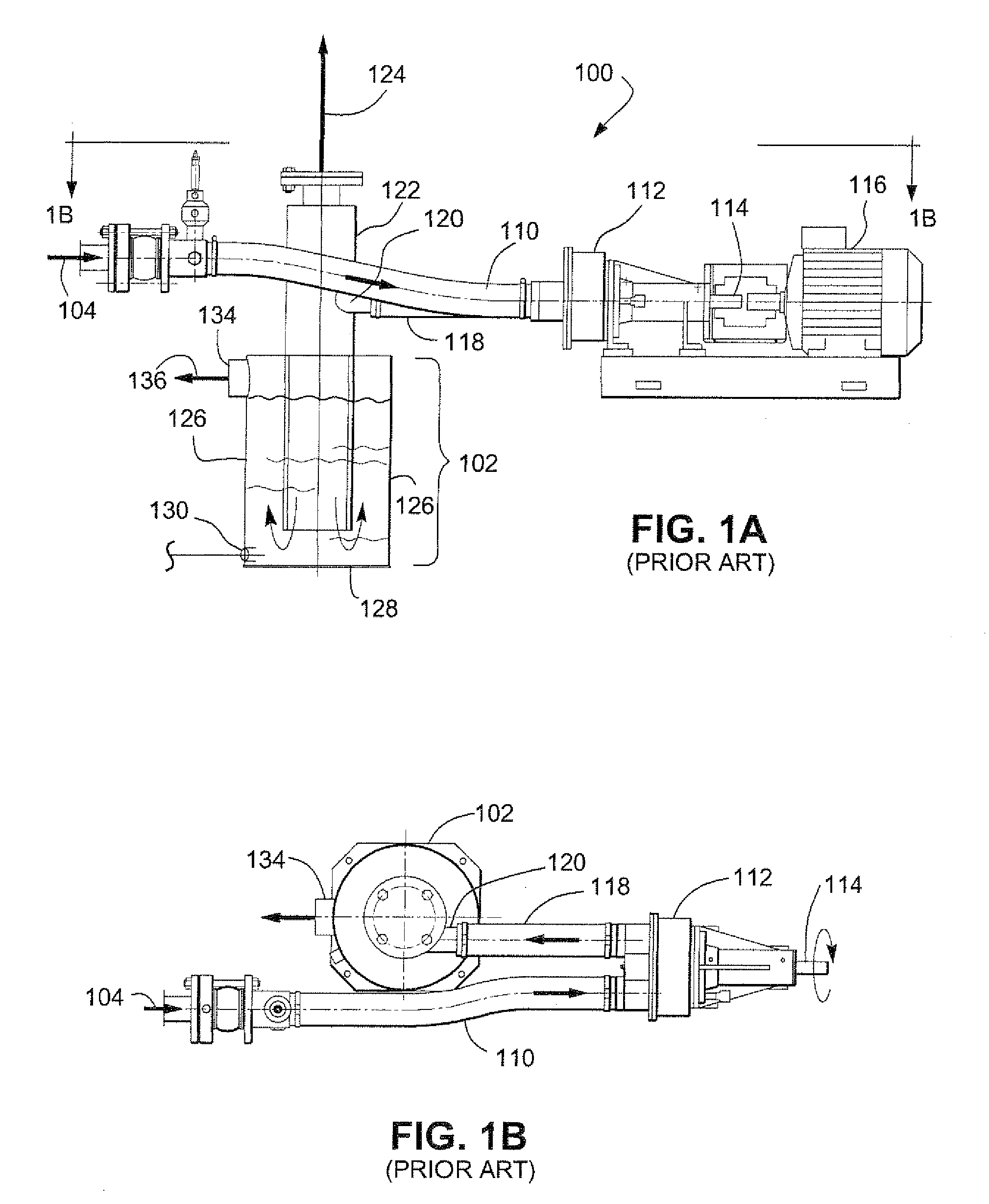

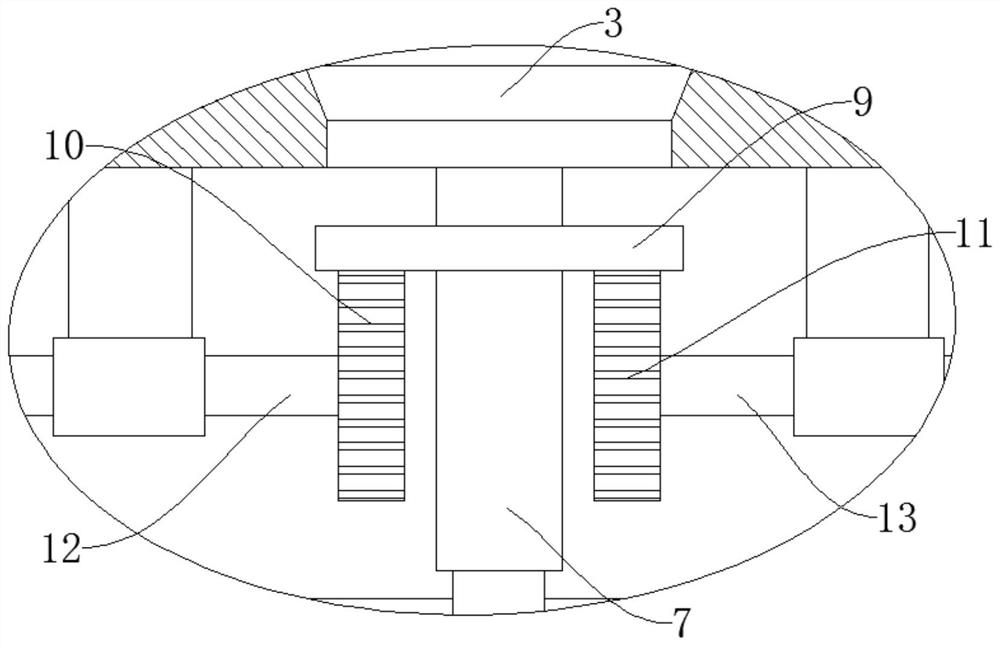

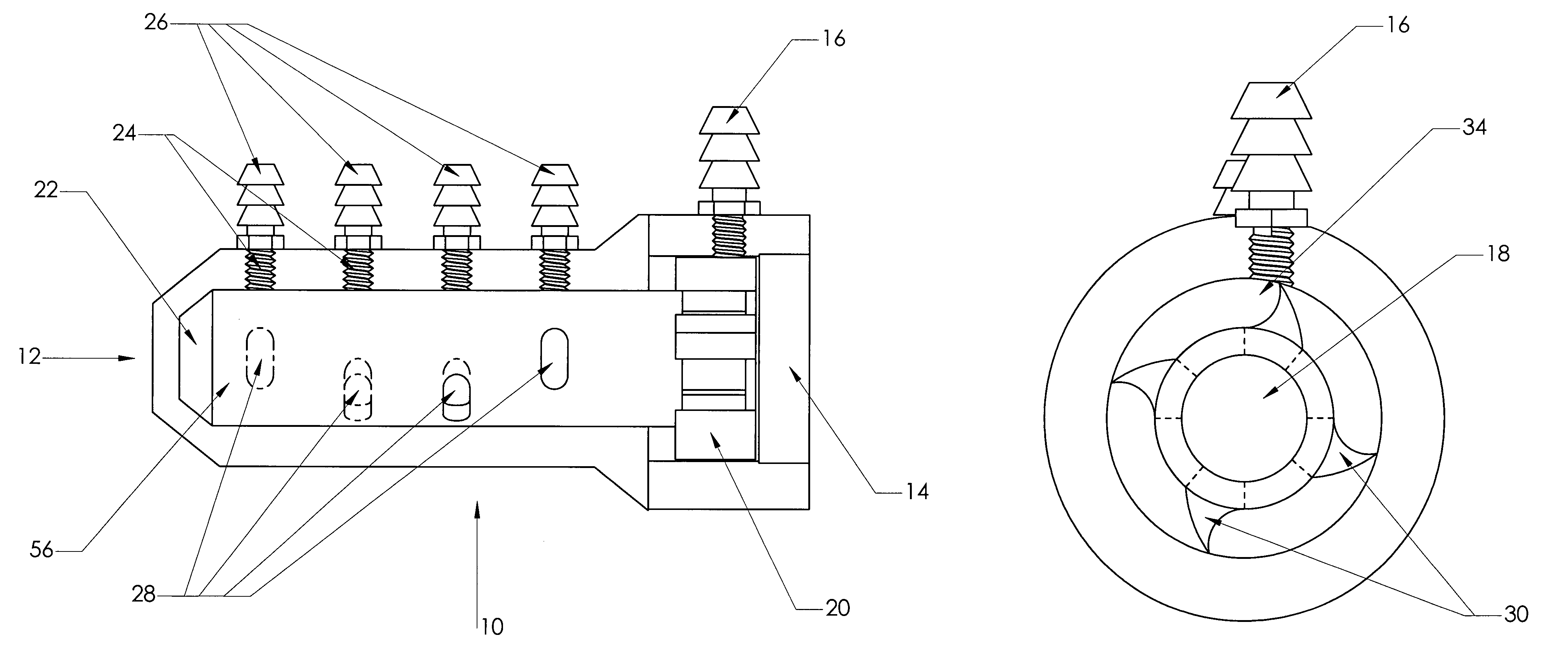

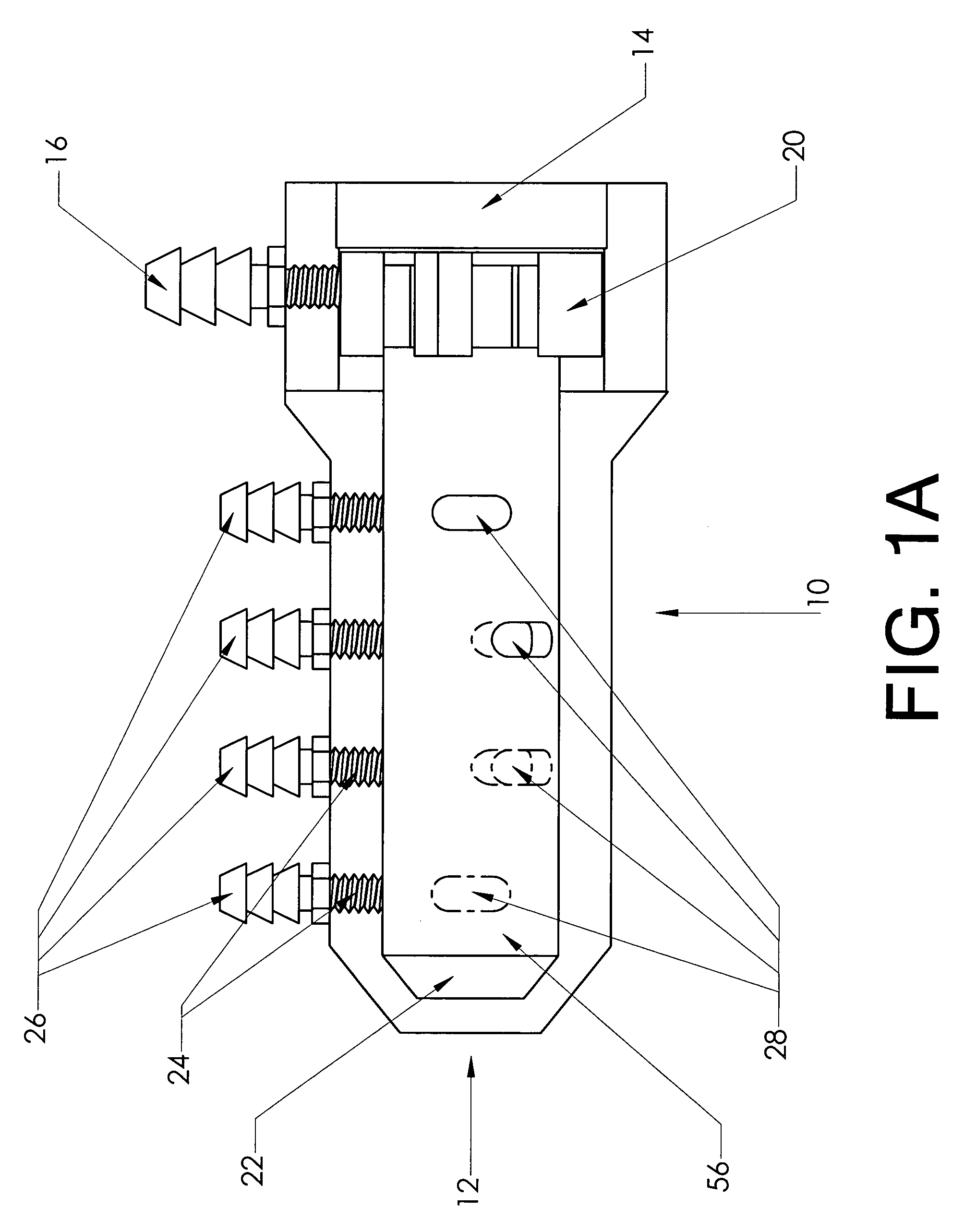

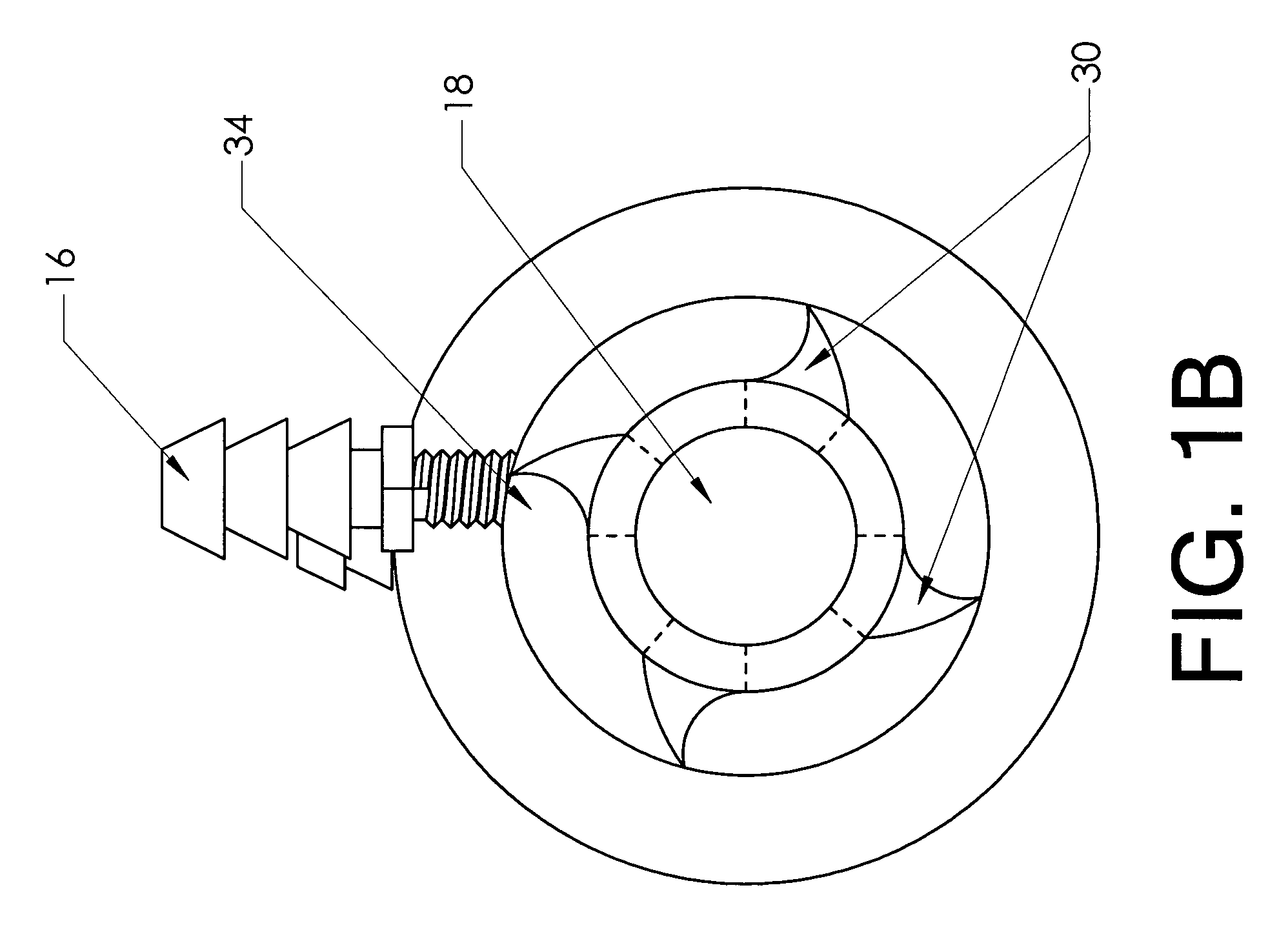

Engine hydrocarbon adsorber

ActiveUS20090282793A1Superior purgingReduce impactCombination devicesNon-fuel substance addition to fuelStructural elementExternal combustion engine

Devices, systems and methods are provided for adsorbing hydrocarbons from the air intake system of an internal combustion engine. The devices, systems and methods include a hydrocarbon absorbent material, and a structural element configured to hold the hydrocarbon absorbent material within a clean air tube of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

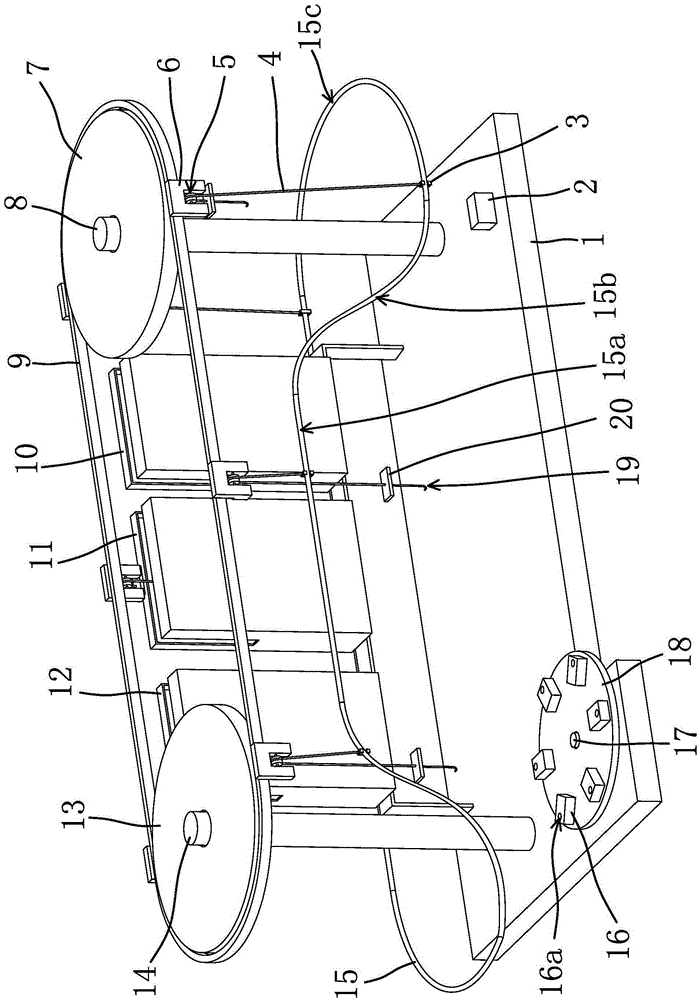

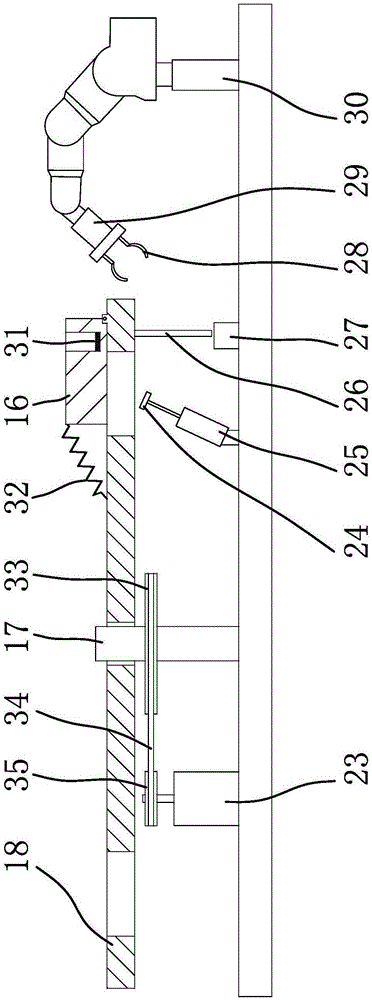

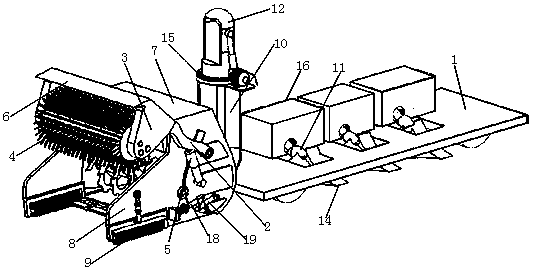

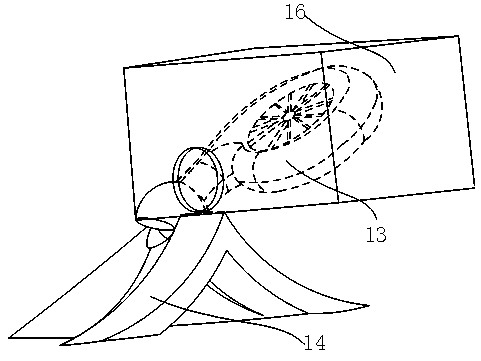

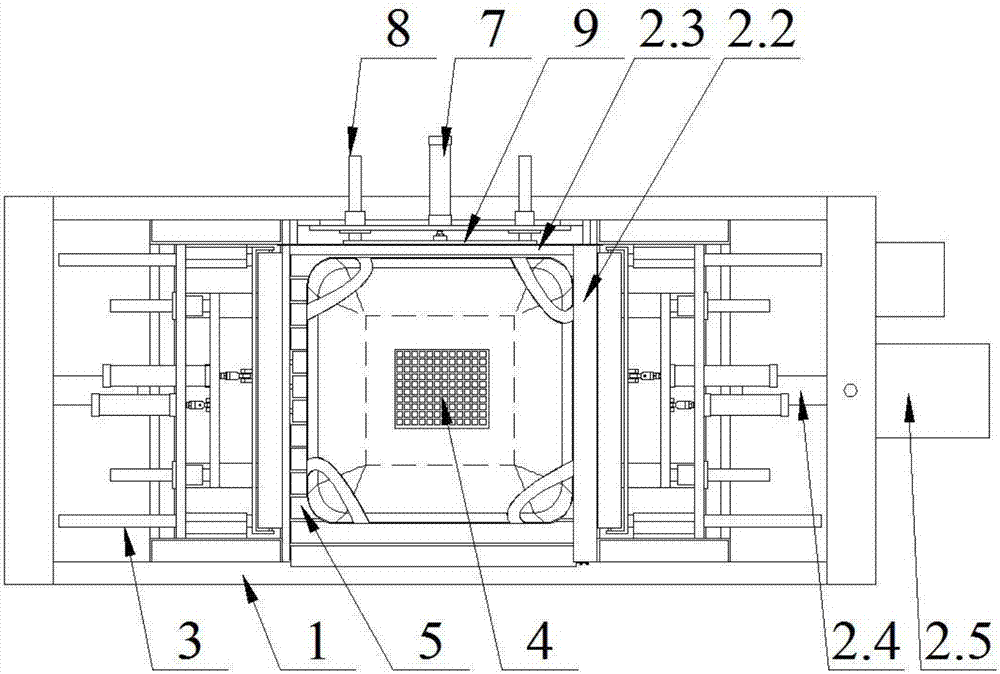

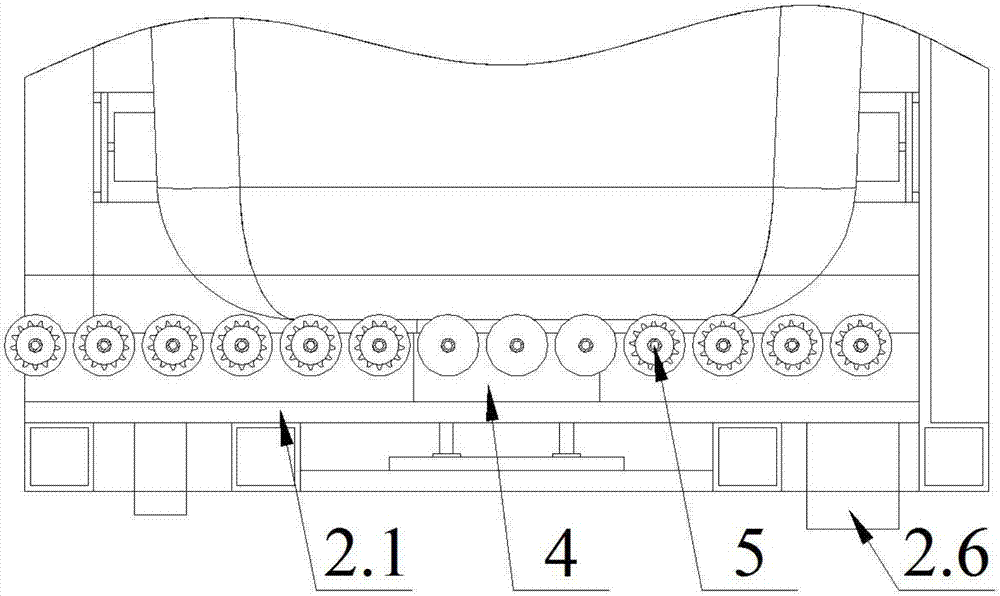

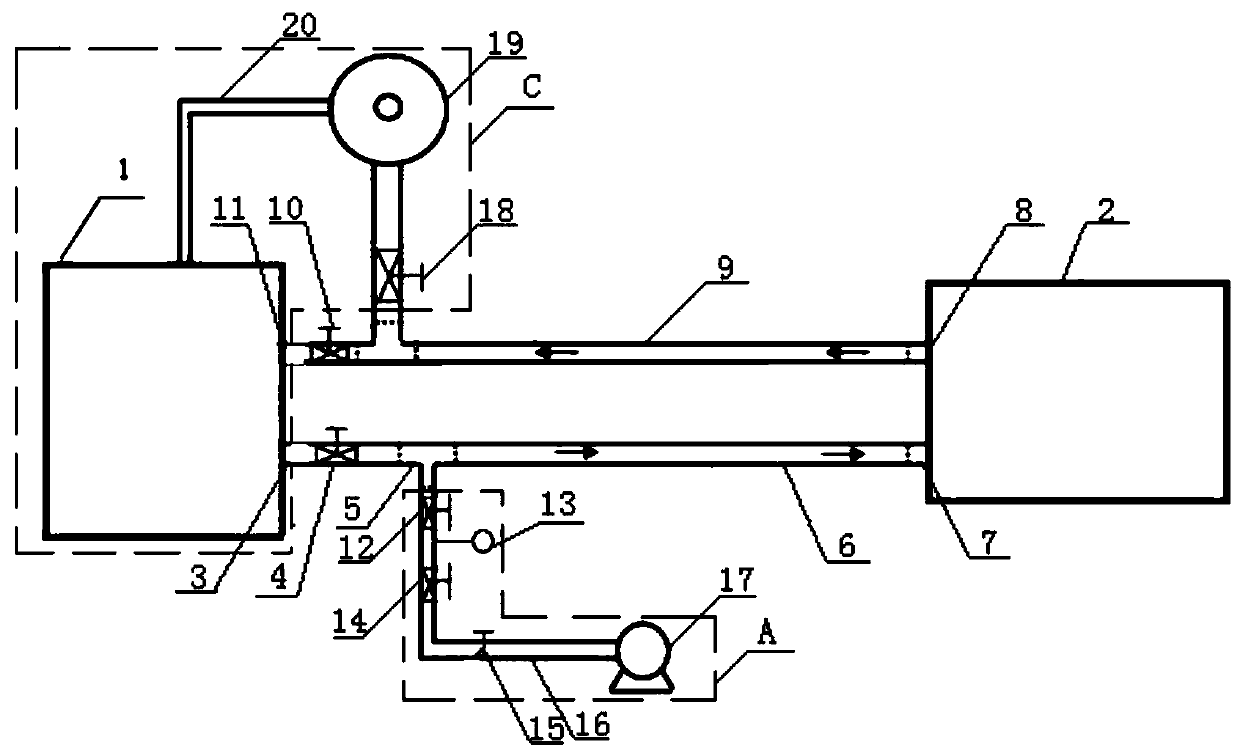

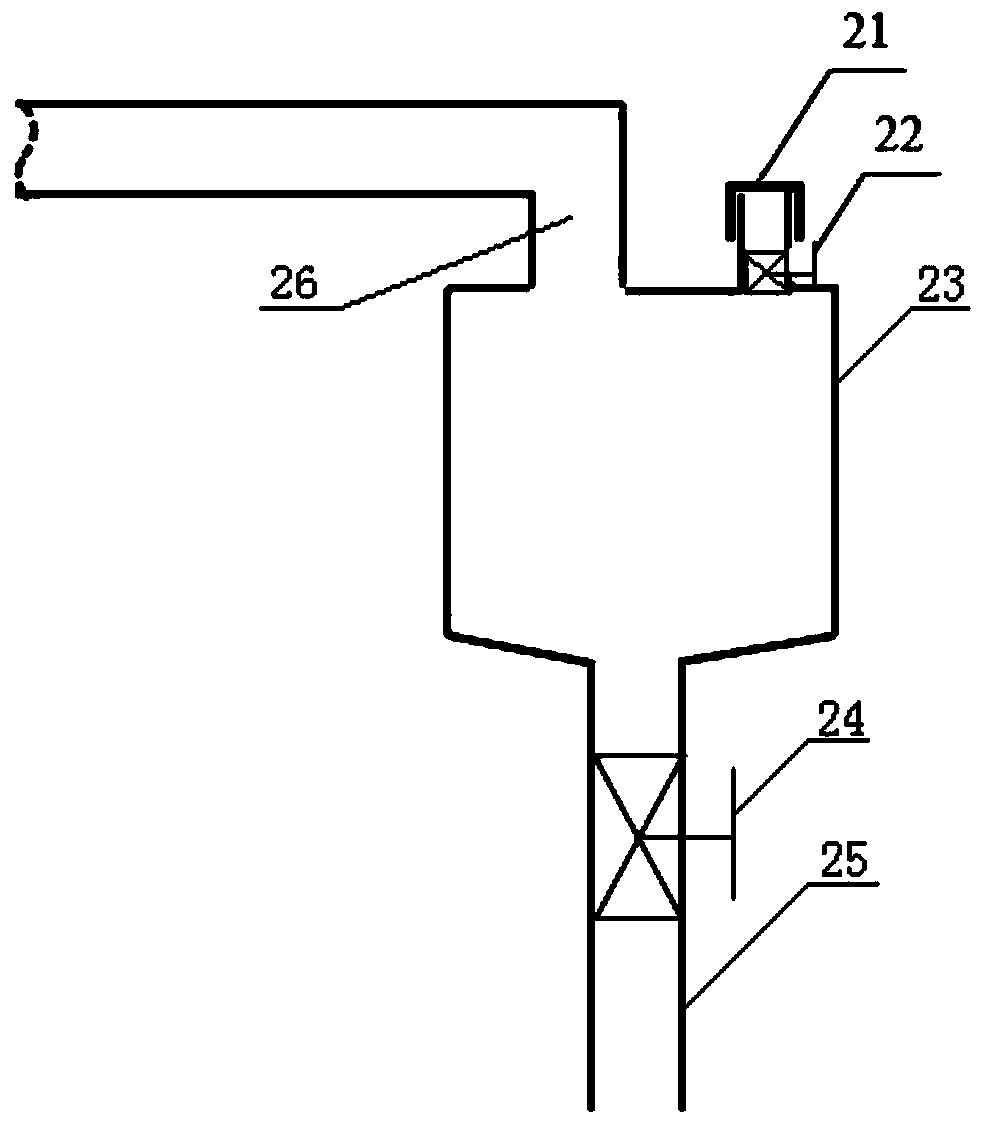

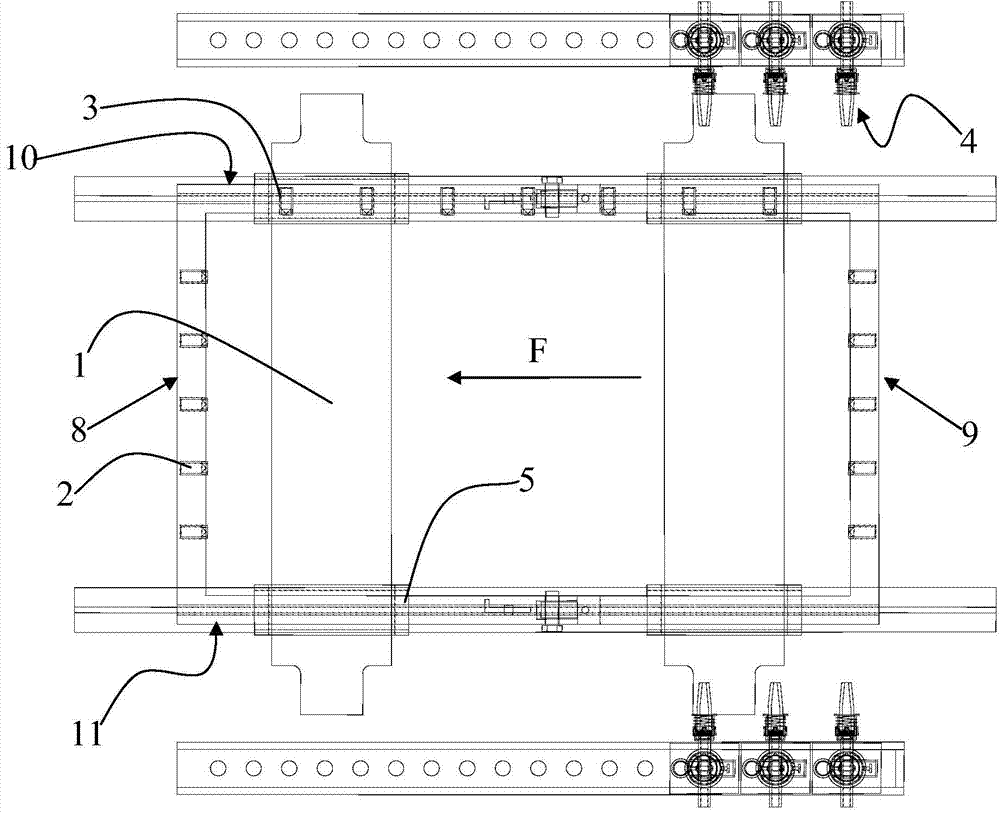

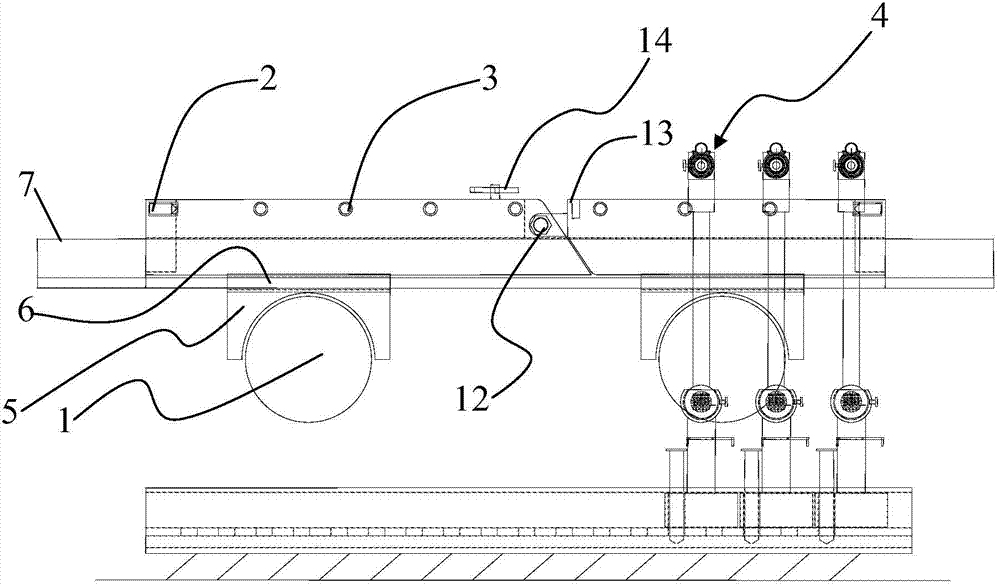

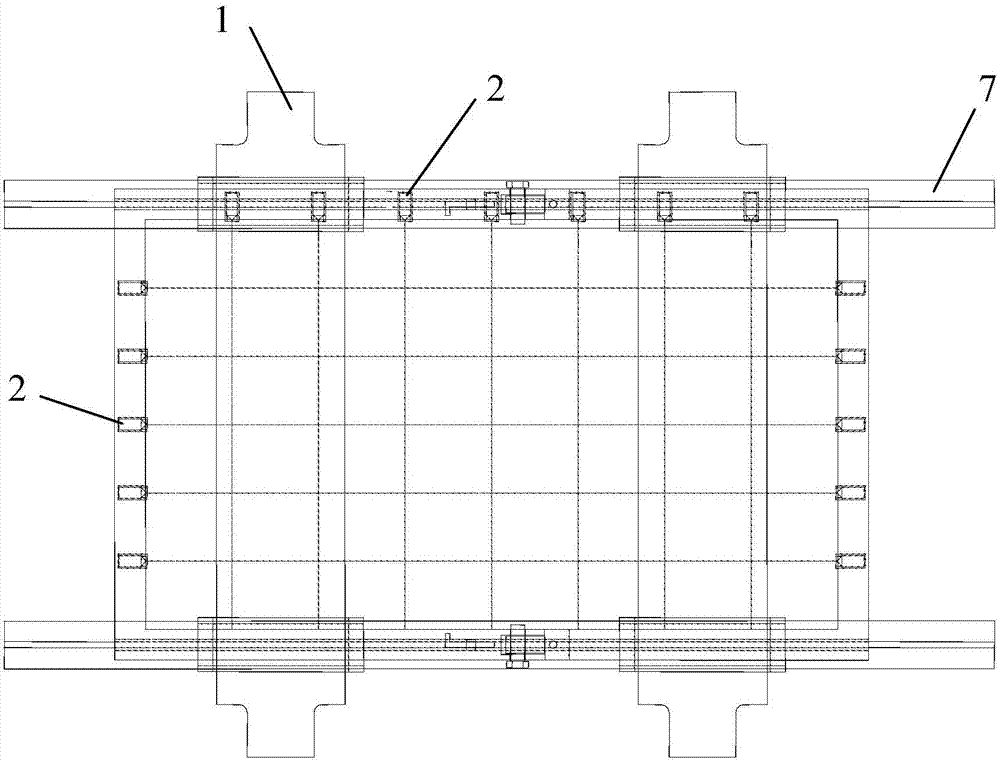

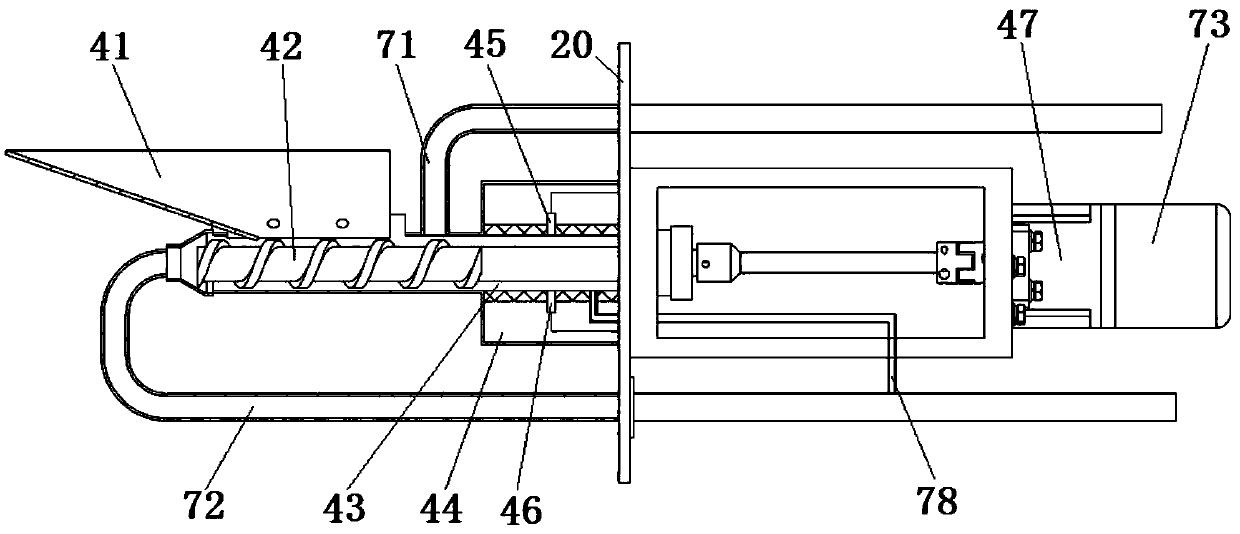

Bag-cage skeleton and paint spraying system thereof

ActiveCN105413338AExtended use timeExtended service lifeLiquid surface applicatorsDispersed particle filtrationLacquerEngineering

The invention provides a bag-cage skeleton and a paint spraying system thereof. In the prior art, the conventional paint sprayer does not have a delivering structure, a blowing and washing structure, a drying structure, and a feeding structure; thus a bag-cage skeleton has to be delivered, blown, washed, dried, and fed through artificial operation; the operation is complicated, and the extremely-long skeleton is inconvenient for delivering. The provided bag-cage skeleton comprises a first skeleton body and a second skeleton body; the first skeleton body and the second skeleton body are connected through a detachable structure; the length ratio of the first skeleton body to the second skeleton body is 1:1 or 2:1; the first skeleton body and second skeleton body are both covered by a layer of protective paint, and the paint is sprayed on the first skeleton body and second skeleton body through a paint spraying system. The bag-cage skeleton also comprises a paint spraying system. The bag-cage skeleton and paint spraying system have the advantages of convenient transportation and paint spraying.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

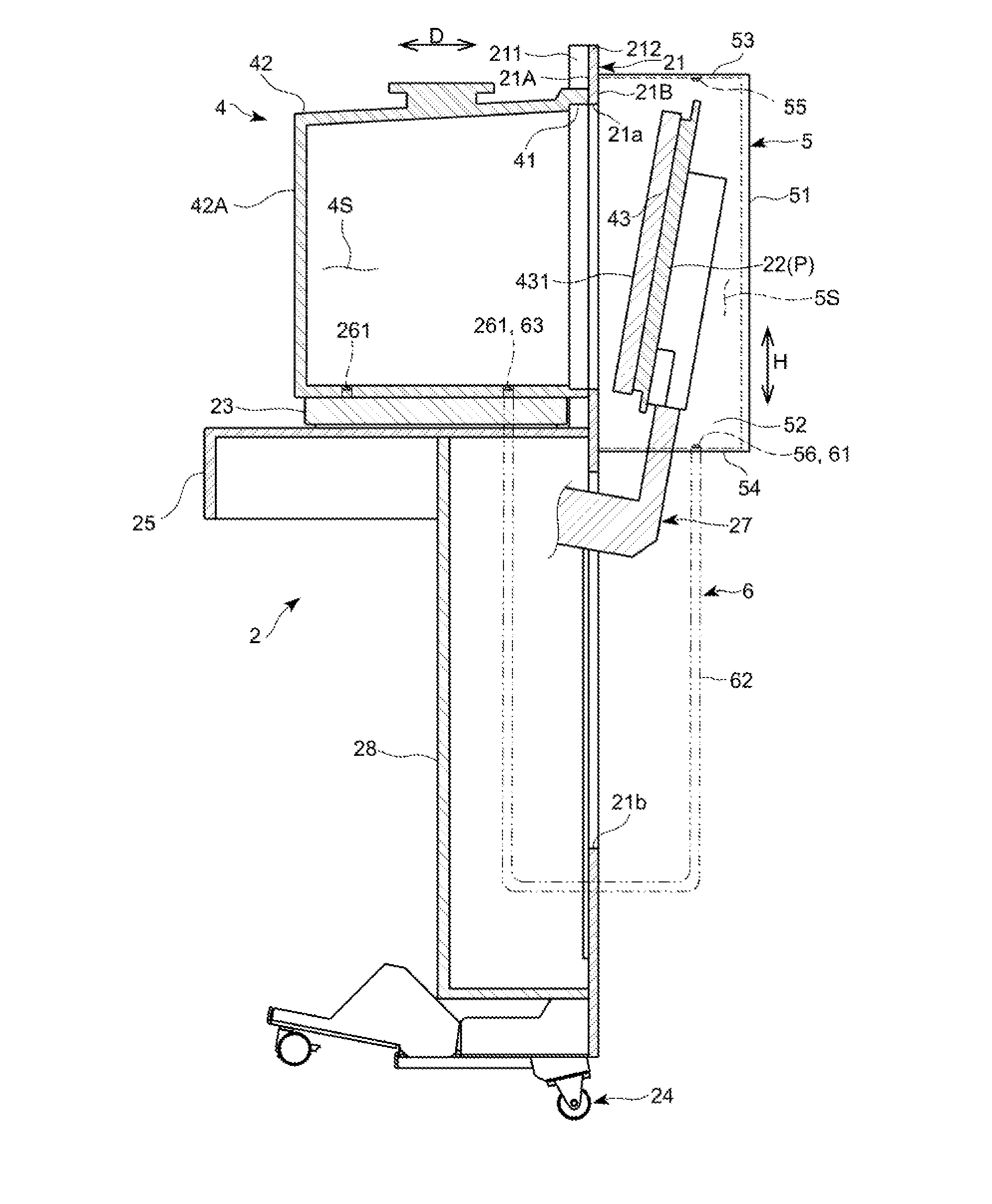

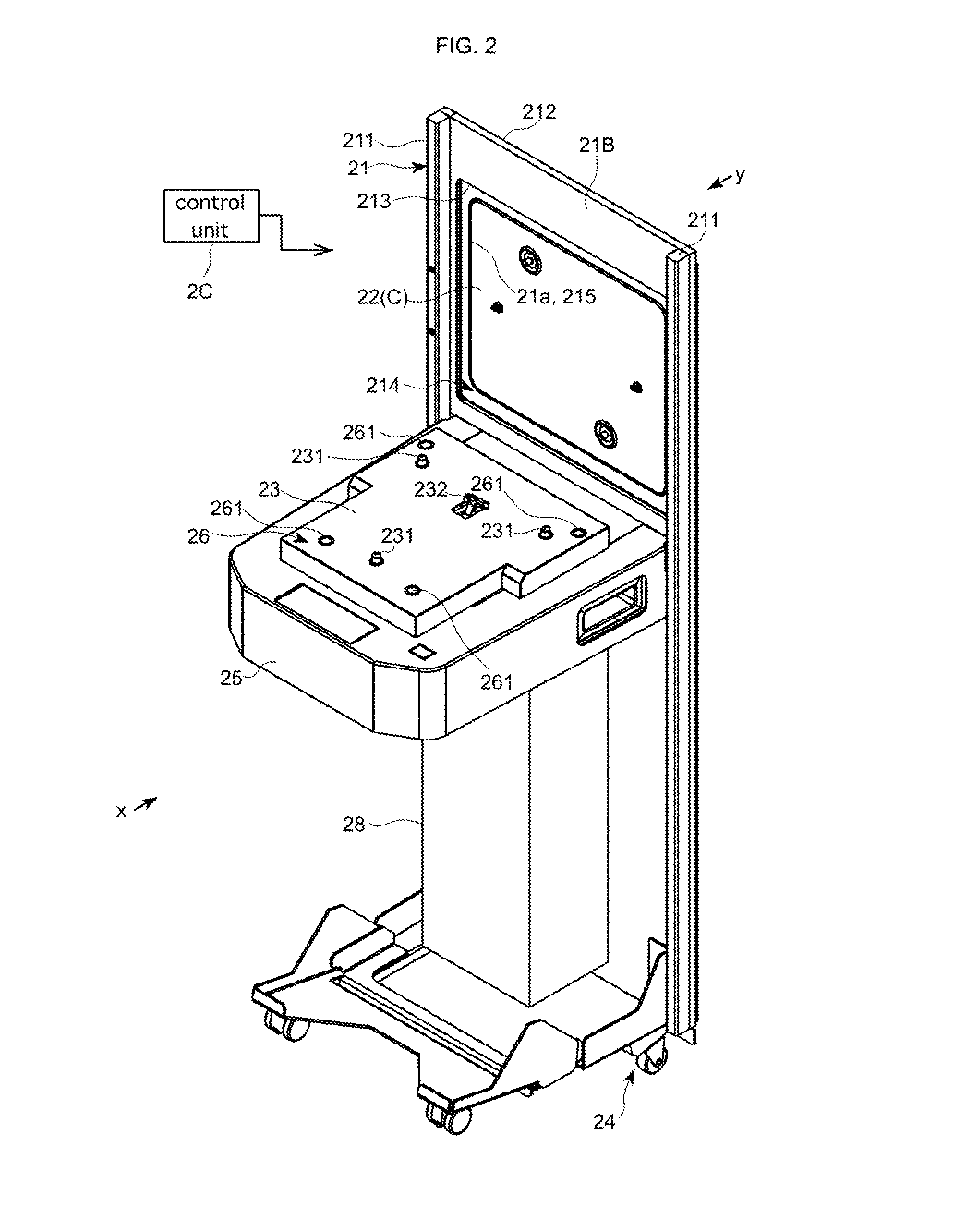

Door opening and closing apparatus, transfer apparatus, and storage container opening method

InactiveUS20160260627A1Reduce spacingPrevent and suppressSemiconductor/solid-state device manufacturingConveyor partsInterior spaceEngineering

A door opening and closing apparatus includes: a frame that structures part of a wall surface of a transfer room and is provided with an opening for opening the transfer room; a door part capable of opening and closing the opening: a placing pedestal on which a storage container can be placed; a chamber provided at a position on the transfer room side so as to face the opening, and having an inner space to be subjected to a purge process with an environmental gas; and a pressure adjusting part causing the inner space of the chamber and the inner space of the storage container to communicate with each other using a route other than the opening. The door opening and closing apparatus can be applied to a wafer transfer apparatus or the like.

Owner:SINFONIA TECHNOLOGY CO LTD

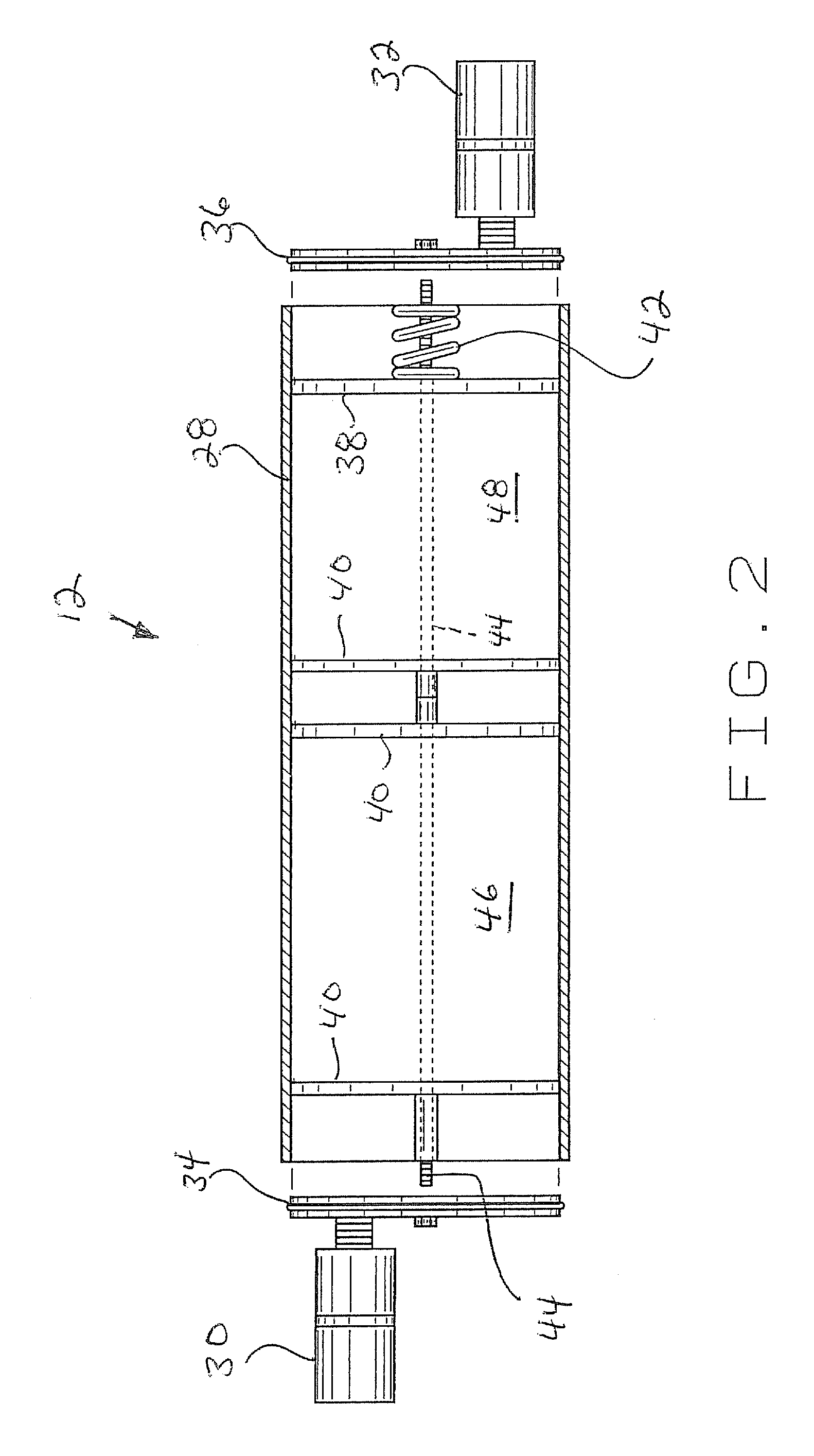

Engine hydrocarbon adsorber

ActiveUS7918912B2Easy to purgeReduce restrictionsCombination devicesNon-fuel substance addition to fuelExternal combustion engineEngineering

Devices, systems and methods are provided for adsorbing hydrocarbons from the air intake system of an internal combustion engine. The devices, systems and methods include a hydrocarbon absorbent material, and a structural element configured to hold the hydrocarbon absorbent material within a clean air tube of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

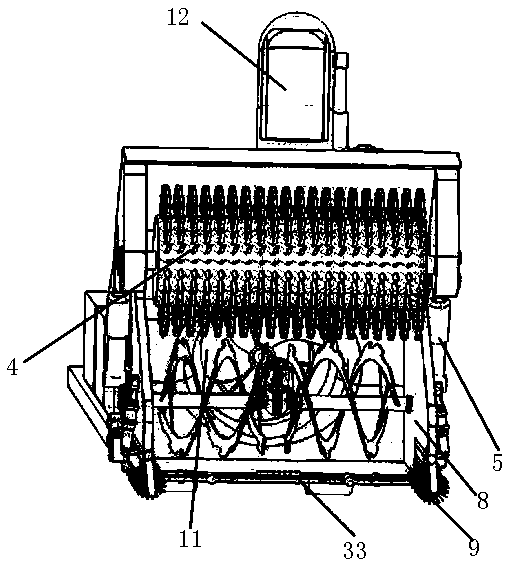

Efficient energy-saving snow sweeper

ActiveCN103452074AImprove snow removal efficiencyOvercome low snow removal efficiencyRailway cleaningEngineering

The invention discloses an efficient energy-saving snow sweeper and mainly solves the problems that the existing snow sweeper is low in sweeping efficiency and poor in effect and the like. The efficient energy-saving snow sweeper comprises a sweeper head and a sweeper body. The sweeper head comprises a front-open snow collection hopper, a front ice breaker, a snow thrower, and a power system, wherein the front ice breaker locating at the front end of the snow collection hopper is rotatably connected with the snow collection hopper, the snow thrower communicated with the snow collection hopper is disposed at the rear end of the snow collection hopper, and the power system powers the sweeper head to operate. A thermal turbine snow blower used for blowing accumulated snow on rails is detachably connected to the bottom of the sweeper body. A pneumatic rotary deicing device and a moisturizing antifreezing solution applicator are further disposed at the top of the sweeper body. The efficient energy-saving snow sweeper is reasonable in design and compact in structure, is far more efficient and effective than the existing all snow sweepers in sweeping. Therefore, the efficient energy-saving snow sweeper is suitable for popularization and application.

Owner:CHANGZHOU LUHANG RAILWAY TRANSPORTATION TECH

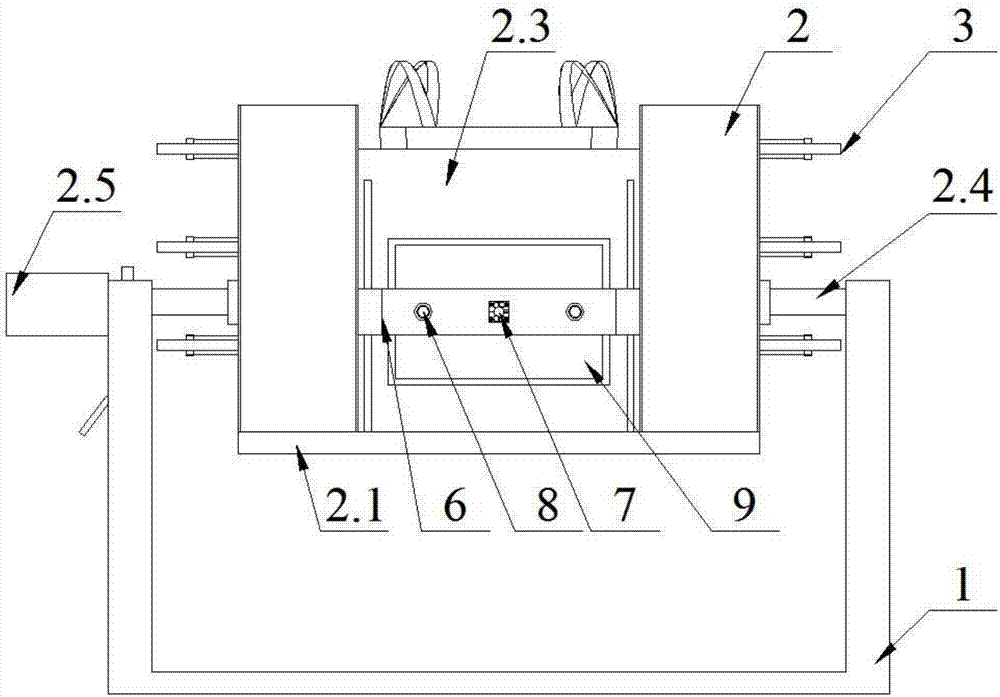

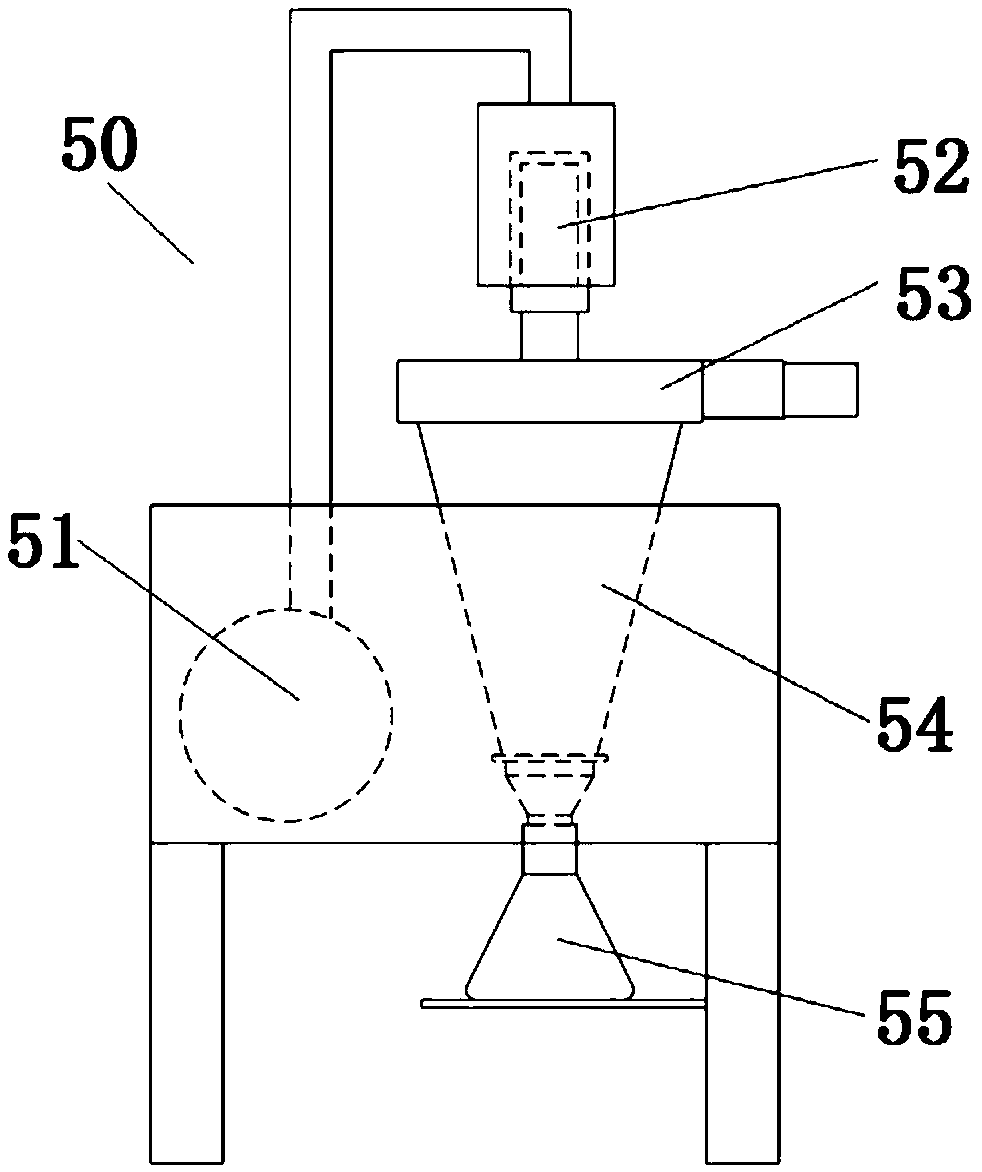

Full-automatic crushed material unloading device and method

ActiveCN107324072AImprove unloading efficiencyEasy to collect and process manuallyBottle emptyingGrain treatmentsEngineeringHanging basket

The invention relates to the technical field of ton bag unloading device structures, in particular to a full-automatic crushed material unloading device and method. The device comprises a rack and an overturn hanging basket. The overturn hanging basket is of a frame structure rotatably connected to the rack through a rotary shaft and is provided with at least one opening used for enabling ton bags to enter, and a gaseous disk used for adsorbing and fixing the ton bags is arranged at the bottom of the overturn hanging basket; a plurality of extruding units arranged on the peripheries of the ton bags correspondingly and capable of applying transverse extruding and pushing acting force to the ton bags are arranged on the inner side of the overturn hanging basket; and the multiple extruding units are vertically arranged at intervals along the ton bags. According to the full-automatic crushed material unloading device and method, the structure is simple, operation is convenient, ton bag materials can be quickly poured through grading unloading and extruding crushing, the ton bags can be conveniently and quickly collected by using a movable plate and a purging structure, damage to the ton bags cannot be caused, working procedures for manual operation are reduced, and the device and method have extremely large popularization value.

Owner:HUBEI UNIV OF TECH

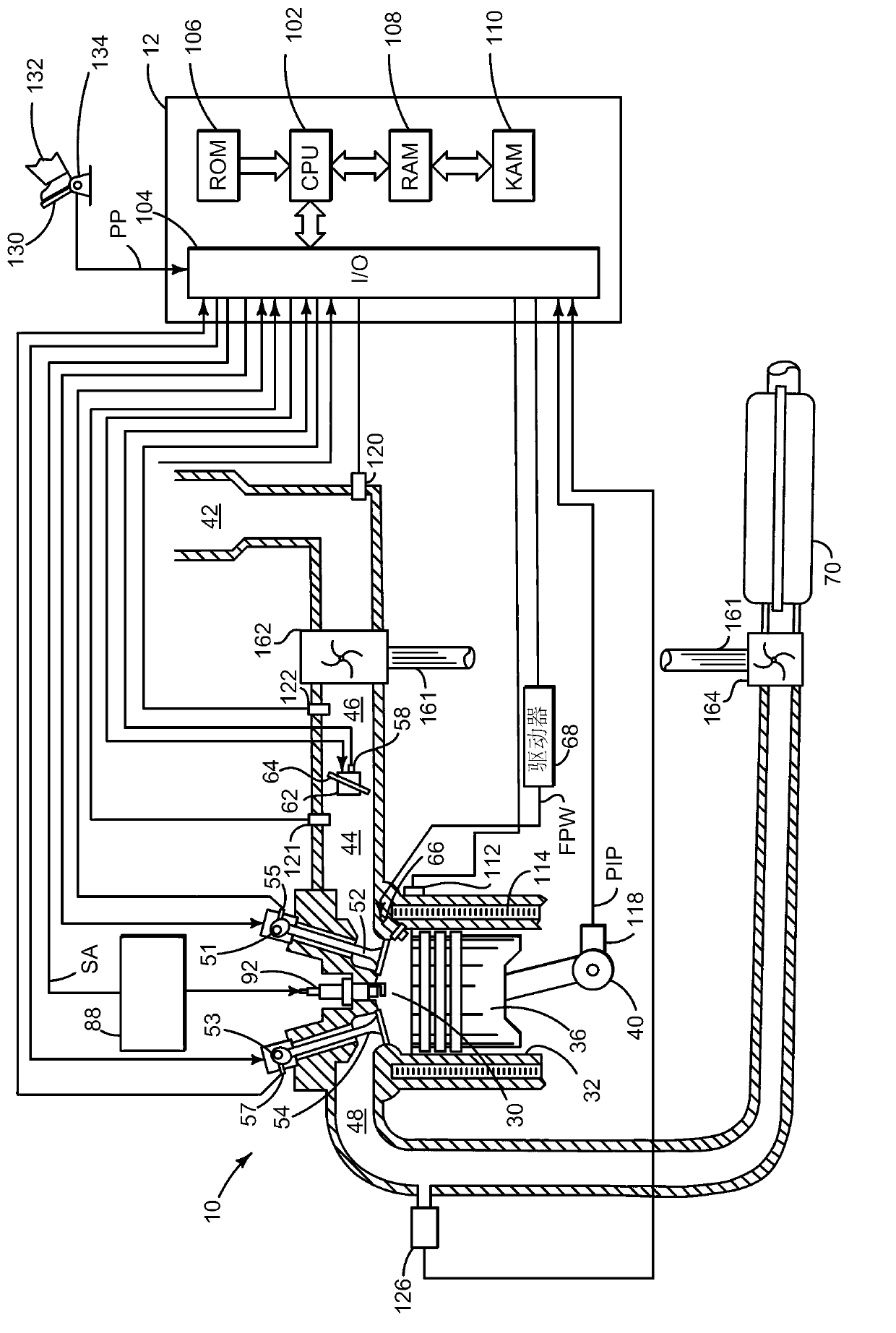

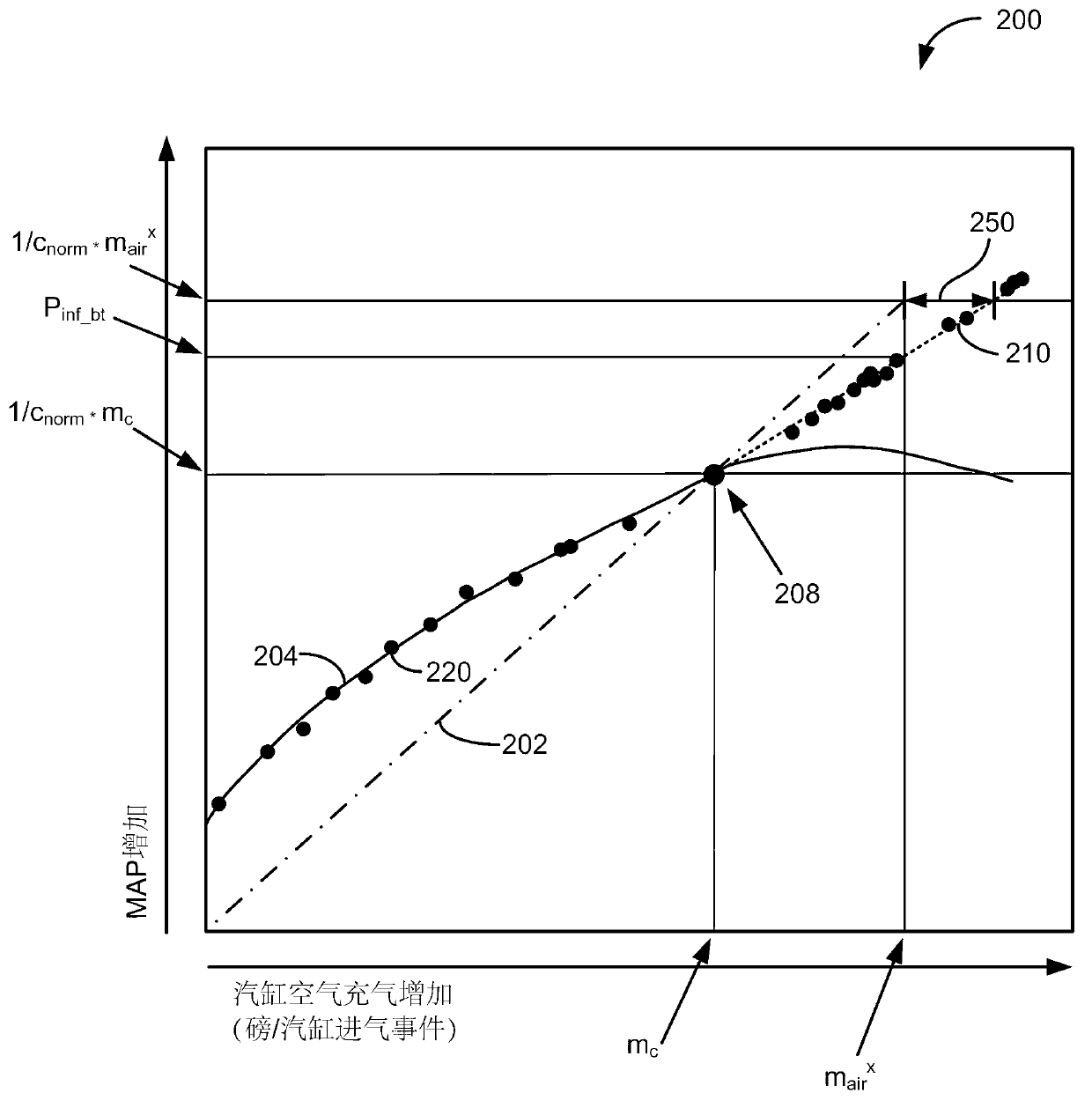

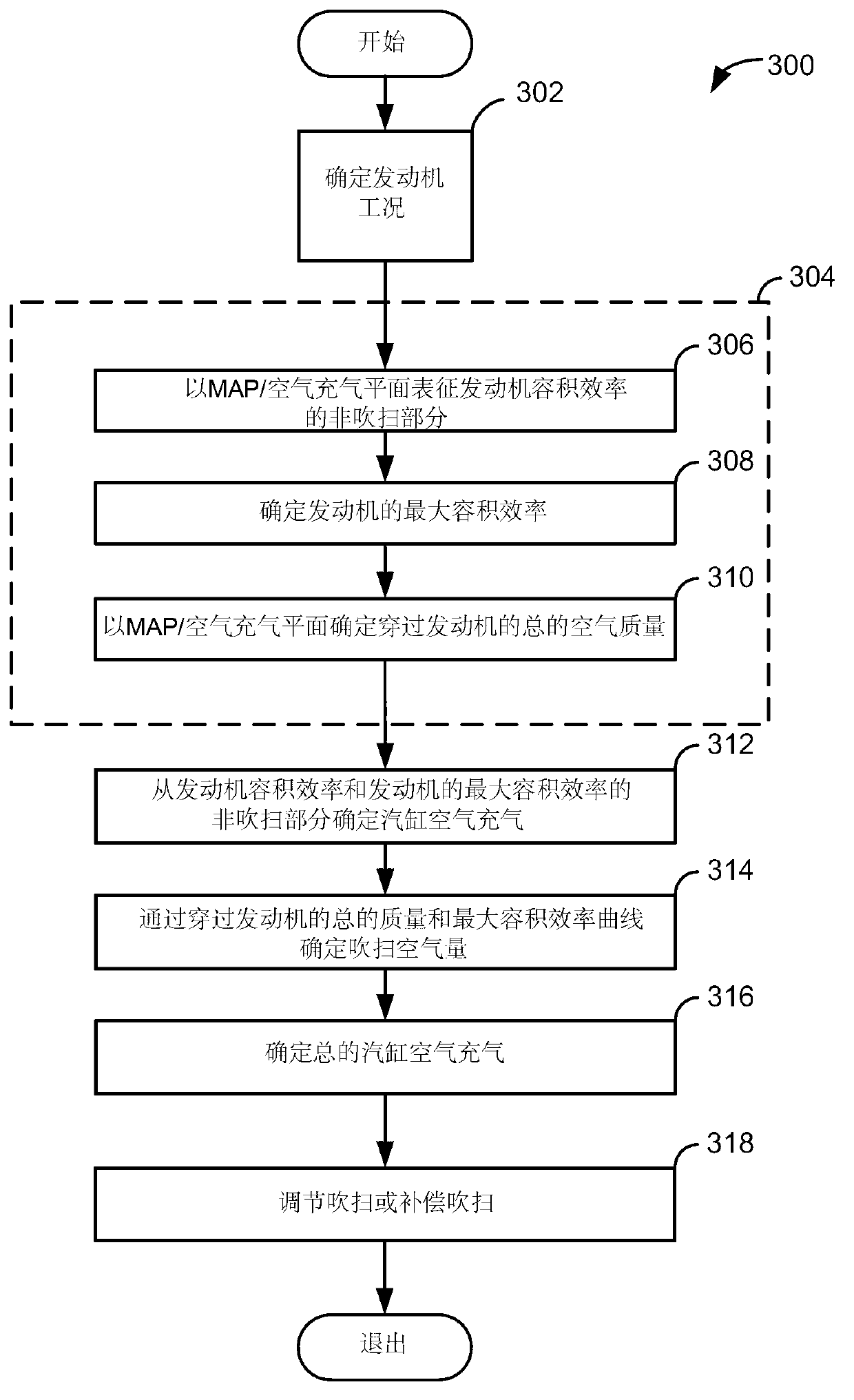

Method for determining and compensating engine blow-through air

ActiveCN103104366AEmission reductionImprove conversion efficiencyElectrical controlInternal combustion piston enginesAfter treatmentEngineering

A method for determining cylinder blow-through air via engine volumetric efficiency is disclosed. In one example, the method provides a way to adjust cylinder blow-through to promote and control a reaction in an exhaust after treatment device. The approach may simplify cylinder blow-through calculations and improve engine emissions via providing improved control of constituents reaching an exhaust after treatment device.

Owner:FORD GLOBAL TECH LLC

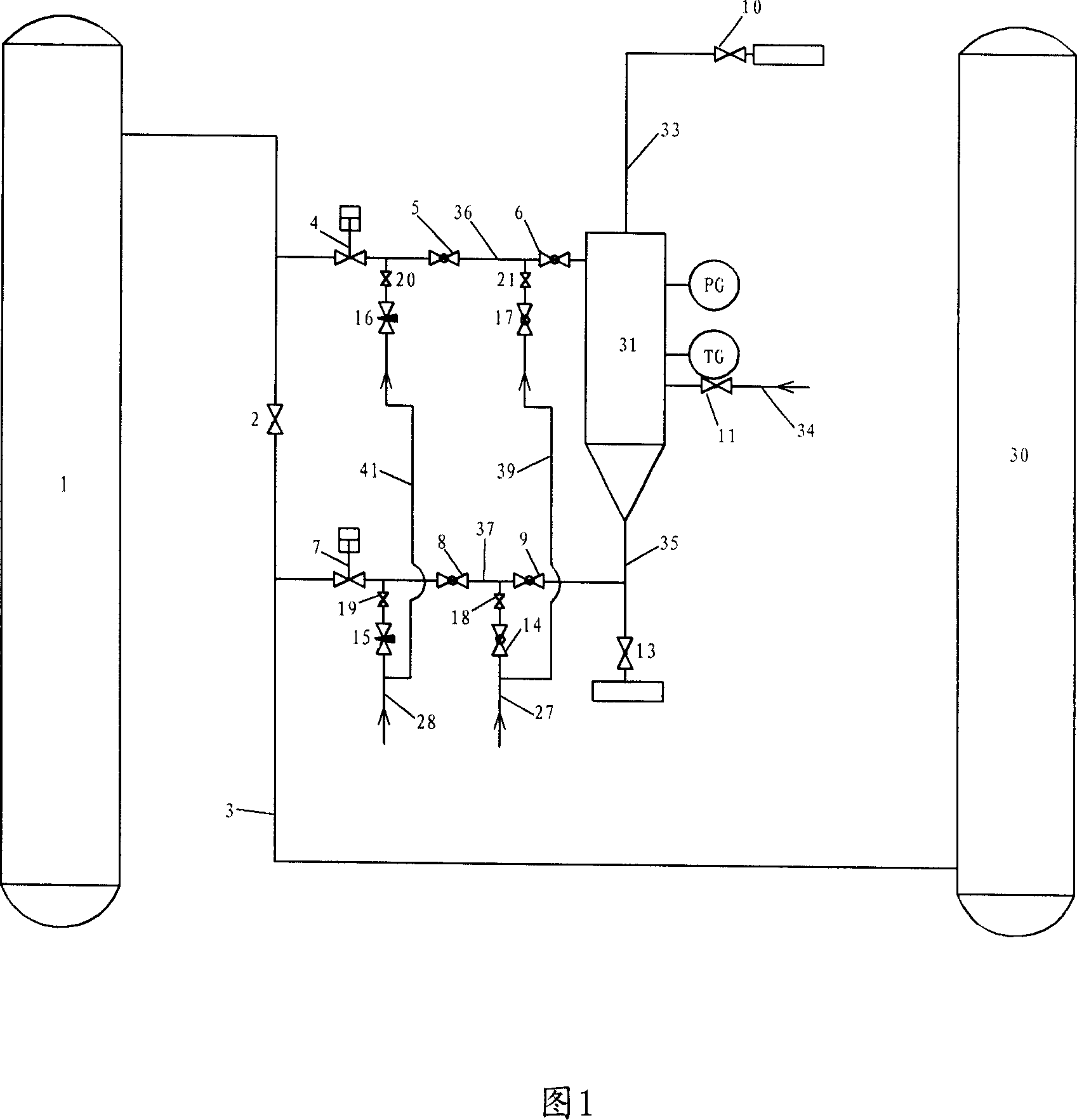

Coal slurry reactant sampling device

ActiveCN1945259ATrue reflection of changeRepresentativeWithdrawing sample devicesBorehole/well accessoriesHydrogenSolvent

The coal slurry reactant sampling device includes one sampling container connected through pipes with valves to the material conveying pipeline; solvent oil pipes with valve; hydrogen pipes; one gas sampling pipe in the upper part of the sampling container; one sampling pipe in the lower part of the sampling container; and one inert gas pipe communicated to the sampling container. The coal slurry reactant sampling device is accurate and reliable in sampling, convenient and safe in operation, and can sampling repeatedly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

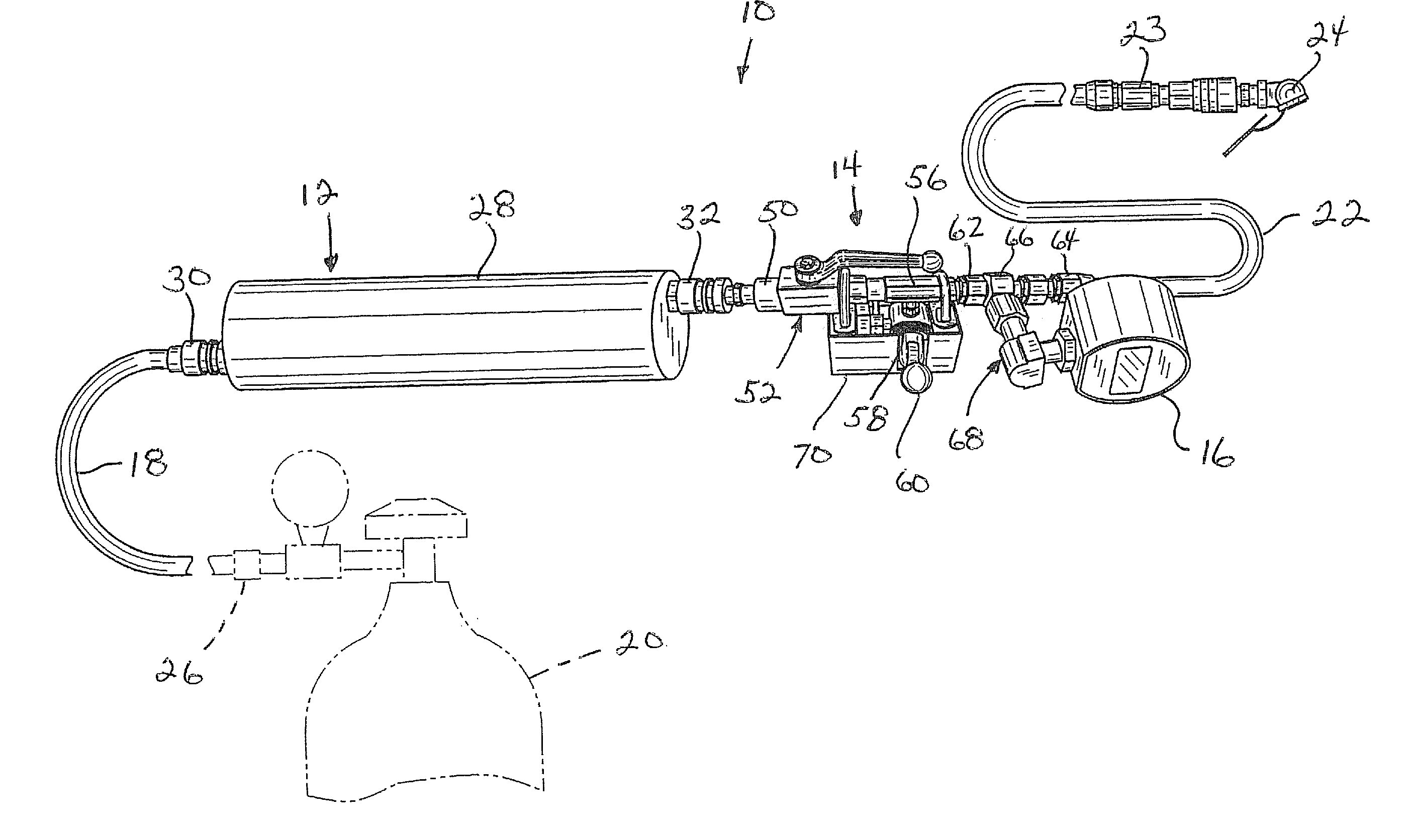

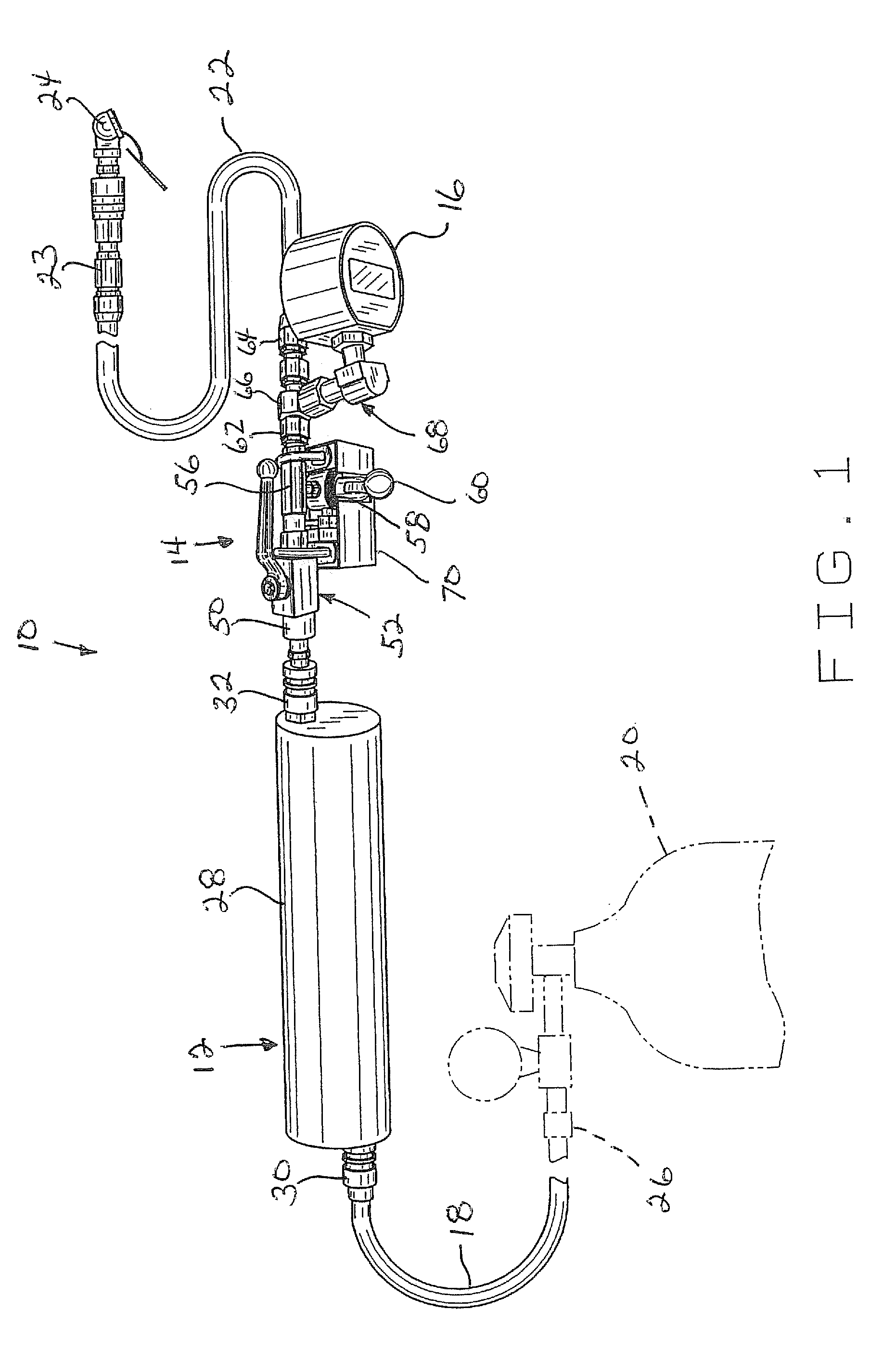

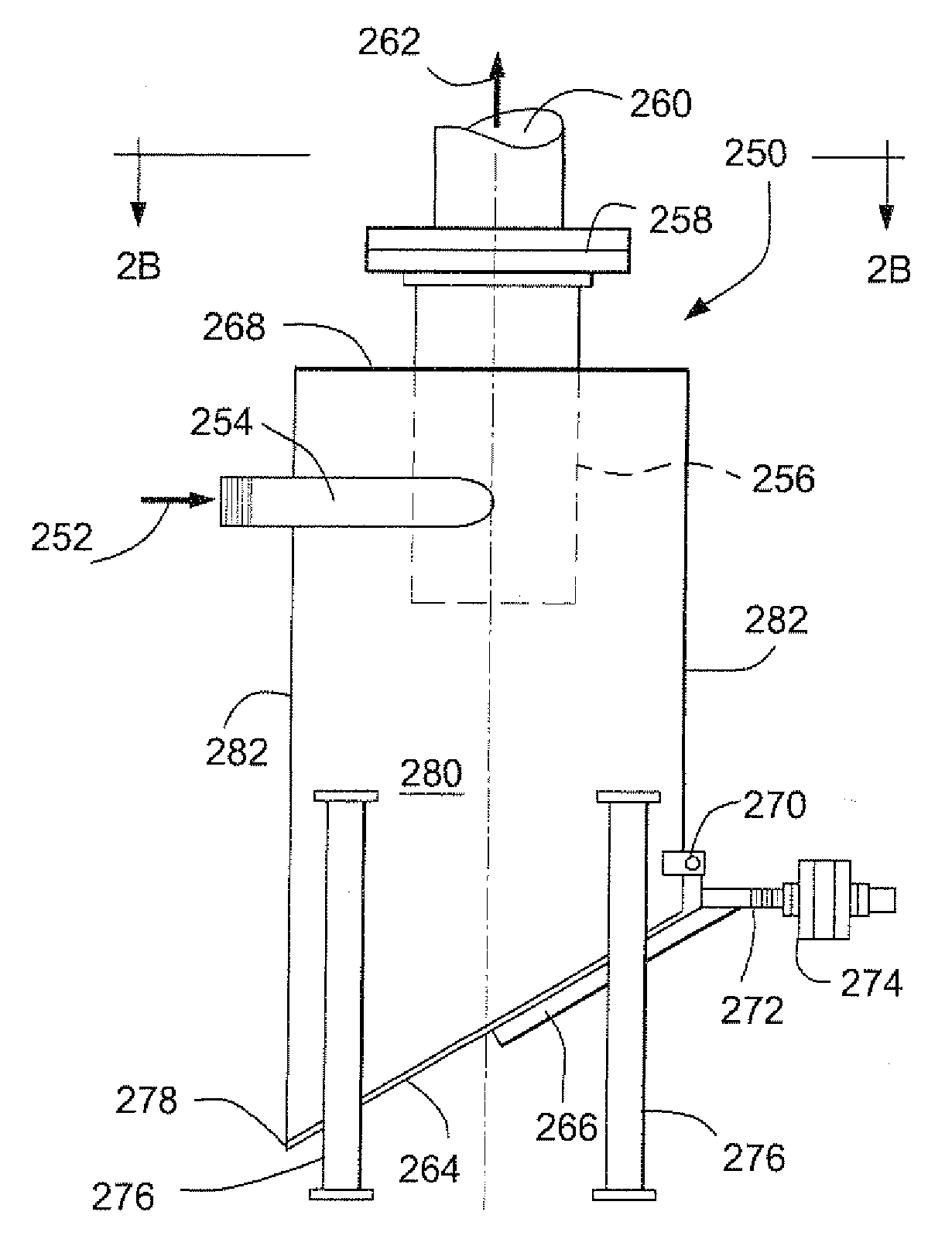

Tire purge/fill apparatus and method for use in a racing environment

InactiveUS7174925B2Increasing consistency and purityIncrease exhaustPackaging by pressurising/gasifyingSolid materialNitrogenEngineering

A tire purge / fill apparatus for both purging air and other contaminants from a tire to be filled and for filling a tire with nitrogen or other gases to a pre-determined pressure, the apparatus including a supply of gas, a filter member for filtering the gas before entry into the tire to be filled, a valve mechanism for controlling the purging and filling operations, a vacuum pump coupled in fluid communication with the valve mechanism, and a supply hose for attachment to the tire to be purged and / or filled, the valve mechanism including at least one user selectable member positionable in at least one position for effecting the filling operation and positionable in at least another position for effecting the purging operation. A manifold member is also disclosed for attachment to the present apparatus for use in filling a plurality of tires at the same time.

Owner:RACING AIR PRODS

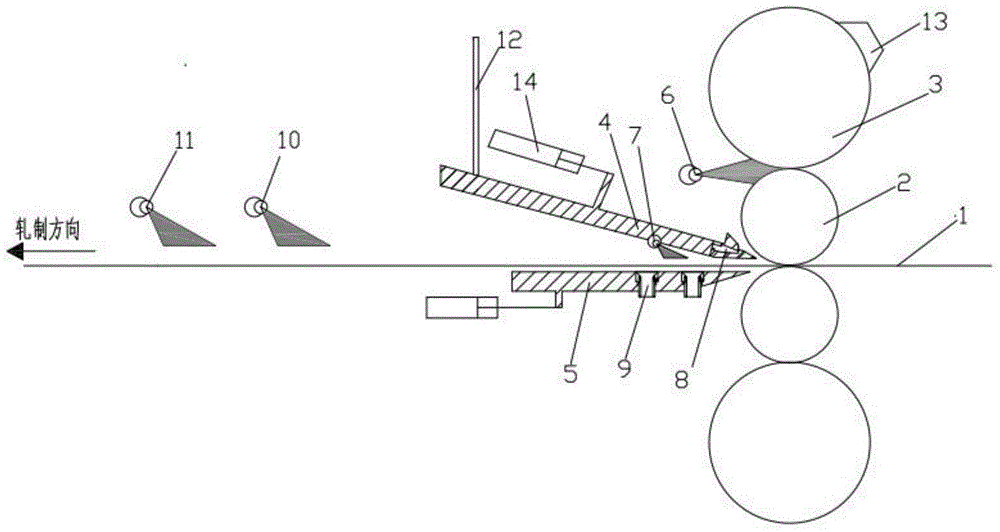

Device and method for removing emulsion on surfaces of cold-rolled steel strips

InactiveCN104646440AImproves the effectiveness of peeling emulsionsSolve the shortcomings of suctionWork treatment devicesMetal rolling arrangementsEmulsionWhole body

The invention discloses a device and a method for removing emulsion on surfaces of cold-rolled steel strips. The device comprises an upper working roller, an upper support roller seam purging mechanism, a steel strip upper surface emulsion sealing mechanism, an upper working roller surface emulsion removing mechanism, a steel strip lower surface emulsion removing mechanism, a steel strip upper surface purging mechanism and an upper support roller surface emulsion removing mechanism. The method is mainly characterized by reasonably controlling the sequence of opening and closing an emulsion injecting system and an emulsion removing device; a plurality of removing methods synergistically cooperate to form a whole body; the effect of removing the emulsion on the surfaces of the steel strips on the outlet side of a rolling mill is further improved; meanwhile, the residues of the emulsion in special parts of heads, tails, sides and the like of the steel strips can be removed; the surface quality of the finished steel strips can be improved.

Owner:SHANDONG IRON & STEEL CO LTD

Coolant purging device and purging method for battery assembly testing

PendingCN110783648AMeet the needs of rapid dischargeAvoid harmFuel cell controlSecondary cells testingProcess engineeringCooling fluid

The invention discloses a coolant purging device for battery assembly testing. The coolant purging device comprises a battery assembly, a compressed gas control unit for purging the coolant and a liquid storage unit for recovering and circulating the coolant, wherein the battery assembly and the liquid storage unit are connected through a coolant outlet pipe and a coolant inlet pipe and the compressed gas control unit is connected with the coolant inlet pipe. The invention also discloses a coolant purging method for battery assembly testing. With application of the coolant purging device and purging method for battery assembly testing, the gas purging function can be realized, the purging efficiency is high and the purging effect is better.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for reducing engine oil dilution

ActiveUS9394843B2Increase fuel consumptionReduced fuel economyElectrical controlInternal combustion piston enginesEvaporationCrankcase

Owner:FORD GLOBAL TECH LLC

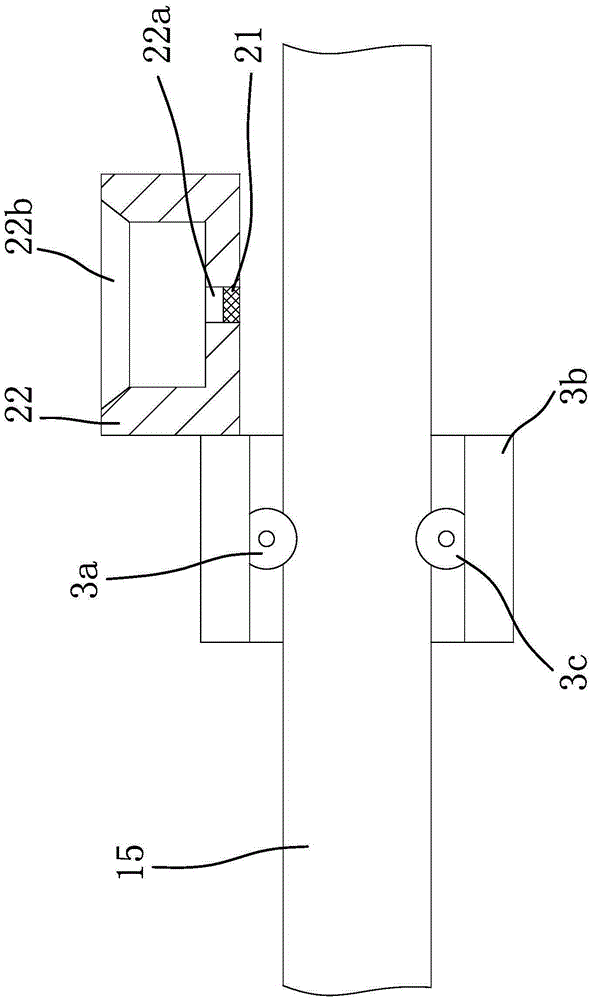

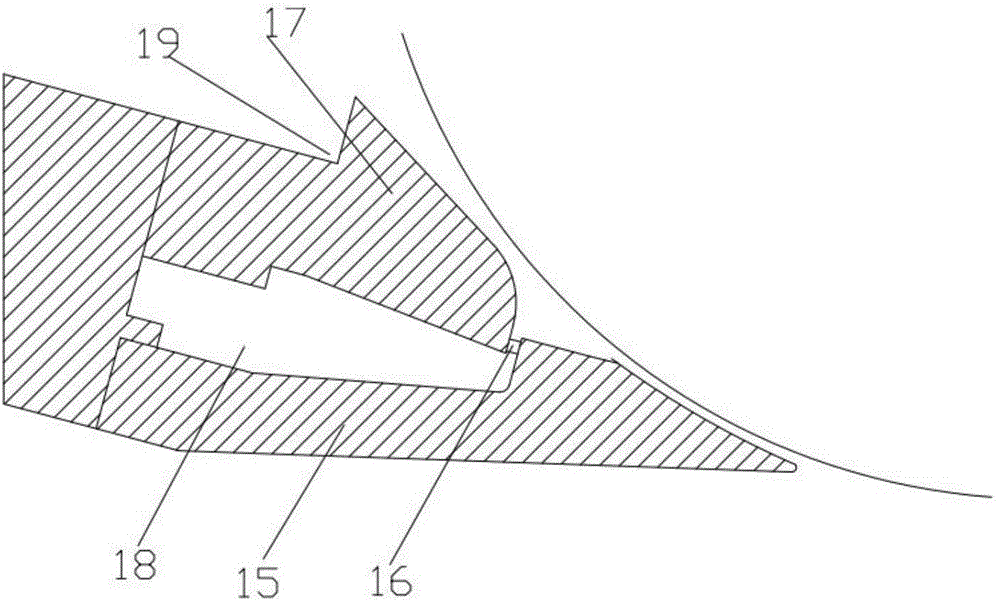

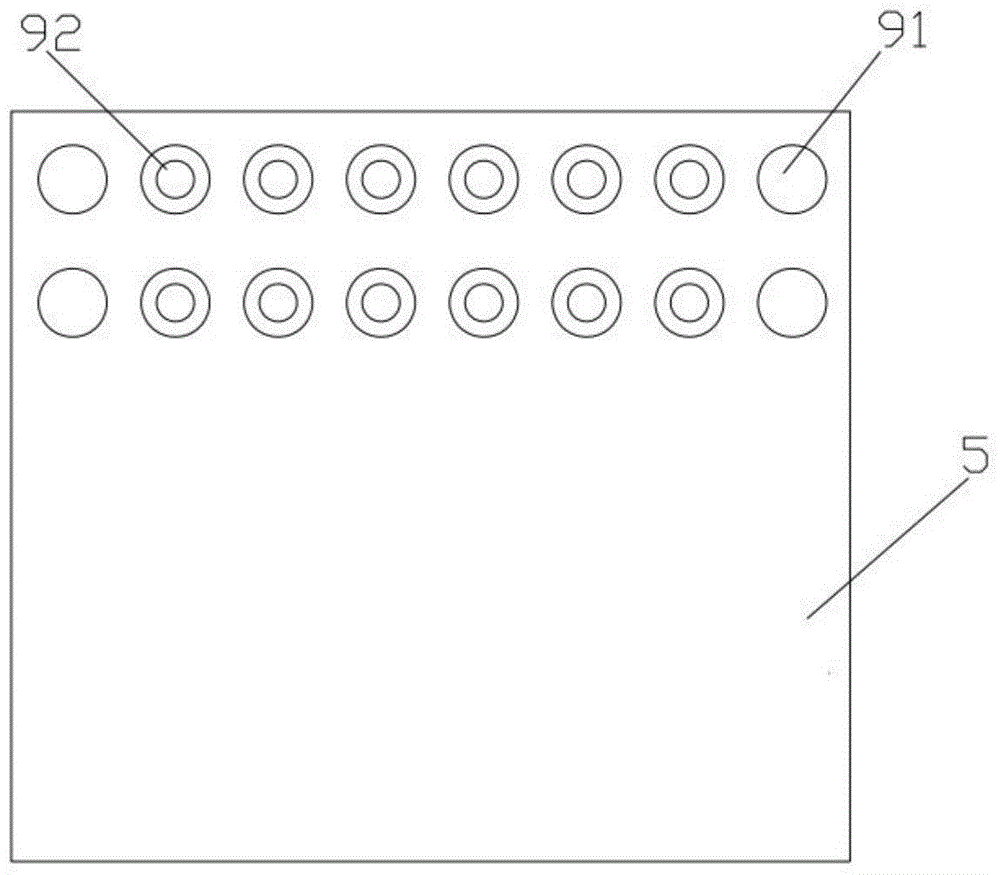

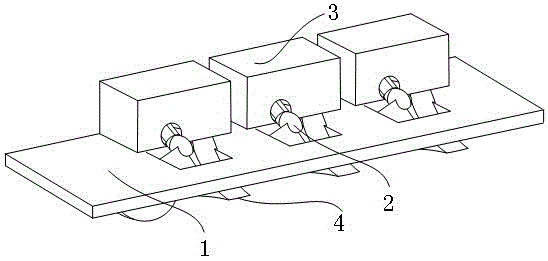

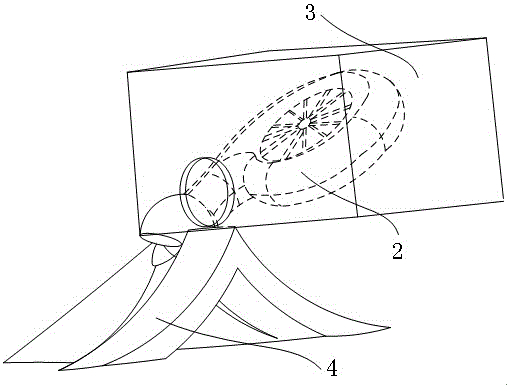

Online-detection side spraying angle adjusting device and adjusting method

ActiveCN104841702AImprove purge efficiencyEasy to purgeWork treatment devicesMeasuring devicesEngineeringInverted-T shape

The invention discloses an online-detection side spraying angle adjusting device and adjusting method. The device comprises four semicircular arc-shaped plates matched with working rollers, two long T-shaped strips and four photoelectric detection blocks. Sliding grooves penetrating the upper ends of the arc-shaped plates in the longitudinal direction are formed in the upper portions of the arc-shaped blocks, and cross sections of the two long T-shaped strips are in inverted-T shapes; the long T-shaped strips are embedded in the sliding grooves of the front arc-shaped plate and the rear arc-shaped block respectively; sliding grooves are formed in the two photoelectric detection blocks which are oppositely and transversely arranged, and the photoelectric detection blocks are mounted on the T-shaped strips through the sliding grooves in a sliding manner; and a plurality of photoelectric tubes are arranged on three of the photoelectric detection blocks respectively in the longitudinal direction and the transverse direction so as to divide a blowing area into a plurality of small areas. The adjusting method comprises the steps that the blowing area is divided into the small areas through the plurality of red photoelectric tubes which are longitudinally and transversely arranged; each gas blowout part is provided with one photoelectric tube which can emit red light beams; and each gas blowout part controls one longitudinal area, and all the gas blowout parts cover the whole width range. According to the method and device, the gas blowout blowing efficiency and the blowing locating accuracy are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

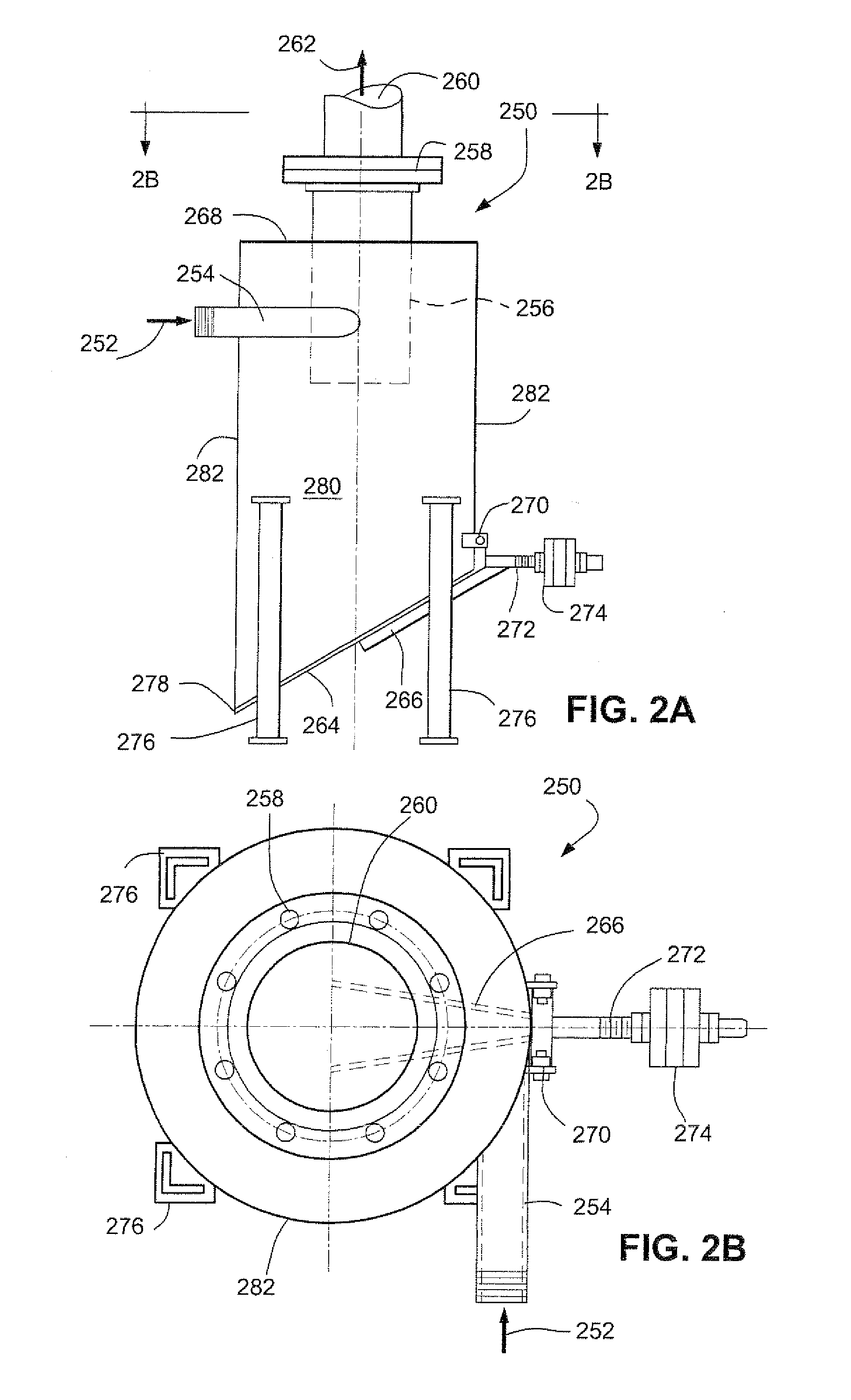

Degassing method and apparatus for separating gas from liquids and possibly solids

ActiveUS20090020480A1Convenience to workEasy to cleanSettling tanks feed/dischargeFlash degasificationDegasserProduct gas

A degasser having a flapper opening including a hinge. The hinge may permit purging of any liquids and solids without regular human intervention. There may be a fixed opening at the base of the degasser, such that there is a constant emptying from the bottom of the tank. The separation of gas from liquid may be involved in applications pertaining to pulping and oxygen delignification.

Owner:ANDRITZ INC

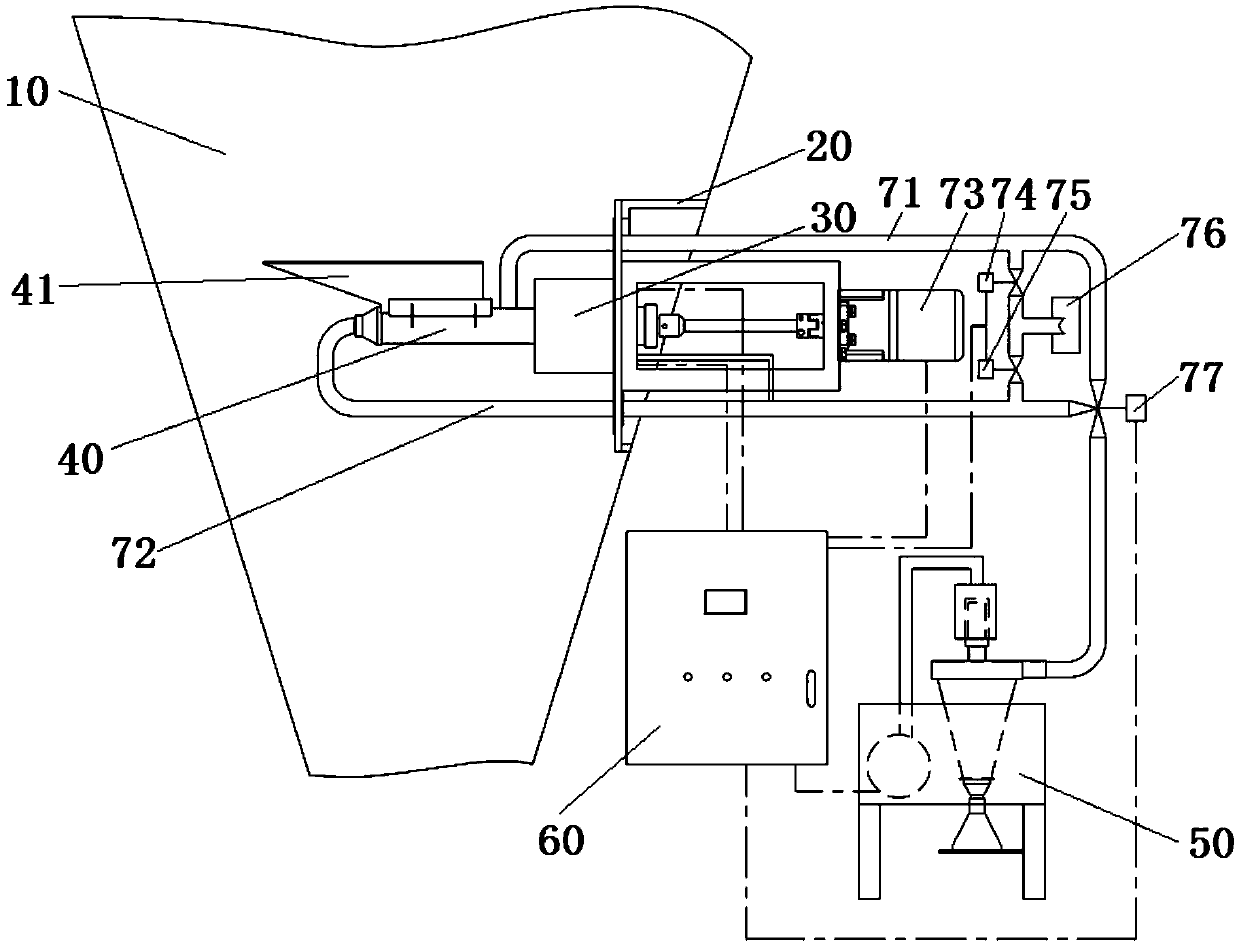

System and device for measuring carbon in fly ash

PendingCN109557261AGuaranteed accuracyProcess stabilityCleaning using gasesGas analyser construction detailsFly ashCyclonic spray scrubber

The invention relates to the technical field of equipment for measuring carbon content in fly ash, and particularly provides a system and a device for measuring carbon in the fly ash. The system and the device are possible to solve a problem that the equipment is easily blocked when measuring the carbon content in the fly ash in the prior art. The system for measuring the carbon content in the flyash comprises the device for measuring the carbon in the fly ash. The device for measuring the carbon in the fly ash comprises a fixed mounting structure fixedly connected with a wall surface of an ash bucket. The fixed mounting structure has a connecting surface connected to the wall surface of the ash bucket. The device for measuring the carbon in the fly ash further comprises an ash collectingstructure disposed on the side of the connecting surface near the center of the ash bucket. The ash collecting structure has an ash receiving port and a detection chamber for absorbing a fly ash sample collected in the ash port. The device for measuring the carbon in the fly ash further comprises a detecting element corresponding to the detection chamber for detecting the carbon content of the fly ash sample. The device for measuring the carbon in the fly ash further comprises a cleaning structure for cleaning the fly ash in the detection chamber. The system for measuring the carbon in the fly ash further comprises a suction pump and a cyclone dust collector connected to the detection chamber of the device for measuring the carbon in the fly ash.

Owner:GL TECH CO LTD

Pre-treatment equipment and treatment method for concrete prefabricated part production

InactiveCN112008841AEasy to polishEasy to closePretreated surfacesCeramic shaping apparatusCrankGear wheel

The invention discloses pre-treatment equipment and a pre-treatment method for concrete prefabricated part production, and belongs to the technical field of concrete prefabricated part production. Thepre-treatment equipment for concrete prefabricated part production comprises a box, a box door and a conveyor belt, the box door is rotationally connected to the side wall of the box body, the conveying belt is located in the box body, a cleaning chamber is arranged in the box body, a baffle is rotationally connected to the side wall of the cleaning chamber, a discharging port is formed in the side wall of the box body, a first air cylinder is arranged in the box body, a motor is arranged on the box body, and a gear disc is fixedly connected to the output end of the motor. According to the pre-treatment equipment, the grinding disc is arranged, so that the template is conveniently ground; a gear disc, a first gear, a first rotating shaft, a crank, a reciprocating mechanism, a first push rod, a first air cylinder, a first piston, a first exhaust pipe and a first spray head are arranged so that chippings cleaned by the grinding disc can be blown and swept conveniently, and a baffle is arranged so that the cleaning chamber can be sealed conveniently and ground chippings can be prevented from splashing out of the cleaning chamber.

Owner:陈庆森

Marine engine super flushing and corrosion control system

InactiveUS6997766B1Increase hydropowerEasy to purgePower plants using condensersLiquid coolingControl systemEngineering

A marine engine flushing system for super flushing the cooling system of a marine engine comprising an off-axis inlet port for receiving the flow of fresh water, a rotary distribution cylinder, and a plurality of axial outlet ports for proportionately discharging the flow of fresh water. The rotary distribution cylinder provides enhanced hydrodynamic forces that help break up salt and mineral deposits in a fashion superior to all existing methods.

Owner:BROGDON DOUGLAS O +1

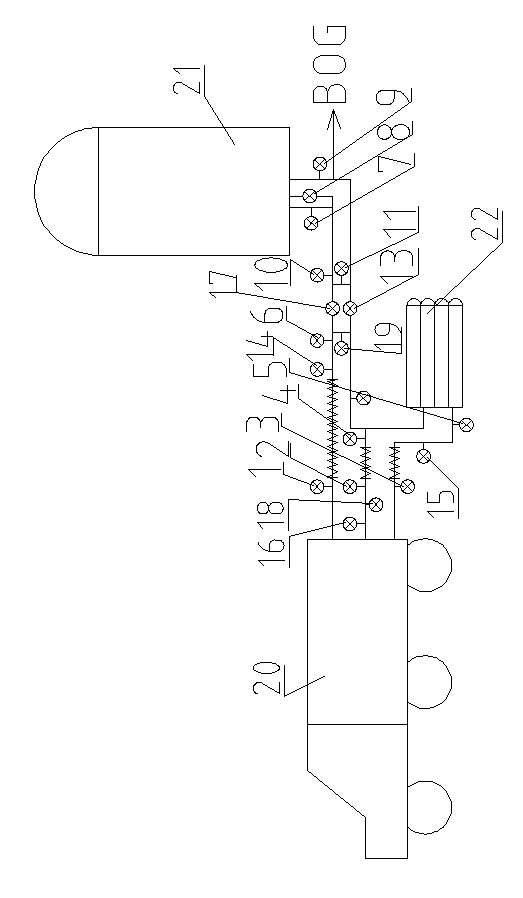

Sweeping method of LNG tank car before unloading

In order to solve the problems that according to a traditional sweeping method, the sweeping range is large, a pipeline is long, an LNG tank car is not easily swept clean, and air is easily taken into a pipe net and a vaporizer, the invention provides a sweeping method of an LNG tank car before unloading. The sweeping method of the LNG tank car before unloading is characterized in that an unloading table hose is well and correspondingly connected with the LNG tank car, sweeping is prepared, a self-pressurization liquid phase hose is swept, a self-pressurization gas phase hose is swept, a liquid inlet hose is swept, and sweeping is finished. The sweeping method of the LNG tank car before unloading can well sweep the pipe net, the sweeping range is small, the LNG tank car is swept clean, and air cannot be brought into the pipe net.

Owner:LUOYANG XINAO HUAYOU GAS

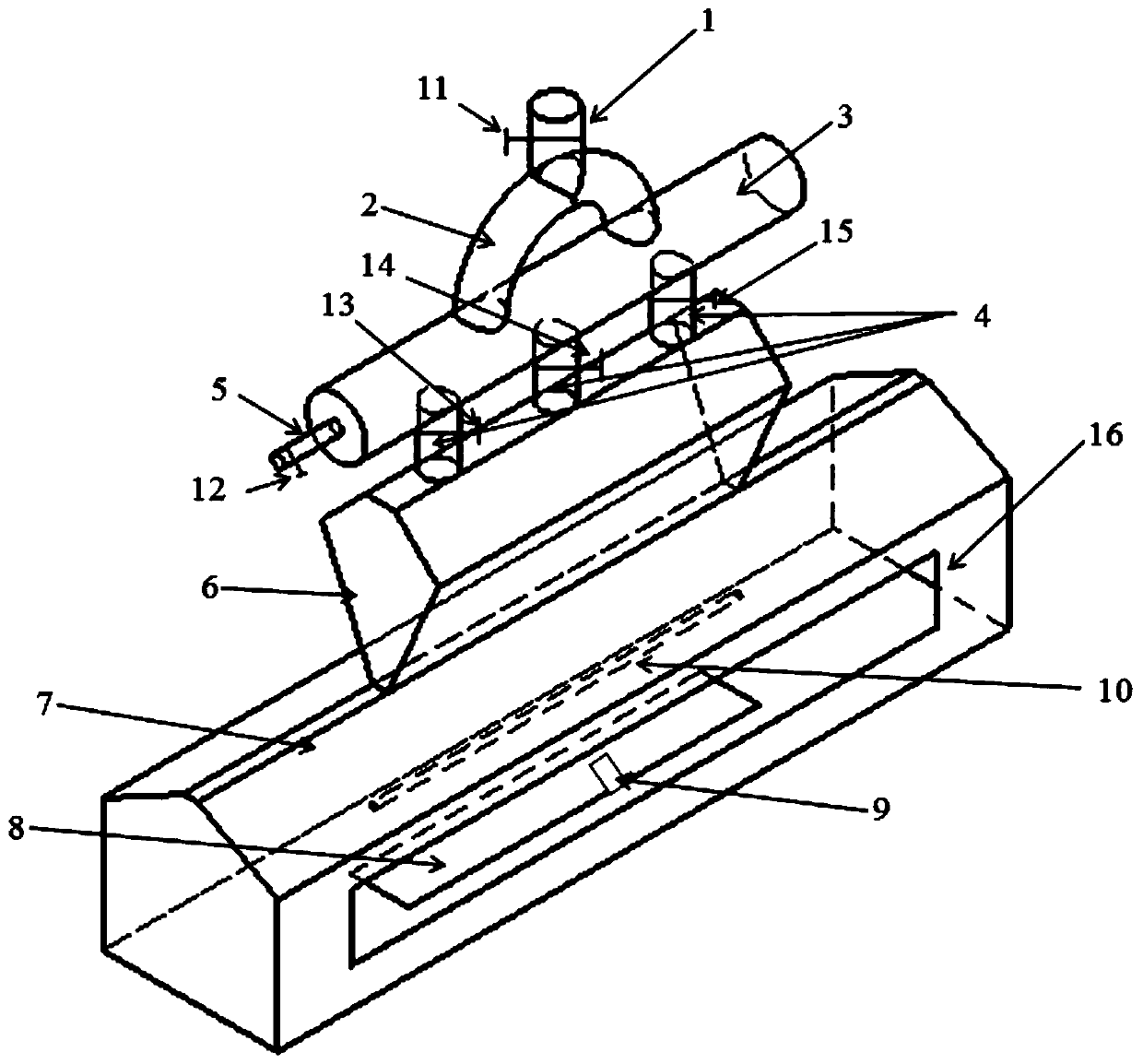

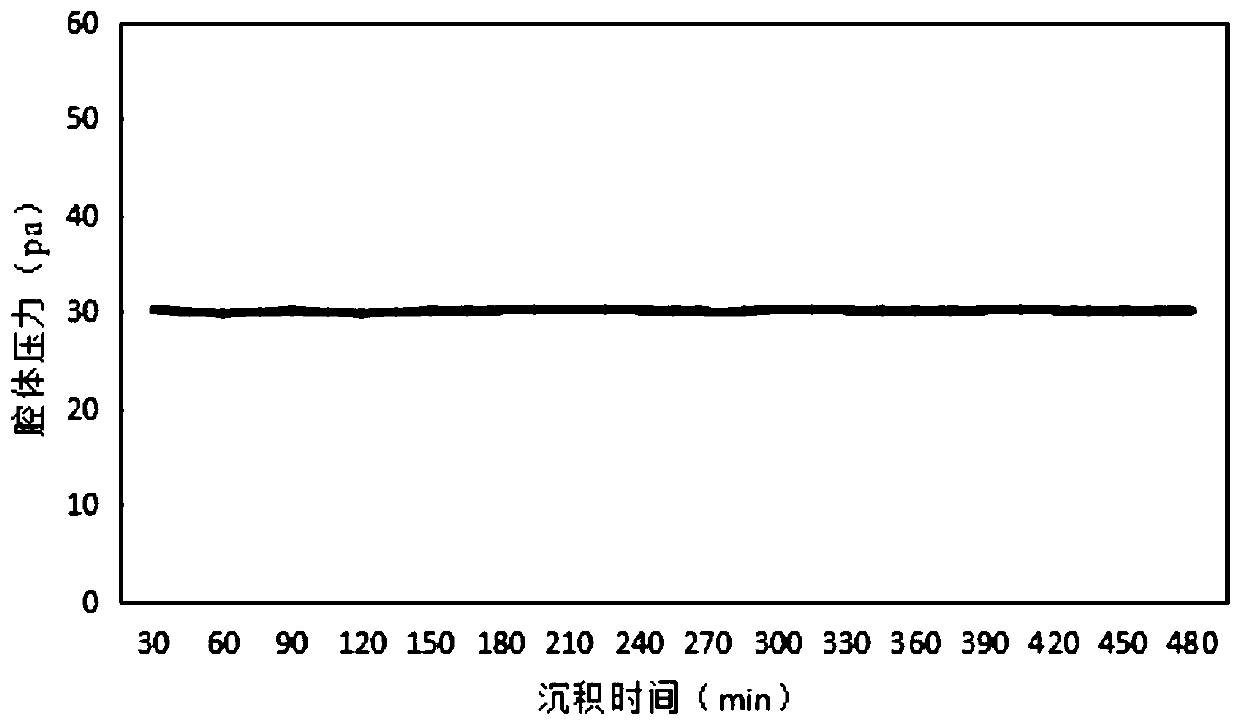

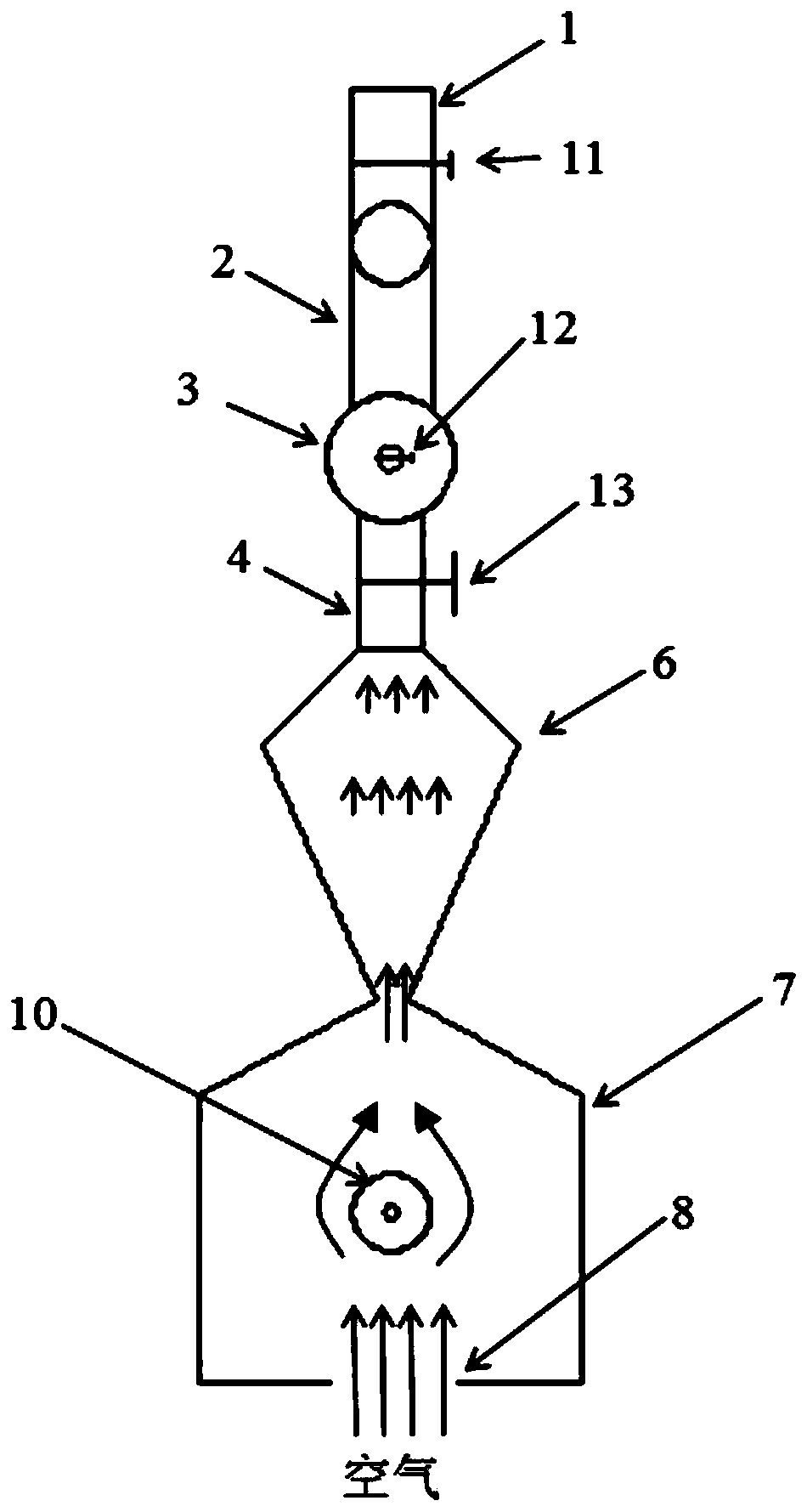

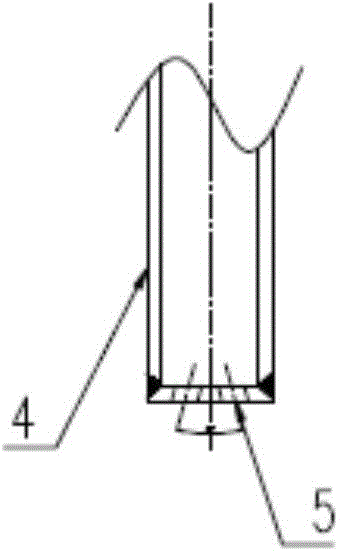

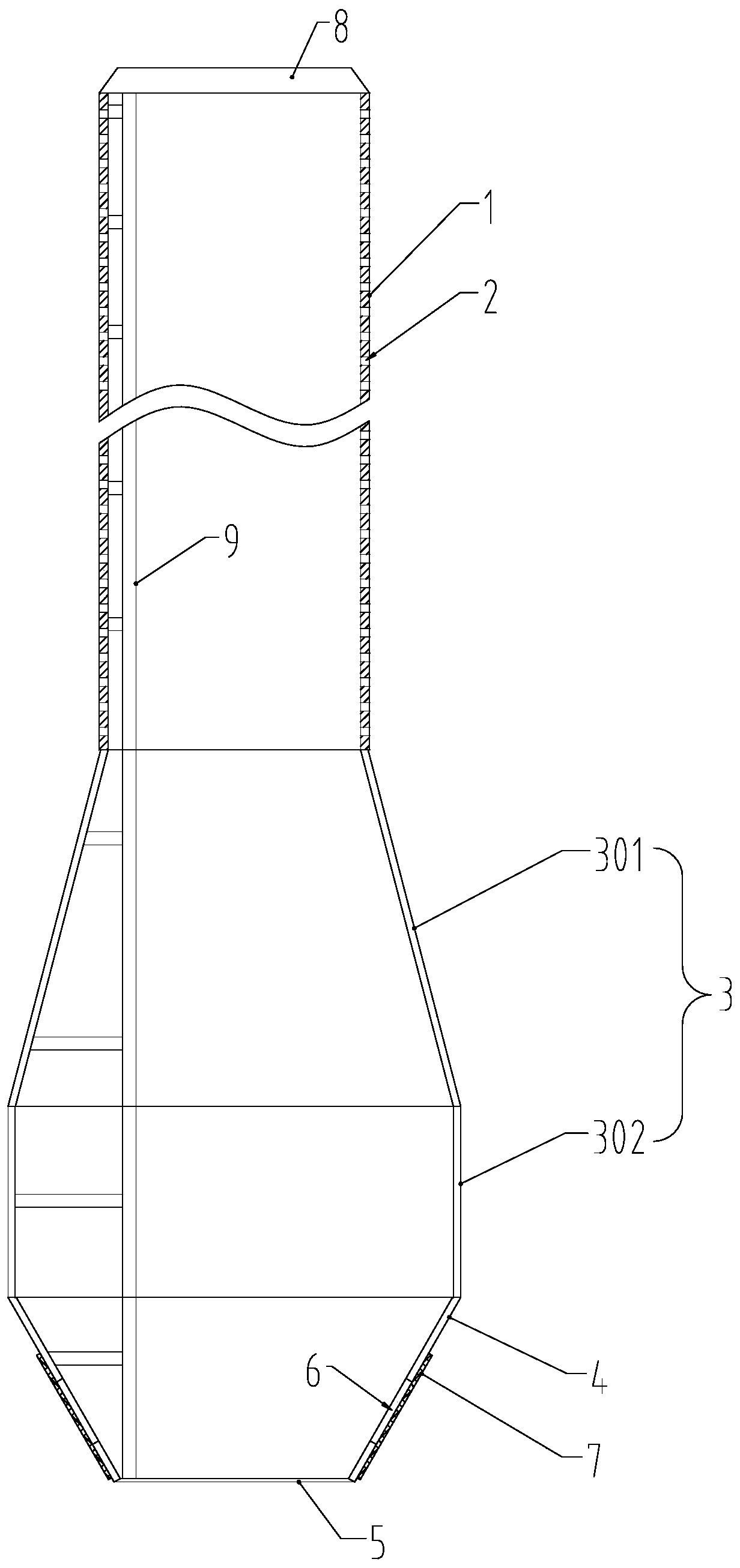

OVD deposition cavity device for preparing optical fiber preform

ActiveCN110963696AUniform suction pressureAxially distributed evenlyGlass making apparatusGlass productionEngineeringExhaust pipe

The invention relates to an OVD deposition cavity device for preparing an optical fiber preform. The device comprises an exhaust pipe, a first-stage buffer chamber, a second-stage buffer chamber and adeposition chamber, wherein the exhaust pipe, the first-stage buffer chamber, the second-stage buffer chamber and the deposition chamber are sequentially arranged from top to bottom, a wind inlet isformed in the bottom of the deposition chamber, a deposition core rod and a deposition blow lamp are arranged in the deposition chamber, the deposition chamber is in a house shape, the upper portion of the deposition chamber is trapezoidal, the lower portion of the deposition chamber is square, the top of the deposition chamber is in butt joint with the slit of the second-stage buffer chamber, thelower portion of the second-stage buffer chamber is inverted trapezoidal, the first-stage buffer chamber is in a circular tube shape, a wind supplementing pipe is arranged on the end surface of the first-stage buffer chamber, a wind supplementing valve is arranged on the wind supplementing pipe and used for adjusting the opening and closing size of the wind supplementing pipe, the first-stage buffer chamber is vertically communicated with the second-stage buffer chamber through a plurality of second-stage branch pipes distributed side by side in the axial direction, and the exhaust pipe is communicated with the first-stage buffer chamber through two arc-shaped pipes in a bilateral symmetry manner. According to the invention, the distribution uniformity of the gas flow in the deposition chamber along the axial direction of the deposition core rod is improved, the air pressure in the deposition chamber is stabilized, the wrapping area of the flame of the blow lamp on the deposition corerod is increased, and the collection rate of SiO2 powder is increased.

Owner:JIANGSU FASTEN PHOTONICS +2

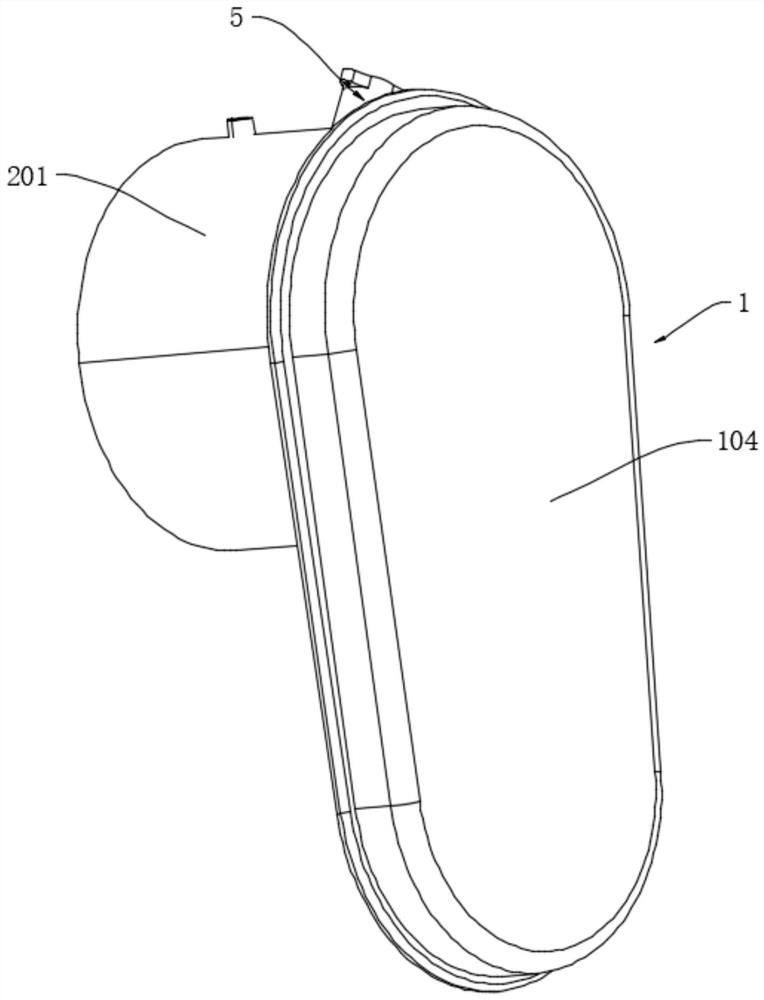

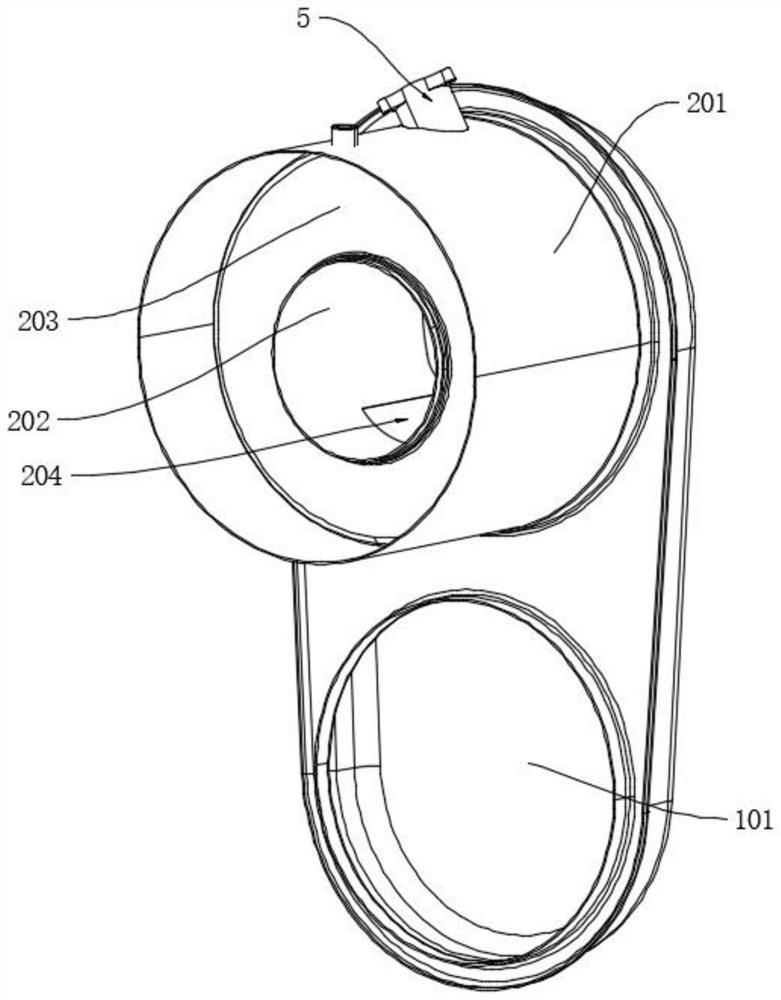

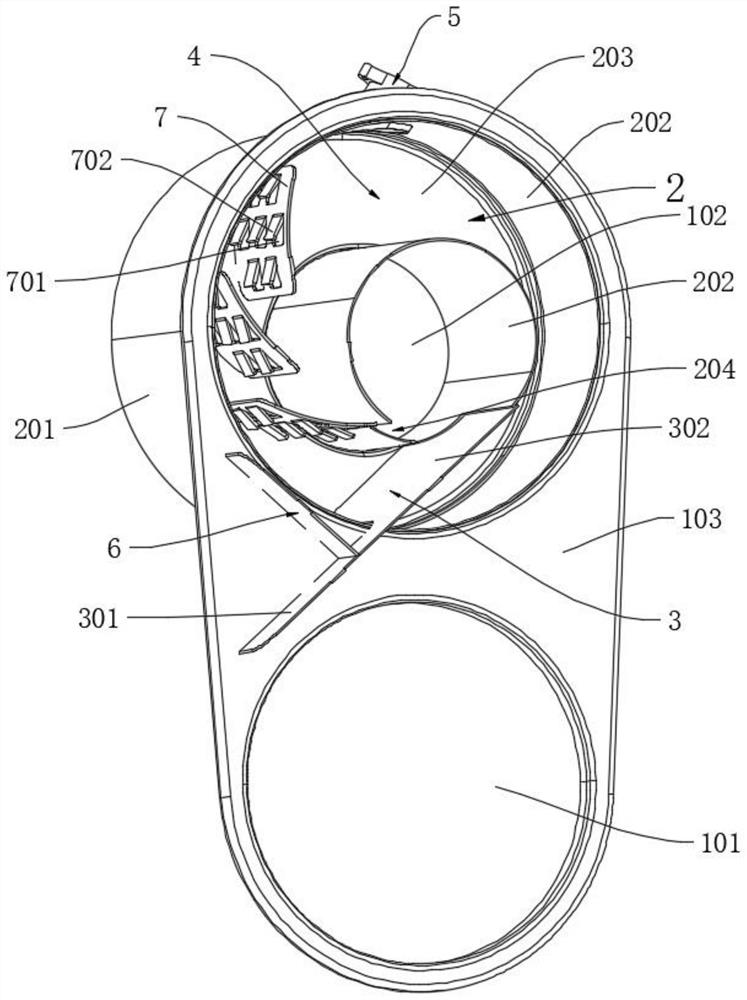

Mixer for U-shaped tail gas after-treatment device and U-shaped tail gas after-treatment device

PendingCN113446092AExtended heating pathGood for atomization and crushingSilencing apparatusMachines/enginesEngineeringMechanical engineering

The invention provides a mixer for a U-shaped tail gas after-treatment device and the U-shaped tail gas after-treatment device comprising the mixer. The heating path of air flow to urea is prolonged, the heat utilization efficiency of tail gas is improved, the urea fully absorbs heat and exerts the heat, the risk of urea crystallization is effectively reduced, the mixer comprises a mixer shell, the mixer shell comprises a gas inlet connected to a DPF unit and a gas outlet connected to an SCR unit, a mixing cavity is formed in the mixer shell, the mixer is characterized in that a flow guide plate is arranged at the position, close to the gas inlet, in the mixer shell, a gas mixing channel is formed in the mixing cavity, a urea nozzle is arranged on the gas mixing channel, and gas entering from the gas inlet is guided by the flow guide plate to enter the gas mixing channel, and is discharged from the gas outlet after flowing through the gas mixing channel.

Owner:无锡恒和环保科技有限公司

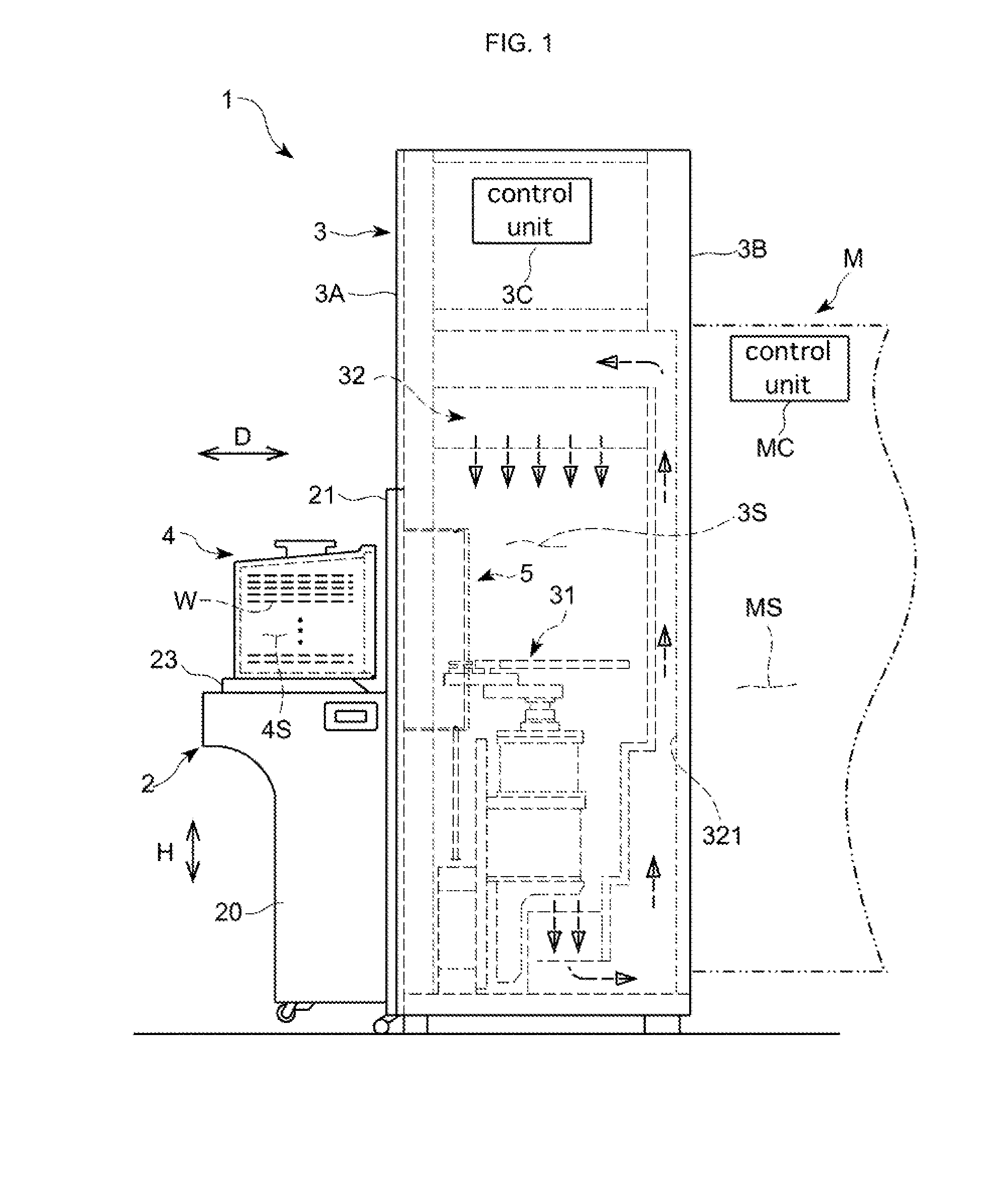

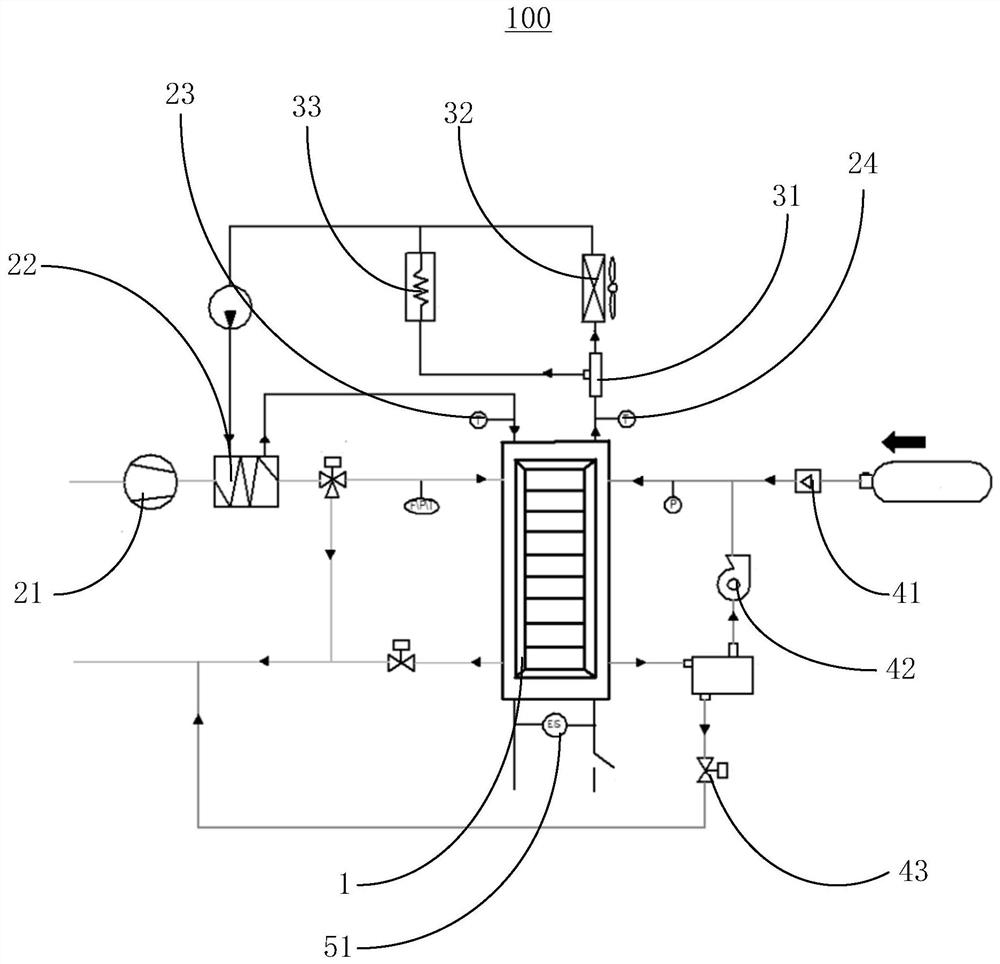

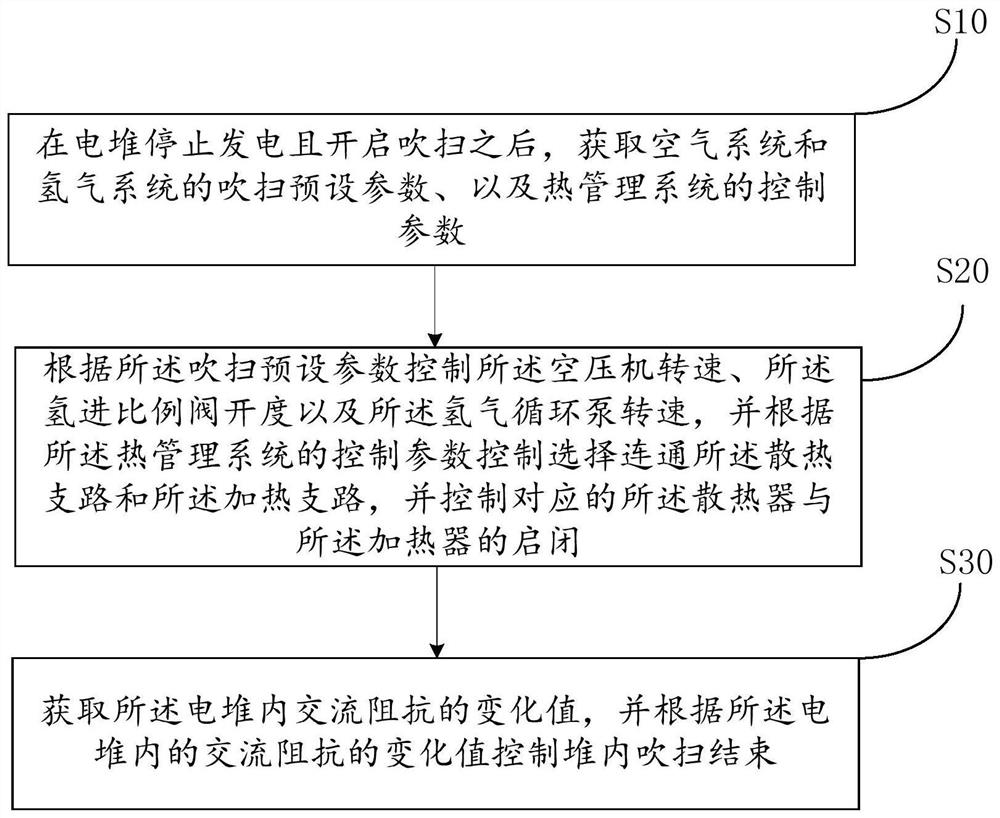

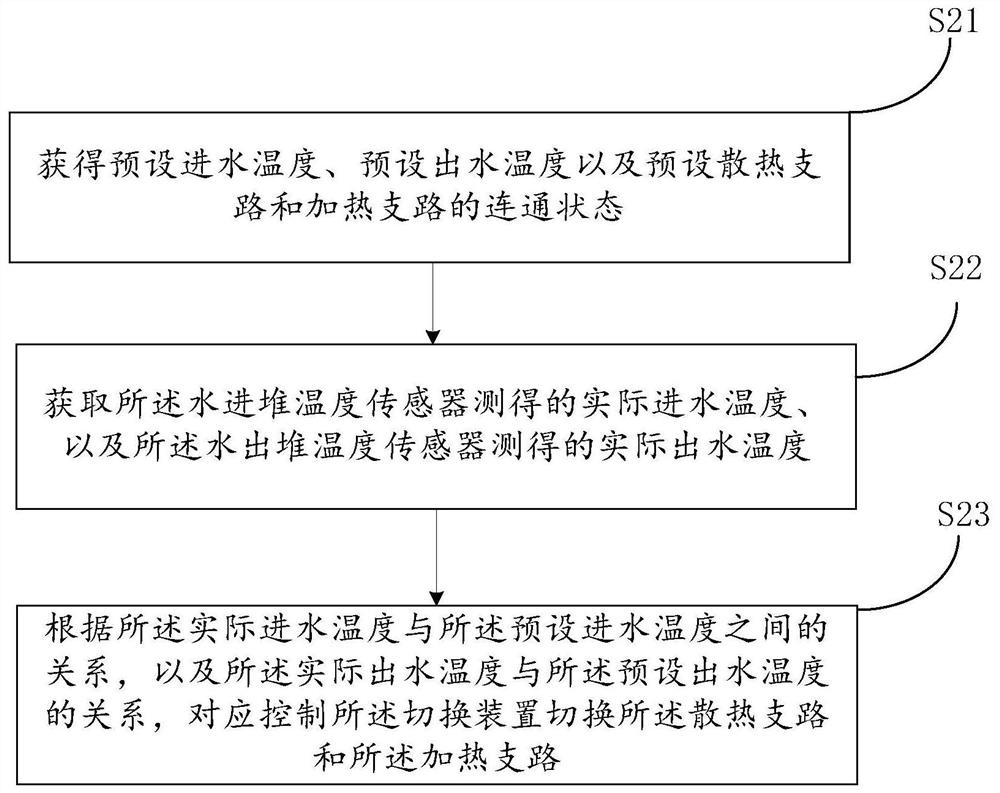

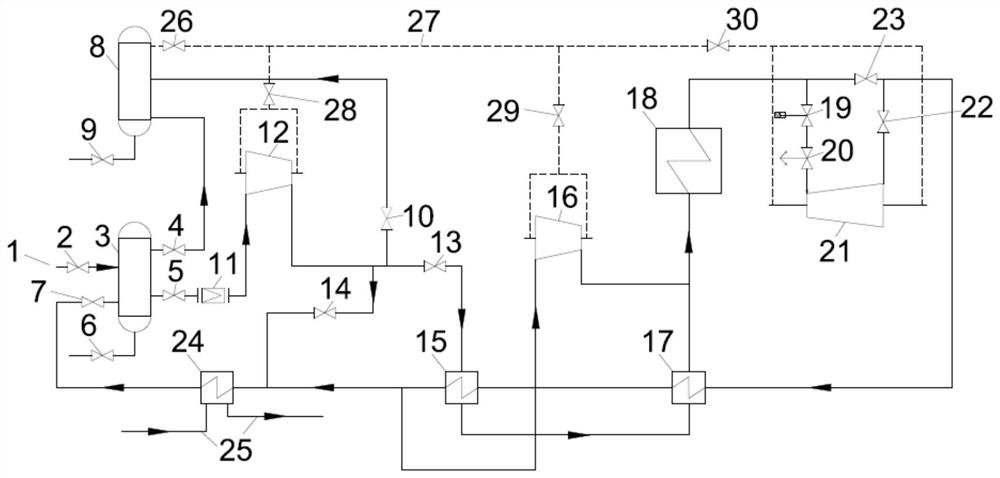

Fuel cell purging system and control method

ActiveCN112751056AIncrease temperatureImprove the heating effectWater management in fuel cellsHeat managementFuel cells

The invention discloses a fuel cell purging system and a control method. The control method comprises the following steps of: after a galvanic pile stops power generation and starts purging, acquiring purging preset parameters of an air system and a hydrogen system, and control parameters of a thermal management system; controlling a rotating speed of an air compressor, an opening degree of a hydrogen inlet proportional valve and a rotating speed of a hydrogen circulating pump according to the purging preset parameters, controlling and selectively communicating a heat dissipation branch and a heating branch according to control parameters of a heat management system, and controlling on and off of a corresponding heat dissipater and a corresponding heater; and acquiring a change value of alternating current impedance in an electric pile, and controlling the ending of in-pile purging according to the change value of the internal resistance of the electric pile. Through switching of the heating branch and the heat dissipation branch, purging of moisture in the electric pile is accelerated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

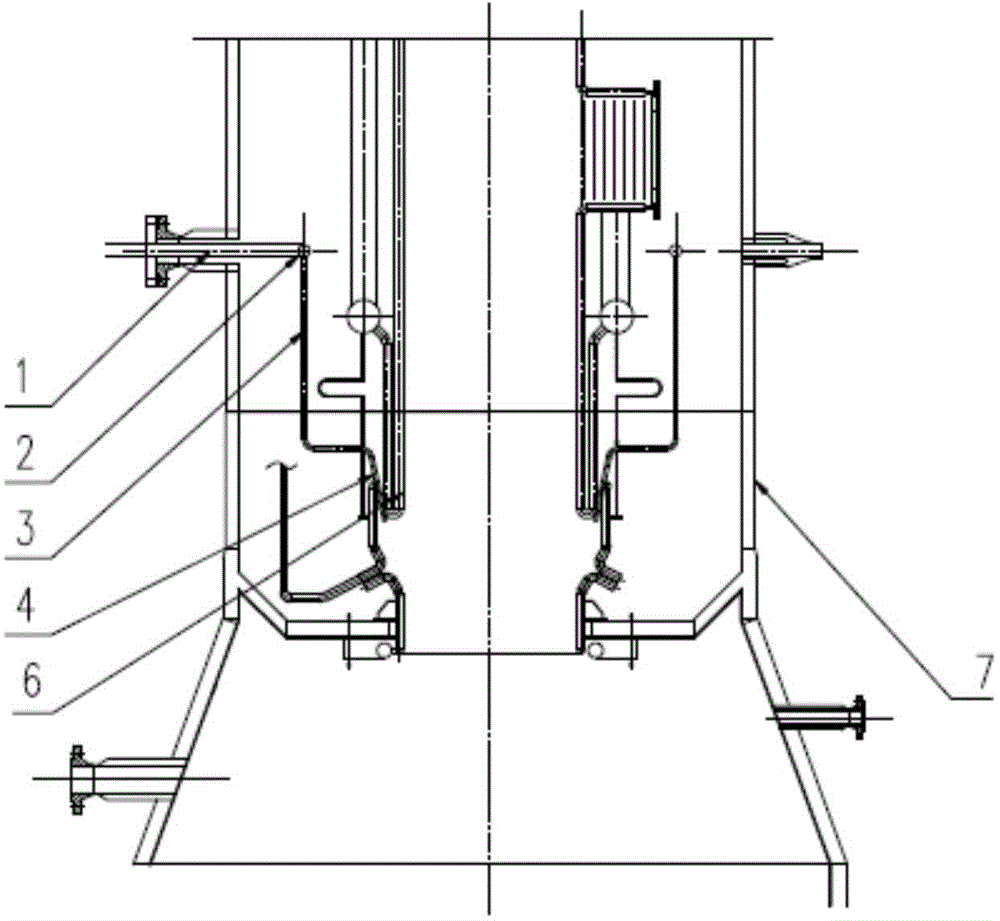

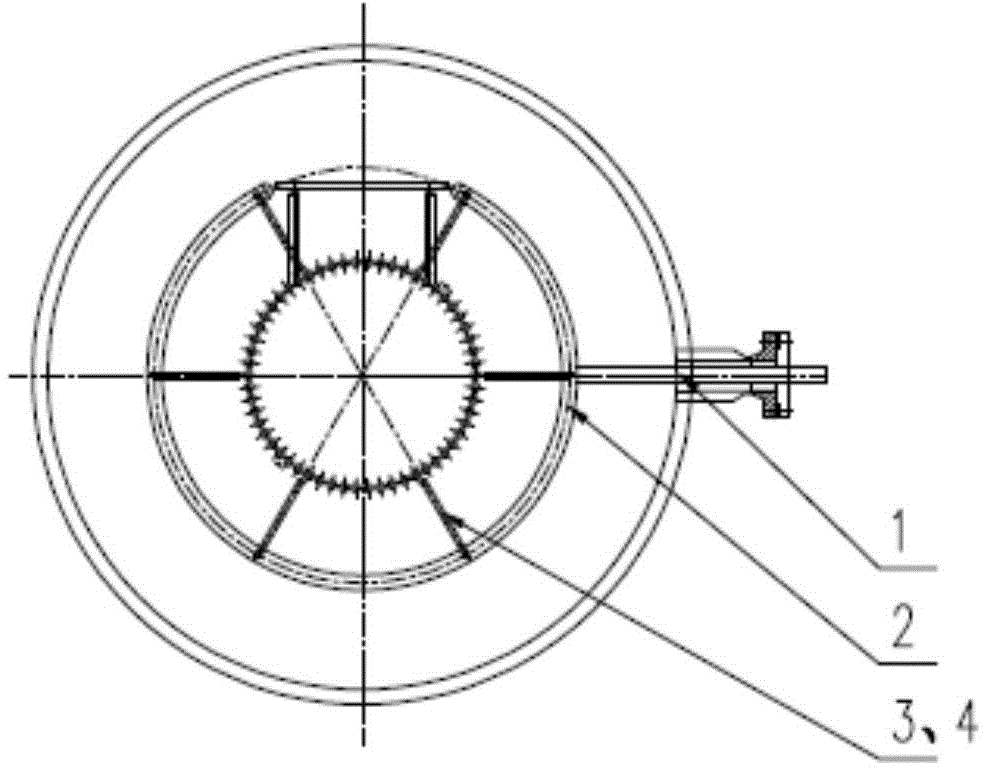

Device and method for blowing ash in entrained flow gasifier

ActiveCN104673399AReduce stickingSmall gas consumptionGasifier mechanical detailsGasification processes detailsEngineeringNitrogen gas

The invention discloses a device and a method for blowing ash in an entrained flow gasifier. The device comprises a pipe joint, an annular main pipe, a plurality of first branch pipes and a plurality of second branch pipes, wherein the pipe joint is welded on the shell of the entrained flow gasifier and extends into the entrained flow gasifier, the annular main pipe is arranged between the shell of the entrained flow gasifier and the water cooled wall of the entrained flow gasifier and is connected with the pipe joint, the first branch pipes are communicated with the annular main pipe, and the second branch pipes are communicated with the first ash blower branch pipes respectively, penetrate through the water cooled wall of the entrained flow gasifier and are arranged on the inner surface of the water cooled wall of the entrained flow gasifier. The head part of each second ash blower branch pipe is provided with two small holes, and the small holes are aligned to the ash deposition position of the water cooled wall 6 of the entrained flow gasifier. The method comprises the following steps: introducing N2 or CO2 into the device, and blowing the surface of the water cooled wall of the entrained flow gasifier continuously through the small holes to prevent the deposition of ash. By adopting the device and the method, the deposition of the ash and the formation of an adhesive bottom layer can be inhibited, the flying ash can be blown away before being adhered onto the heated surface, and the adhesion of the flying ash can be reduced. The device and the method have the characteristics of good ash blowing effect and low consumption of gases for ash blowing.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

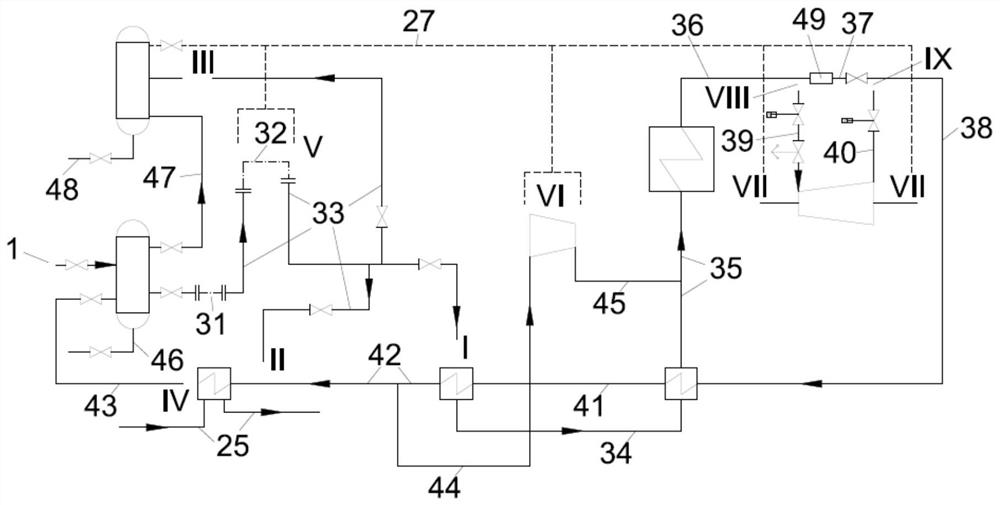

Pipeline pre-purging system and method suitable for supercritical carbon dioxide Brayton cycle

ActiveCN112808714AEasy to purgeQuick and efficient purgingHollow article cleaningPipeline systemsBrayton cycleSteam line

The invention discloses a pipeline pre-purging system and method suitable for a supercritical carbon dioxide Brayton cycle. The pipeline pre-purging system comprises a CO2 storage tank arranged in a pipeline of the supercritical carbon dioxide Brayton cycle, wherein the CO2 storage tank is filled with a CO2 working medium with certain pressure; the CO2 working medium in the CO2 storage tank purges a low-temperature pipeline; and a pipeline which is not directly connected with the CO2 storage tank is arranged. A compressor in the system is used for building working medium circulation, and impurities in the pipelines are filtered through a filter and a particle collector. According to the system and the method, negative problems to a supercritical carbon dioxide Brayton cycle system caused by adopting conventional chemical cleaning and steam line blowing methods of a thermal power plant are avoided, and the purging process of a supercritical carbon dioxide Brayton cycle power generation system is simpler and more economical.

Owner:XIAN THERMAL POWER RES INST CO LTD

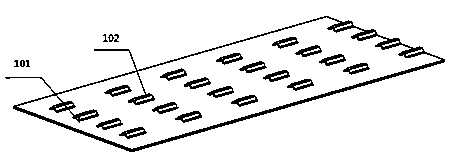

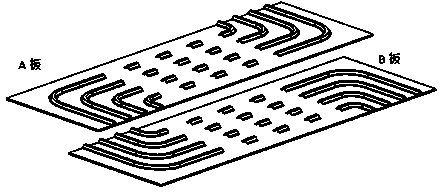

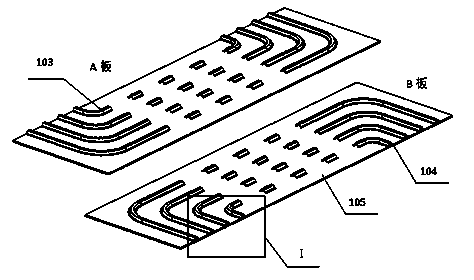

Heat exchanger plate bundle having guiding function

InactiveCN104215112ASolve the problem of uneven flow distributionNo vibrationChemical industryHeat exchanger casingsEngineeringMechanical engineering

The invention discloses a heat exchanger plate bundle having a guiding function. The heat exchanger plate bundle comprises a flat plate, wherein guide strips are arranged at a medium inlet and a medium outlet at the two ends of the flat plate; a gas-phase medium is introduced into a heat transfer area on the middle part of the flat plate through the guide strips; the middle part of the flat plate is fixedly connected with a supporting block, thereby forming a heat transfer flat plate; the top of the supporting block is in contact with the plane of another flat plate, and a sealing strip is welded between the two flat plates, thereby forming a single heat transfer plate tube; a plurality of heat transfer plate tubes are piled together to form the heat exchanger plate bundle having the guiding function. The heat exchanger plate bundle has the characteristics of small resistance loss, prevention of dust accumulation and coking, easiness in sweeping, freeness from a flowing dead zone, and safety and reliability in equipment running.

Owner:GANSU LANPEC TECH +1

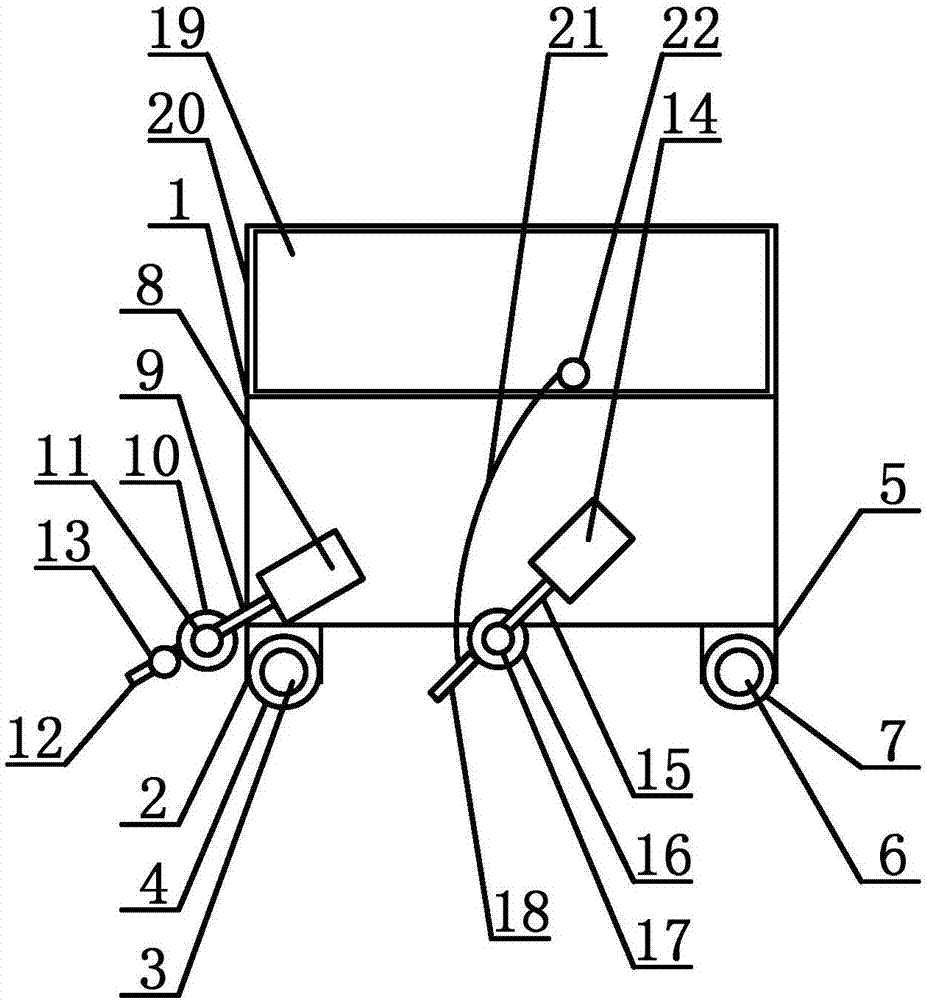

Workshop water sprinkling and sweeping robot

InactiveCN107157405AEasy to installEasy to move and adjustCarpet cleanersFloor cleanersHydraulic cylinderVehicle frame

The invention discloses a workshop water sprinkling and sweeping robot, which comprises a vehicle frame, wherein a first hydraulic cylinder is arranged at the bottom of the interior of the vehicle frame; a first piston rod is arranged at the lower side of the first hydraulic cylinder; first mounting shafts are arranged at two sides of the lower end of the first piston rod; first movable pipes sleeve the middles of the first mounting shafts; air-blowing pipes are arranged at the outer sides of the first movable pipes; air pumps are arranged on the air-blowing pipes; a second hydraulic cylinder is arranged at the bottom of the interior of the vehicle frame; a second piston rod is arranged at the lower side of the second hydraulic cylinder; second mounting shafts are arranged at two sides of the lower end of the second piston rod; second movable pipes sleeve the outer circumferential surfaces of the second mounting shafts; water flushing pipes are arranged at the lower sides of the second movable pipes; water outlets are formed in the lower ends of the water flushing pipes; a water tank is arranged at the top of the interior of the vehicle frame; and the water tank is connected to the water flushing pipes by virtue of water conveying pipes. According to the workshop water sprinkling and sweeping robot provided by the invention, floors of workshops can be flushed conveniently by virtue of the water conveying pipes, so that efficiency of cleaning the workshops is greatly improved.

Owner:MACROSCOPIC CENTURY TIANJIN CO LTD

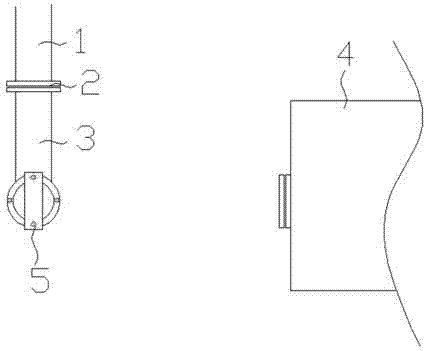

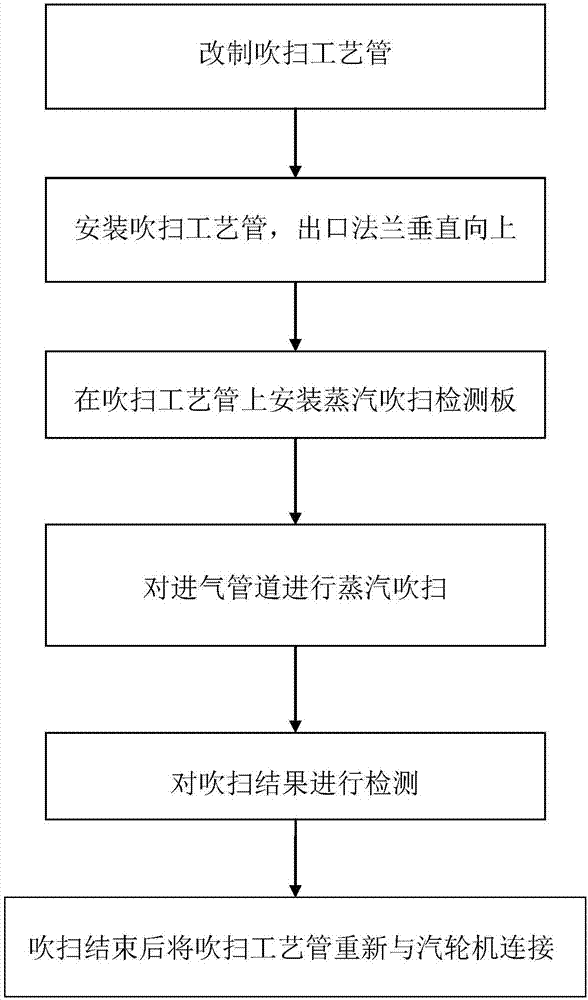

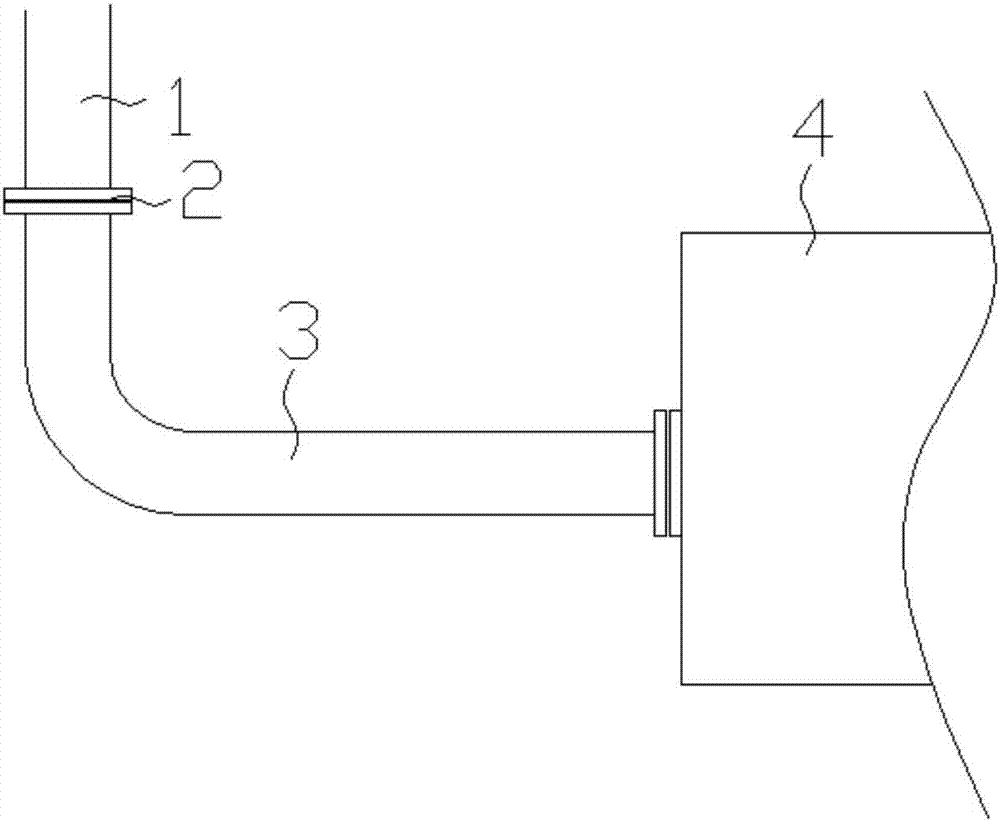

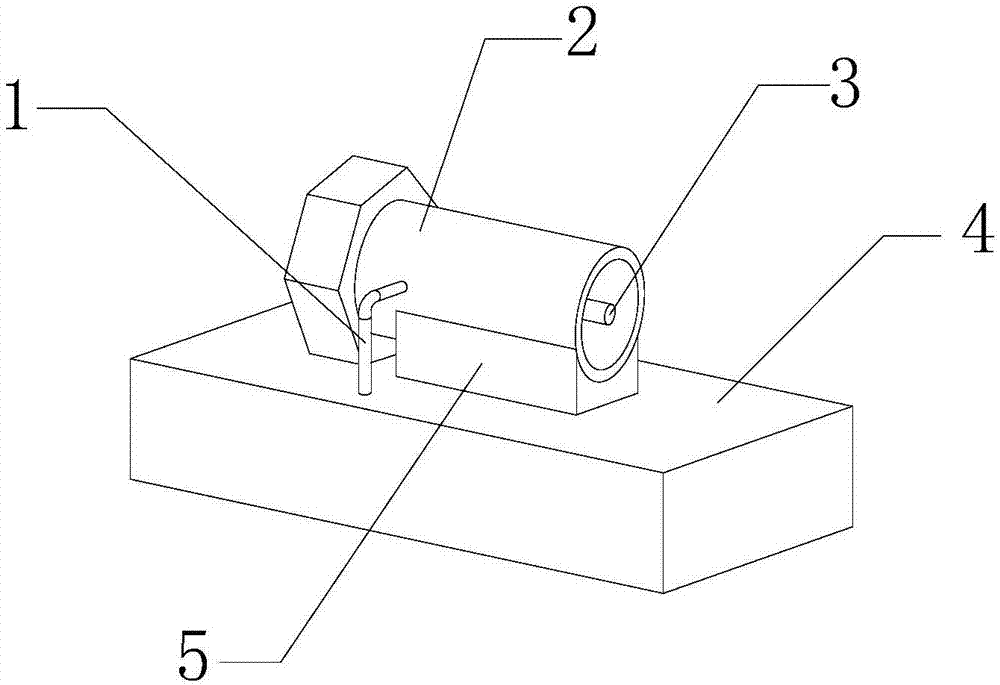

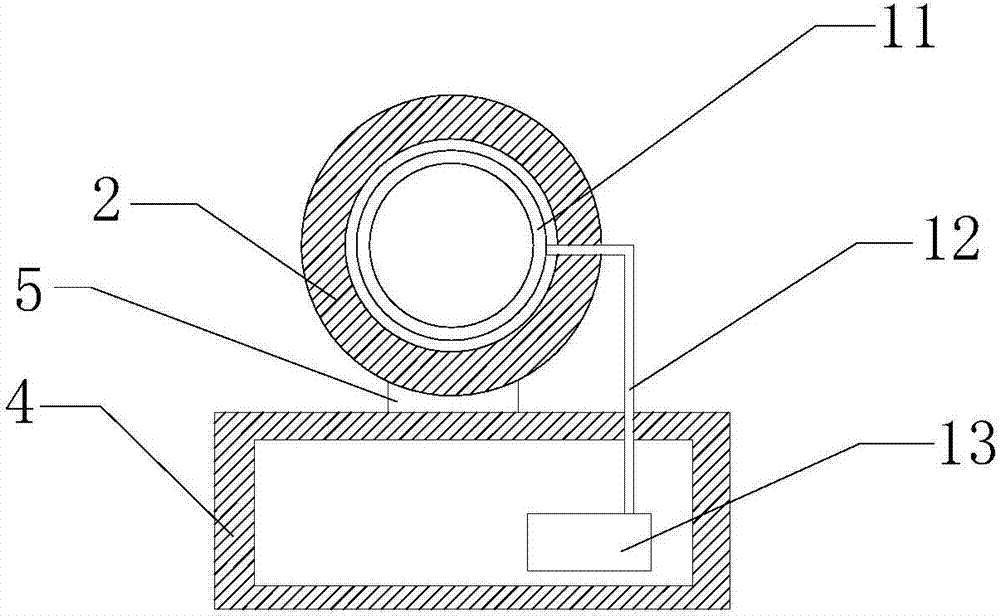

Rapid steam blowing method and device for gas inlet pipeline of turbine

ActiveCN107327319AReduce the workload of disassembly and assemblyLow production costMachines/enginesSafety/regulatory devicesButt jointEngineering

The invention provides a rapid steam blowing method for a gas inlet pipeline of a turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine comprises the following steps that (1) a last section of gas inlet pipeline close to an entrance part of the turbine is cut and taken to be remanufactured into a blowing process pipe, the blowing process pipe is a right-angle bend pipe which is bent by 90 degrees, flanges are fixedly arranged at the two ends of the blowing process pipe, the butt-joint flange is fixedly arranged at one end of the blowing process pipe and is connected with a flange at the tail end of the gas inlet pipeline of the turbine, and the exit flange is fixedly arranged at the other end of the blowing process pipe and is connected with the turbine; (2) the position of the blowing process pipe is upwardly rotated by 90 degrees, and the blowing process pipe is installed in a state with the exit flange vertically upward; (3) a target plate serves as a steam blowing detecting plate and is installed on the exit flange of the blowing process pipe; (4) steam is injected into the gas inlet pipeline for blowing; (5) the steam blowing detecting plate is disassembled after each time of blowing and a blowing result is detected until a detecting result meets the requirement; and (6) after blowing for all is finished, the connecting direction of the blowing process pipe is changed and the blowing process pipe is re-connected with the turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine has the advantages that steam blowing is rapid and convenient, working efficiency is high, and cost is low.

Owner:HUDONG HEAVY MACHINERY

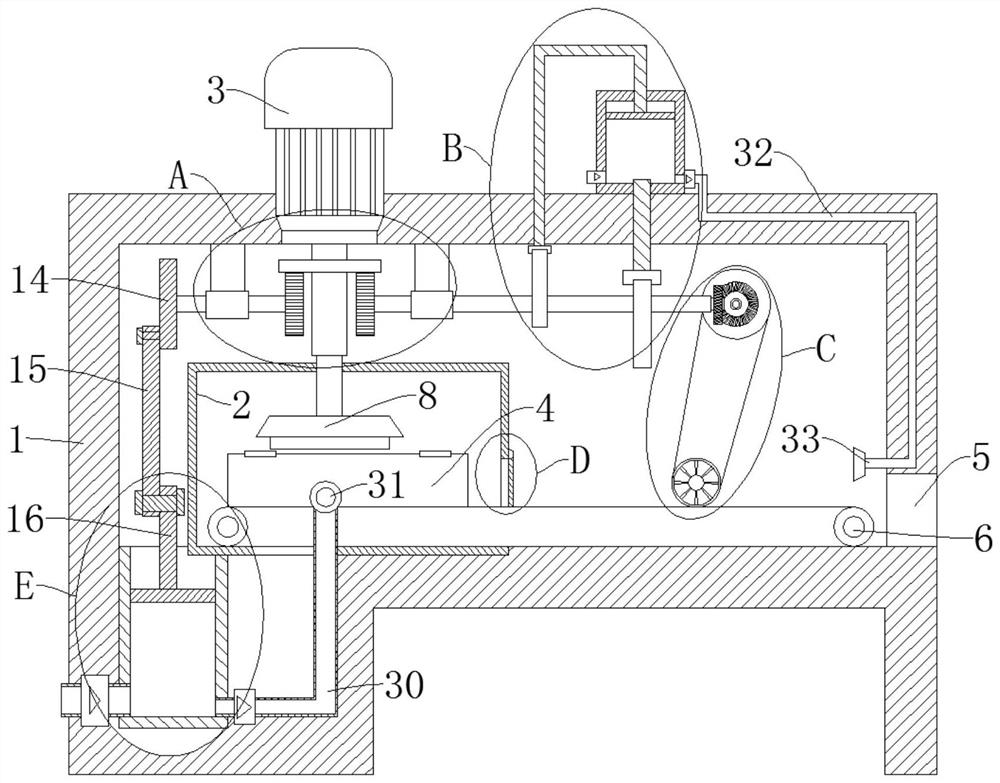

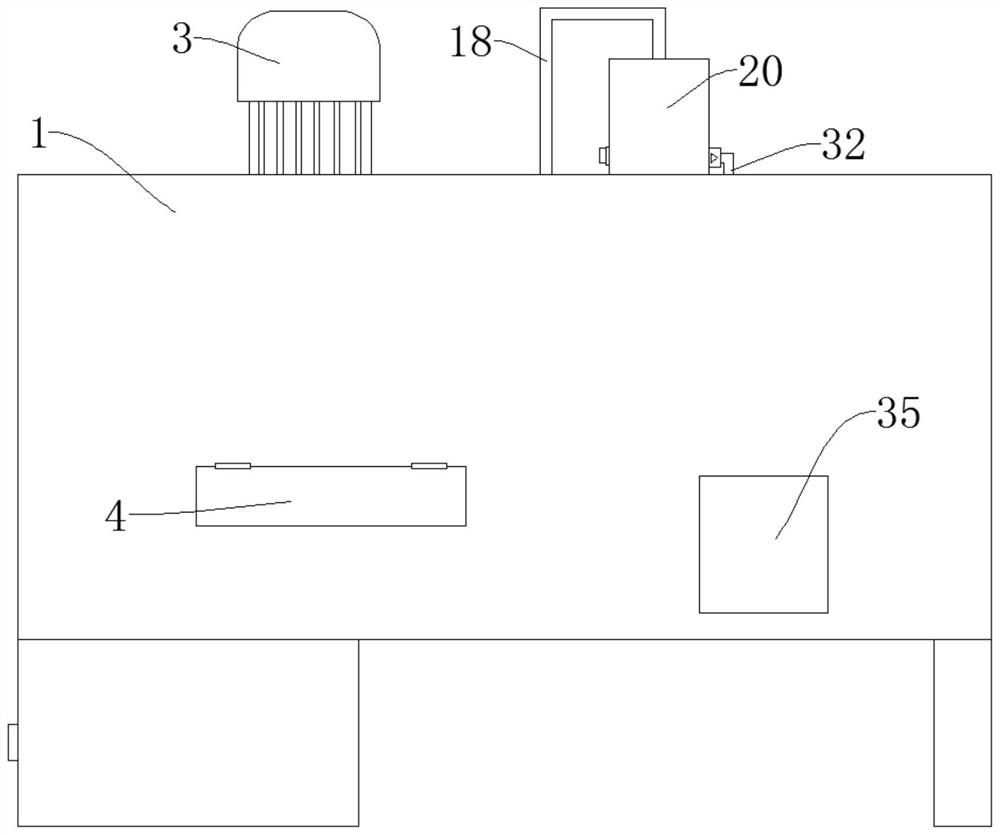

Motorcycle part machining iron chip processing system

InactiveCN106584190AEasy and effective cleaningEasy to useMaintainance and safety accessoriesGrinding/polishing safety devicesMachining systemWaste management

The invention relates to a motorcycle part machining iron chip processing system which comprises a flushing system, a collecting system and a machining system. The collecting system is installed on the upper portion of the flushing system. The machining system is installed on the upper portion of the collecting system. A filter mechanism is fixedly installed between the flushing system and the collecting system. A multi-layer supporting and connecting mechanism is installed between the machining system and the collecting system. A power system is installed on the side face of the machining system. A liquid fetching system and a draught fan system are installed in the power system. An inlet in the liquid fetching system is provided with an oil supply pipe which is connected with the filter mechanism installed at the bottom of the flushing system. An outlet of the liquid fetching system is provided with an oil outlet pipe. An air blowing pipe is arranged on the draught fan system. By the adoption of the motorcycle part machining iron chip processing system, motorcycle part machining iron chips can be removed conveniently and effectively, using is convenient, oil for cleaning can be recycled in the cleaning process, purging is convenient, cleanliness is maintained, and the using effect is good.

Owner:重庆市友路机械有限公司

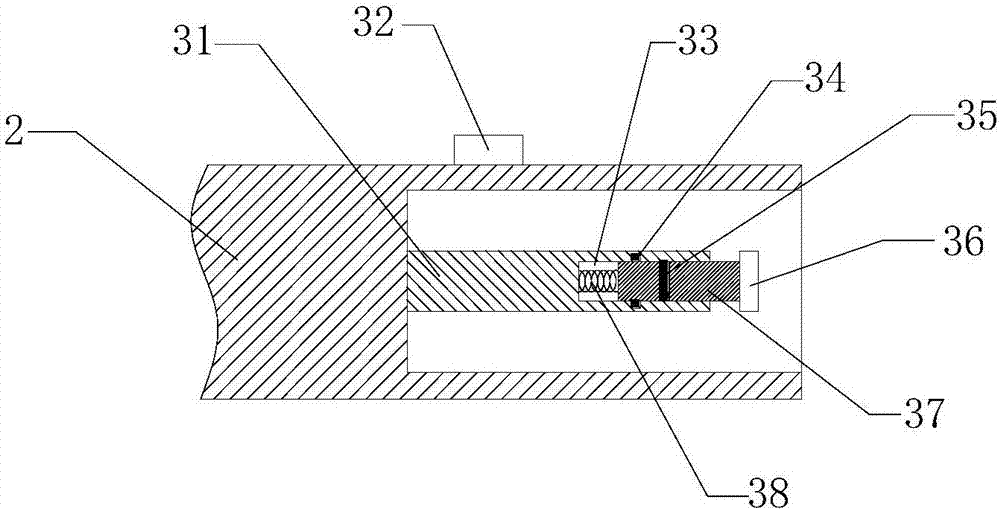

A passive device testing intermodulation device

InactiveCN107462787AQuick clean upReduce difficultyMeasuring interference from external sourcesCleaning using gasesEngineeringAir blower

The invention provides a passive device testing intermodulation device comprising an annular pipe, a connecting pipe, an air blower, an indicating lamp, a hollow cavity, a first contact sheet, a second contact sheet, a front conductor sheet, an insulation rod and a spring. The annular pipe is disposed in an adapter; the upper end of the connecting pipe penetrates the annular side surface of the adapter and is connected with the annular pipe; the lower end of the connecting pipe penetrates the upper end face of a bottom box and is connected with the air blower, so that scraps can be cleaned quickly; the indicating lamp is arranged on the annular side surface of the adapter; the right end of the insulation rod is installed on the middle position of the left end surface of the front conductor sheet; the left end of the spring is fixed to the left end surface of the inside of the hollow cavity; the first contact sheet is mounted on the inner wall of the hollow cavity and the second contact sheet is mounted on the annular side surface of the insulation rod. The passive device testing intermodulation device has a location indicating function, and is high in stability and reliability; the passive device testing intermodulation device can clean scraps quickly.

Owner:ANHUI LUXUN ELECTRONICS TECH

Central gas collecting pipe of shift converter

PendingCN111250000AQuality improvementImprove job stabilityChemical/physical processesThermodynamicsPtru catalyst

The invention relates to a central gas collecting pipe of a shift converter. The central gas collecting pipe comprises a pipe body, wherein gas inlet holes are fully distributed in the pipe body; thelower end of the pipe body is connected with an expansion pipe with a diameter larger than the diameter of the pipe body; the lower end of the expansion pipe is connected with a gas distributing pipe;the lower end of the gas distributing pipe is sealed by a bottom plate; and a large number of gas outlet holes are evenly distributed in the wall of the gas distributing pipe. The central gas collecting pipe can guide finished gas to enter a catalyst layer again for a secondary reaction so as to improve the quality of the finished gas.

Owner:JIANGSU PUGE MACHINERY

Snow plow with thermal turbine snow blower

ActiveCN103469759BImprove snow removal effectTo achieve the purpose of blowing and snow removalRailway cleaningElectricitySnow removal

Owner:河南国研中卓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com