Heat exchanger plate bundle having guiding function

A heat exchanger and functional technology, which is applied in the field of heat exchanger plate bundles for gas-to-air heat exchange, can solve the problems of air preheater, such as bulky floor space, inability to use pressurized gas for heat exchange, and no mention of flow state. , to achieve the effect of compact structure, small footprint, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

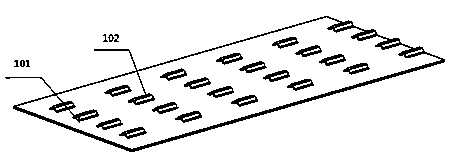

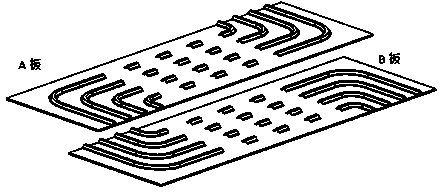

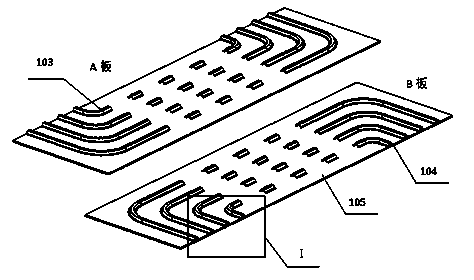

[0033] Example 1: Refer to the implementation mode of I / U-shaped plate bundle with guiding function figure 1 , 3, 4, 5, the flow of the medium on the I-type plate is straight in and straight out, and there is only a support block on one side of the heat transfer area of the I-type plate. The U-shaped board is divided into A and B boards, and the A board is rotated 180 degrees horizontally to form the B board. The U-shaped board is equipped with guide bars and support blocks. Connect a U-shaped A-plate (or B-plate) 3 with support blocks and guide strips on the side with an I-shaped plate without support blocks, and then set U-shaped around the non-medium inlet and outlet periphery 101 The sealing strips 202 are combined, and a single I / U-shaped plate tube 5 can be obtained after welding. Finally, an I-shaped plate sealing strip 201 is added between a plurality of I / U-shaped plate tubes, and the plate tubes are stacked to form an I / U-shaped plate bundle with a guiding functio...

Embodiment 2

[0034] Example 2: I / Z-shaped plate bundle with guiding function for reference figure 1 , 2 , 7, 8. The implementation of the plate bundle is the same as that of Example 1, except that: Z-shaped sealing strips 203 are added in the implementation of the plate tubes; and I-shaped plate sealing strips 201 are added between the plate tubes in the implementation of the plate bundles.

Embodiment 3

[0035] Embodiment 3: The U / U-shaped plate bundle with guiding function is implemented with reference to Figs. 3, 9 and 10. The implementation of the plate bundle is the same as that in Example 1, except that: U-shaped sealing strips 202 are added in the implementation of the plate tubes; U-shaped sealing strips 202 are added between the plate tubes in the implementation of the plate bundles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com