Device and method for blowing ash in entrained flow gasifier

A technology of soot blowing device and gasifier, which is applied in the mechanical details of gasification device, gasification process, granular/powdered fuel gasification, etc., and can solve the problems of equipment failure, fly ash difficulty, and large amount of purge gas, etc. problems, to achieve the effect of reducing the cohesiveness of fly ash, good effect of soot blowing, and small gas consumption of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

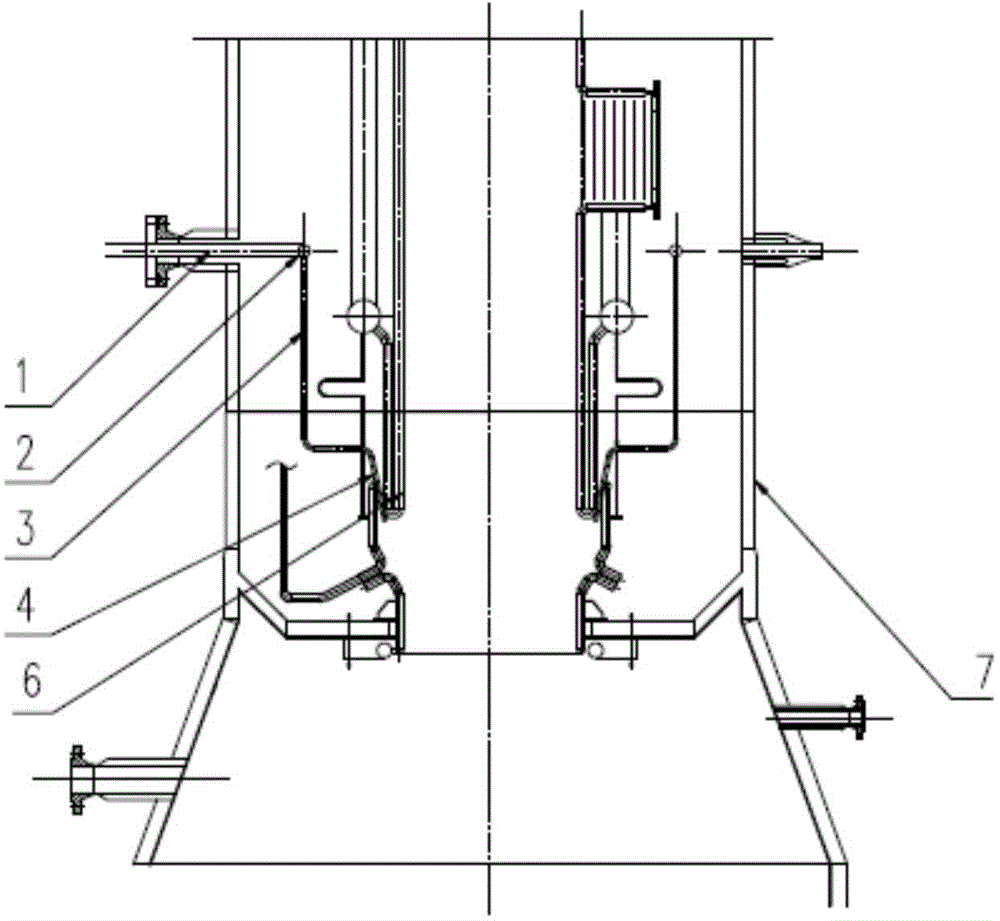

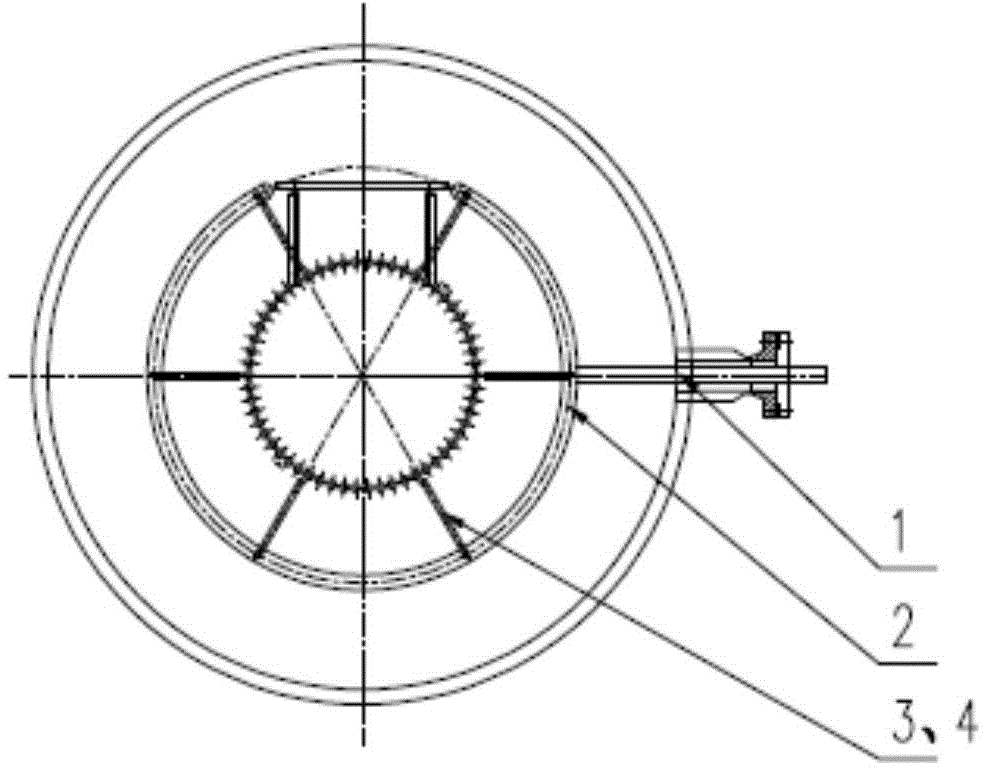

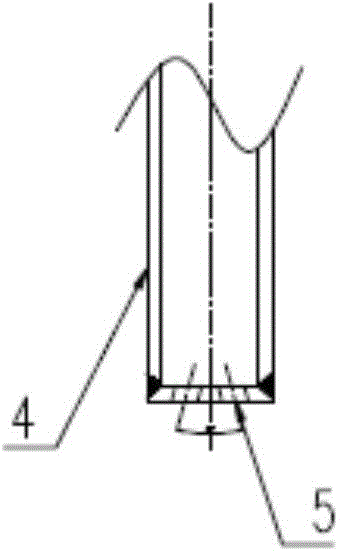

[0022] like Figure 1a , Figure 1b , Figure 2a and Figure 2b As shown, the present invention is a soot blowing device used in an entrained bed gasifier, including a soot blower pipe joint 1 welded on the gasifier shell 7 and extending into it, arranged on the gasifier shell 7 The annular soot blower main pipe 2 connected with the soot blower pipe joint 1 between the water wall 6 of the gasifier, the multiple first soot blower branch pipes 3 communicated with the annular soot blower main pipe 2, and each first The second soot blower branch pipe 4 communicated with the soot blower branch pipe 3, the second soot blower branch pipe 4 passes through the water cooling wall 6 of the gasification furnace, and is arranged on the inner surface of the water cooling wall 6 of the gasification furnace, and the second soot blower branch pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com