Efficient energy-saving snow sweeper

An energy-saving snow removal vehicle technology, which is applied in track cleaning, construction, cleaning methods, etc., can solve problems such as inability to remove ice from catenary, endless snow removal, self-excited vibration of wires, etc., to overcome low snow removal efficiency and realize flexible and multi-purpose Variable, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

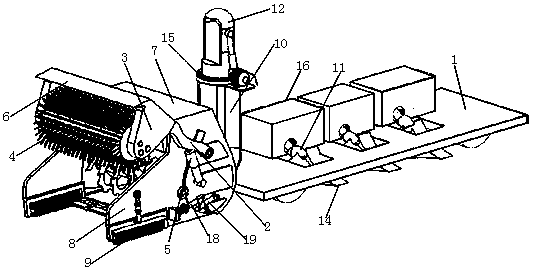

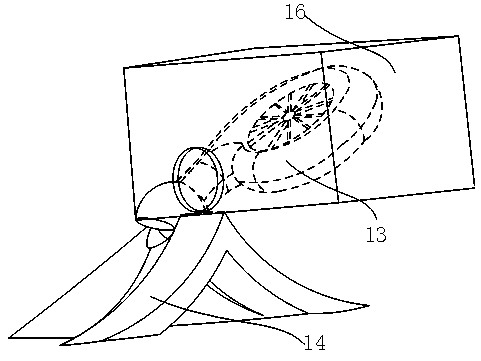

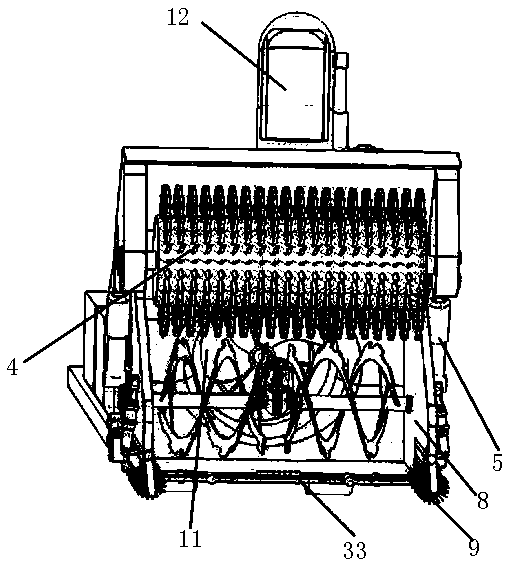

[0061] This embodiment provides a kind of high-efficiency and energy-saving snow removal vehicle, such as Figures 1 to 9 As shown, the snow removal vehicle mainly includes two parts, the snow removal head and the snow removal body 1 . The improvement of the present invention to the existing snow removal vehicle mainly includes two aspects, one is the improvement of the snow removal vehicle for track snow removal; the other is the improvement of the snow removal vehicle for contact net deicing. Among them, the track snow removal is mainly carried out through two aspects: first, the snow treatment of the track surface; second, the snow treatment of the gap between the track surface and the sleepers.

[0062] 1. Improvement of snow removal vehicles for track snow removal

[0063]The snow treatment on the track surface is mainly completed by the newly designed snow removal head. Specifically, in this embodiment, the snow removal head mainly includes four parts: the snow bucket, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com