Electric power cabinet snow removing device

A technology for power cabinets and stepping motors, applied in switchgear, electrical components, cleaning methods and appliances, etc., can solve problems such as grounding or short-circuit accidents of high-voltage live equipment, low snow-clearing efficiency, and low safety performance, so as to ensure personal safety. The effect of safety, reducing the difficulty of operation and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments:

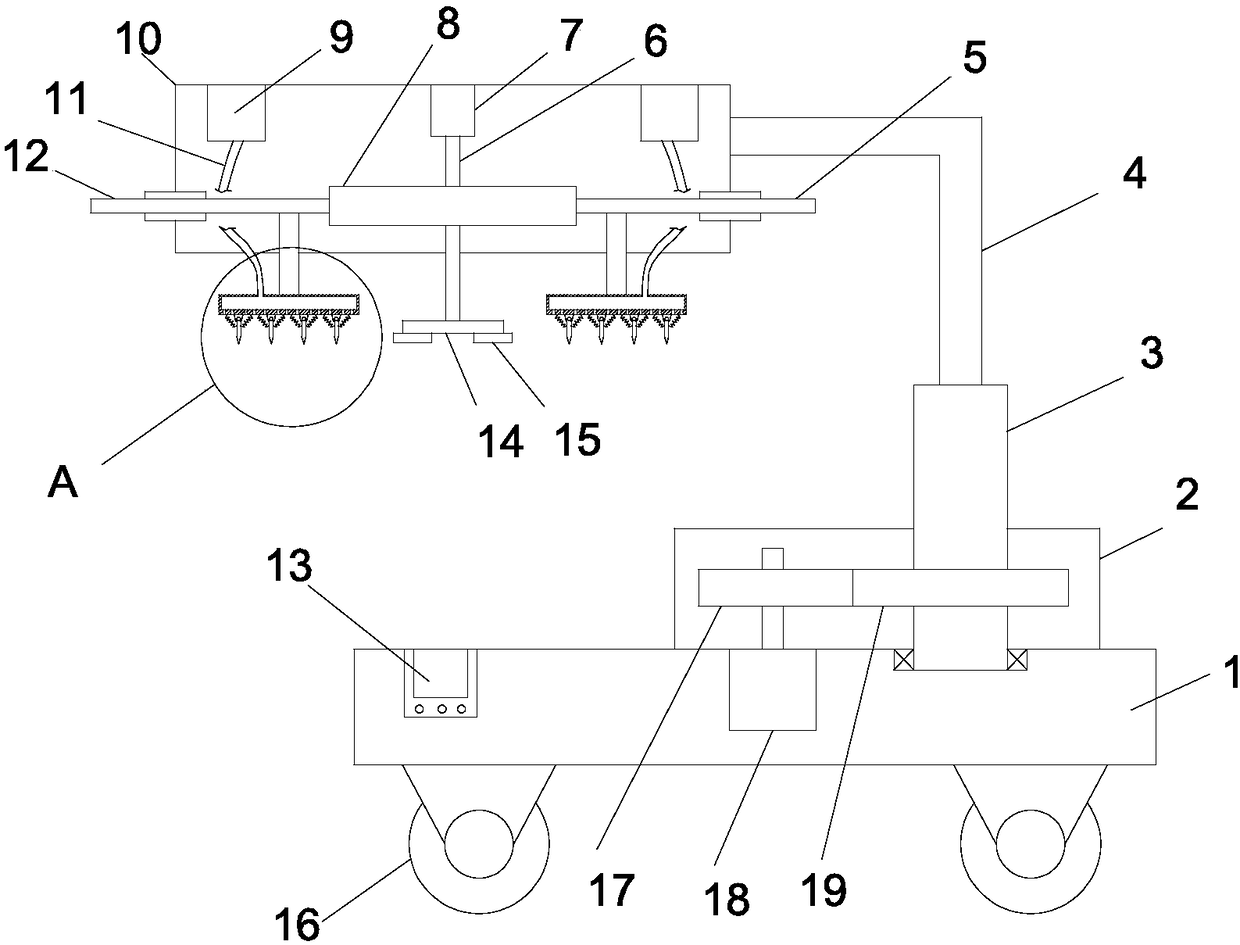

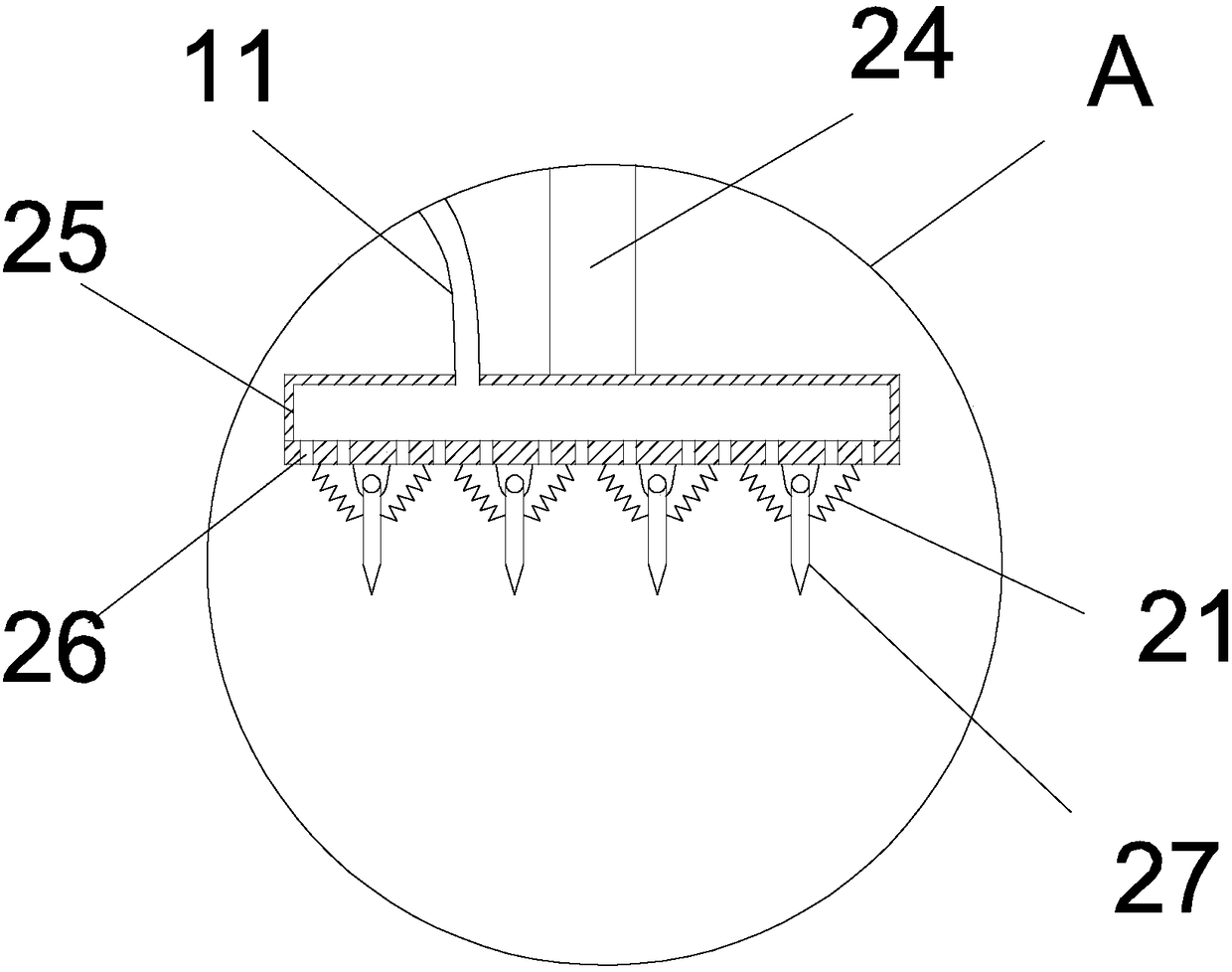

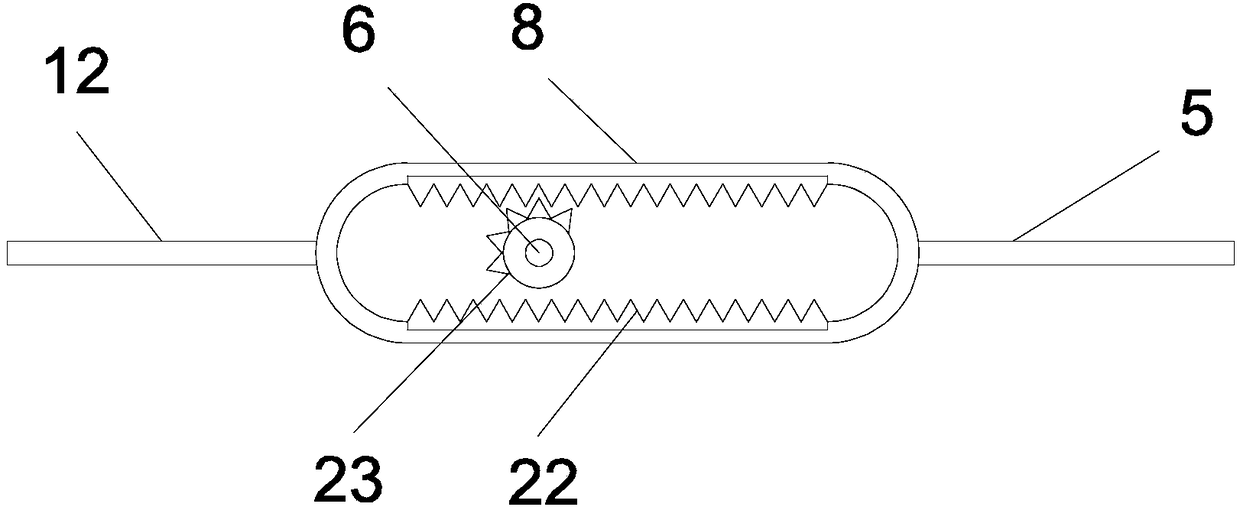

[0019] see Figure 1-3 , a kind of snow clearing device of electric power cabinet, comprises bottom box 1, and bottom box 1 bottom rotation is provided with several rollers 16, and described bottom box 1 is provided with hydraulic cylinder 3 rotatingly, and transmission box is fixedly installed on bottom box 1 2. The hydraulic cylinder 3 runs through the transmission box 2 upwards. The driven gear 19 is fixedly installed on the surface of the transmission box 2. The bottom box 1 is equipped with a stepping motor 18, and the output shaft of the stepping motor 18 is coaxially fixed and installed. There is a driven gear 19 meshed with a driven gear 19; a lifting rod 4 is fixedly installed on the telescopic rod of the hydraulic cylinder 3, and an operation box 10 is fixedly installed on the left end of the lifting rod 4, and an operation box 10 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com