High-voltage line deicing device based on electric cylinder knocking

A technology of high-voltage wires and electric cylinders, which is applied to the installation of cables, electrical components, overhead installations, etc., and can solve problems such as disconnection, stretching, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

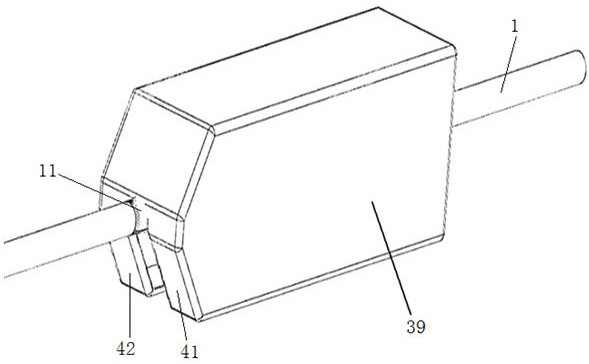

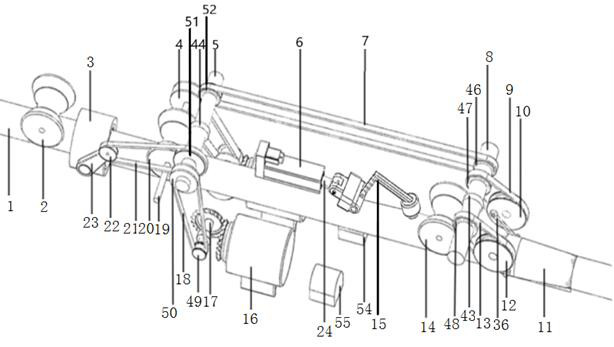

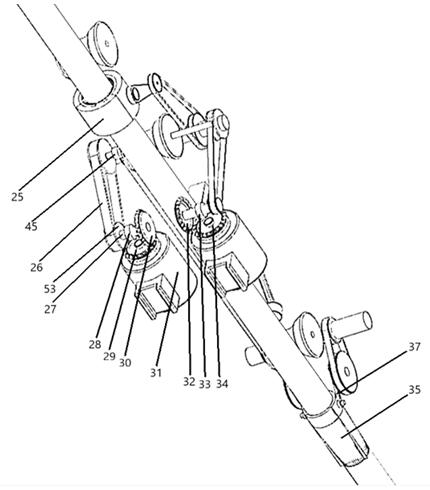

[0036] For the high-voltage line deicing device based on electric cylinder knocking in this embodiment, please refer to Figure 1-Figure 11 , including a box body 39 erected on the high-voltage line 1, a walking drive mechanism for driving the whole device to walk along the length direction of the high-voltage line 1, a cutting knife barrel mechanism for cutting ice on the surface of the high-voltage line 1, and a The knocking mechanism for knocking the ice on the high-voltage line, and the brush cleaning mechanism for cleaning the ice debris on the surface of the high-voltage line 1;

[0037] The specific structure of the walking driving mechanism: the walking driving mechanism includes a walking motor 31, and the walking motor 31 drives the walking driving wheel 20 to move along the length direction of the high-voltage line 1 through the walking transmission wheel assembly. The driven wheel 2, the driving wheel 20, the front driven wheel 14, and the rear driven wheel 2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com