Coal slurry reactant sampling device

A sampling device and reactant technology, applied in sampling devices, wellbore/well components, earth-moving drilling, etc., can solve the problems of inability to sample container sampling, sampling method and equipment sampling, etc., and achieve simple purging and cleaning, Easy to operate, accurate sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

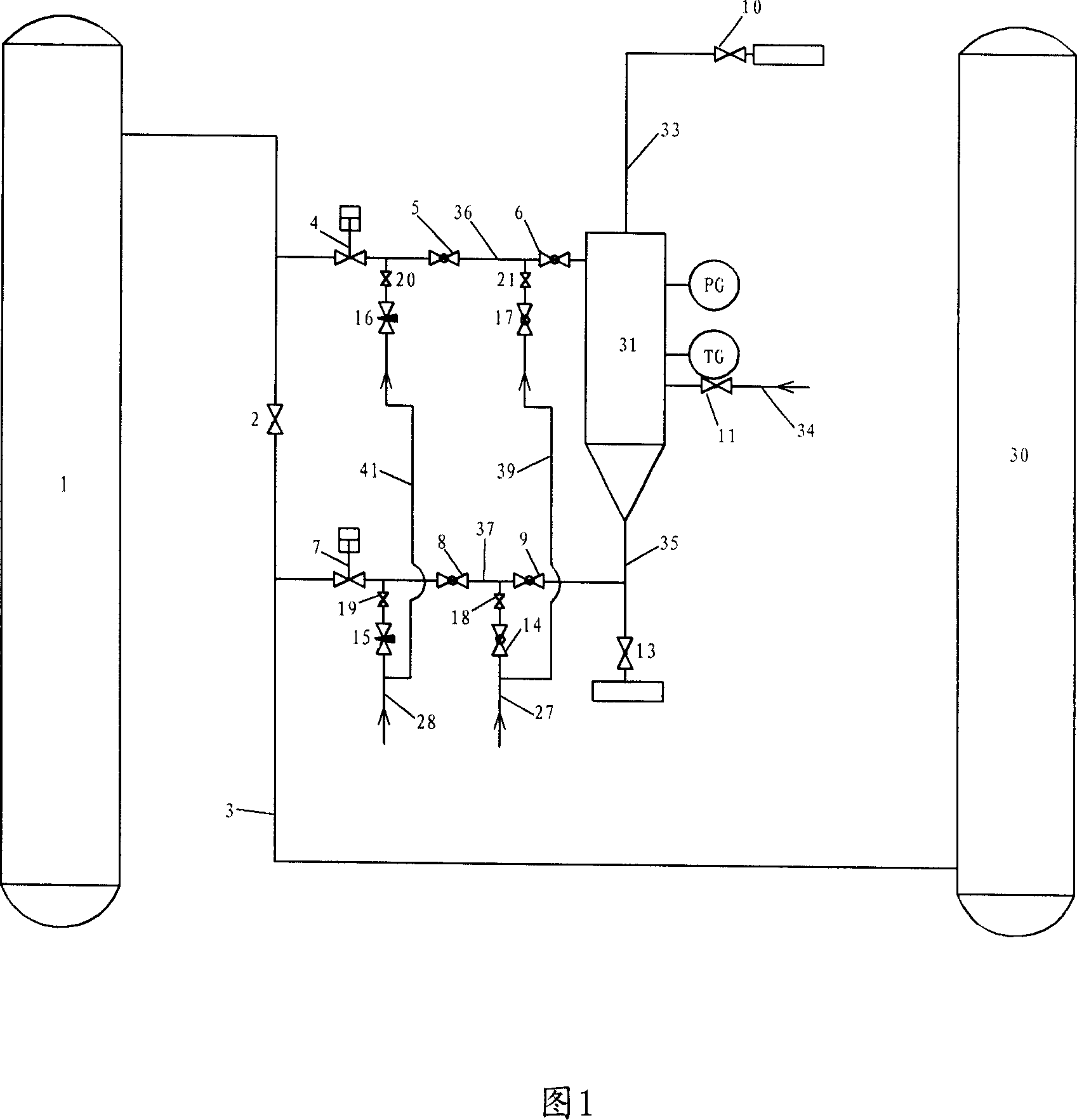

[0054] This embodiment illustrates: the application of the sampling device provided by the present invention in the coal direct liquefaction reaction system.

[0055] The raw material of the direct coal liquefaction unit is coal slurry prepared from 100-mesh coal powder (content 45% by weight), solvent oil, and catalyst. Coal slurry and hydrogen enter the first reactor, and after 45 minutes of reaction, enter the second reactor through valve 2 and pipeline 3. The specific operation steps are as follows:

[0056] 1. Open valves 5, 6, 8, 9, 10 and 11, replace the gas in the sampling device with nitrogen, and then close valves 5, 6, 8, 9, 10 and 11;

[0057] 2. Close valves 4 and 7, and close valves 15 and 16;

[0058] 3. Open valves 5, 6, 8 and 9. If the pressure in sampling container 31 is lower than 20MPa, open valves 14 and 17 to inject high-pressure solvent oil into the sampling container and pipeline. When the pressure reaches 20.0MPa, the pneumatic valve will Pressure b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com