Patents

Literature

47results about How to "Reduce the workload of disassembly and assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

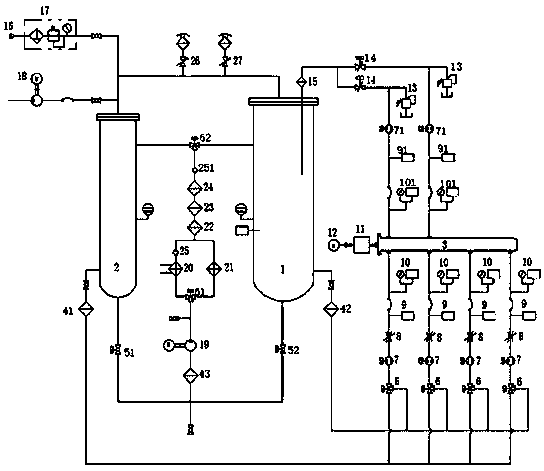

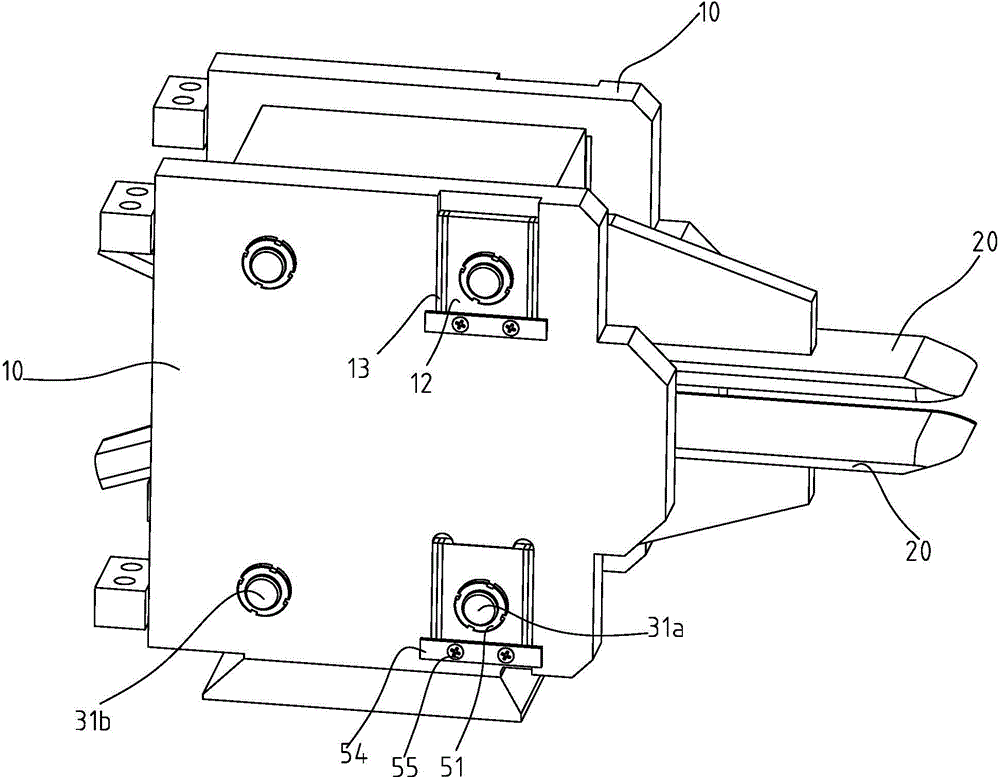

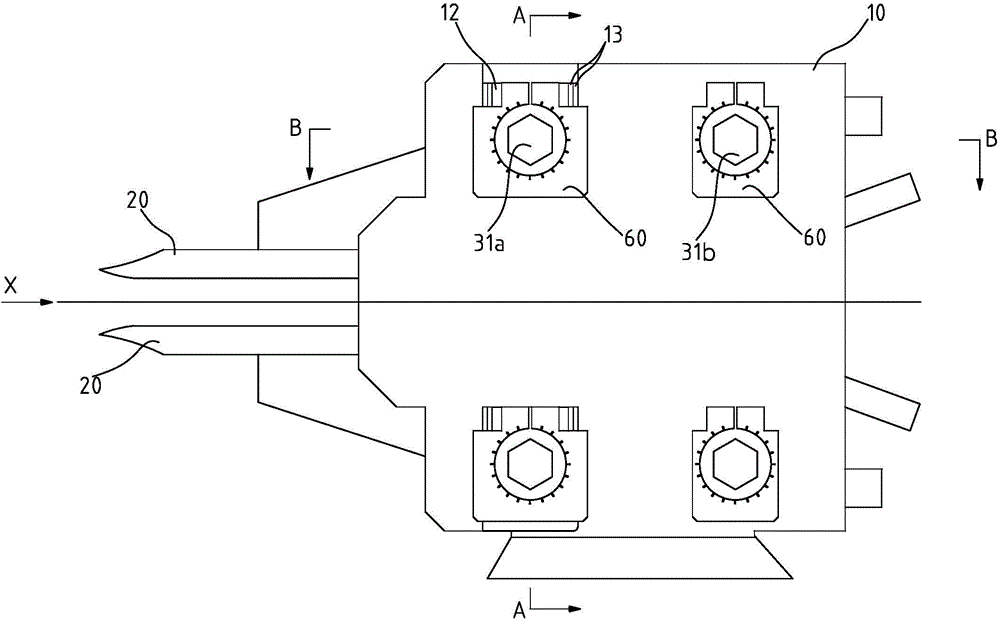

Aviation sliding oil pump comprehensive testbed

InactiveCN110439799AWide applicabilityReduce the workload of disassembly and assemblyPump testingPositive-displacement liquid enginesDrive motorPneumatic pressure

The invention provides an aviation sliding oil pump comprehensive testbed. The aviation sliding oil pump comprehensive testbed comprises a metering oil tank, a main oil tank and a tested sliding oil pump, and is characterized in that the tested sliding oil pump is connected with the lower end of the main oil tank and the lower end of the metering oil tank through four oil supply pipelines, and thetested sliding oil pump is connected with the top of the main oil tank through two oil return pipelines; a circulating oil way and an air pressure adjusting loop are arranged between the metering oiltank and the main oil tank respectively; and the tested sliding oil pump is connected with a driving motor through a gearbox. According to the aviation sliding oil pump comprehensive testbed, the requirements of the sliding oil pumps with different specifications and multiple test items can be met; and each test item of the tested sliding oil pump can be completed by one-time installation, and the disassembly and assembly workload is reduced.

Owner:九江七所精密机电科技有限公司

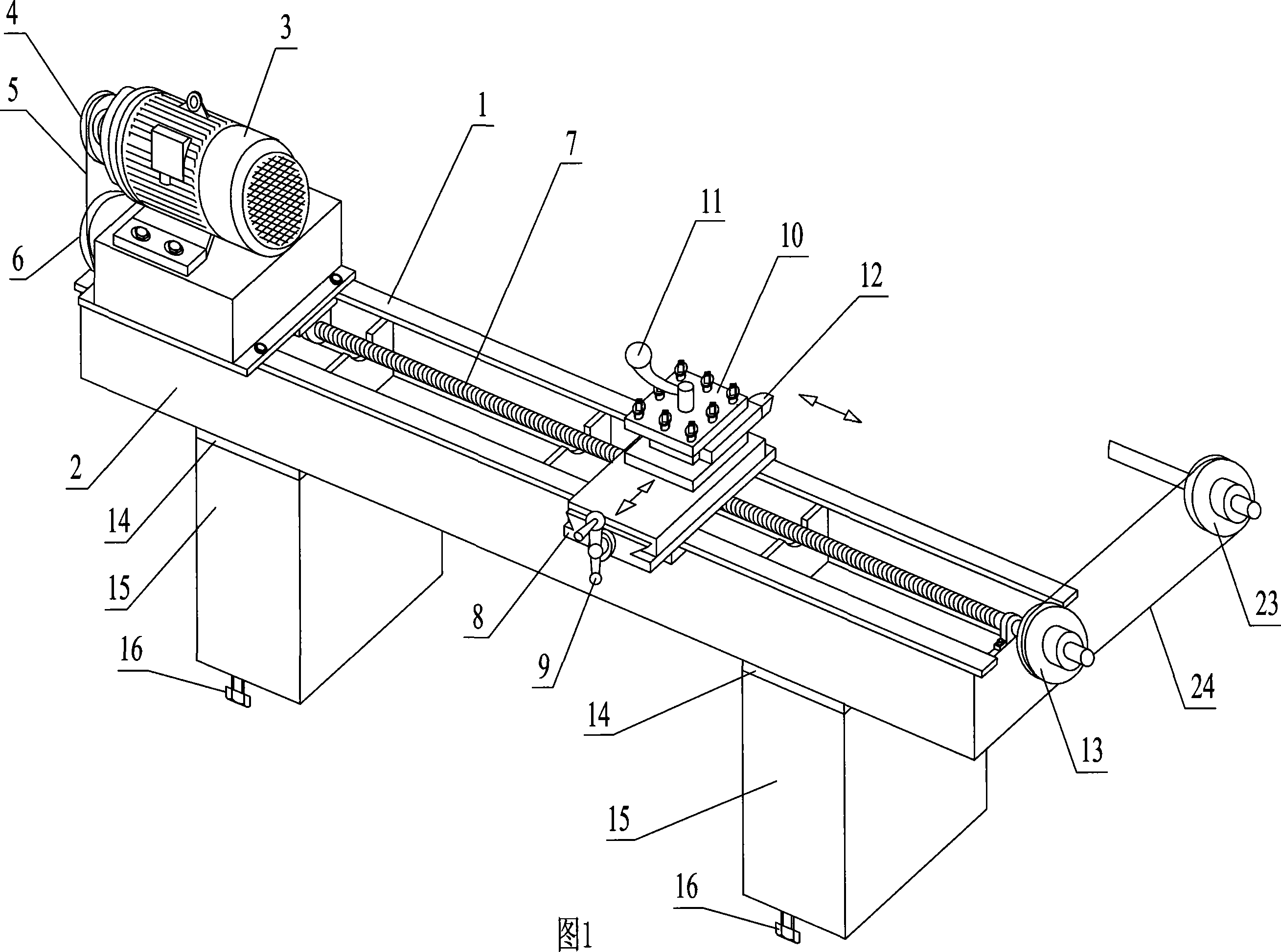

Special movable device for barrel cutting

InactiveCN101085468AHigh precisionReduce the workload of disassembly and assemblyFeeding apparatusLarge fixed membersSprocketEngineering

The movable cylinder cutter comprises the guide track cushion installed on the alight base, frame with guide track, bottom of the alight base having adjustable alighting device, left of the guide track installed with frequency changing generator with belt wheel, leather belt wheel and sprocket silk bar installed at left and right ends of the frame, with the belt wheel connecting with the triangle belt and frequency changing generator, the sprocket connected to the one on the cutting cylinder shaft through chains, with support plates installed on the thread bar along the guide track and handle knife base on the support plate with handle adjustable knife knob installed on the knife base. It can fine cut the surface of the cylinder to improve the precision of the hackling parts.

Owner:宋晓波

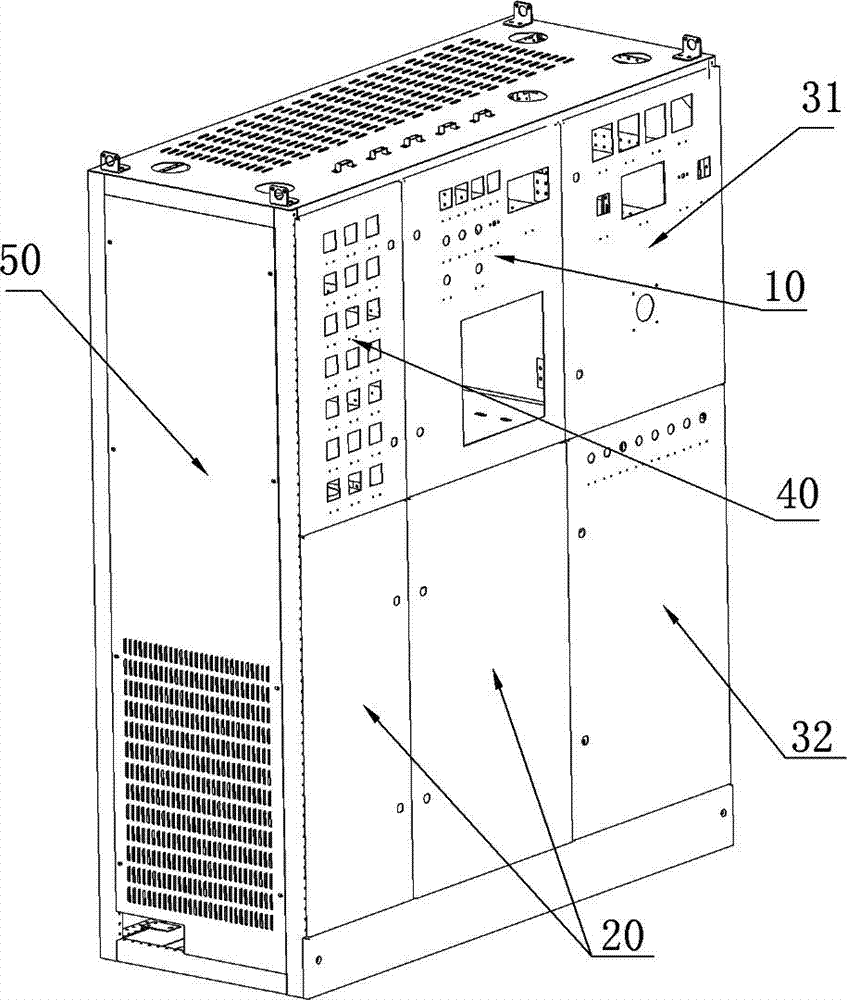

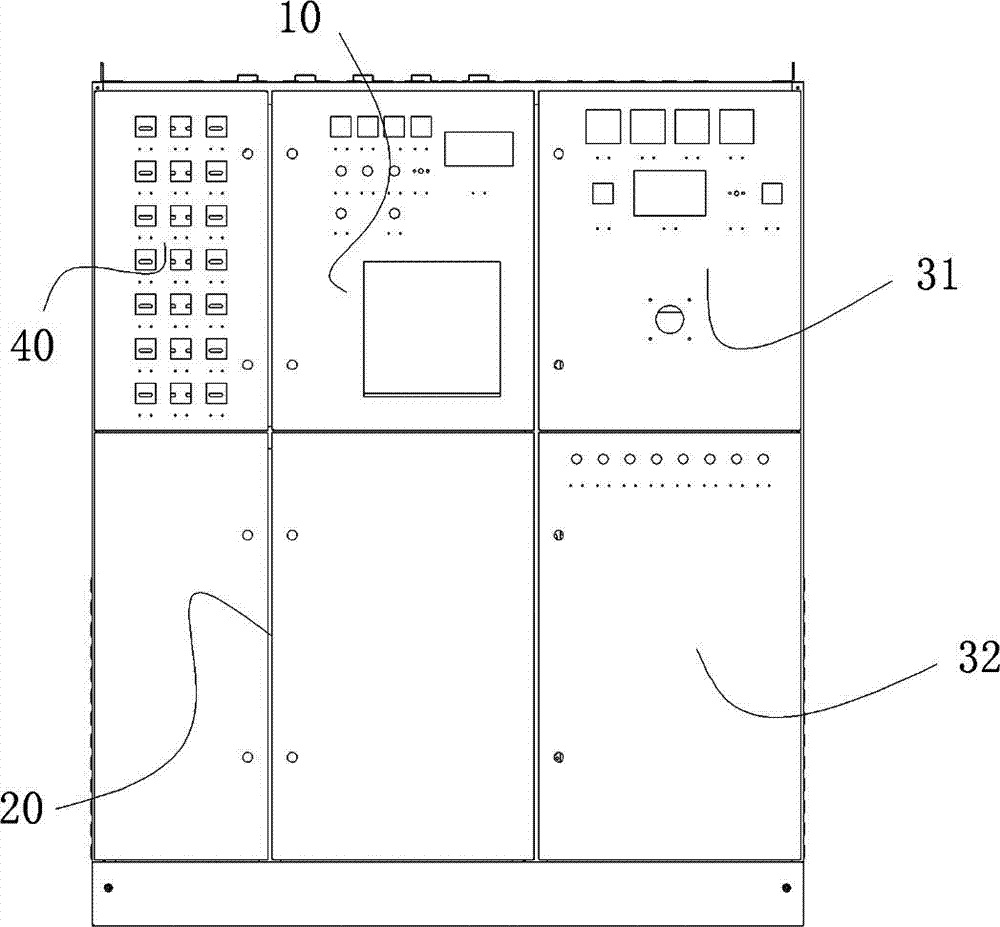

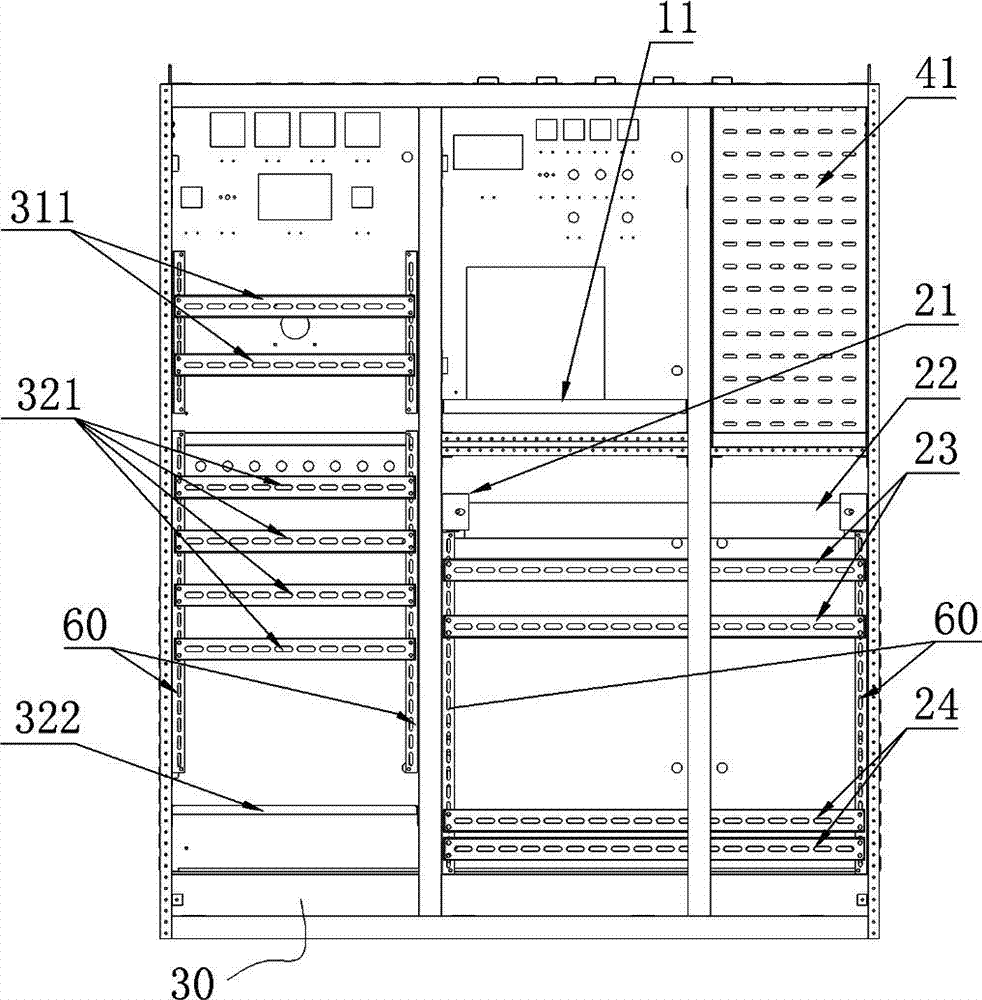

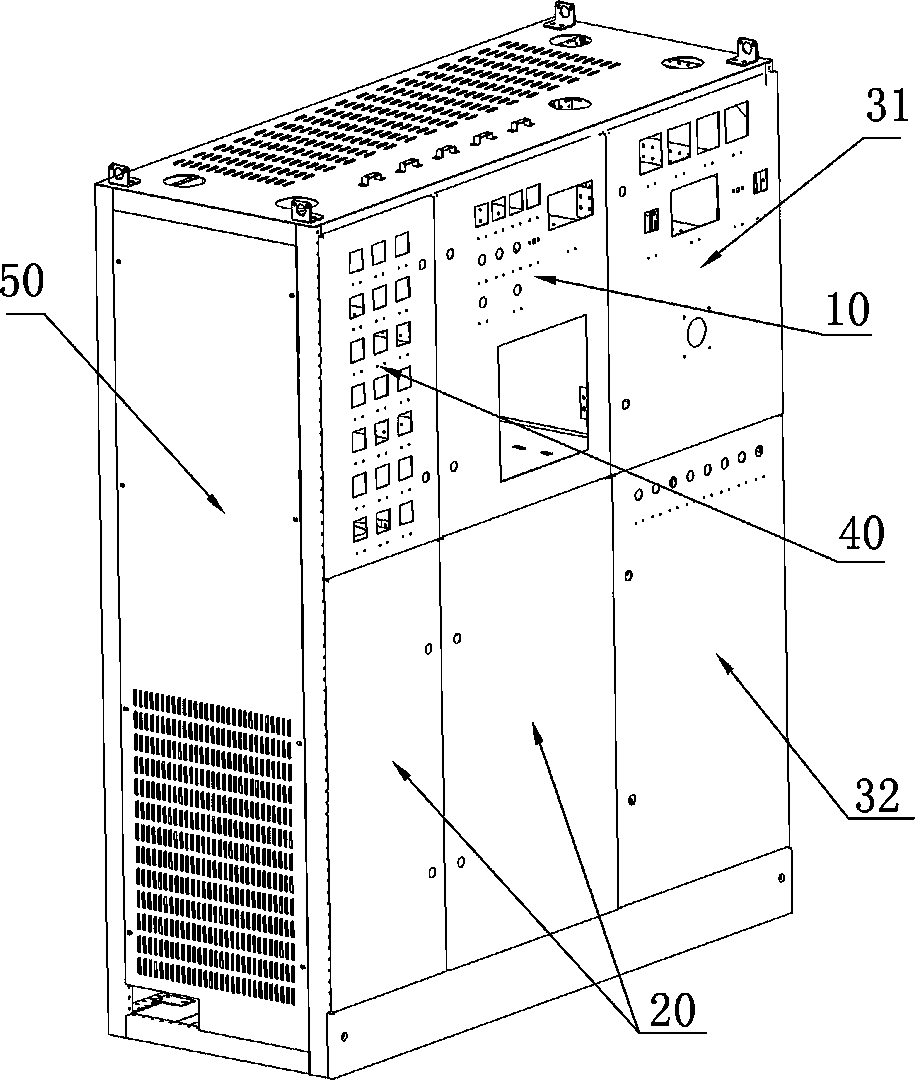

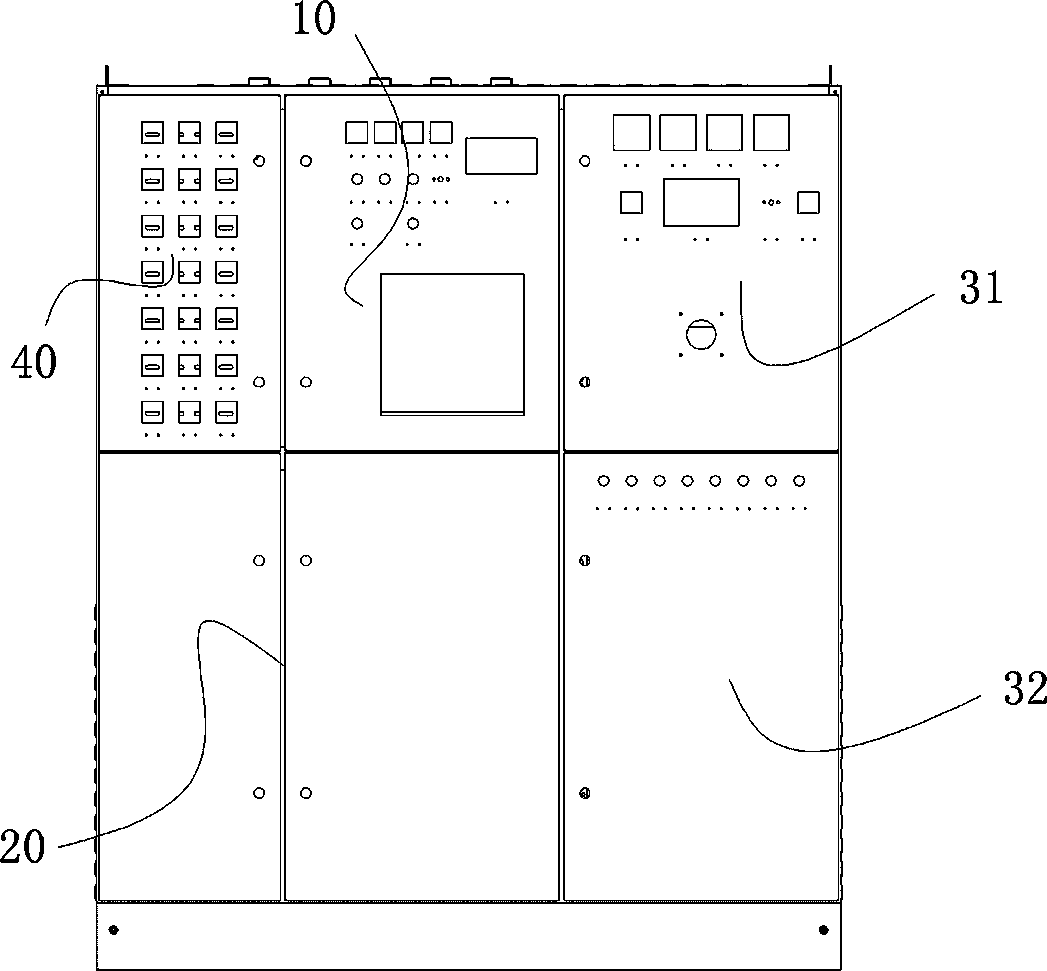

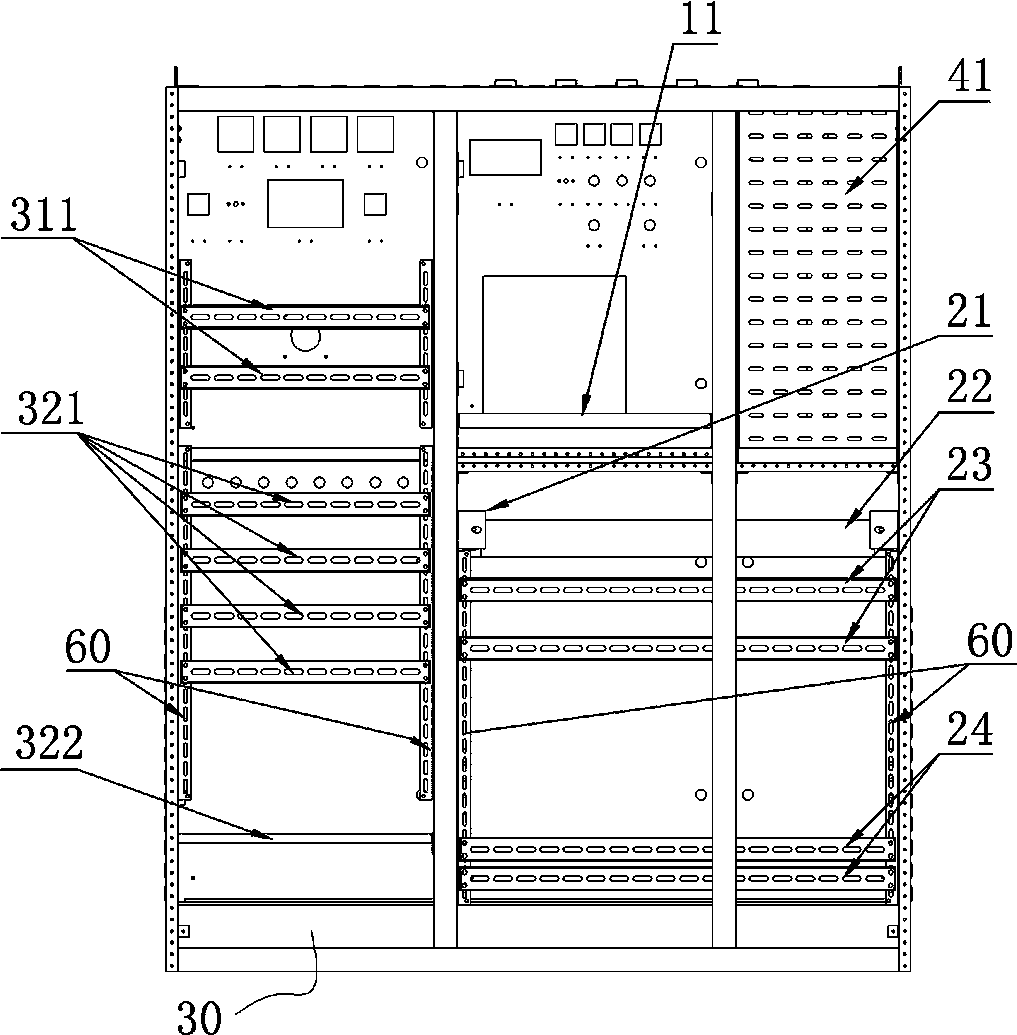

Low-voltage cabinet of box-type transformer station, and box-type transformer station with same

ActiveCN104332855AFirmly connectedEasy assembly and maintenanceBoards/switchyards circuit arrangementsFuse disposition/arrangementCapacitanceTransformer

The invention relates to a low-voltage cabinet of a box-type transformer station, and the box-type transformer station with same, wherein the low-voltage cabinet of the box-type transformer station comprises a wire inlet unit, a feeder line unit, a capacitance compensating unit and a secondary instrument unit. The wire inlet unit, the feeder line unit, the capacitance compensating unit and the secondary instrument unit are arranged in one cabinet body and furthermore are separated from one another through corresponding baffle plates. The wire inlet unit and the secondary instrument unit are parallelly arranged in the transverse direction of the cabinet body. The feeder line unit is arranged below the wire inlet unit and the secondary instrument unit. The capacitance compensating unit is arranged at one side of the wire inlet unit in the transverse direction, which deviates the secondary instrument unit, and furthermore the lower part of the capacitance compensating unit is arranged parallelly with the feeder line unit in the transverse direction. The wire inlet unit of the low-voltage cabinet is arranged at the middle part of the cabinet body in the transverse direction, thereby realizing convenient connection with other units. Furthermore the capacitance compensating unit and the feeder line unit can be distributed to relatively large spaces, thereby realizing reasonable layout and high space utilization rate. Furthermore, the units are arranged in a same cabinet body, thereby realizing benefit for assembling and maintenance, reducing detaching workload and improving operation efficiency.

Owner:STATE GRID CORP OF CHINA +2

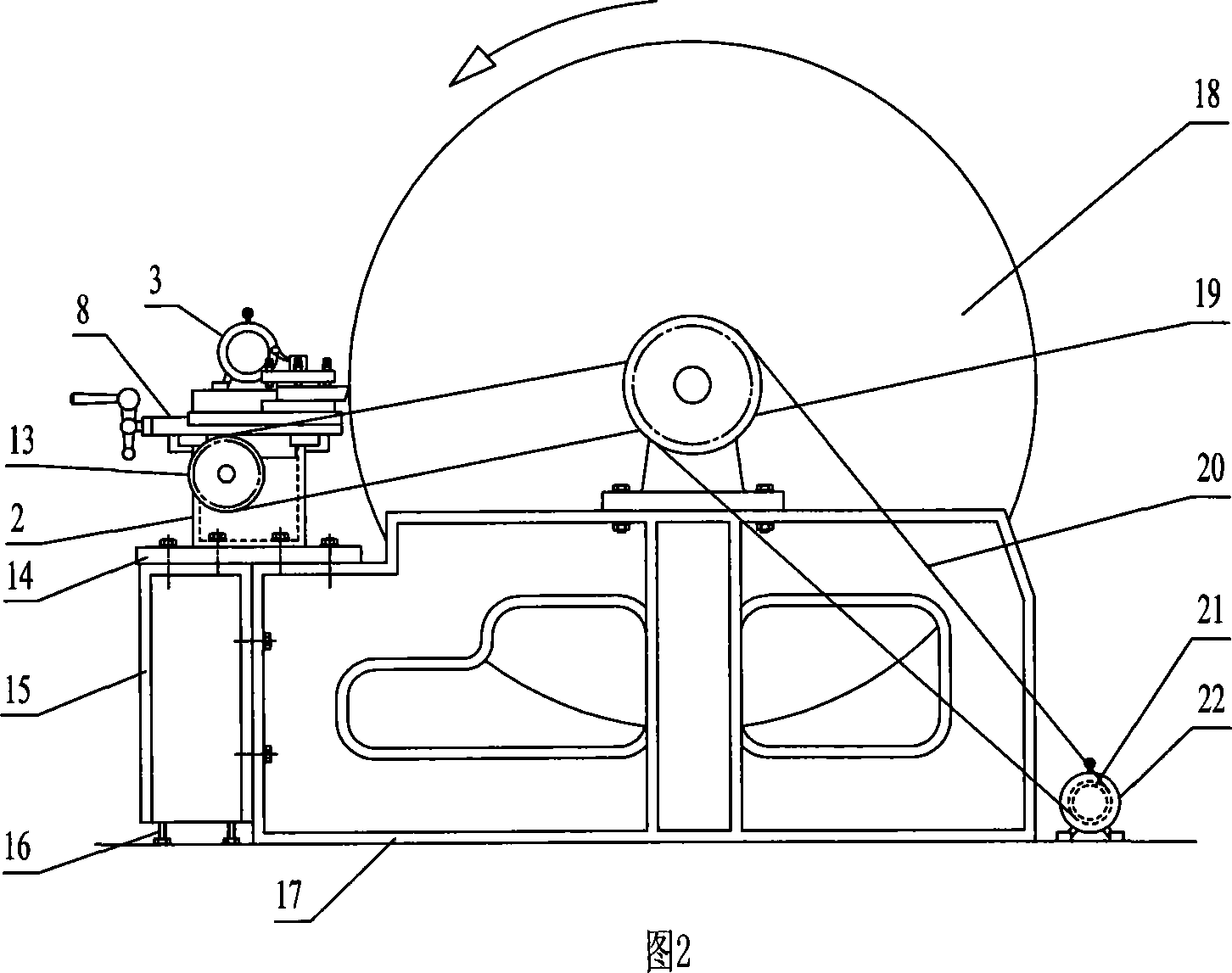

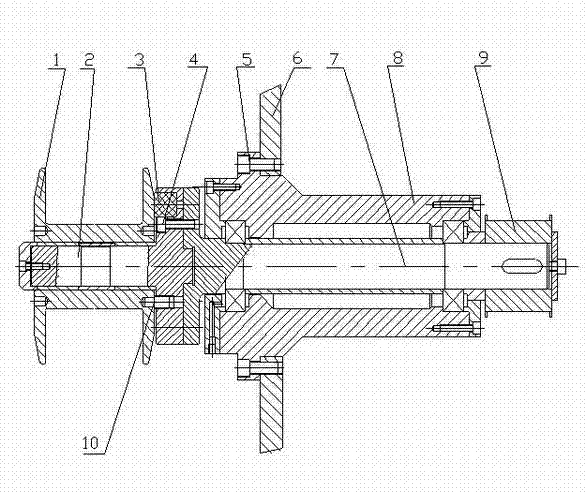

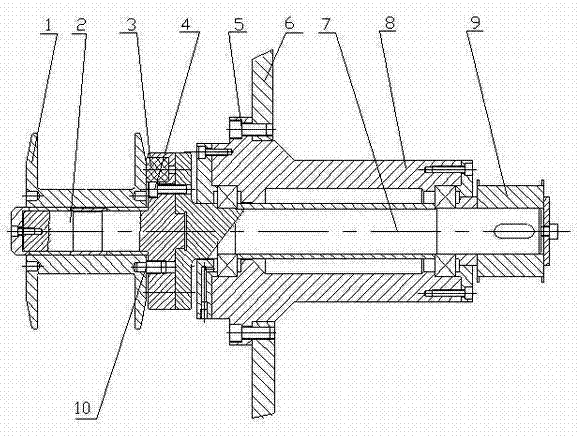

Detachable type wire withdrawing spool spindle of water tank drawing mill

InactiveCN102641914AEasy to removeReduce the workload of disassembly and assemblyEngineeringMechanical engineering

The invention relates to the technical field of metal wire processing equipment, and particularly relates to a detachable type wire withdrawing spool spindle of a water tank drawing mill. The detachable type wire withdrawing spool spindle of the water tank drawing mill comprises a front shaft and a rear shaft, wherein a boss of the front shaft is arranged in a groove of the rear shaft, and is fastened by coupling screws, the shaft end of the front shaft, which is contacted with the rear shaft, is provided with a boss and an unthreaded hole, and the shaft end of the rear shaft, which is contacted with the front shaft, is provided with the groove and a screw hole. The detachable type wire withdrawing spool spindle provided by the invention has the beneficial effects that the wire withdrawing spool spindle is divided into the front shaft and the rear shaft, the rear shaft is fixed and unchangeable, and the front shaft can be conveniently disassembled to be exchanged according to different standards of spools, thus the disassembling workload can be reduced, and the production cost is lowered.

Owner:JIANGSU GAOHE INTELLIGENT EQUIP CO LTD

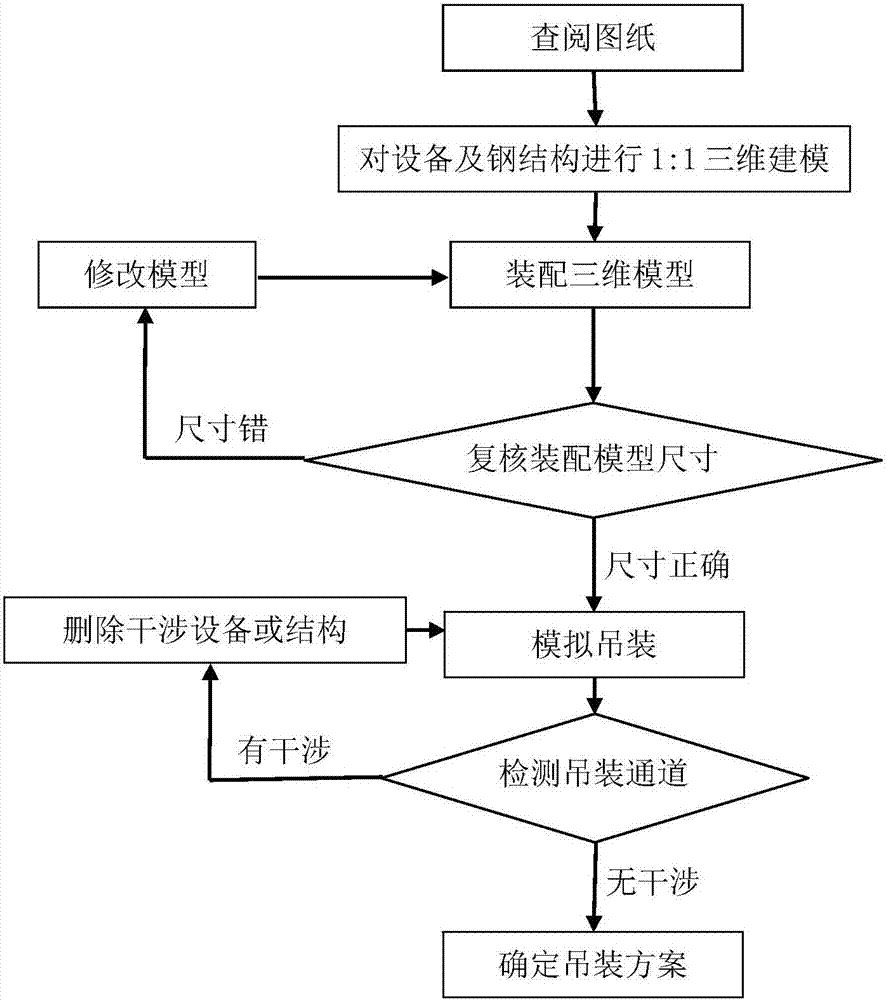

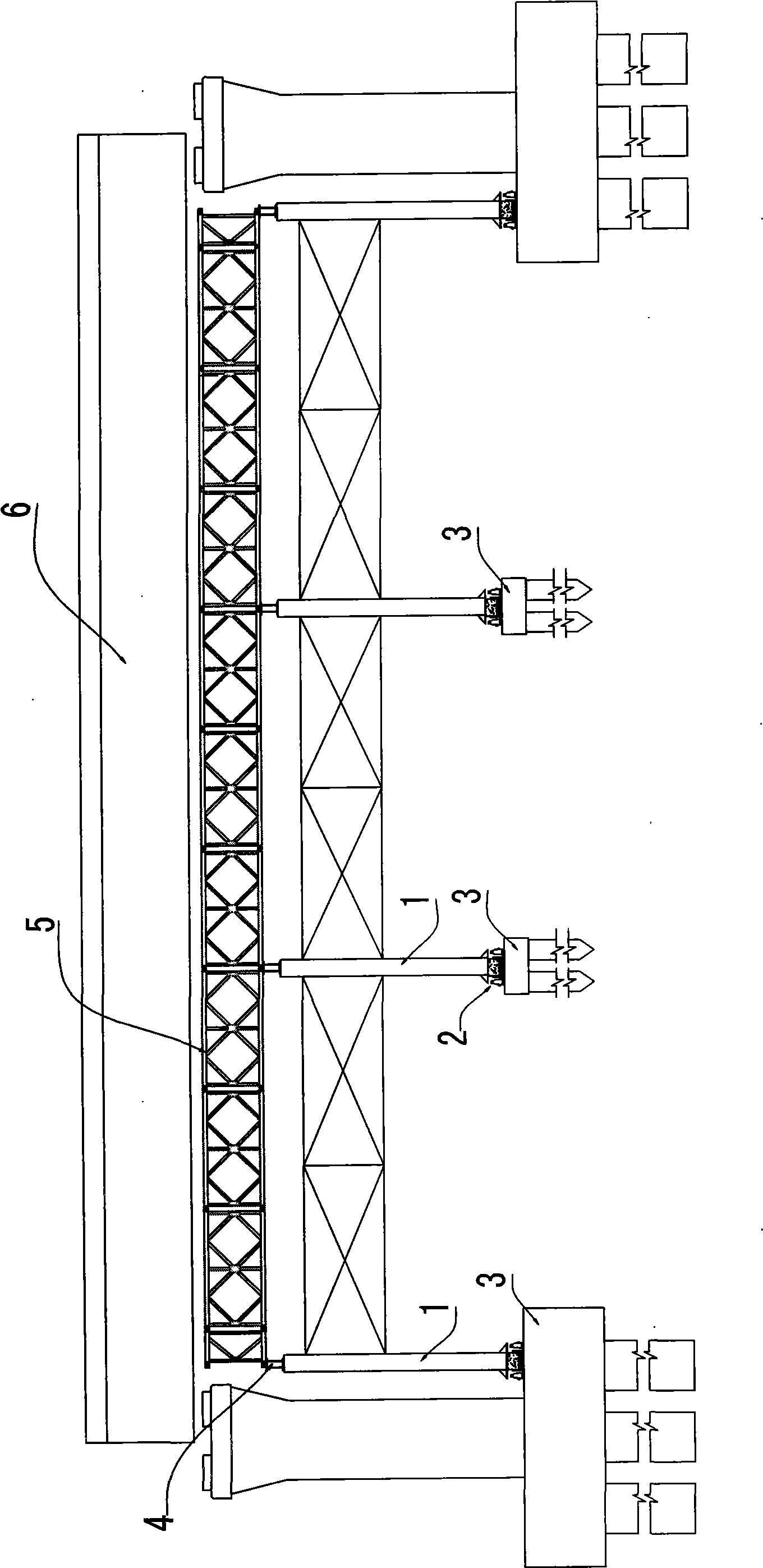

Upper smoke hood hoisting method based on BIM technology

InactiveCN107513599AReduce the workload of disassembly and assemblyGuarantee unimpededManufacturing convertersDimensional modelingWorkload

The invention provides an upper smoke hood hoisting method based on a BIM technology. The method comprises the following steps that (1) all span steel structures and devices are subjected to 1:1 three-dimensional modeling through BIM software according to drawing sizes of all the span steel structures and the devices; (2) three-dimensional models are assembled, specifically, the three-dimensional models of all the span steel structures and the devices are effectively assembled according to the field and process assembling drawing requirements, and the effect that the assembled models of the span steel structures and the devices are consistent with field assembled bodies is ensured; (3) the sizes of the assembled models are rechecked; (4) hoisting is simulated; (5) a hoisting channel is detected; and (6) a hoisting scheme is determined, specifically, after the situation that the hoisting channel is unblocked is ensured, the whole-process hoisting scheme is generated through a computer and saved to a video format file. Through the method, unnecessary device and steel structure dismounting workload can be reduced, the device down time is reduced, the safety coefficient of the hoisting process and field construction efficiency are improved, and influences of upper smoke hood hoisting to other converter production time are reduced.

Owner:MCC BAOSTEEL TECH SERVICE

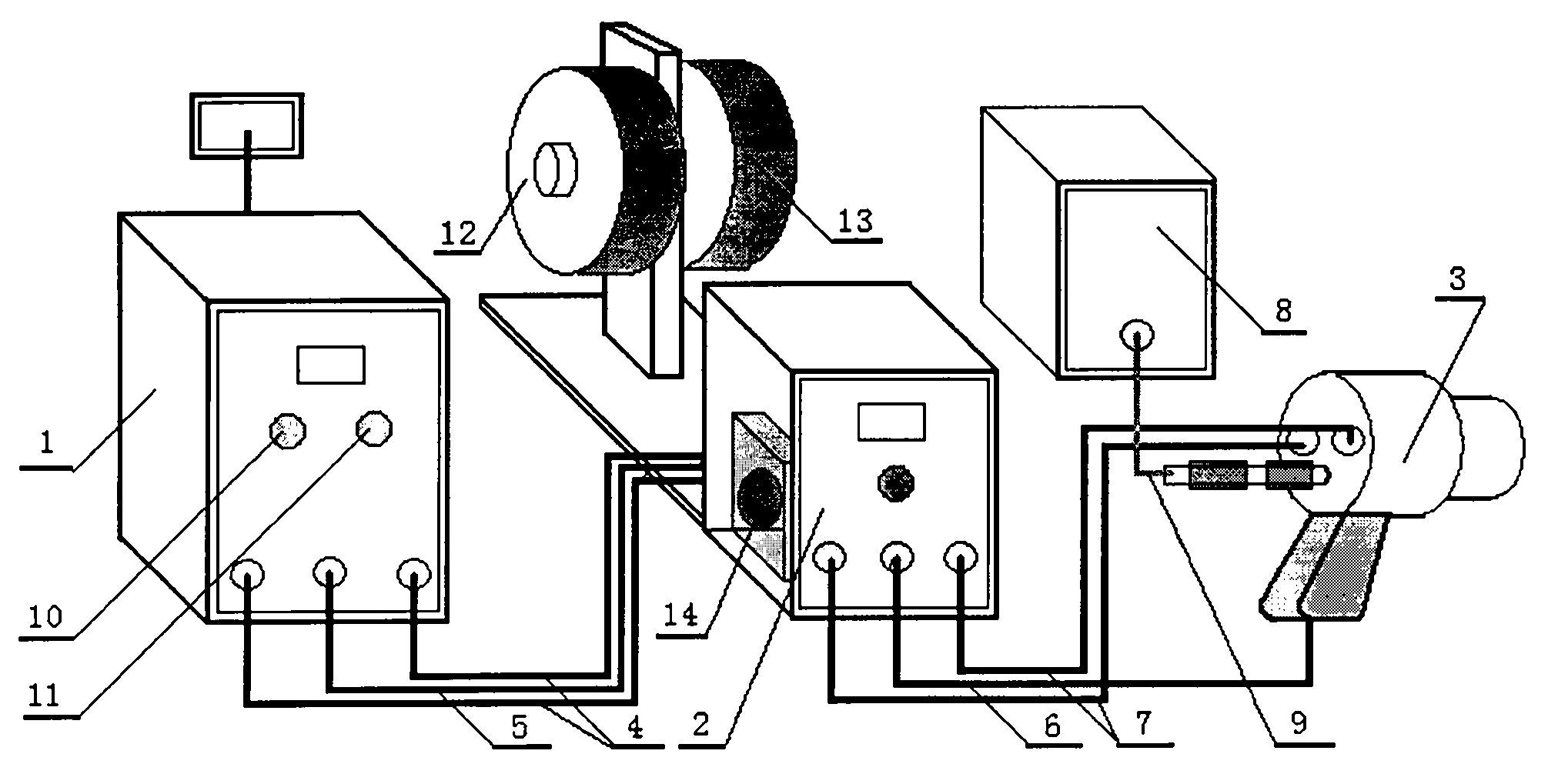

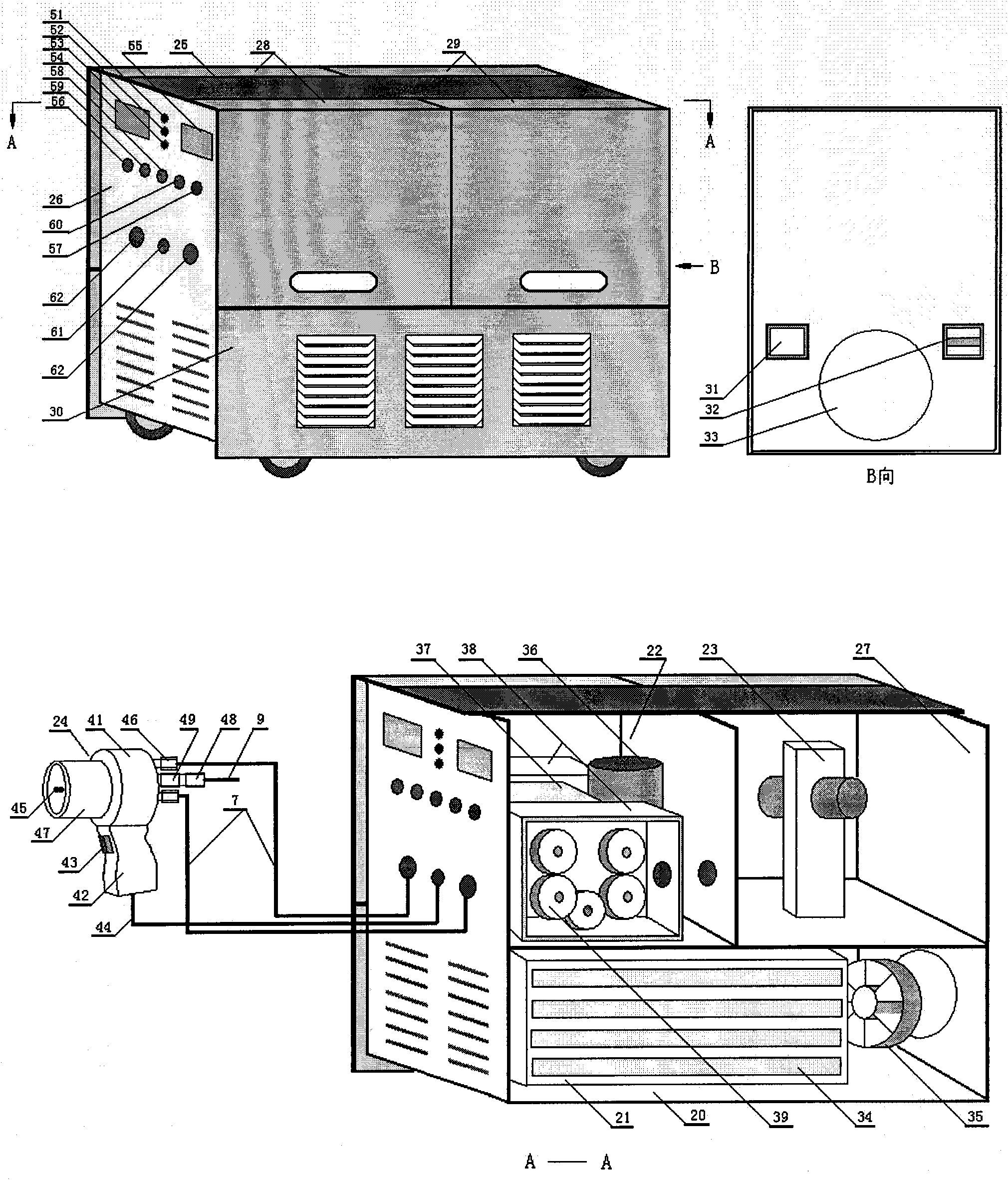

Integral push-wire-type electric arc spraying equipment

InactiveCN101864550AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingWhole body

The invention relates to an integral push-wire-type electric arc spraying equipment used for thermal spraying, which can be seen in an attached figure of the abstract. The equipment adopt an inverter-type spraying power supply, has the technical scheme of combining and closing the spraying power supply, a wire feed device and a wire reel bracket (including a wire reel) into a whole body, and is matched with a home-made electric arc spray gun. The integral push-wire-type electric arc spraying equipment solve the problems of heavy weight, large volume, dispersed devices, more externally connected cables and the like of the push-wire-type electric arc spraying equipment. The equipment have the function of stepless regulation for output voltage within the range of 10-50V, and can freely adjust the parameters without stopping a machine in the spraying process; the equipment is provided with a manual / automatic spraying and wire detection / spraying switch, thus being convenient for the selection of operation way and preventing electric arc from hurting people and damaging equipment when in the process of installing, adjusting and checking spraying wires; and due to the full-closed structure, the blockage phenomenon of a wire guide pipe is avoided. The equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like.

Owner:慈溪光华金属复合材料有限公司

Beam-column type support and method for constructing multi-section adjacent bridges using same

InactiveCN101532336ADisassembly and assembly work is halvedReduce the workload of disassembly and assemblyShoresBeam columnBuilding construction

Owner:中铁二十二局集团第一工程有限公司

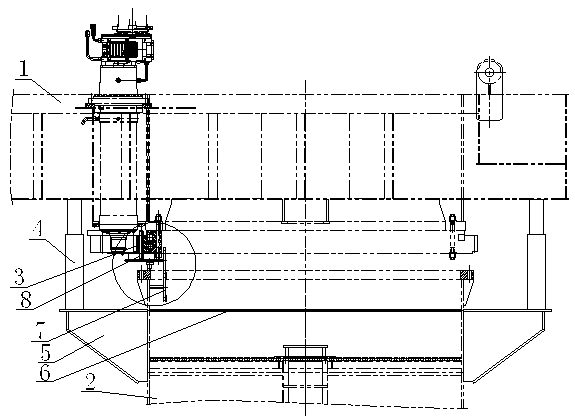

Maintenance method and device for slewing bearing part of gantry crane

ActiveCN104786002AReduce the workload of disassembly and assemblyShorten maintenance cycleFeeding apparatusMetal working apparatusGantry craneSlewing bearing

The invention provides a maintenance method and device for a slewing bearing part of a gantry crane. The maintenance device comprises jacking supports (5) fixed to a cylinder (2) and jacks (4) arranged between the jacking supports (5) and a rotary table (1). In the maintenance process, a connecting bolt between a slewing bearing (3) and the cylinder (2) is detached. The jacks (4) are operated to jack the rotary table (1) upwards, and then the portion above the slewing bearing (3) of the gantry crane is jacked upwards. When the slewing bearing (3) is separated from the slewing bearing face of the cylinder (2) at a certain gap, the connecting bolt between the slewing bearing (3) and the rotary table (1) is detached. The damaged slewing bearing (3) is pulled out from the jacked space gap. A complete slewing bearing is fed to an original installation position. The slewing bearing is connected to the lower portion of the rotary table (1) through a bolt. The jacks (4) are adjusted, the slewing bearing (3) falls to make contact with the slewing bearing face of the cylinder (2), connecting fastening is conducted through a bolt, and maintenance work is finished.

Owner:TIDFORE HEAVY IND

Box type substation

ActiveCN104332855BFirmly connectedEasy assembly and maintenanceBoards/switchyards circuit arrangementsFuse disposition/arrangementCapacitanceTransformer

The invention relates to a low-voltage cabinet of a box-type transformer station, and the box-type transformer station with same, wherein the low-voltage cabinet of the box-type transformer station comprises a wire inlet unit, a feeder line unit, a capacitance compensating unit and a secondary instrument unit. The wire inlet unit, the feeder line unit, the capacitance compensating unit and the secondary instrument unit are arranged in one cabinet body and furthermore are separated from one another through corresponding baffle plates. The wire inlet unit and the secondary instrument unit are parallelly arranged in the transverse direction of the cabinet body. The feeder line unit is arranged below the wire inlet unit and the secondary instrument unit. The capacitance compensating unit is arranged at one side of the wire inlet unit in the transverse direction, which deviates the secondary instrument unit, and furthermore the lower part of the capacitance compensating unit is arranged parallelly with the feeder line unit in the transverse direction. The wire inlet unit of the low-voltage cabinet is arranged at the middle part of the cabinet body in the transverse direction, thereby realizing convenient connection with other units. Furthermore the capacitance compensating unit and the feeder line unit can be distributed to relatively large spaces, thereby realizing reasonable layout and high space utilization rate. Furthermore, the units are arranged in a same cabinet body, thereby realizing benefit for assembling and maintenance, reducing detaching workload and improving operation efficiency.

Owner:STATE GRID CORP OF CHINA +2

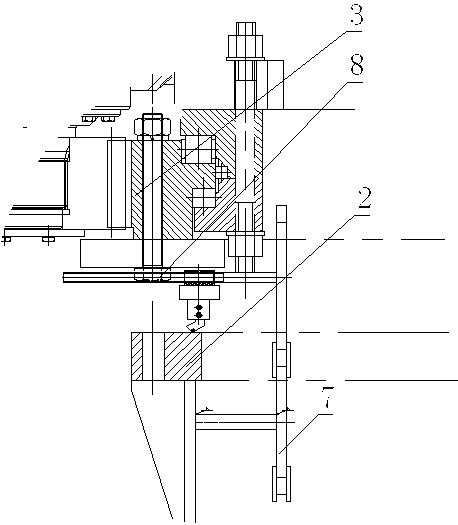

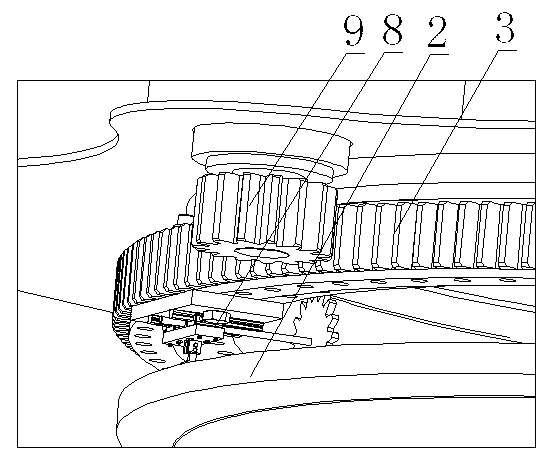

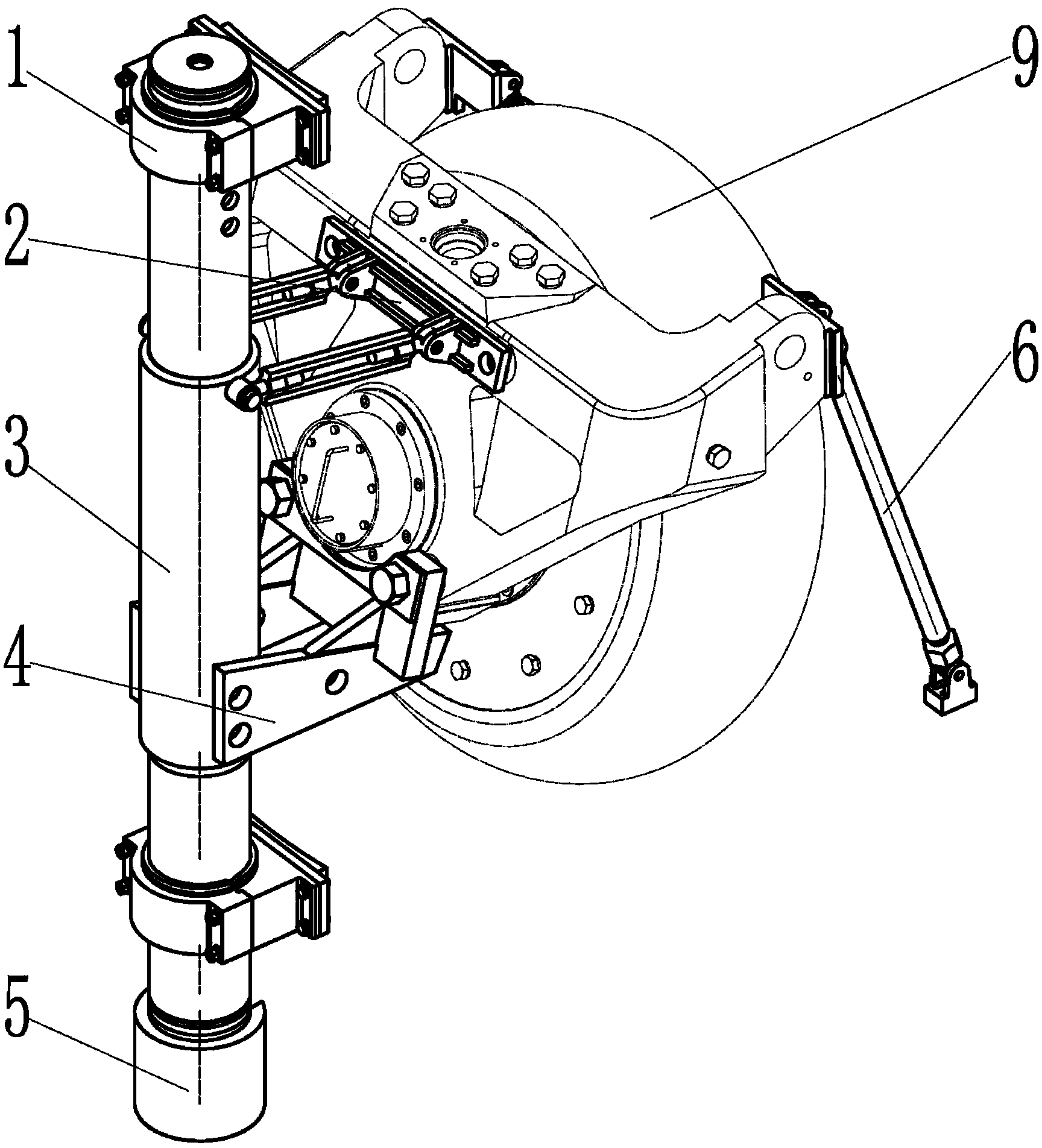

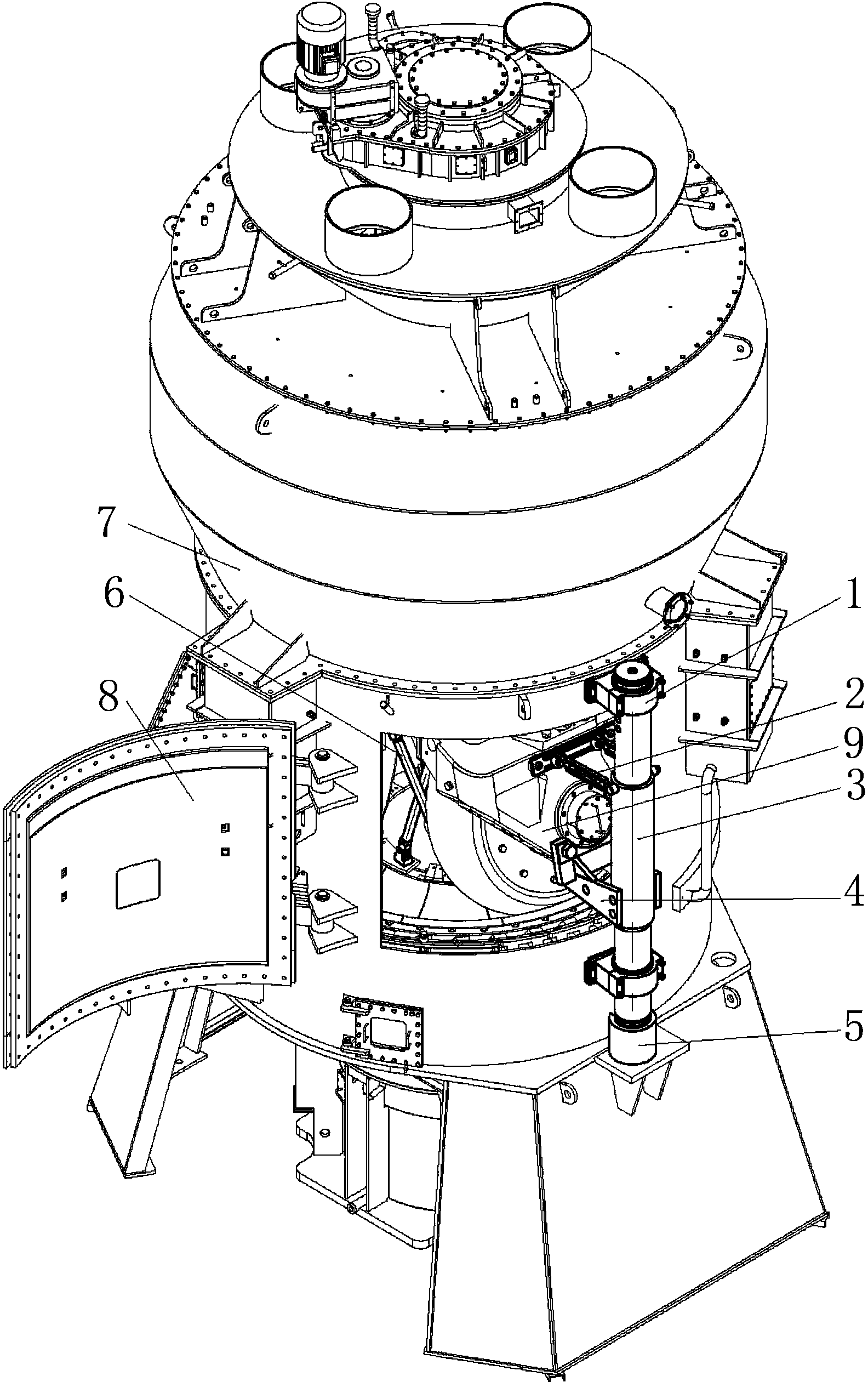

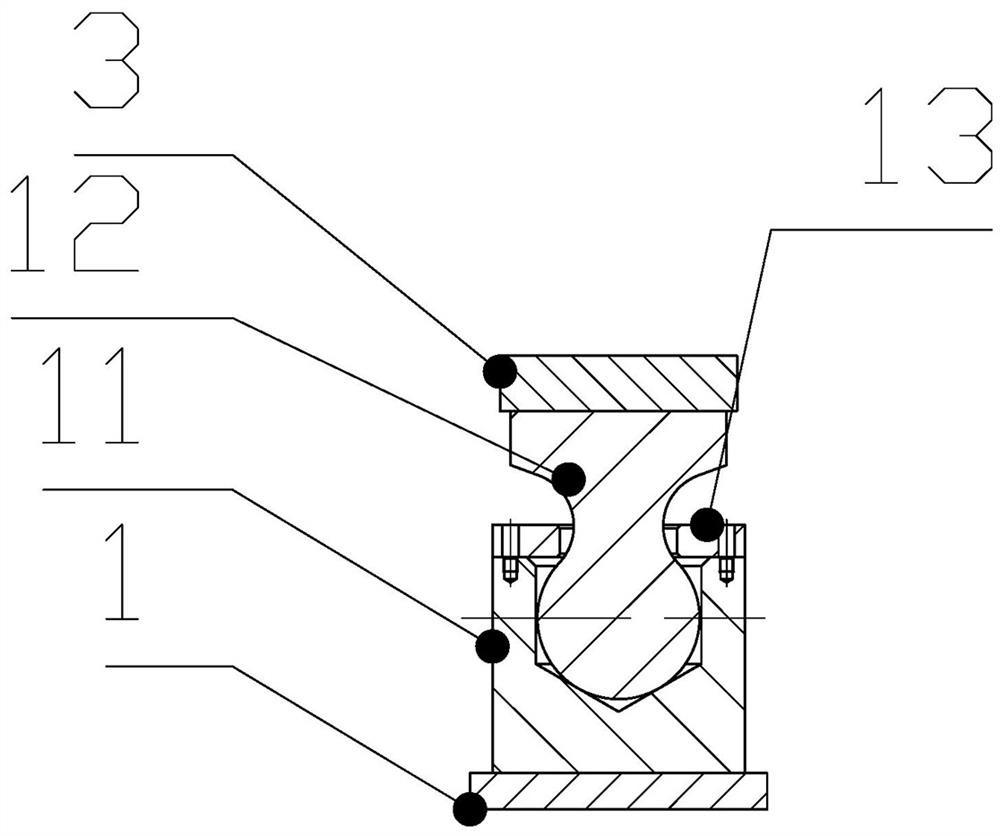

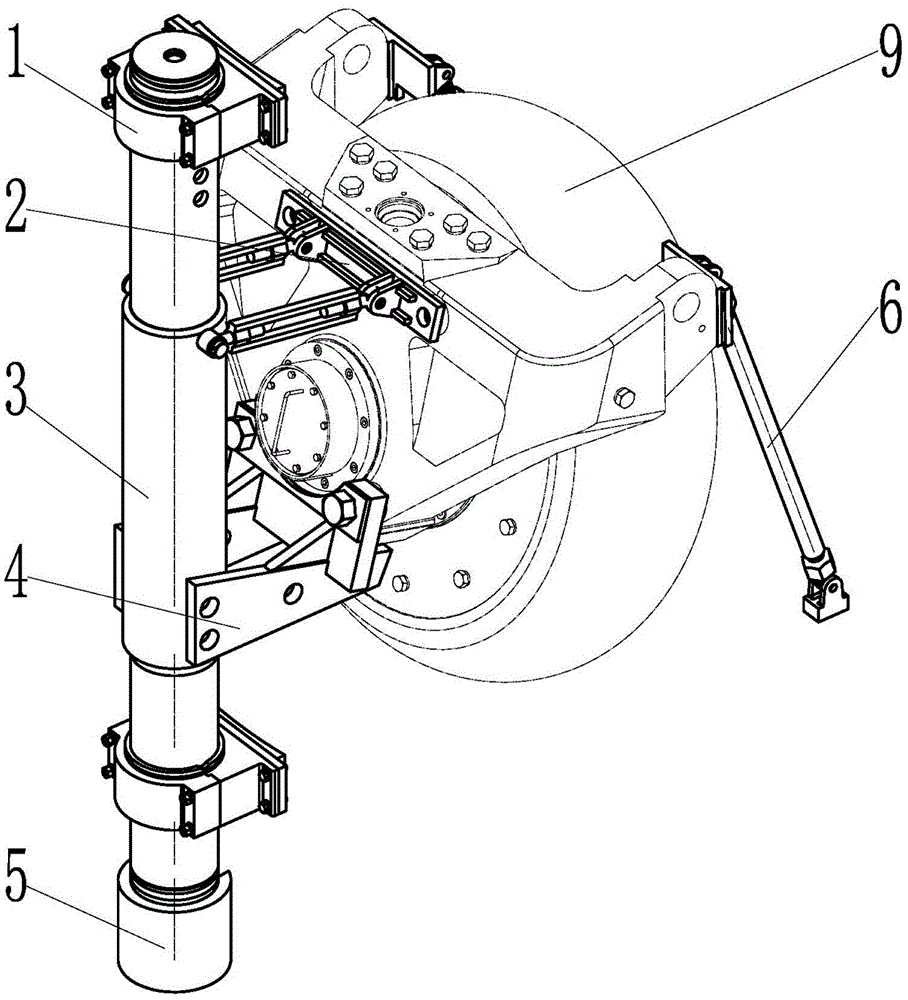

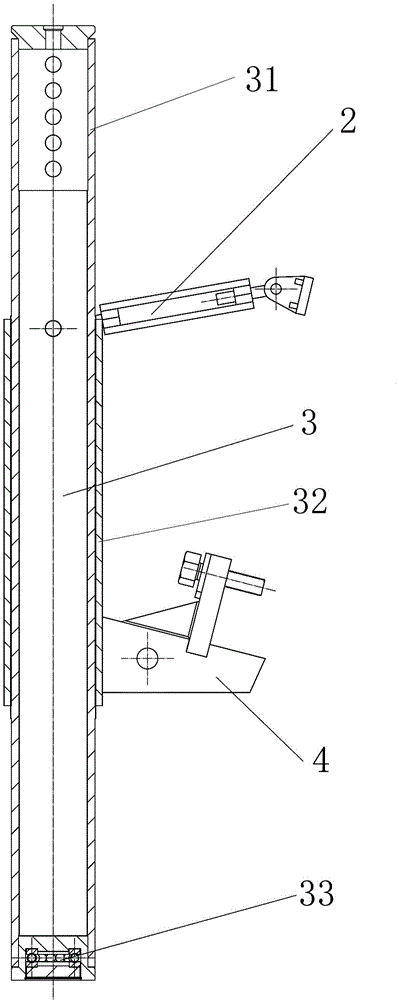

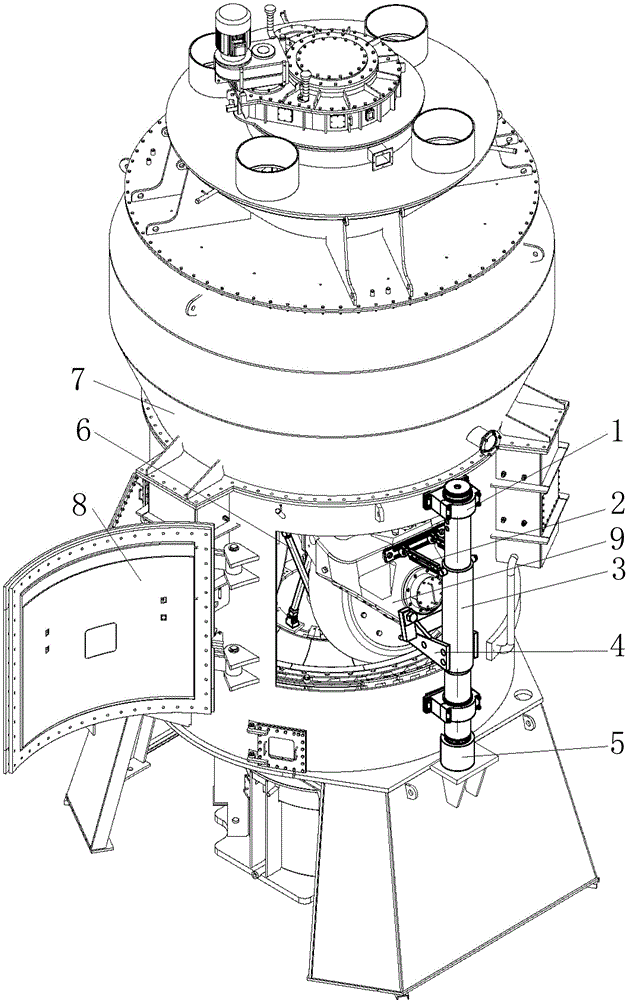

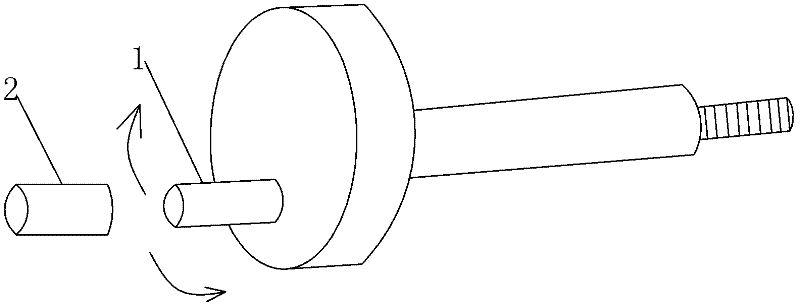

Rotate tool for disassembly and assembly of grinding roller device of medium-speed roller-type coal pulverizer

ActiveCN103816982AFlexible operationEasy and flexible operationGrain treatmentsPulp and paper industryCoal

The invention relates to a rotate tool for disassembly and assembly of a grinding roller device of a medium-speed roller-type coal pulverizer, a maintenance door (8) is arranged on a housing (11) of the coal pulverizer (10), a rotatable main shaft (3) is arranged on one side of the maintenance door (8), the rotatable main shaft (3) is fixed on the housing (11) of the coal pulverizer (10) by two bearings seats (1), the rotatable main shaft (3) is fixedly connected with the grinding roller device (9) by a bracket (4) and a tensioning device (2), and when the an external force is applied to the grinding roller device (9), the grinding roller device (9) may be turned over to the external of the coal pulverizer (10) in the rotation process of the main shaft (3). The rotate tool has the advantages of flexible operation, less occupied space, reduction of the labor intensity of workers, shortening of the maintenance cycle and reduction of the maintenance cost.

Owner:BEIJING POWER EQUIP GRP

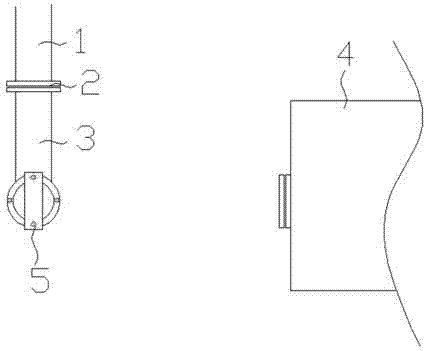

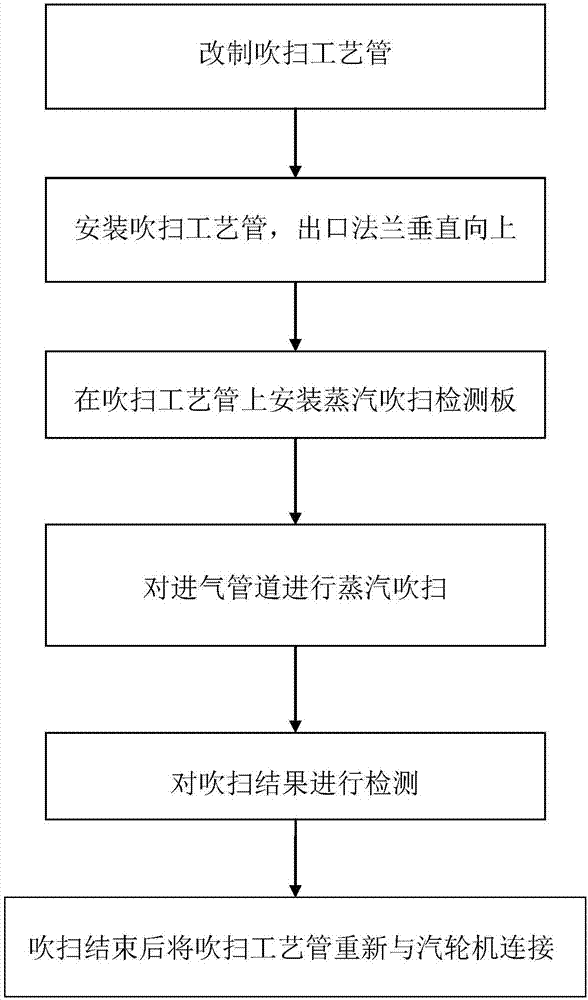

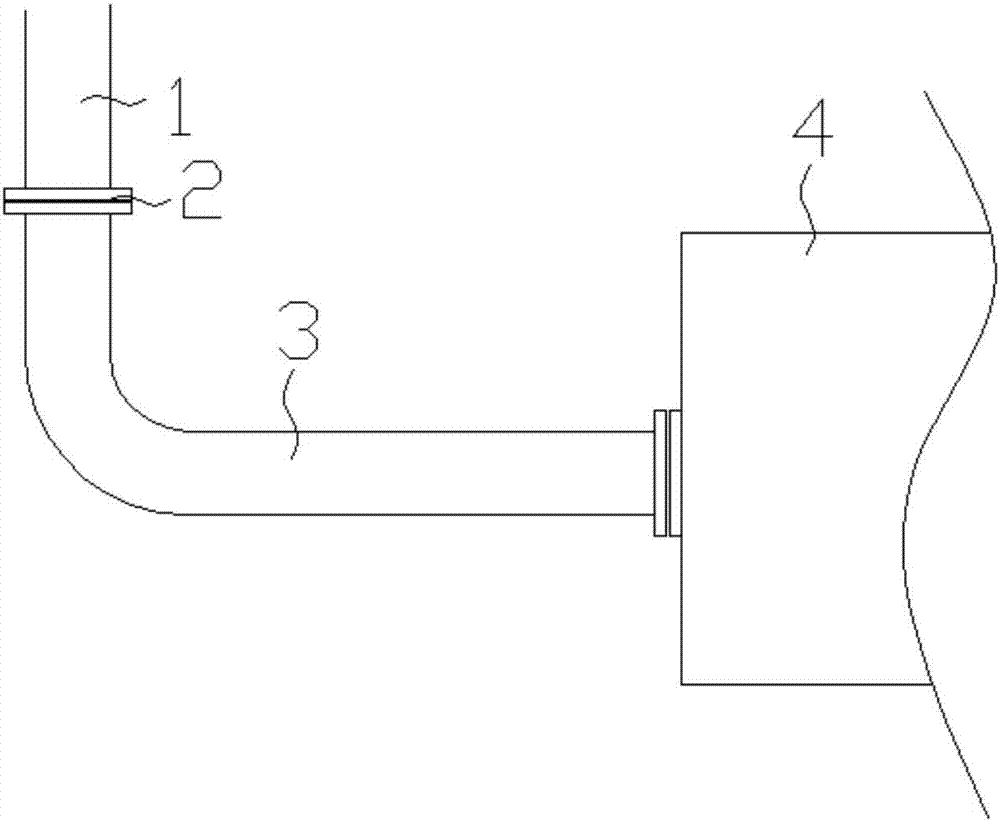

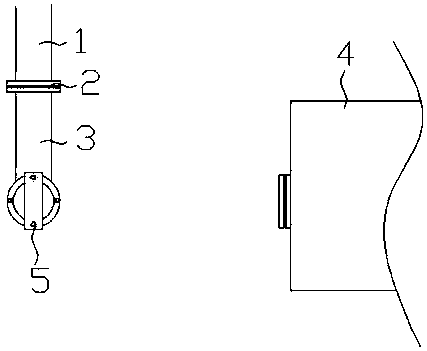

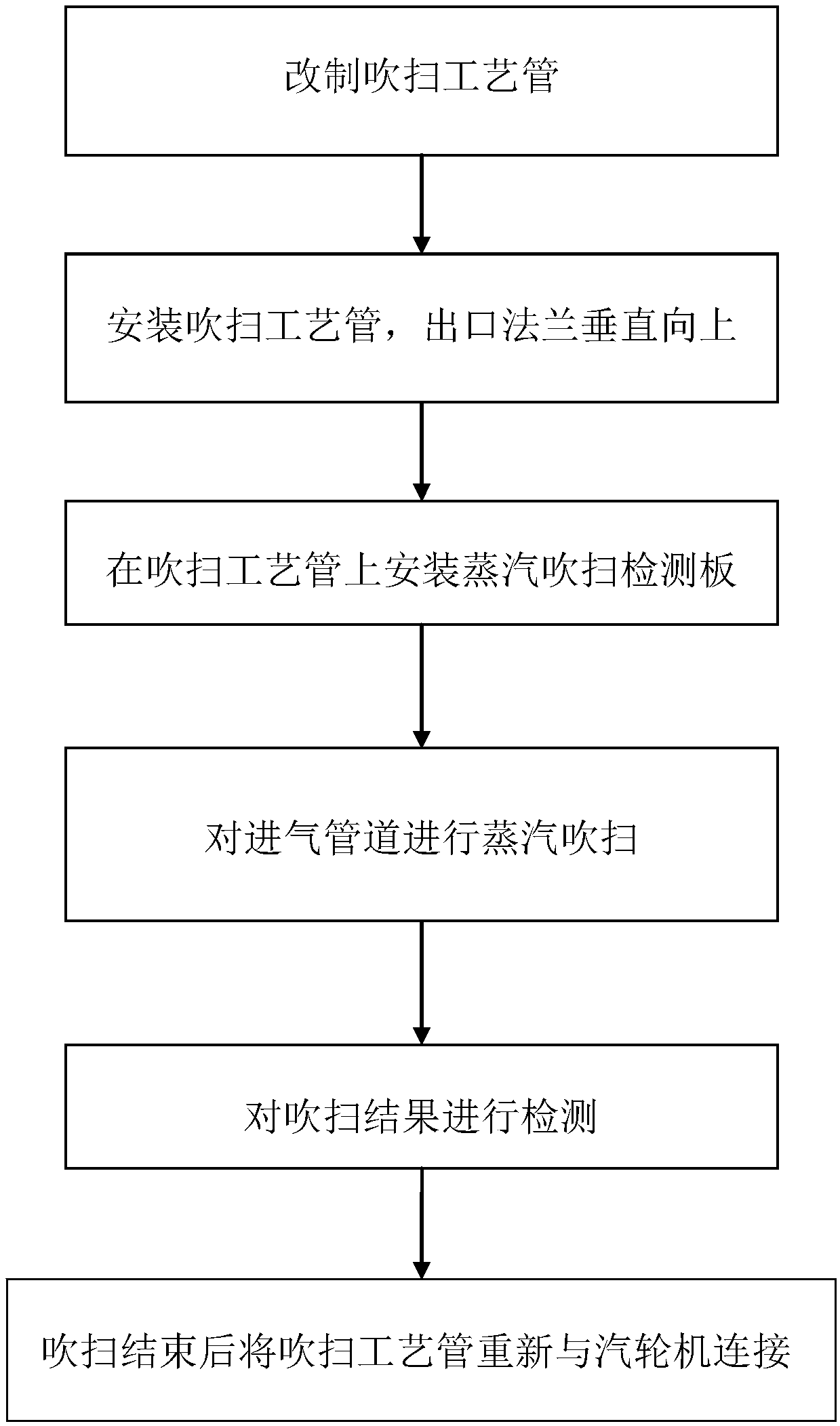

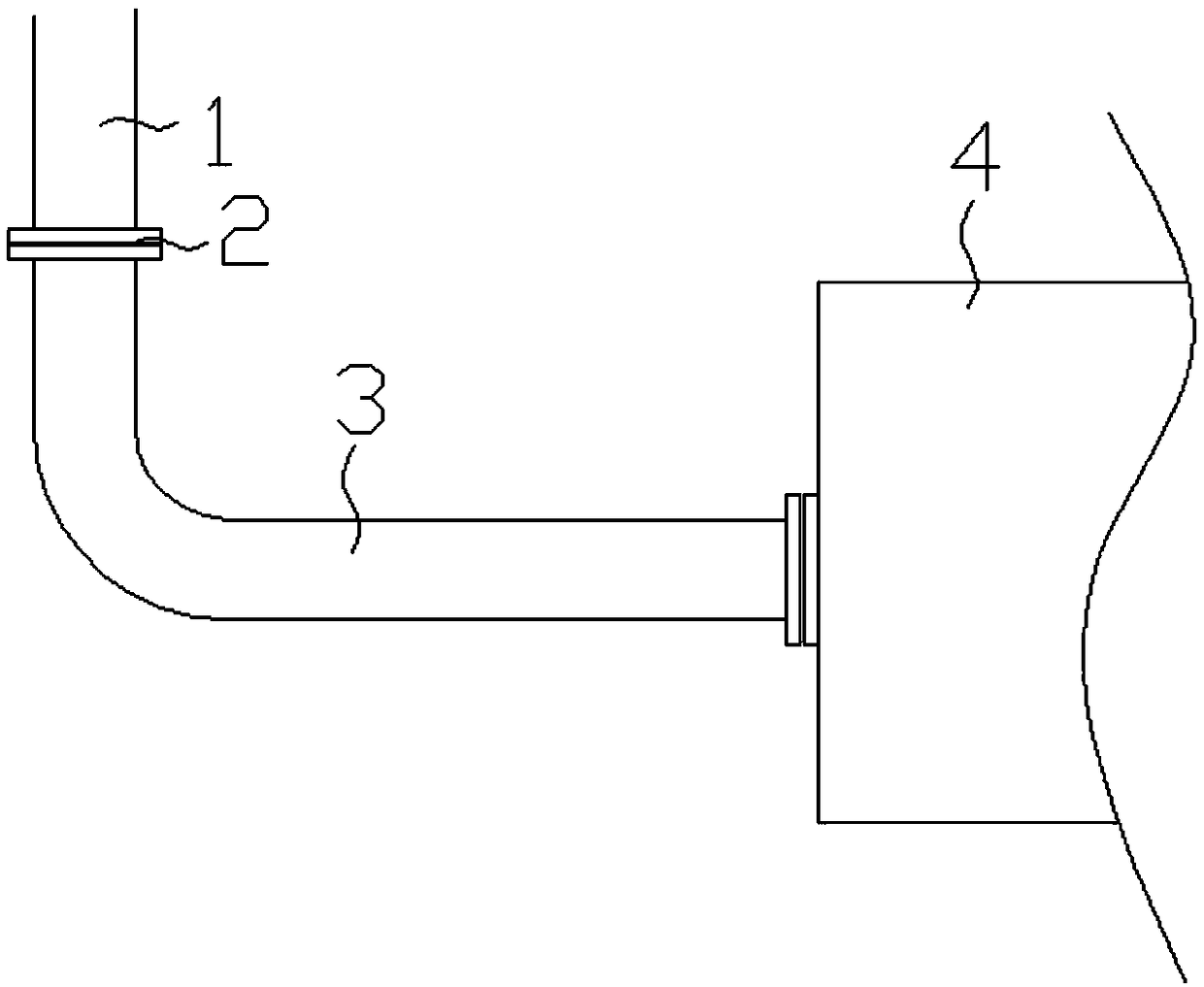

Rapid steam blowing method and device for gas inlet pipeline of turbine

ActiveCN107327319AReduce the workload of disassembly and assemblyLow production costMachines/enginesSafety/regulatory devicesButt jointEngineering

The invention provides a rapid steam blowing method for a gas inlet pipeline of a turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine comprises the following steps that (1) a last section of gas inlet pipeline close to an entrance part of the turbine is cut and taken to be remanufactured into a blowing process pipe, the blowing process pipe is a right-angle bend pipe which is bent by 90 degrees, flanges are fixedly arranged at the two ends of the blowing process pipe, the butt-joint flange is fixedly arranged at one end of the blowing process pipe and is connected with a flange at the tail end of the gas inlet pipeline of the turbine, and the exit flange is fixedly arranged at the other end of the blowing process pipe and is connected with the turbine; (2) the position of the blowing process pipe is upwardly rotated by 90 degrees, and the blowing process pipe is installed in a state with the exit flange vertically upward; (3) a target plate serves as a steam blowing detecting plate and is installed on the exit flange of the blowing process pipe; (4) steam is injected into the gas inlet pipeline for blowing; (5) the steam blowing detecting plate is disassembled after each time of blowing and a blowing result is detected until a detecting result meets the requirement; and (6) after blowing for all is finished, the connecting direction of the blowing process pipe is changed and the blowing process pipe is re-connected with the turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine has the advantages that steam blowing is rapid and convenient, working efficiency is high, and cost is low.

Owner:HUDONG HEAVY MACHINERY

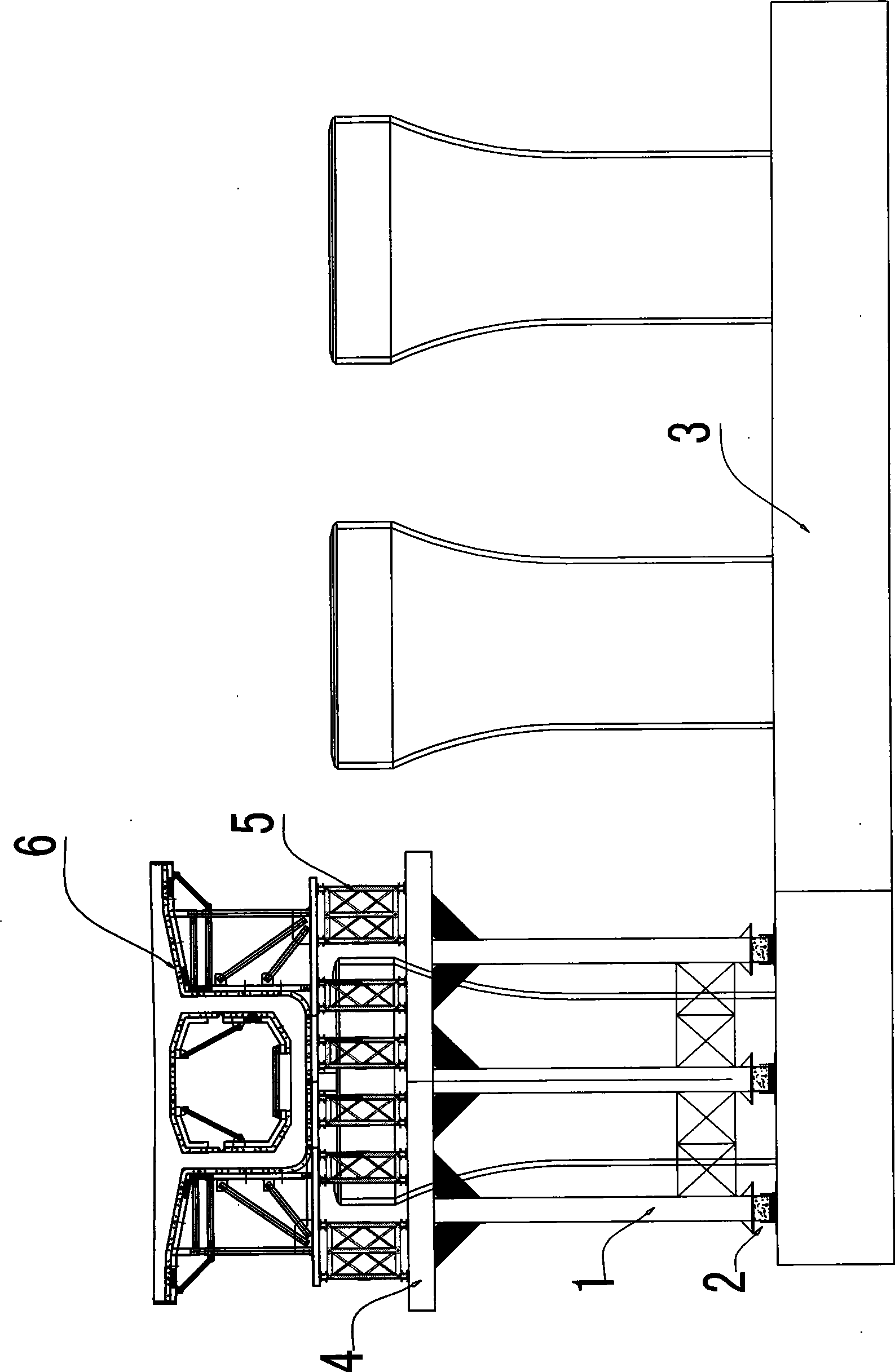

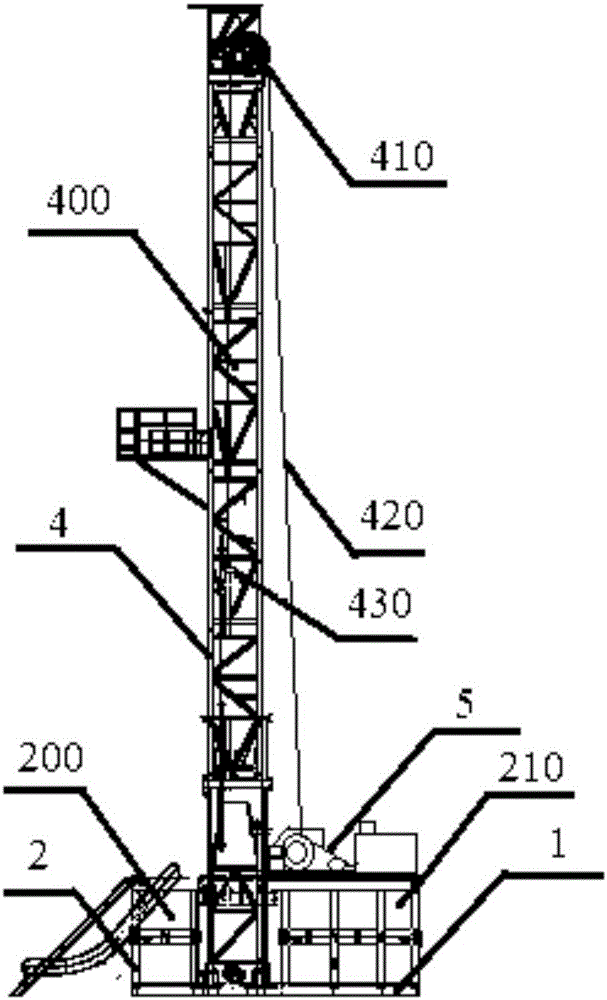

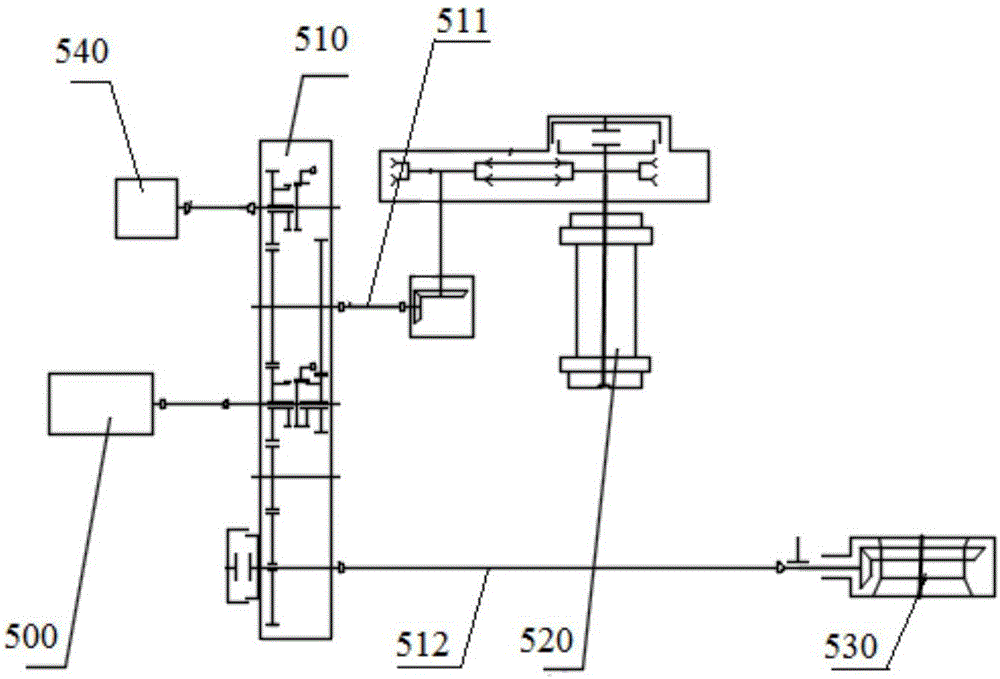

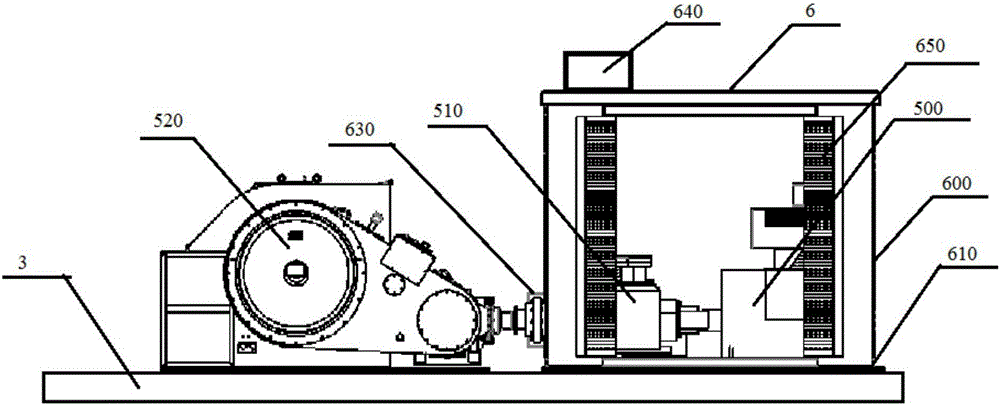

Drilling machine structure for geothermal well drilling

ActiveCN105971520AReduce the workload of disassembly and assemblyImprove securityDerricks/mastsBorehole/well accessoriesTransfer caseDrivetrain

The invention discloses a drilling machine structure for geothermal well drilling. The drilling machine structure comprises a base, a container, a derrick, a power transmission system and a noise reduction device, wherein the container comprises a front container body and a rear container body; the derrick is an upright sleeved self-elevating derrick; the power transmission system comprises a main motor, a transfer case, a first power output shaft, a second power output shaft, a roller and a rotary plate; the noise reduction device comprises an acoustic shield and a damping base, so that an accommodating space used for accommodating the main motor and the transfer case is formed; the main motor and the transfer case are sequentially mounted on the damping base in the direction close to the derrick; a sledding base is mounted at the top of the rear container body; and the noise reduction device and the roller are both mounted on the sledding base. The modularized design is adopted, and the drilling machine structure has the beneficial effects of being small in occupied area and noise pollution, high in transfer efficiency, low in operation cost, and suitable for geothermal well drilling operation in residential communities.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

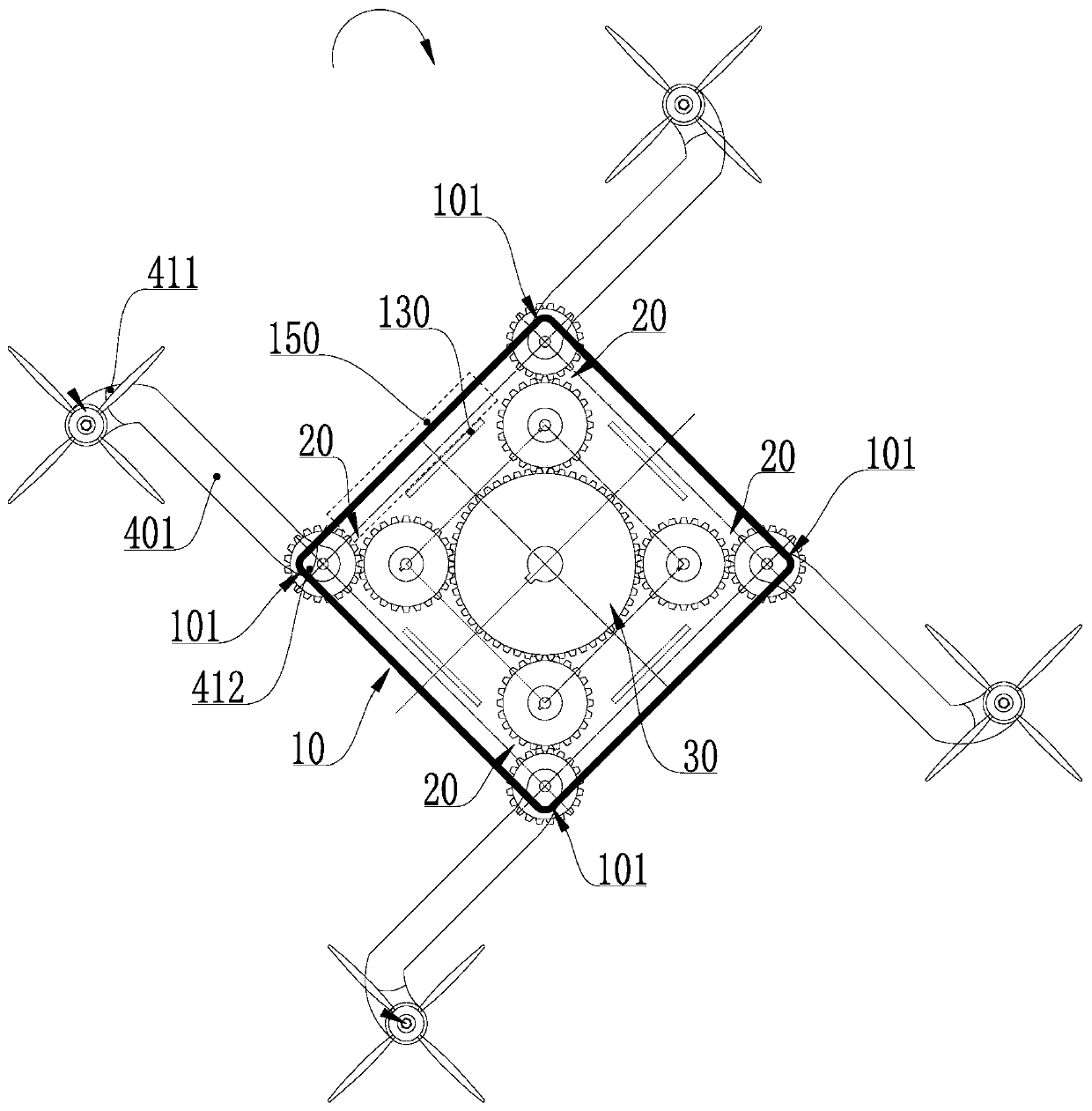

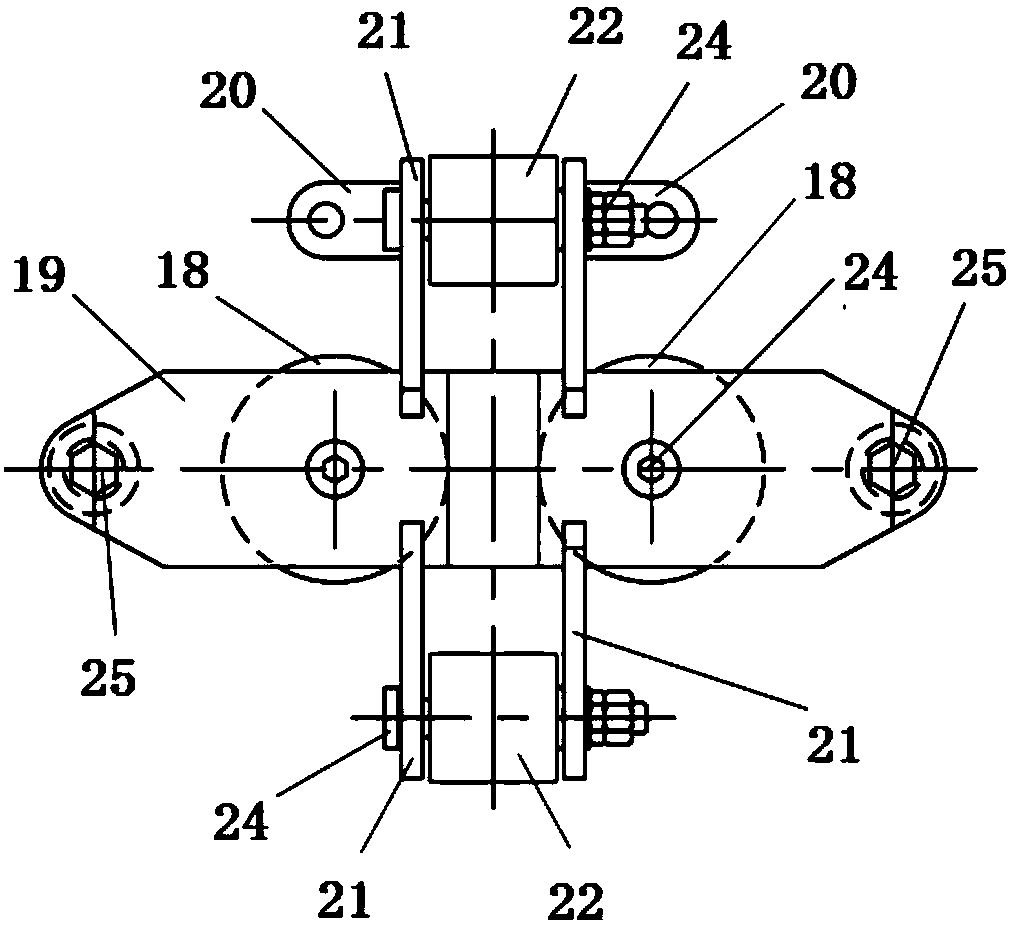

Engine arm synchronous rotation structure and industrial unmanned aerial vehicle with same

PendingCN109911171AReduce volumeImprove foldabilityFuselage framesAir-flow influencersLocking mechanismHelicopter rotor

The invention is an engine arm synchronous rotation structure and an industrial unmanned aerial vehicle with the engine arm synchronous rotation structure, relates to the technical field of industrialunmanned aerial vehicles, and solves the technical problem that the disassembly of the unmanned aerial vehicle wastes operation time. The engine arm synchronous rotation structure comprises a frame body structure, auxiliary transmission mechanisms, a main transmission mechanism, engine arm bodies, and a locking mechanism; the main transmission mechanism is arranged in the middle of the frame bodystructure and is used for simultaneously controlling all the auxiliary transmission mechanisms to rotate in a driving manner; one ends of the engine arm bodies are used for connecting rotor wings, and the other ends are fixedly connected with a group of auxiliary transmission mechanisms; the frame body structure and the engine arm bodies have a folding state and an unfolding state, and the locking mechanism is used for keeping the frame body structure and the engine arm bodies in the folding state or the unfolding state. The engine arm synchronous rotation structure and the industrial unmanned aerial vehicle with the engine arm synchronous rotation structure have the advantages that the operation is fast, no complicated disassembly steps are needed, the operation time is saved, and convenient accommodation and storage are realized.

Owner:杜双昱

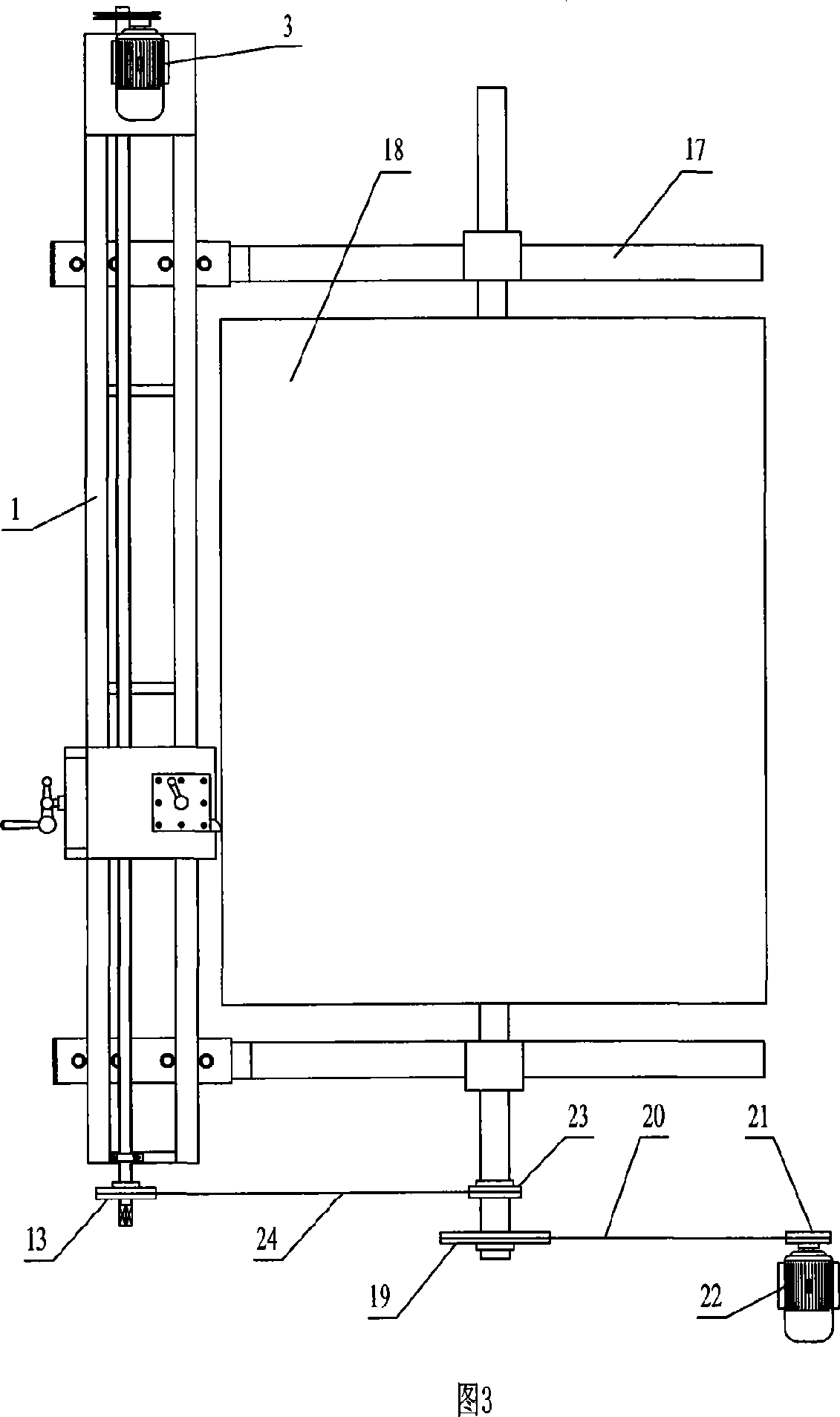

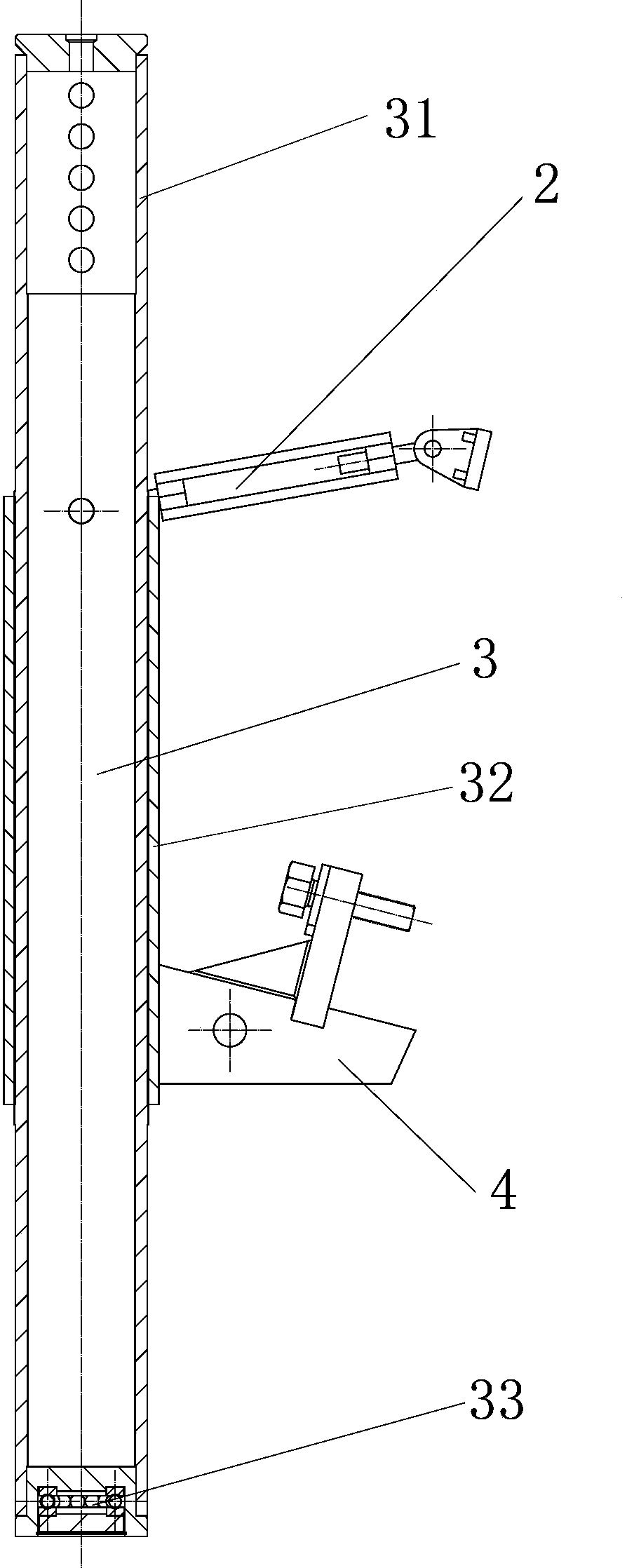

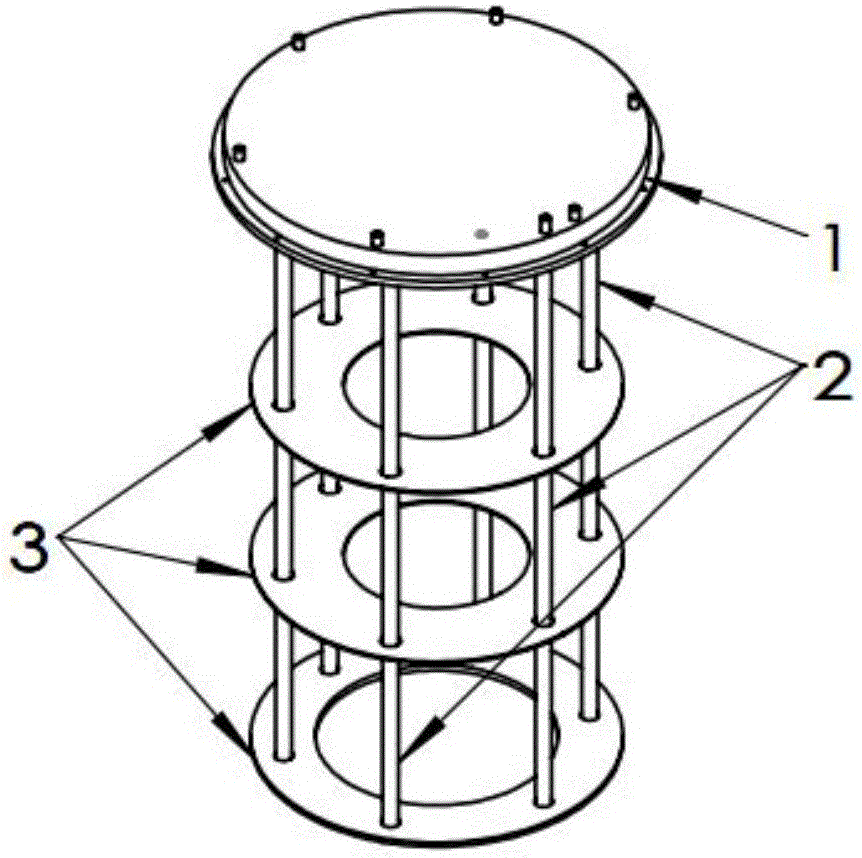

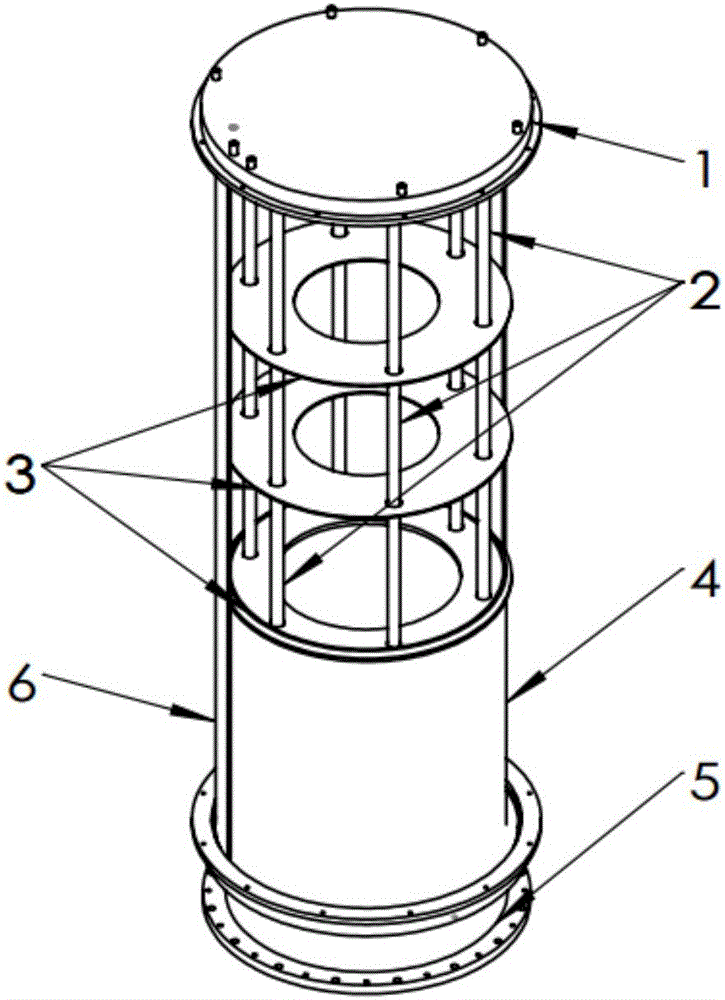

Assembling auxiliary device for large-scale vertical HVPE reaction chamber

ActiveCN106467980AHigh precisionGuaranteed independencePolycrystalline material growthFrom chemically reactive gasesEngineeringMotion range

The invention relates to an assembling auxiliary device for a large-scale vertical HVPE reaction chamber. The assembling auxiliary device is composed of a top flange, a hoisting load-bearing pillar and a precision adjusting bearing plate. Two ends of the hoisting load-bearing pillar are both equipped with a limit moving structure capable of adjusting upper and lower motion range. The load-bearing ratio of weight of the large-scale vertical HVPE reaction chamber on a load-bearing pipe to weight of the large-scale vertical HVPE reaction chamber on an outer sleeve can be adjusted after general assembling of the large-scale vertical HVPE reaction chamber. The precision adjusting bearing plate can bear and accurately adjust concentricity and levelness of parts. For assembling of the large-scale vertical HVPE reaction chamber, two big areas A and B are divided for separate assembly by the assembling auxiliary device, and then overall assembling is carried out. Therefore, the problem of assembling inconvenience caused by too high height of the reaction chamber can be effectively solved, assembling precision and assembling efficiency are obviously enhanced, and the influence on precision of superfluous dismounting of the upper body and equipment stability is avoided during maintenance and dismounting.

Owner:SINO NITRIDE SEMICON

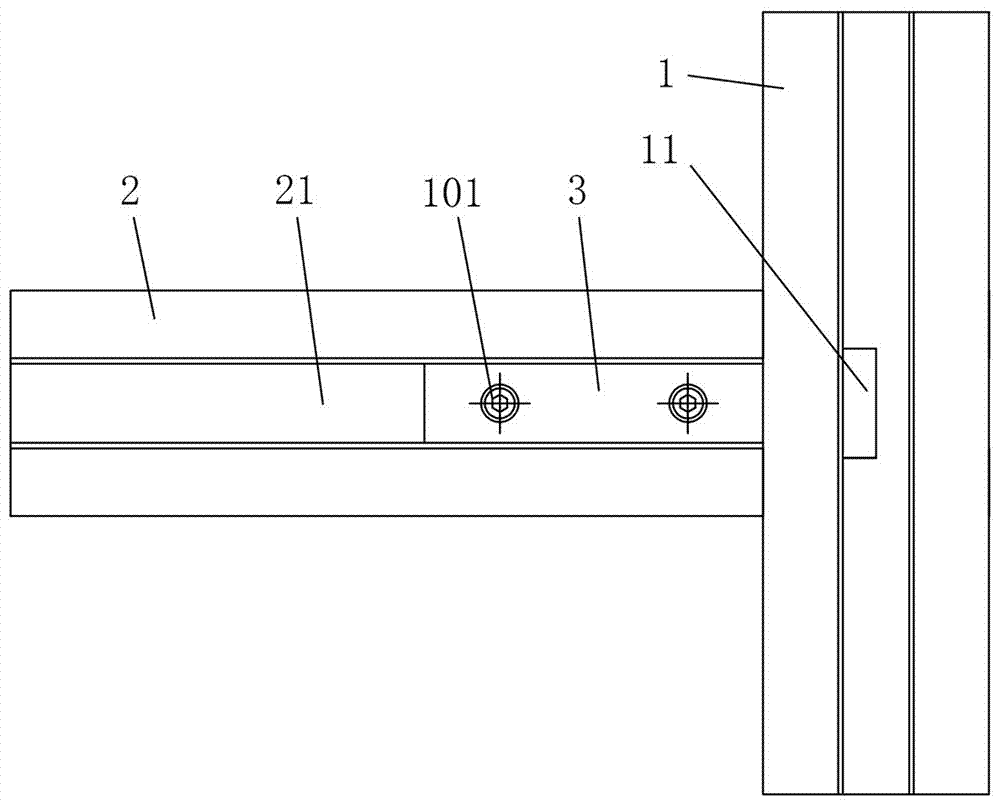

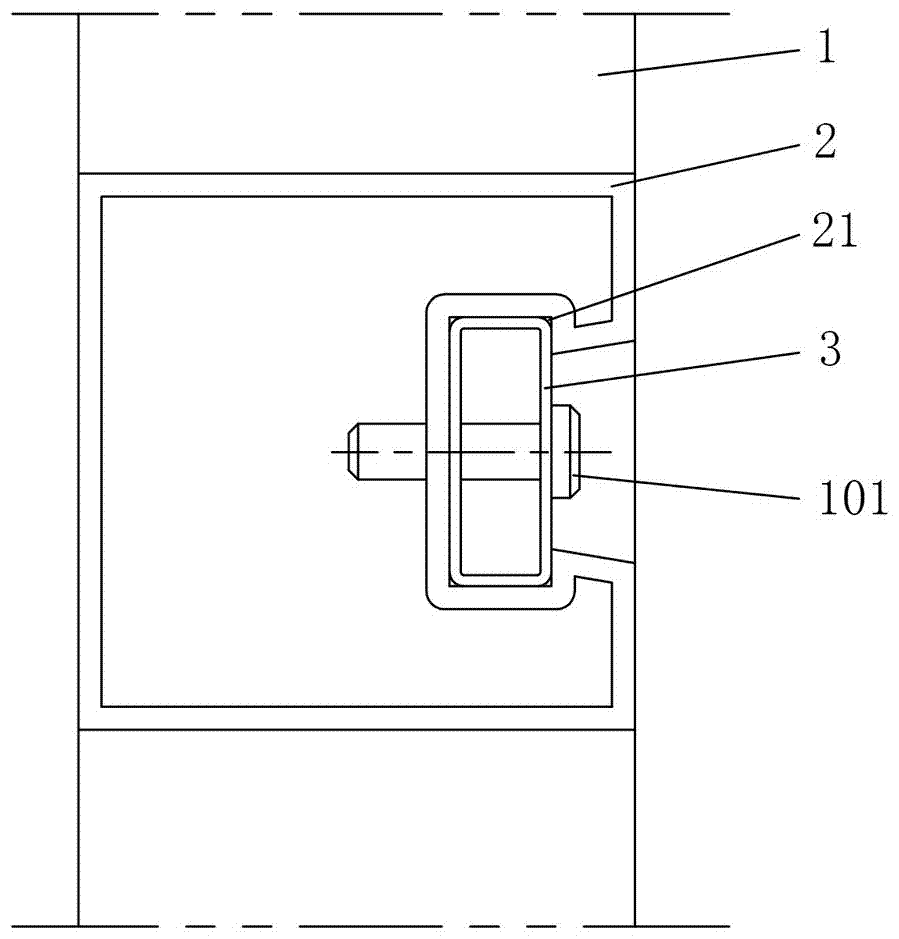

adjustable guide

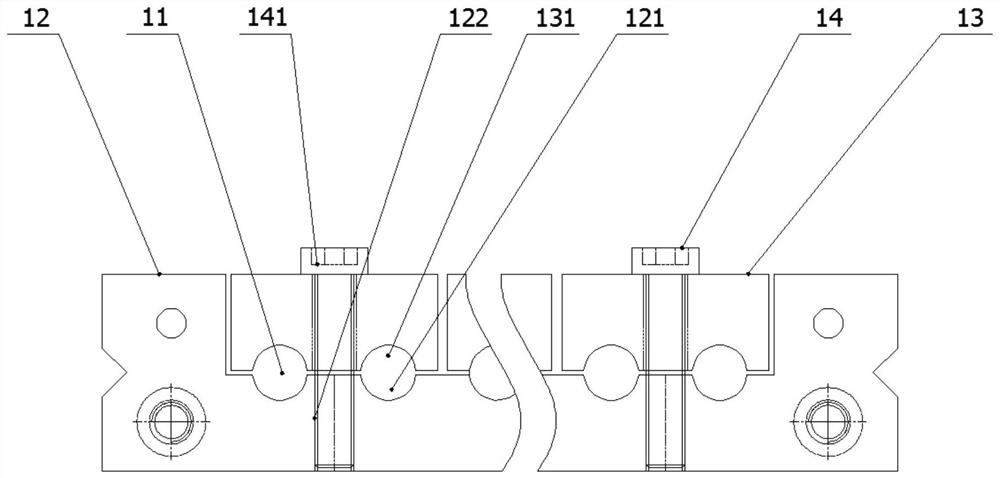

ActiveCN104550271BGuaranteed stable rollingEasy to rollGuiding/positioning/aligning arrangementsEngineeringRolling mill

The invention relates to the field of rolling mill guide, in particular to an adjustable guide. The adjustable guide comprises two guide bodies which are vertically arranged and two guard plates which are correspondingly arranged up and down, wherein the two guide bodies are positioned on the left and right sides of the two guard plates; a connecting shaft group which is horizontally arranged and perpendicular to the guide bodies is connected between the two guide bodies, and consists of two connecting shafts which are arranged in parallel up and down; the two guard plates are fixedly arranged on corresponding connecting shafts respectively; a guide passage for a material to pass through is defined by the two guide bodies and the two guard plates; the guide bodies are provided with square holes of which the hole cores are arranged along the axes of the connecting shafts; square pressing blocks are arranged in the square holes; the middle parts of the pressing blocks are provided with middle holes for the connecting shafts to penetrate through; at least one plug block is arranged between the outer side walls of the pressing blocks along the horizontal direction and the inner hole walls of the square holes; a locking unit for limiting the movement of the pressing blocks along the axes of the connecting shafts is also arranged beside one pressing block. The adjustment is easy, and the working efficiency is improved.

Owner:HEFEI BAISHENG SCI & TECH

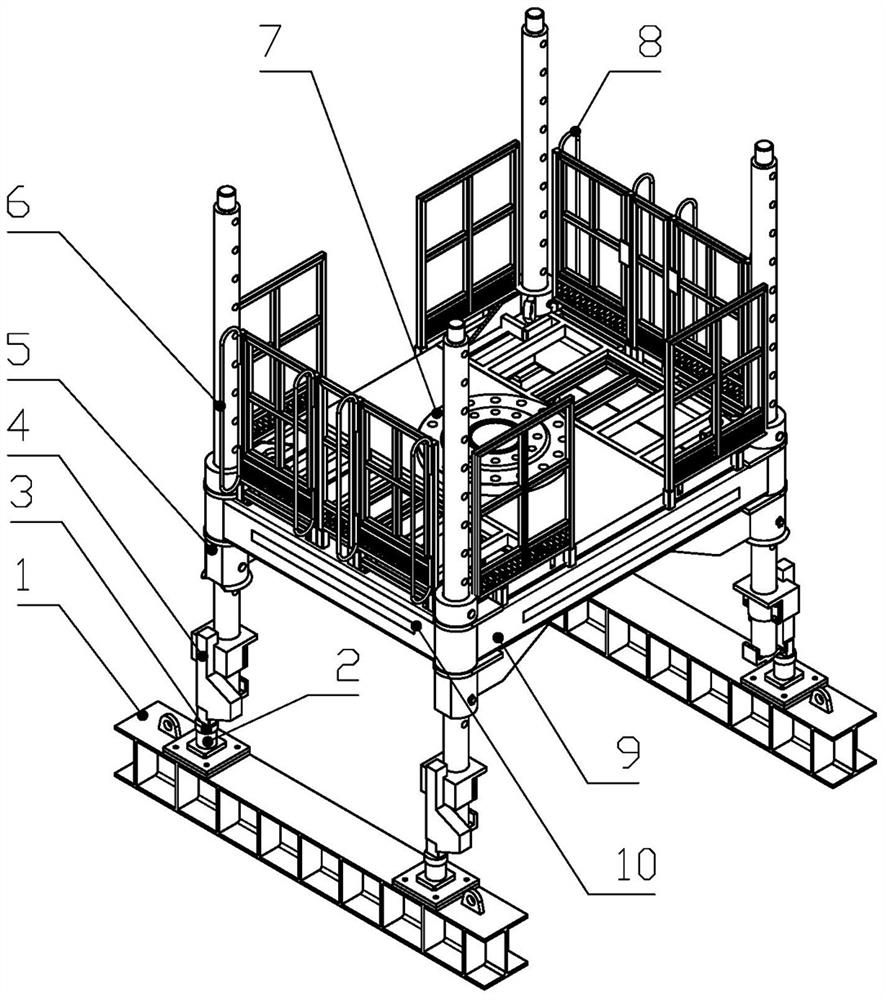

Height-adjustable auxiliary supporting device with load sensor

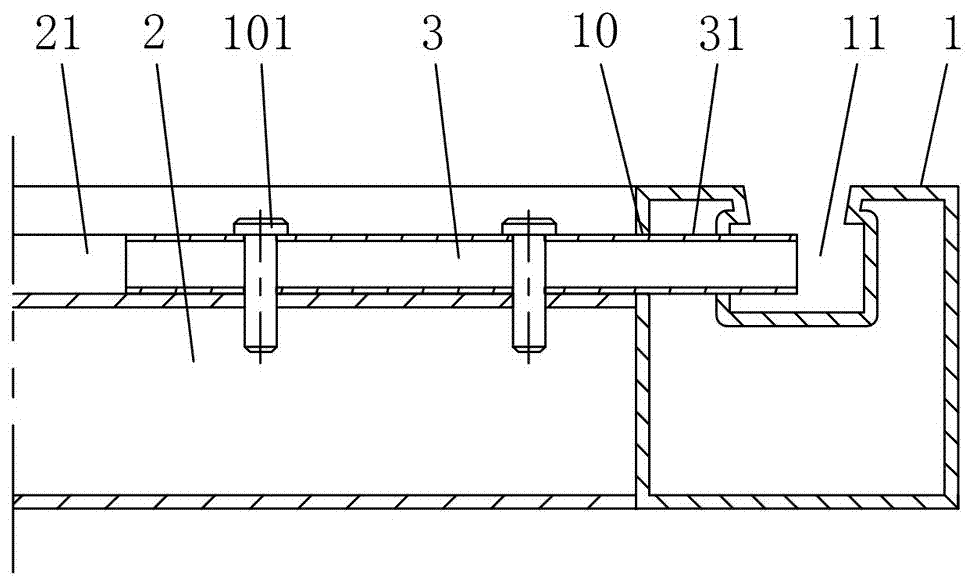

InactiveCN111997336AReduce the workload of disassembly and assemblySave spaceApparatus for force/torque/work measurementScaffold accessoriesElectrical and Electronics engineeringControl engineering

The invention discloses a height-adjustable auxiliary supporting device with a load sensor. The auxiliary supporting device comprises a base (1), a plurality of adjusting upright posts (6) and a supporting platform (9), and a support assembly (2), the load sensor (3), the adjusting upright posts (6) and a hand-cranking straddle top (4) are arranged between the supporting platform (9) and the base(1), so that flexible height adjustment and horizontal information monitoring of the auxiliary supporting device is realized. The height-adjustable auxiliary supporting device aims to overcome the defects that in the prior art, a hydraulic drive type auxiliary supporting device is complex in structure, tedious in installation, long in disassembly and assembly time and high in machining and assembly precision, and solve the technical problems that an existing thread adjusting type auxiliary supporting device is limited in bearing capacity, complex to disassemble and assemble, strenuous in adjustment and high in precision.

Owner:四川宝石机械钻采设备有限责任公司 +1

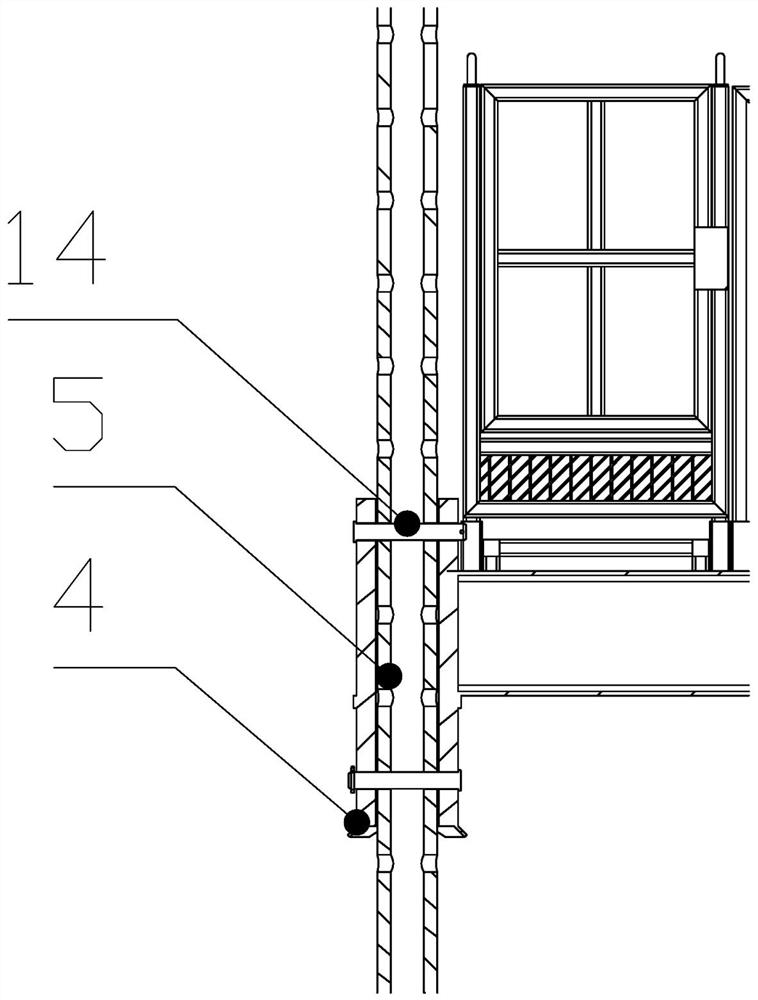

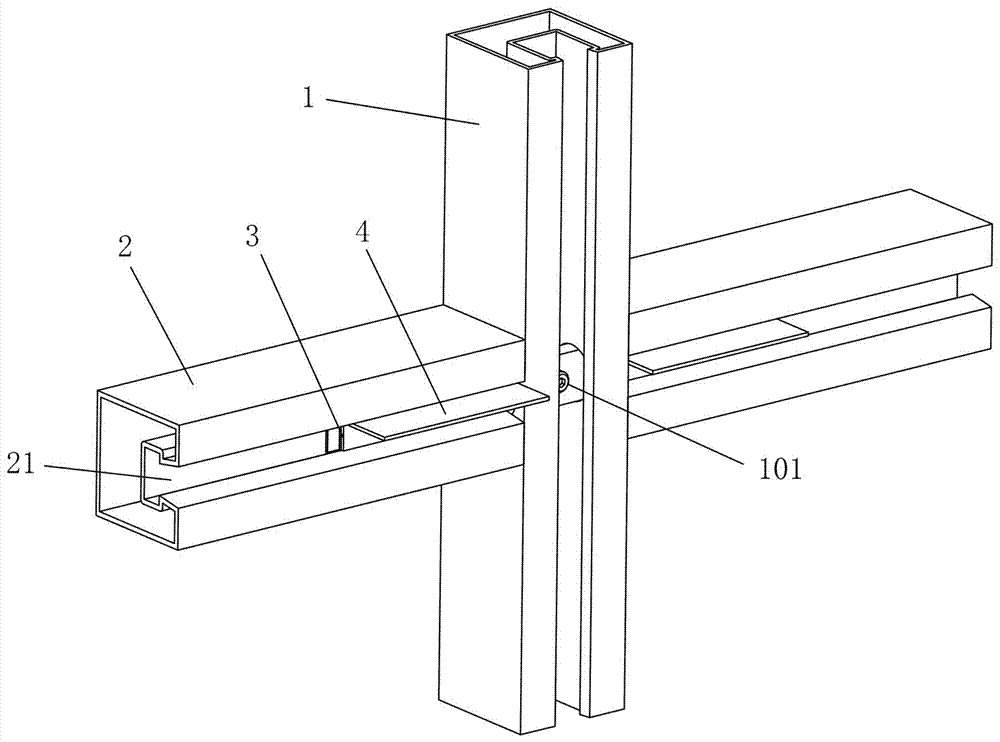

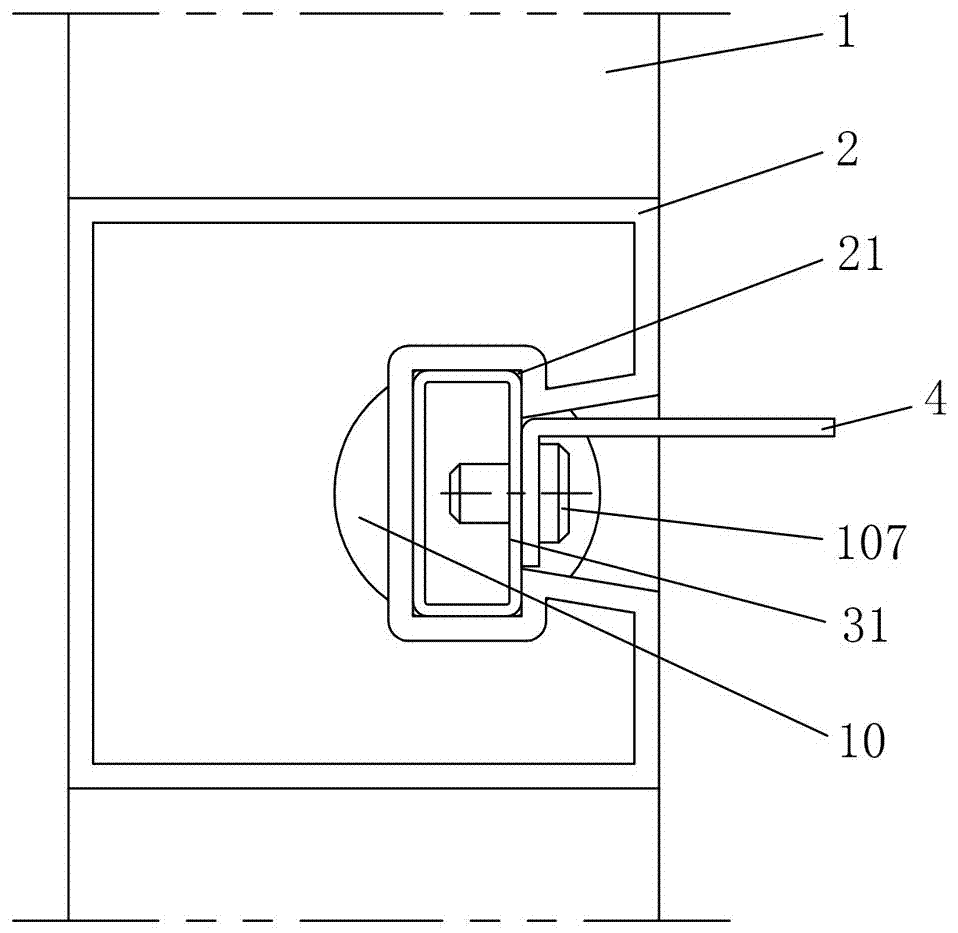

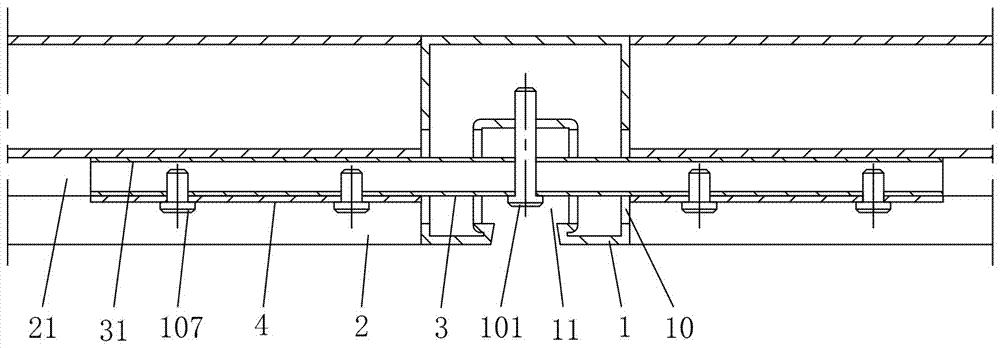

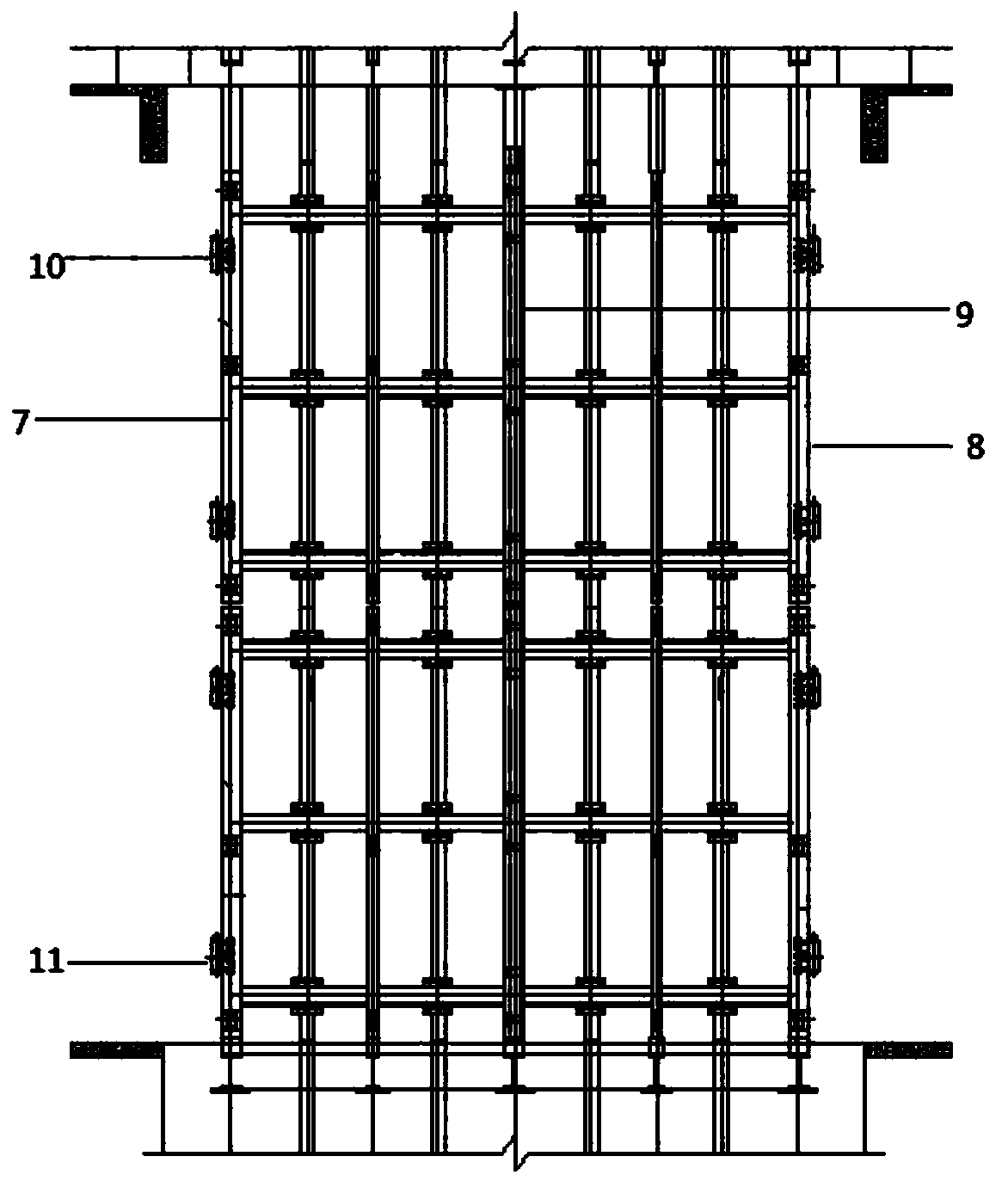

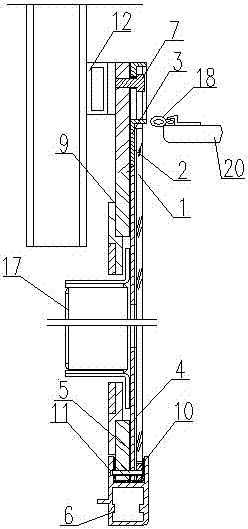

Internal connecting type double-connection structure of curtain wall keel

ActiveCN106948531AWill not affect the installationImprove simplicity and refinementWallsKeelUltimate tensile strength

The invention discloses an internal connecting type double-connection structure of a curtain wall keel. The structure comprises a vertical keel and a transverse keel connected to one side of the vertical keel through a connecting assembly, and the transverse keel is provided with a transverse internal expanding groove; and the connecting assembly comprises a connecting member which is located in the transverse internal expanding groove and can move along the transverse internal expanding groove, the connecting member is provided with an inserting and connecting part which is inserted into the vertical keel and only matched with the vertical keel in a sliding mode, and the transverse keel is connected with the connecting member through a first fastening assembly. The internal connecting type double-connection structure of the curtain wall keel has the advantages of being easy to assemble and disassemble, high in connection strength, high in stability and reliability, low in cost, beneficial to enhancing conciseness and exquisiteness of the appearance of the curtain wall and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

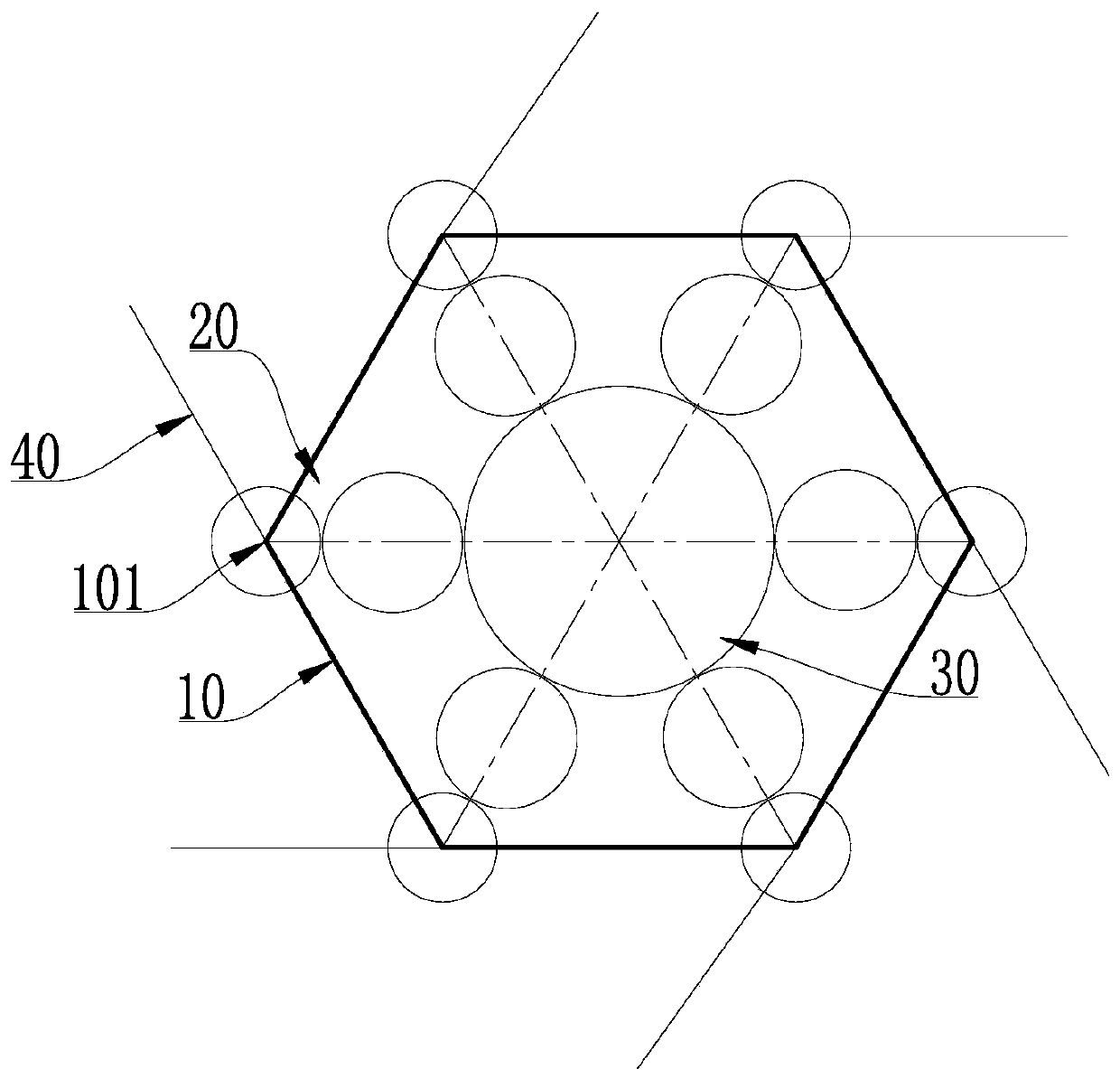

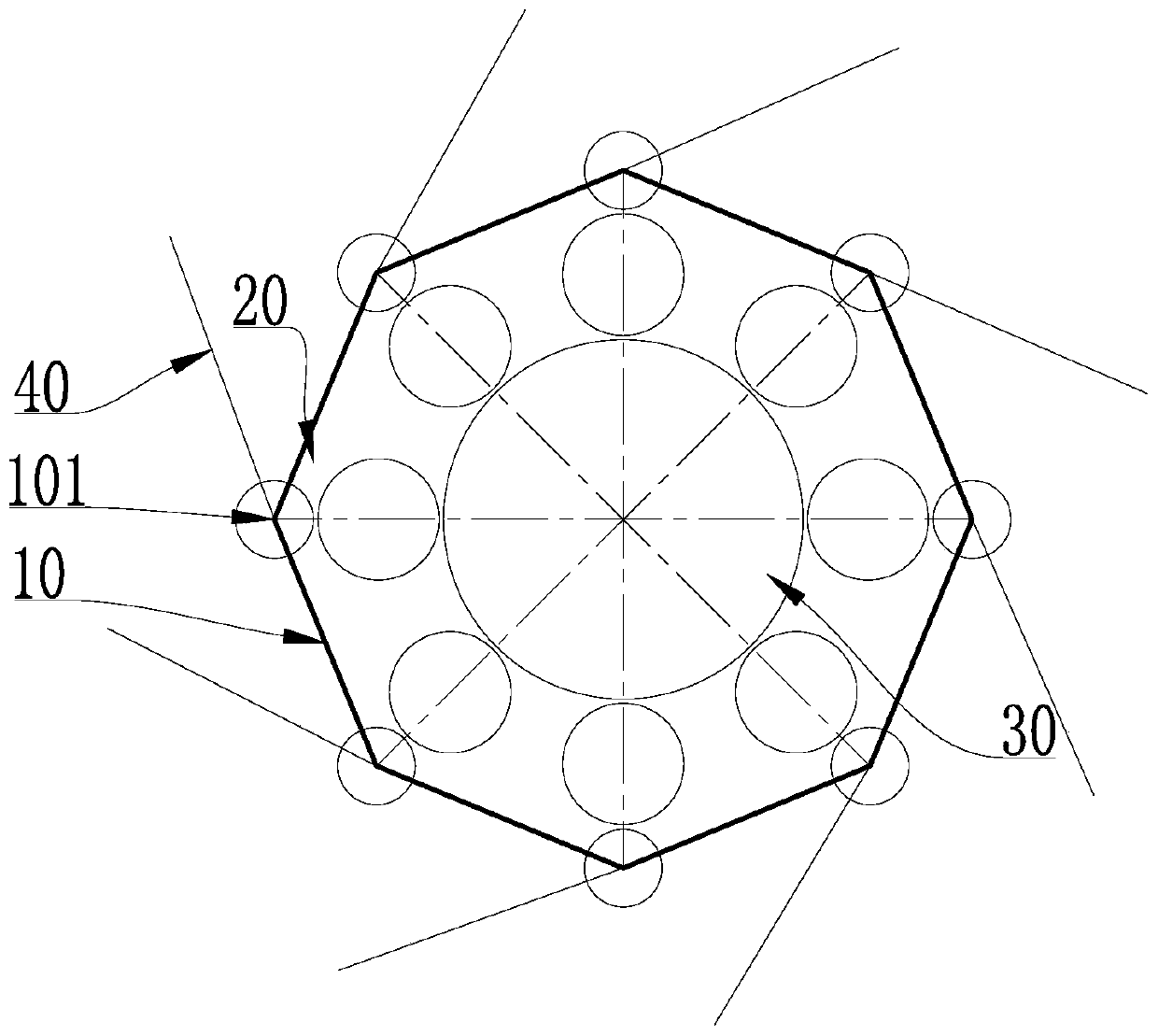

Adjustable type vibration reducing balance weight device

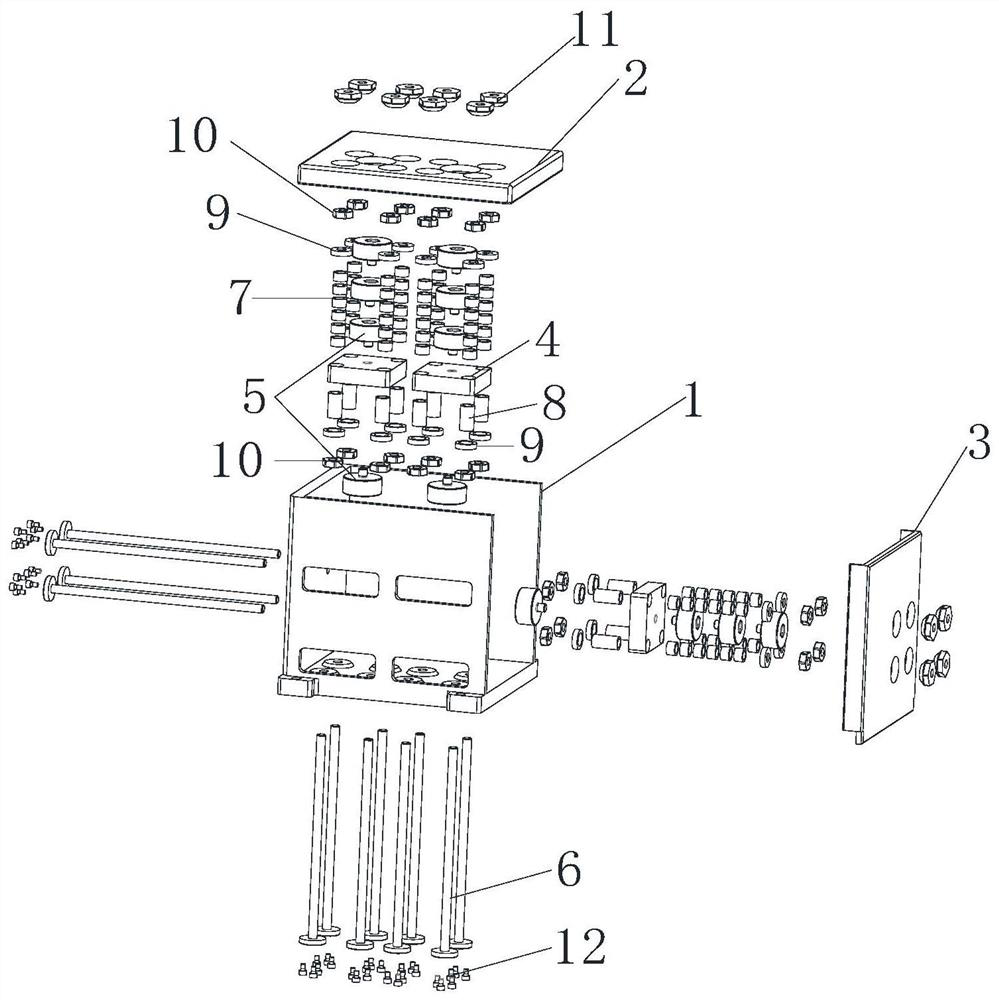

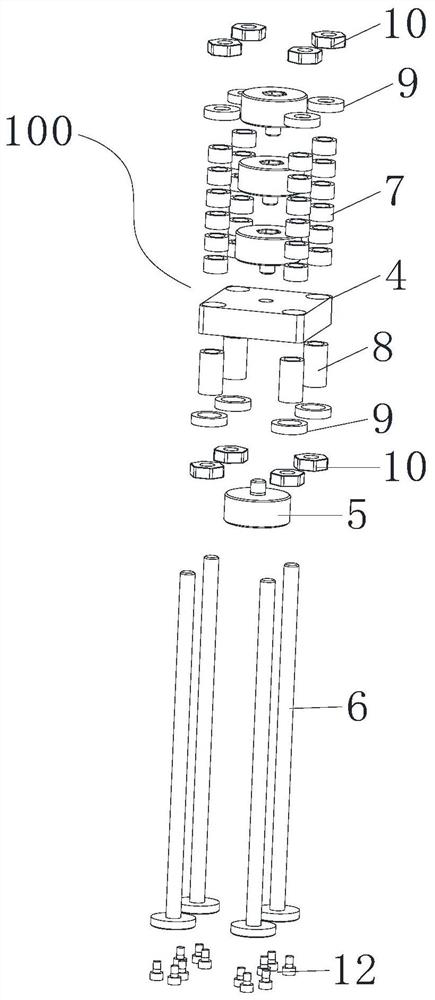

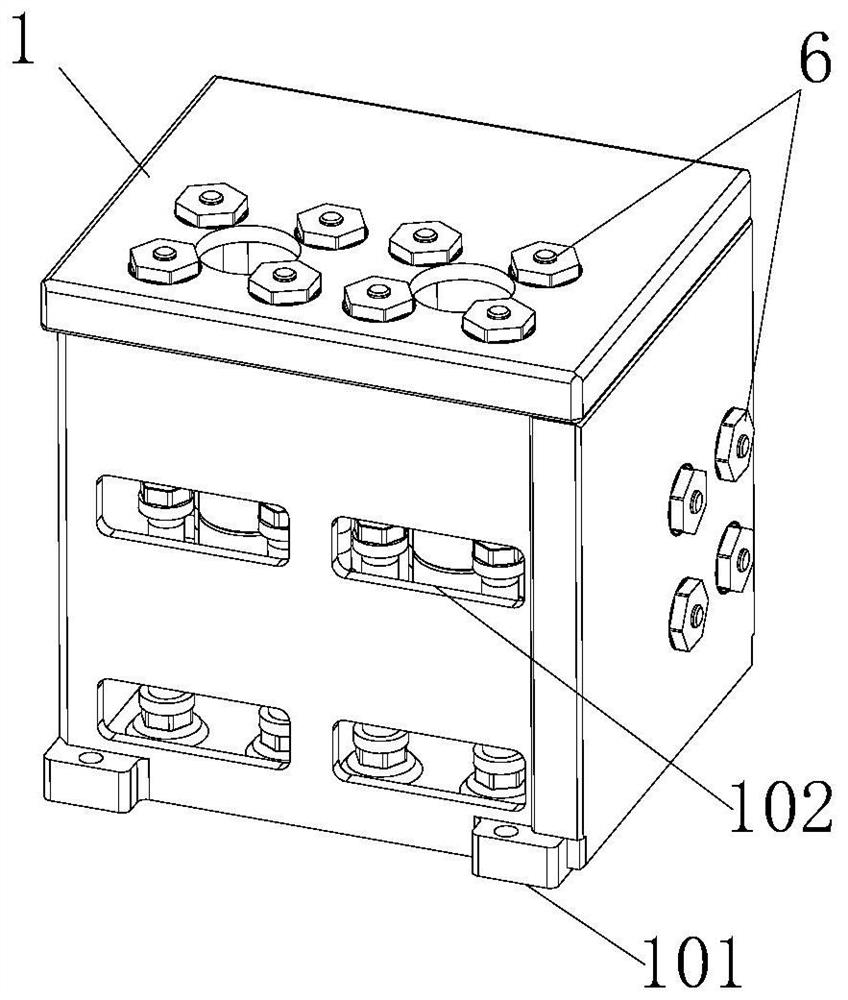

PendingCN112032254AEasy to installIncrease or decrease quantityCounterweightsMechanical engineering technologyEngineering

The invention relates to an adjustable type vibration reducing balance weight device and relates to the technical field of mechanical engineering. The adjustable type vibration reducing balance weightdevice is installed on mechanical equipment. A shell comprises a top cover and a side cover. Some of a plurality of adjusting modules are arranged vertically, and the other adjusting modules are arranged transversely. Each adjusting module comprises multiple supporting rods and multiple weights arranged in a stacked manner. Each supporting rod is provided with multiple first vibration reducing pads in a sleeved manner. When a mass center position, fixed frequency and damp need to be changed, the purpose can be achieved by increasing and reducing the number of the weights in the plurality of adjusting modules, changing the positions of the weights in the adjusting modules, increasing and reducing the number of the first vibration reducing pads and replacing types of the first vibration reducing pads. According to the vibration reducing balance weight device, the fixed frequency and damp of the vibration reducing balance weight device achieve the state meeting the vibration reducing requirement of the mechanical equipment, and the mass center of the mechanical equipment assembled with the vibration reducing balance weight device reaches the state meeting the use requirement of the mechanical equipment.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

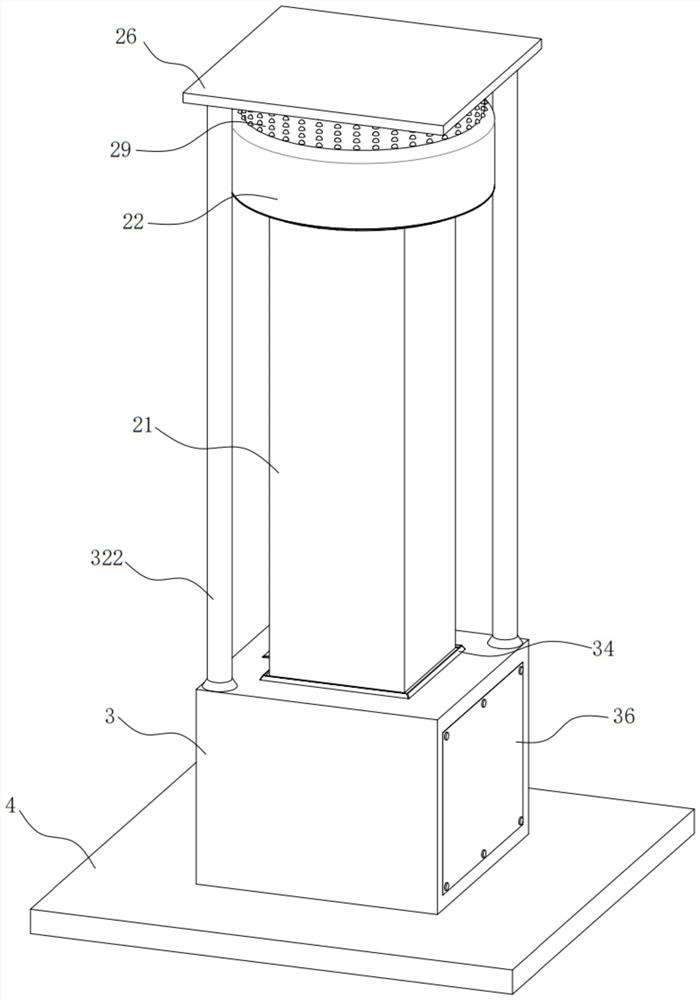

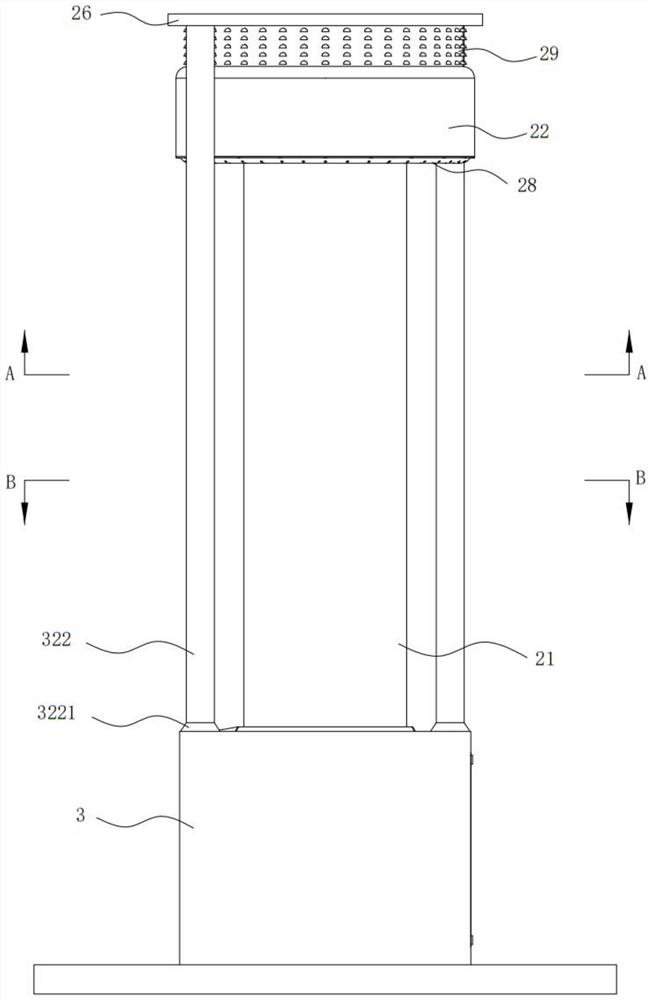

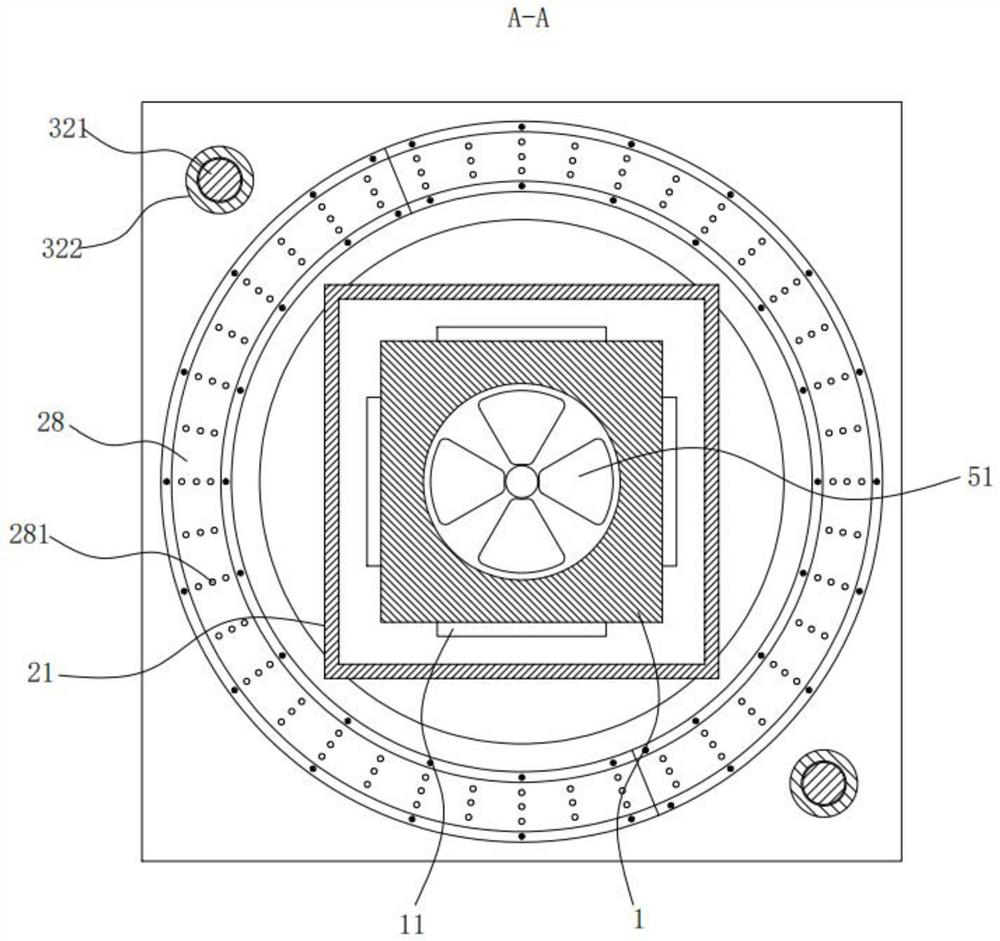

Landscape lamp convenient to disassemble, assemble and maintain

PendingCN112664880AReduce the workload of disassembly and assemblyEasy to disassemble and maintainLighting support devicesLighting heating/cooling arrangementsComputer hardwareMechanical engineering

The invention discloses a landscape lamp convenient to disassemble, assemble and maintain. The lamp comprises a lamp pole, lamp beads arranged on the lamp pole, a shell arranged outside the lamp pole in a sleeving mode, a lamp holder arranged at the bottom of the shell and the bottom of the lamp pole and a fixing base arranged at the bottom of the lamp holder, and the lamp holder is fixedly connected with the lamp pole. A driving mechanism is arranged in the lamp holder, a lifting mechanism capable of driving the shell to move up and down relative to the lamp post is arranged at the top of the lamp holder, and the driving mechanism can drive the lifting mechanism. According to the landscape lamp, the lifting mechanism drives the shell to move up and down relative to the lamp post, maintenance personnel can disassemble, assemble and maintain the landscape lamp conveniently, the disassembling and assembling workload of the maintenance personnel is greatly reduced, the mode is not affected by the body size of the landscape lamp, the operation is easy and convenient, and the landscape lamp is worthy of further application and popularization.

Owner:ANHUI MINGWEI ILLUMINATION EQUIP

Adjustable guide

ActiveCN104550271AGuaranteed stable rollingEasy to rollGuiding/positioning/aligning arrangementsEngineeringRolling mill

The invention relates to the field of rolling mill guide, in particular to an adjustable guide. The adjustable guide comprises two guide bodies which are vertically arranged and two guard plates which are correspondingly arranged up and down, wherein the two guide bodies are positioned on the left and right sides of the two guard plates; a connecting shaft group which is horizontally arranged and perpendicular to the guide bodies is connected between the two guide bodies, and consists of two connecting shafts which are arranged in parallel up and down; the two guard plates are fixedly arranged on corresponding connecting shafts respectively; a guide passage for a material to pass through is defined by the two guide bodies and the two guard plates; the guide bodies are provided with square holes of which the hole cores are arranged along the axes of the connecting shafts; square pressing blocks are arranged in the square holes; the middle parts of the pressing blocks are provided with middle holes for the connecting shafts to penetrate through; at least one plug block is arranged between the outer side walls of the pressing blocks along the horizontal direction and the inner hole walls of the square holes; a locking unit for limiting the movement of the pressing blocks along the axes of the connecting shafts is also arranged beside one pressing block. The adjustment is easy, and the working efficiency is improved.

Owner:HEFEI BAISHENG SCI & TECH

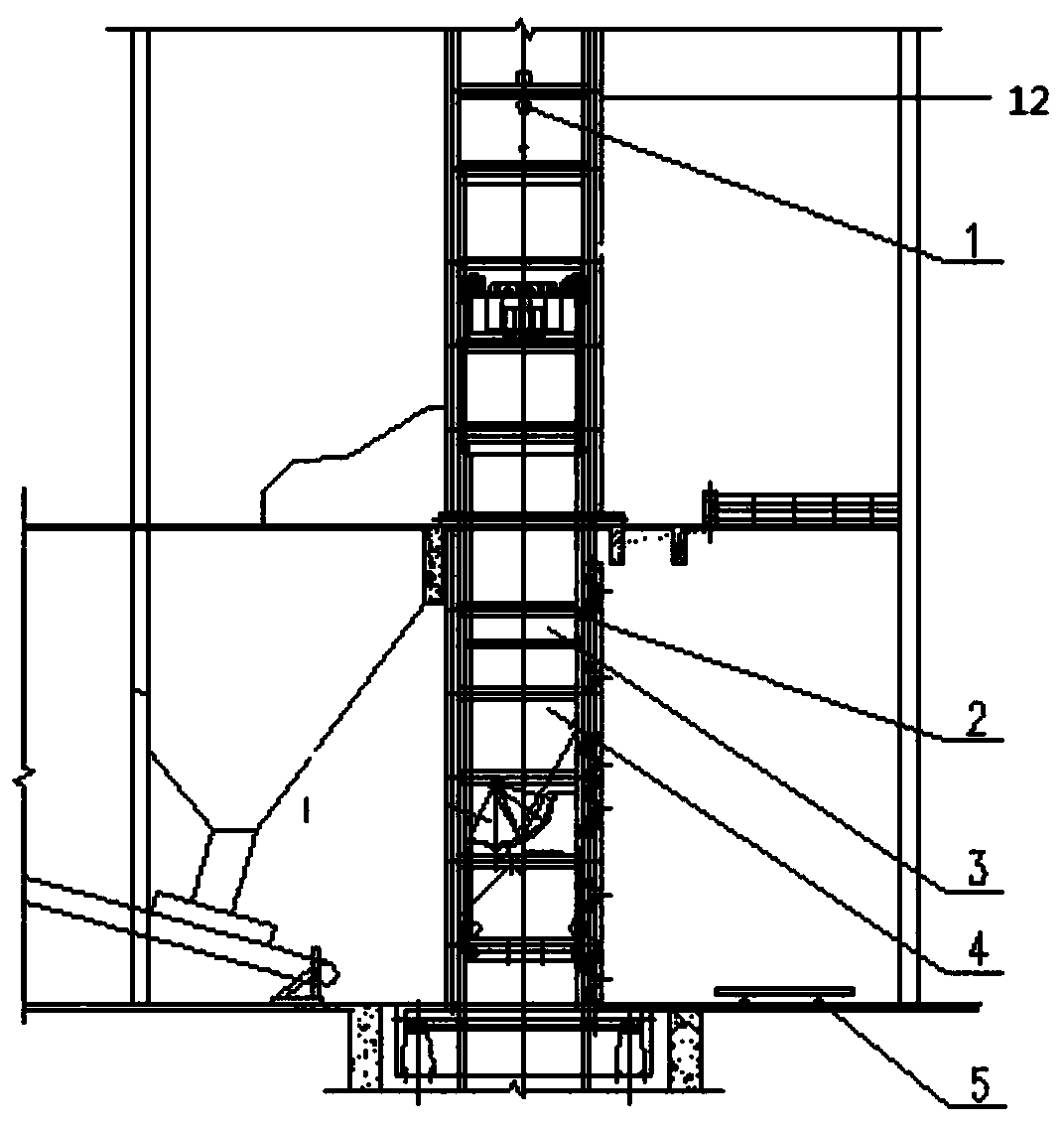

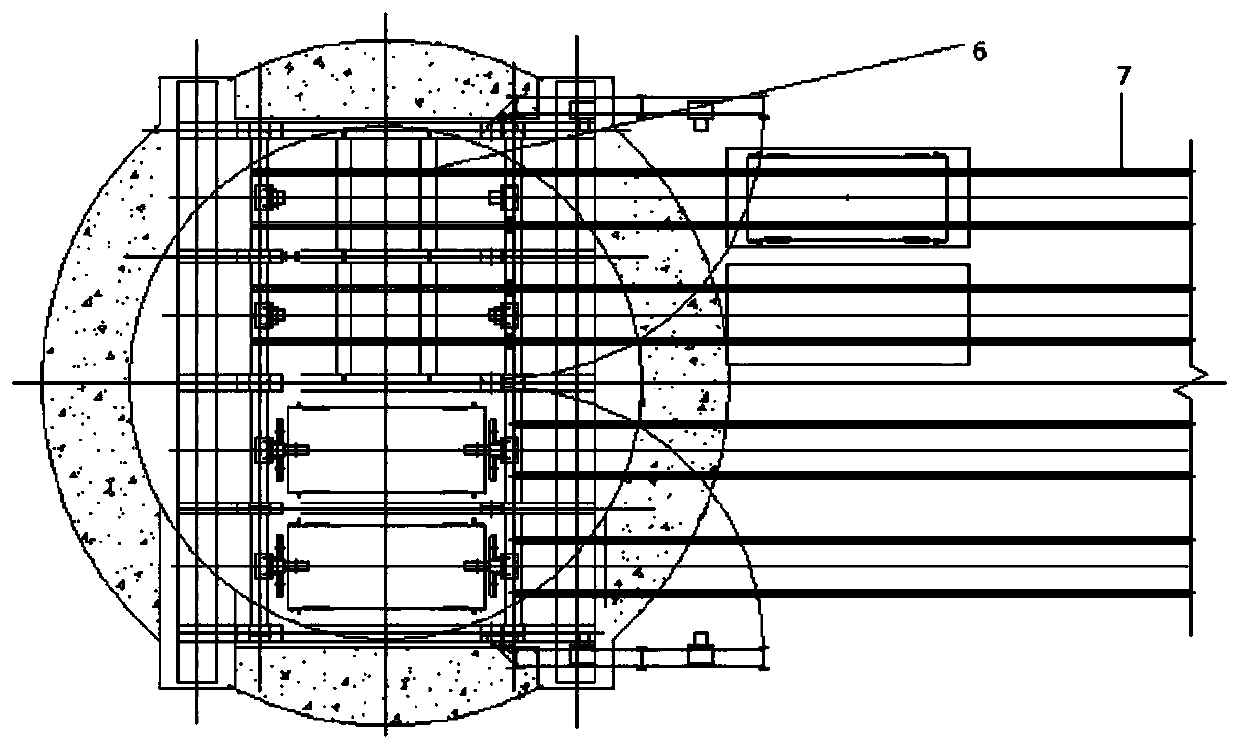

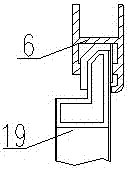

Internal connecting type triple-connection structure of curtain wall keel

ActiveCN106948528AImprove simplicity and refinementImprove rust resistanceWallsKeelUltimate tensile strength

The invention discloses an internal connecting type triple-connection structure of a curtain wall keel. The structure comprises a vertical keel and two transverse keels connected to the two sides of the vertical keel through a connecting assembly, a cut-through installing hole is formed in the vertical keel, and the transverse keels are provided with transverse internal expanding grooves; the connecting assembly comprises a sliding connecting member which can penetrate through the cut-through installing hole and move along the transverse internal expanding grooves, and the sliding connecting member is installed in the cut-through installing hole in a penetrating mode and can rotate relative to the cut-through installing hole; and the sliding connecting member has two connecting parts which are located in the transverse internal expanding grooves of the two transverse keels correspondingly and only matched with the transverse internal expanding grooves in a sliding mode, and the vertical keel is fixedly connected to the sliding connecting member through a first fastening assembly. The internal connecting type triple-connection structure of the curtain wall keel has the advantages of being easy to assemble and disassemble, high in connection strength, high in stability and reliability, low in cost, beneficial to enhancing conciseness and exquisiteness of the appearance of the curtain wall and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

A method for quick replacement of large skips in coal mines

The invention relates to the field of skip devices, and in particular to a method for rapid replacement of a large coal mine skip. The method comprises the steps that an upper body and a lower body ofthe skid are separately conveyed in and out by disassembling a skid middle flange; the height of a first layer heapstead and the height of a sleeve frame in and out of the skip are lowered; an open-close type movable sleeve frame is arranged, and the sleeve frame and a cage guide are opened and closed integrally; the difficulty and workload of dismantling and installing and restoring the sleeve frame are reduced; a spare skid is stored in a warehouse, and the storage in the heapstead or a headframe is canceled; the floor area and load of the heapstead or the headframe and lifting equipment isreduced; a temporary rail mounting beam is reserved during the design of the sleeve frame and is connected with an outer fixing track of the sleeve frame; and a temporary track is installed quickly when the skip is replaced. An outlet headframe is paved on the track, the transfer of the skid in the headframe is avoided, the movement is smooth, and the process is less. The technical defects of high cost, large occupied area and long time consuming in the existing technical problems are solved. The method for rapid replacement of the large coal mine skip is simple, quick, low in cost and practical.

Owner:CHINA COAL SCI & TECH GRP NANJING DESIGN & RES INST CO LTD

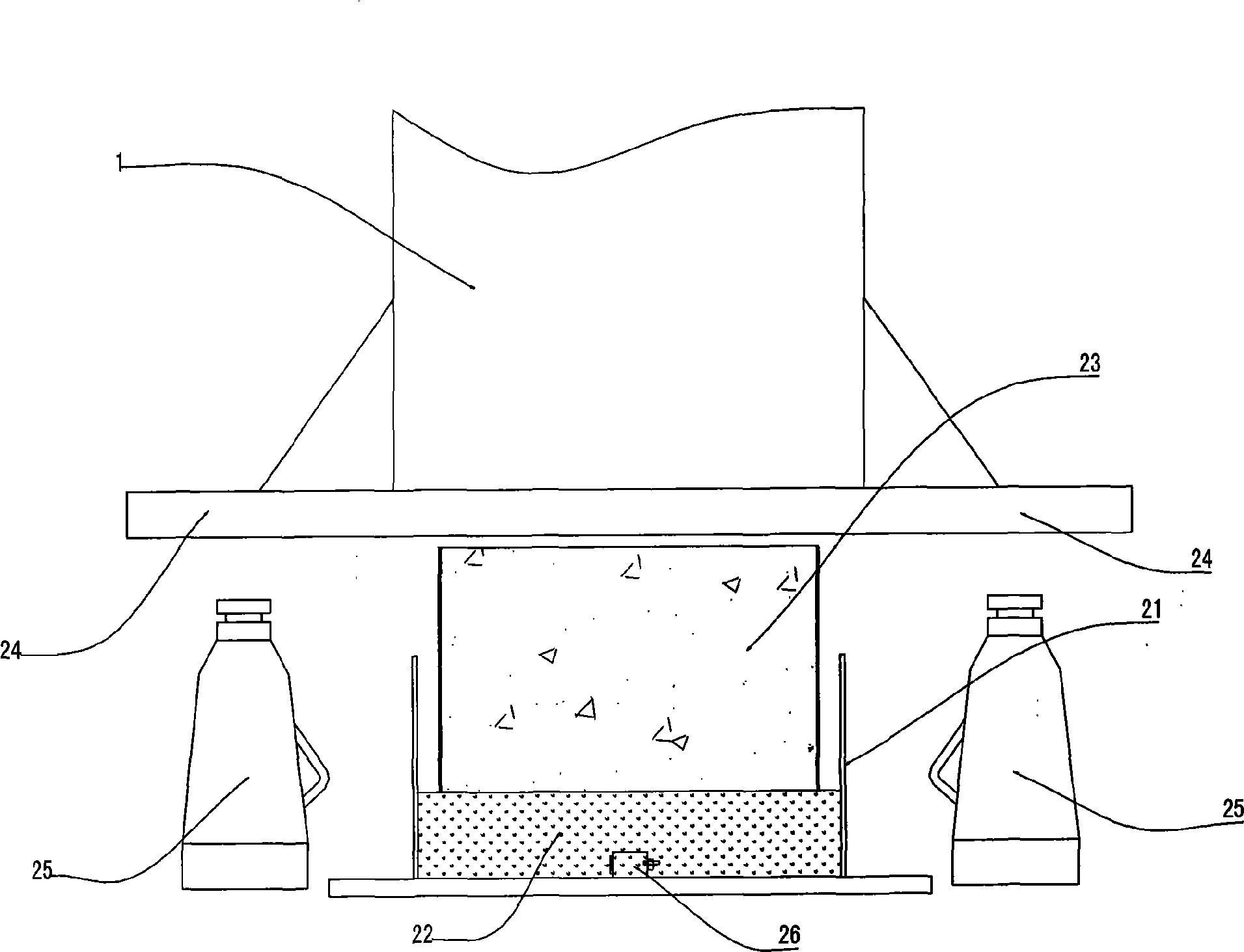

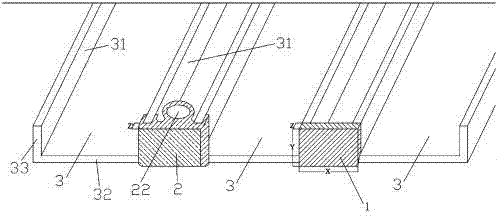

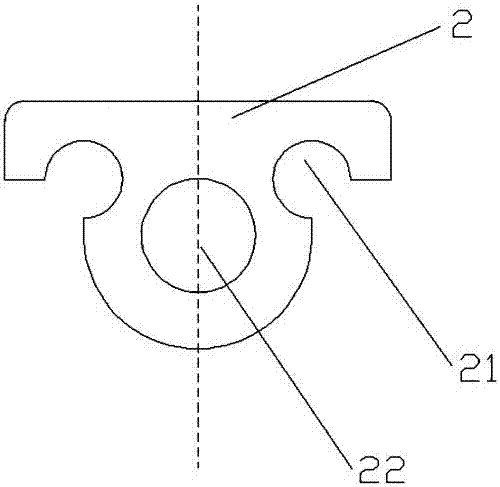

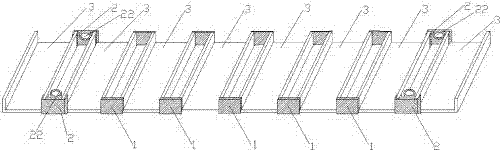

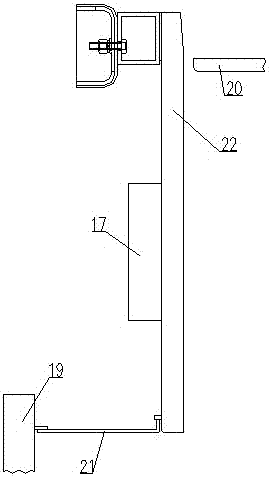

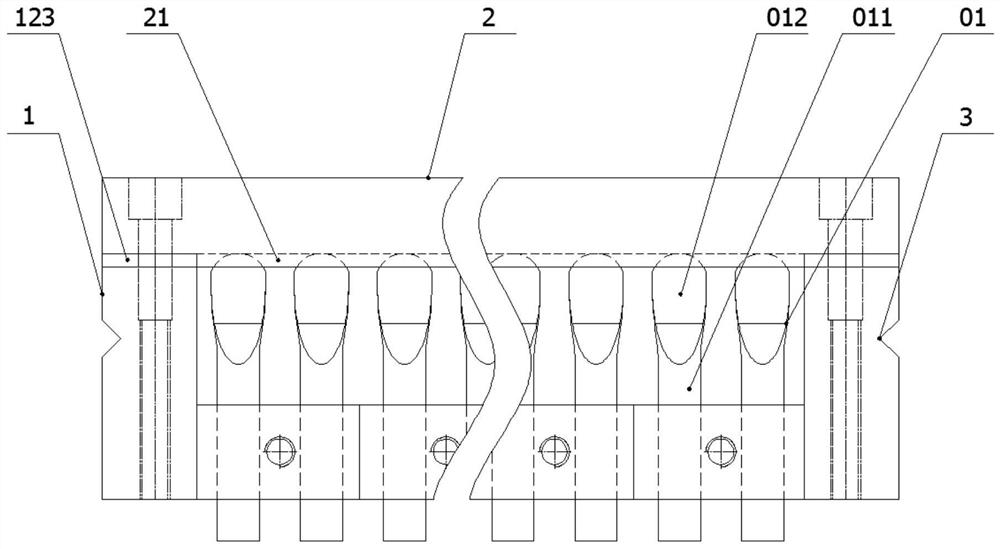

Installation device for U-shaped grooved plates of strip-shaped bubble cap tray

InactiveCN107308892AImprove installation efficiencyReduce the workload of disassembly and assemblyHydrocarbon by hydrocarbon condensationChemical/physical/physico-chemical processesEngineeringWorkload

The invention provides an installation device for a U-shaped groove plate of a strip-shaped bubble cap tray, comprising a first end plug 1, the first end plug 1 is a rectangular block, and the first end plug 1 is welded on the side of the U-shaped groove plate outside, connect the adjacent U-groove plates. The invention can simplify the installation, disassembly and cleaning process of the U-shaped groove plate under the condition that the levelness and leakage of the tray are relatively high in the installation process of the water washing tower tray, so that the installation efficiency of the tray is greatly improved, and at the same time, the reduction of The workload of tray disassembly and assembly is reduced, and the leakage problem during tray installation is reduced.

Owner:倪飞

Partition wall round head structure of vehicle built-in information display and its installation and removal method

The invention discloses a dividing wall round head structure embedded with an information displayer in a vehicle. The structure comprises a left dividing wall round head assembly, a middle dividing wall round head assembly and a right dividing wall round head assembly arranged in sequence and respectively mounted on a vehicle body mounting cross beam, wherein the middle dividing wall round head assembly comprises a wall plate, a displayer mounting base, the information displayer and an edge beam; an opening matched with the information displayer in size is formed in the center position of the wall plate; the displayer mounting base is fixed in the opening at the inner side of the wall plate; the information displayer is mounted on the mounting base; a lining plate is arranged at the outer side of the wall plate; more than one bushings are arranged at the upper part of the lining plate; inverted T-shaped holes are formed in the bushings at one side of the wall plate; hanging pieces are arranged on the wall plate corresponding to the inverted T-shaped holes, and are hung with the inverted T-shaped holes; a light transmitting plate is arranged at the outer side of the lining plate; a groove is formed in the top of the edge beam; and the bottoms of the wall plate, the lining plate and the light transmitting plate are positioned in the groove of the edge beam, and are detachably connected with the edge beam. The structure is convenient for installation, disassembly and maintenance, is beautiful, and saves the space.

Owner:CRRC QINGDAO SIFANG CO LTD

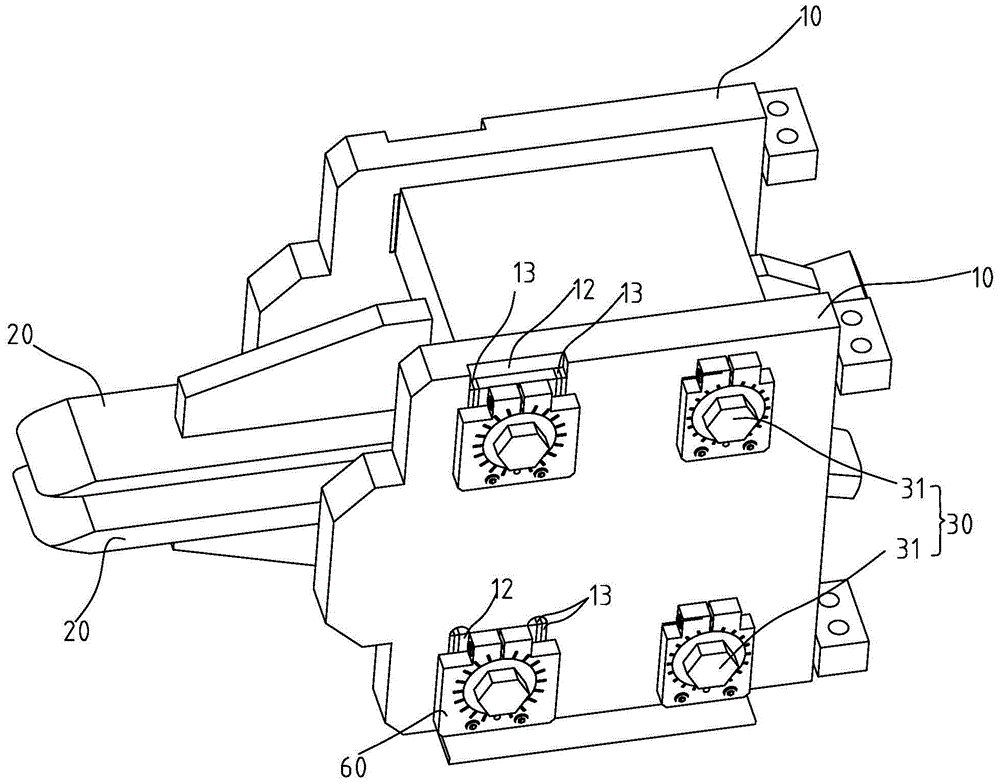

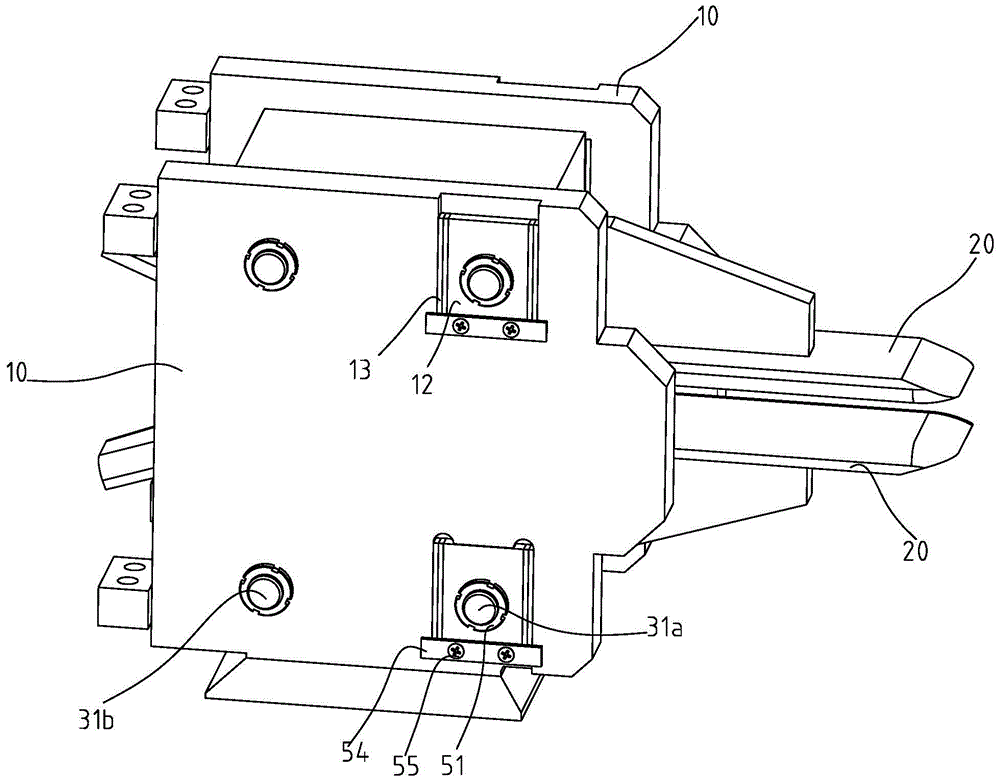

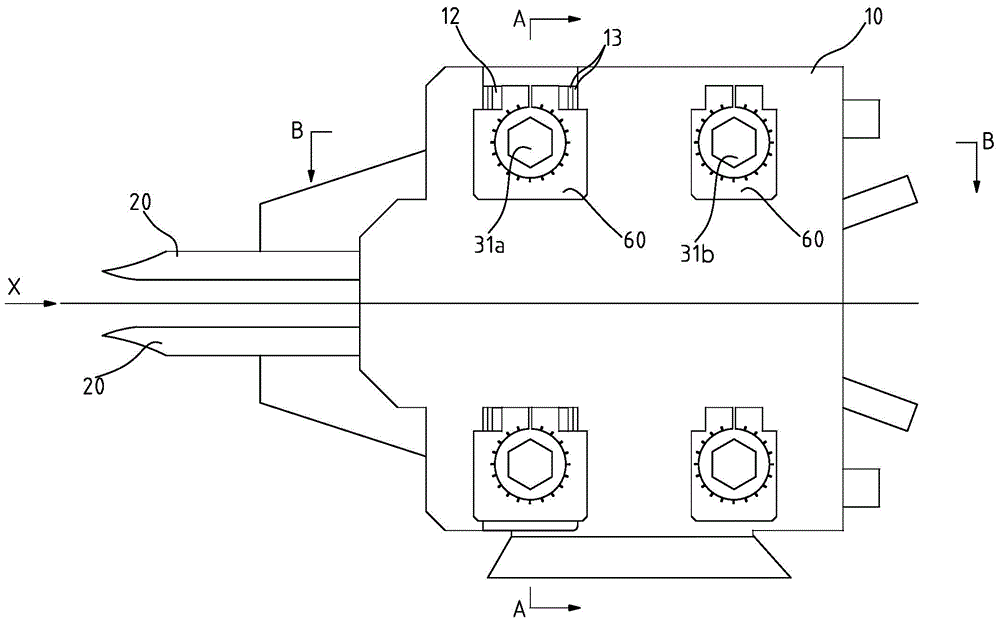

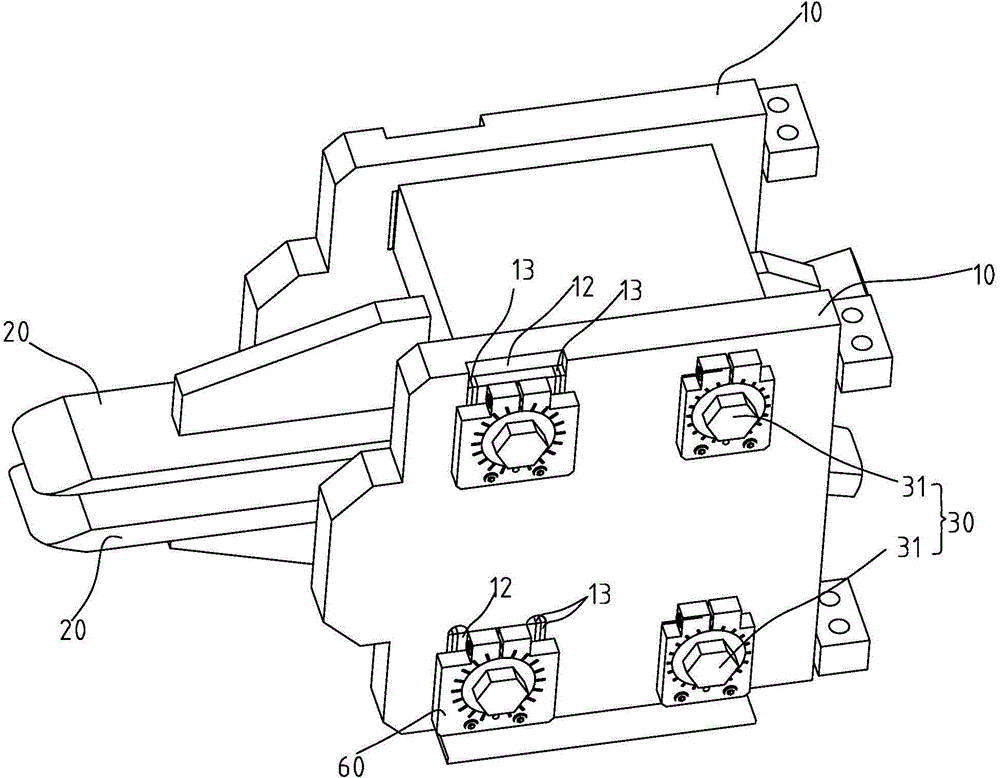

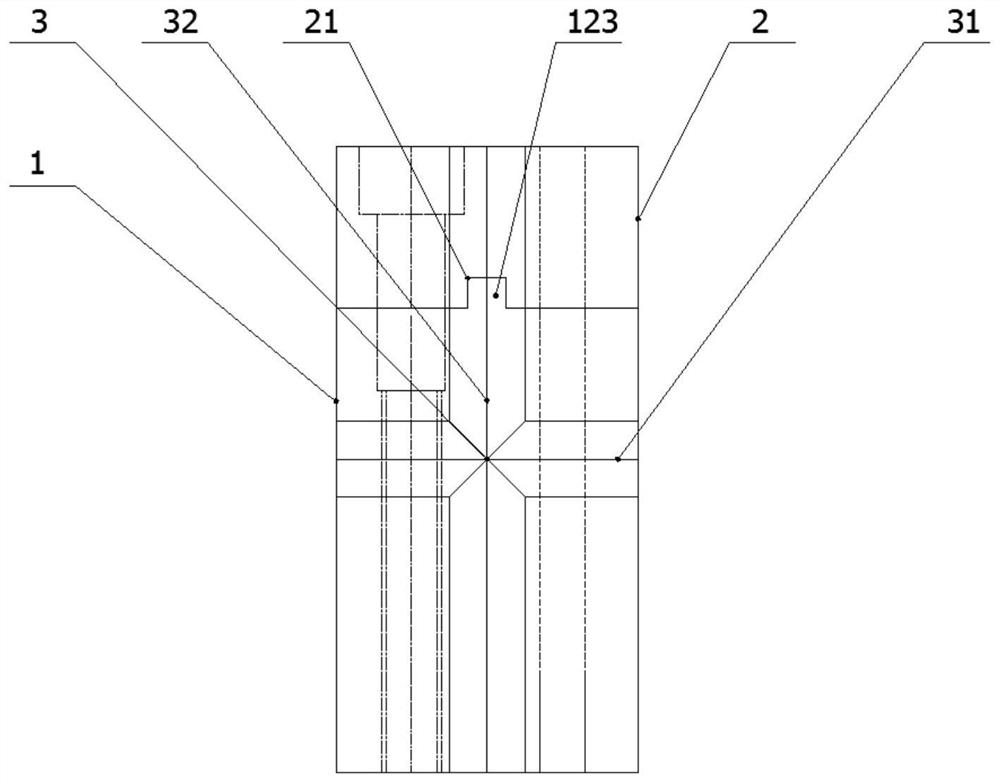

Machining tool used for adjusting connecting rods

PendingCN113352122AImprove processing efficiencyMeet the machining accuracy requirementsWork holdersPositioning apparatusStructural engineeringMachine tool

The invention discloses a machining tool used for adjusting connecting rods. The machining tool comprises a clamping mechanism and a positioning mechanism, the clamping mechanism is used for clamping an adjusting connecting rod blank, the adjusting connecting rod blank is a blank for manufacturing an adjusting connecting rod and comprises a round rod section and a non-round rod section, and the clamping mechanism is provided with multiple clamping holes; and the positioning mechanism is arranged on the side, close to the non-round rod section of the adjusting connecting rod blank, of the clamping mechanism, the positioning mechanism is provided with a positioning groove matched with the non-round rod section, and the positioning groove is used for limiting the direction and the position of the adjusting connecting rod blank. According to the machining tool, the multiple clamping holes are formed in the clamping mechanism, the machining requirement for machining multiple adjusting connecting rods in a single batch is met, and the production efficiency of adjusting connecting rods can be greatly improved; and the positioning groove matched with the non-round rod section is formed in the positioning mechanism, adjusting connecting rod blanks can be aligned in the axis direction, the consistent angle can be kept in the circumferential direction, the dual-positioning purpose can be achieved easily, the positioning time can be remarkably shortened, and the reloading efficiency can be improved.

Owner:锋宏机械制造集团有限公司

Rapid steam purging method and device for steam turbine intake pipe

ActiveCN107327319BReduce the workload of disassembly and assemblyLow production costMachines/enginesSafety/regulatory devicesEngineeringTurbine

The invention provides a rapid steam blowing method for a gas inlet pipeline of a turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine comprises the following steps that (1) a last section of gas inlet pipeline close to an entrance part of the turbine is cut and taken to be remanufactured into a blowing process pipe, the blowing process pipe is a right-angle bend pipe which is bent by 90 degrees, flanges are fixedly arranged at the two ends of the blowing process pipe, the butt-joint flange is fixedly arranged at one end of the blowing process pipe and is connected with a flange at the tail end of the gas inlet pipeline of the turbine, and the exit flange is fixedly arranged at the other end of the blowing process pipe and is connected with the turbine; (2) the position of the blowing process pipe is upwardly rotated by 90 degrees, and the blowing process pipe is installed in a state with the exit flange vertically upward; (3) a target plate serves as a steam blowing detecting plate and is installed on the exit flange of the blowing process pipe; (4) steam is injected into the gas inlet pipeline for blowing; (5) the steam blowing detecting plate is disassembled after each time of blowing and a blowing result is detected until a detecting result meets the requirement; and (6) after blowing for all is finished, the connecting direction of the blowing process pipe is changed and the blowing process pipe is re-connected with the turbine. The rapid steam blowing method for the gas inlet pipeline of the turbine has the advantages that steam blowing is rapid and convenient, working efficiency is high, and cost is low.

Owner:HUDONG HEAVY MACHINERY

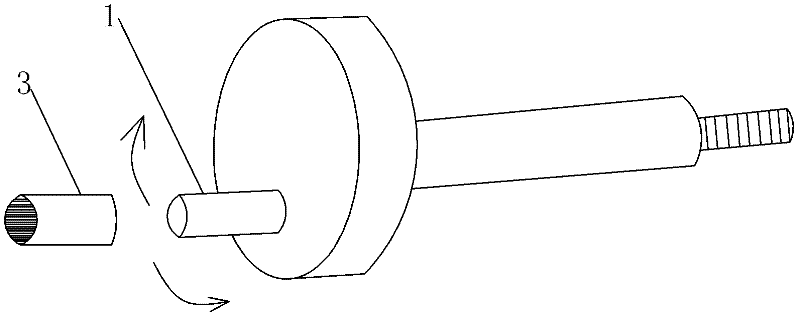

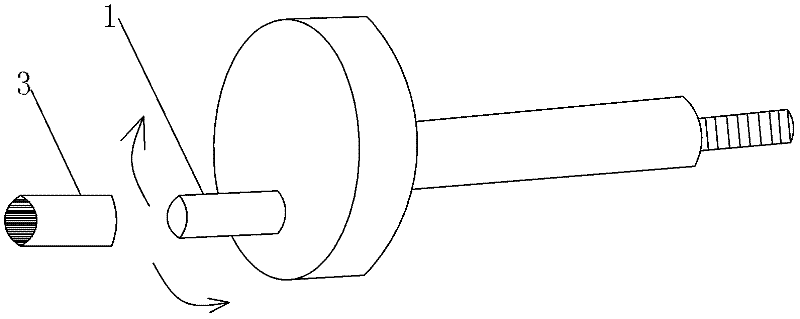

Rotary tool used for dismounting and assembling the grinding roller device of medium-speed roller coal mill

ActiveCN103816982BFlexible operationEasy and flexible operationGrain treatmentsPulp and paper industryUltimate tensile strength

The invention relates to a rotate tool for disassembly and assembly of a grinding roller device of a medium-speed roller-type coal pulverizer, a maintenance door (8) is arranged on a housing (11) of the coal pulverizer (10), a rotatable main shaft (3) is arranged on one side of the maintenance door (8), the rotatable main shaft (3) is fixed on the housing (11) of the coal pulverizer (10) by two bearings seats (1), the rotatable main shaft (3) is fixedly connected with the grinding roller device (9) by a bracket (4) and a tensioning device (2), and when the an external force is applied to the grinding roller device (9), the grinding roller device (9) may be turned over to the external of the coal pulverizer (10) in the rotation process of the main shaft (3). The rotate tool has the advantages of flexible operation, less occupied space, reduction of the labor intensity of workers, shortening of the maintenance cycle and reduction of the maintenance cost.

Owner:BEIJING POWER EQUIP GRP

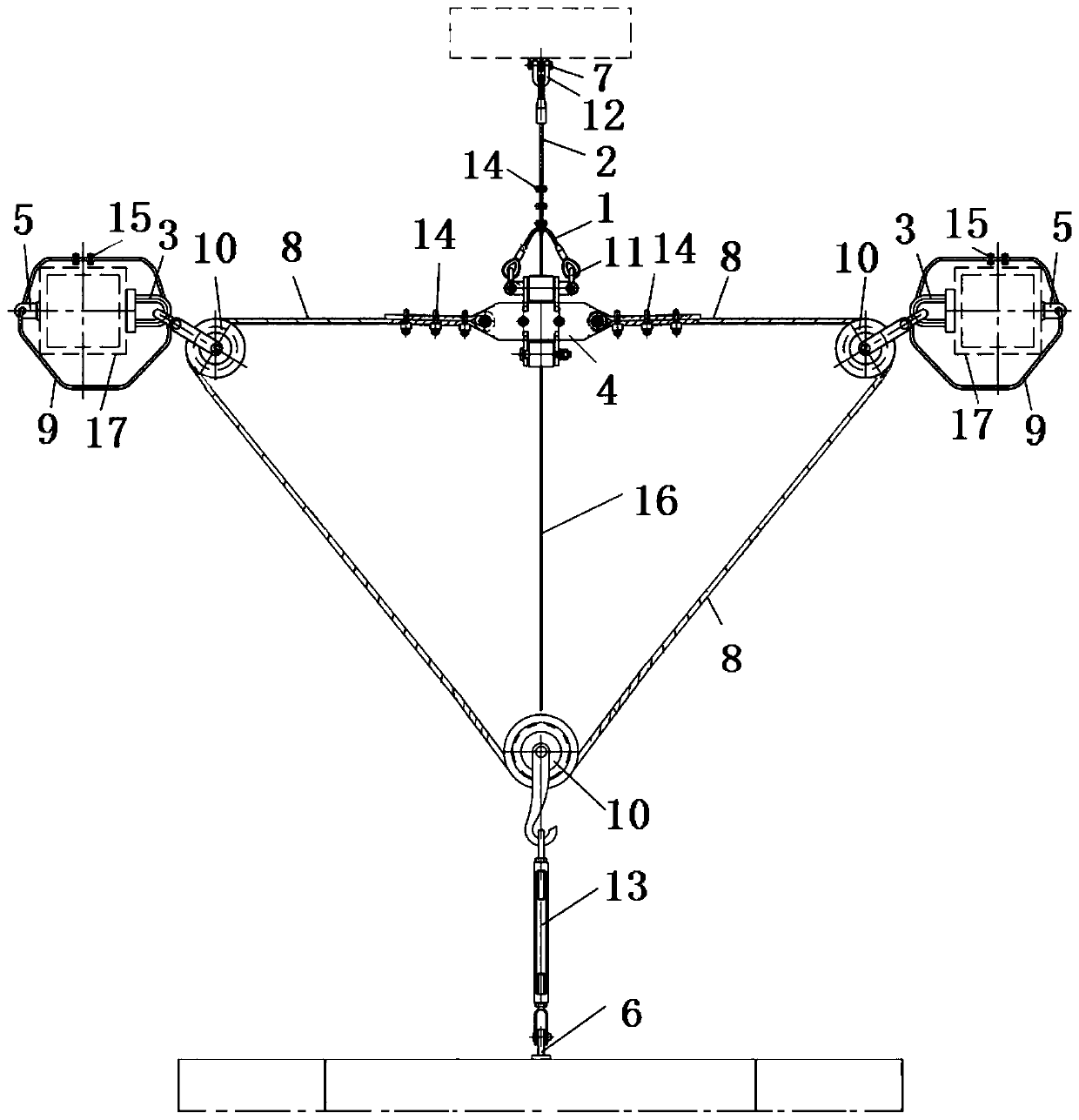

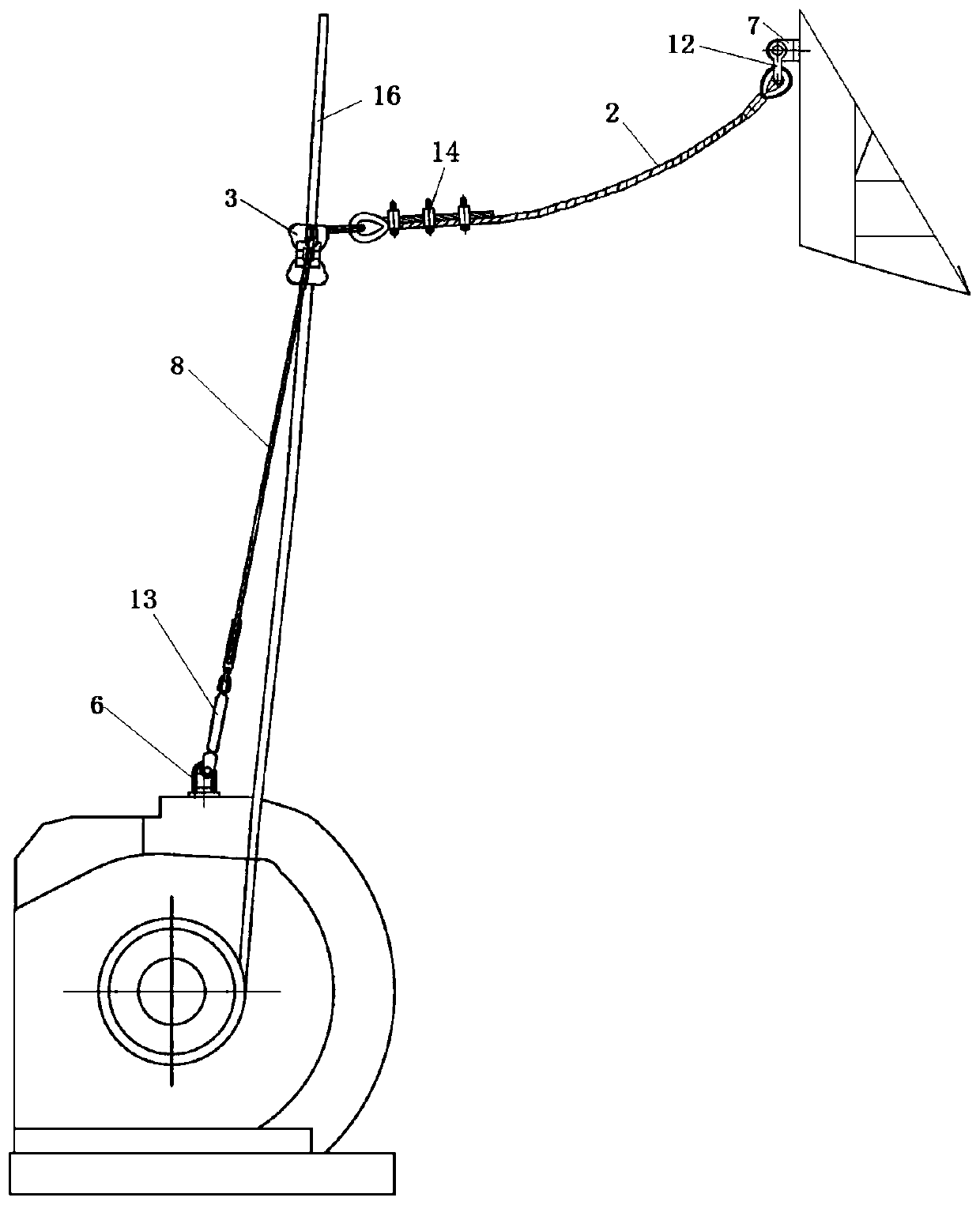

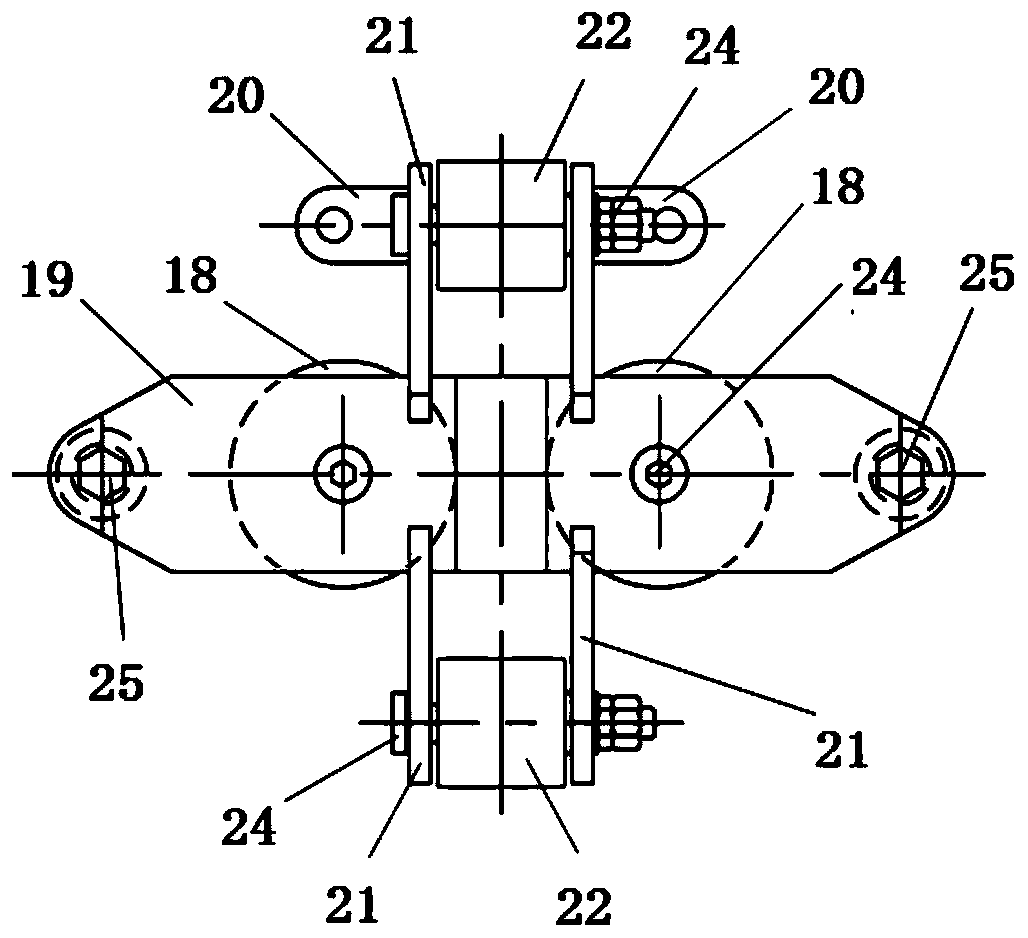

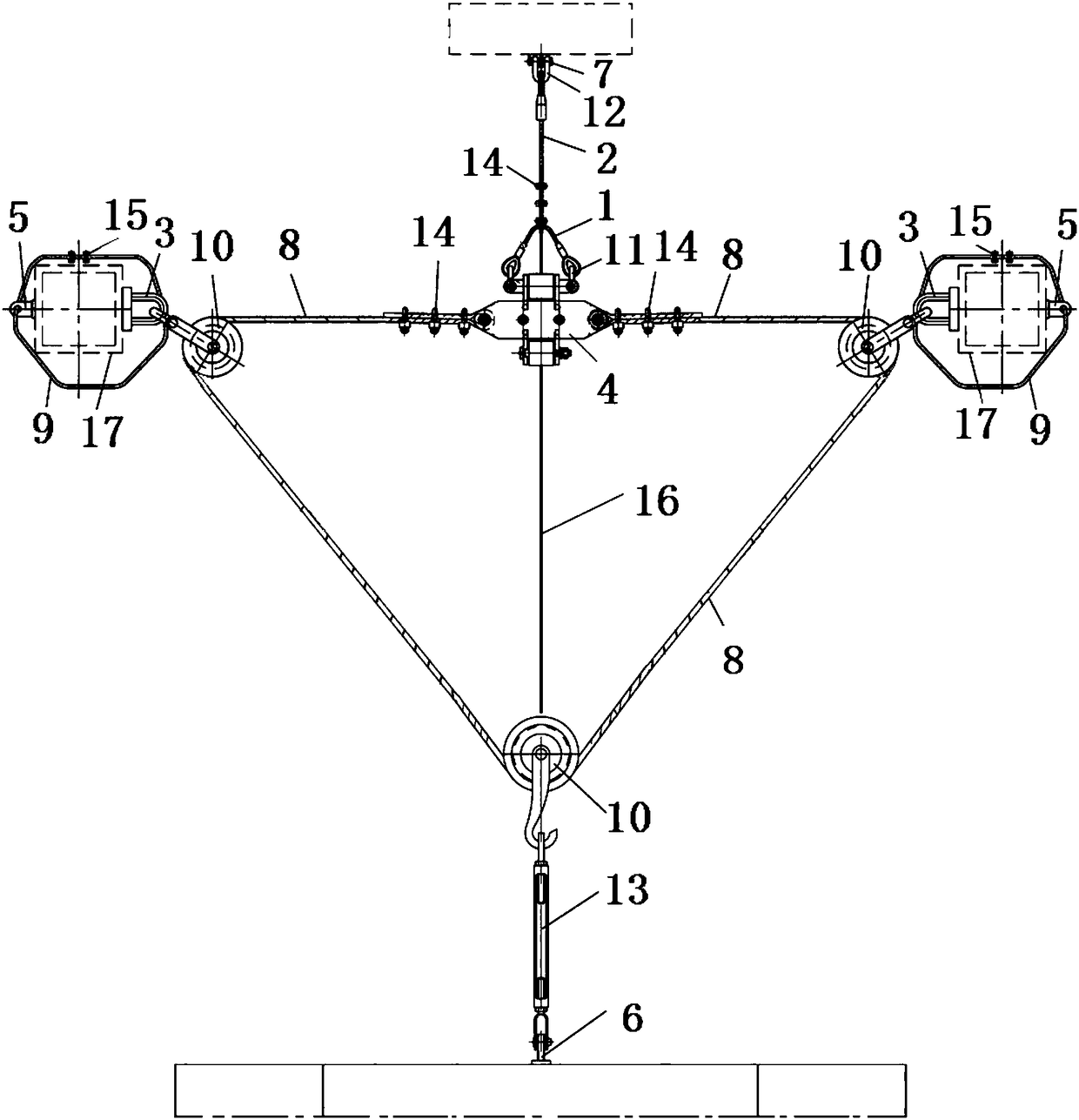

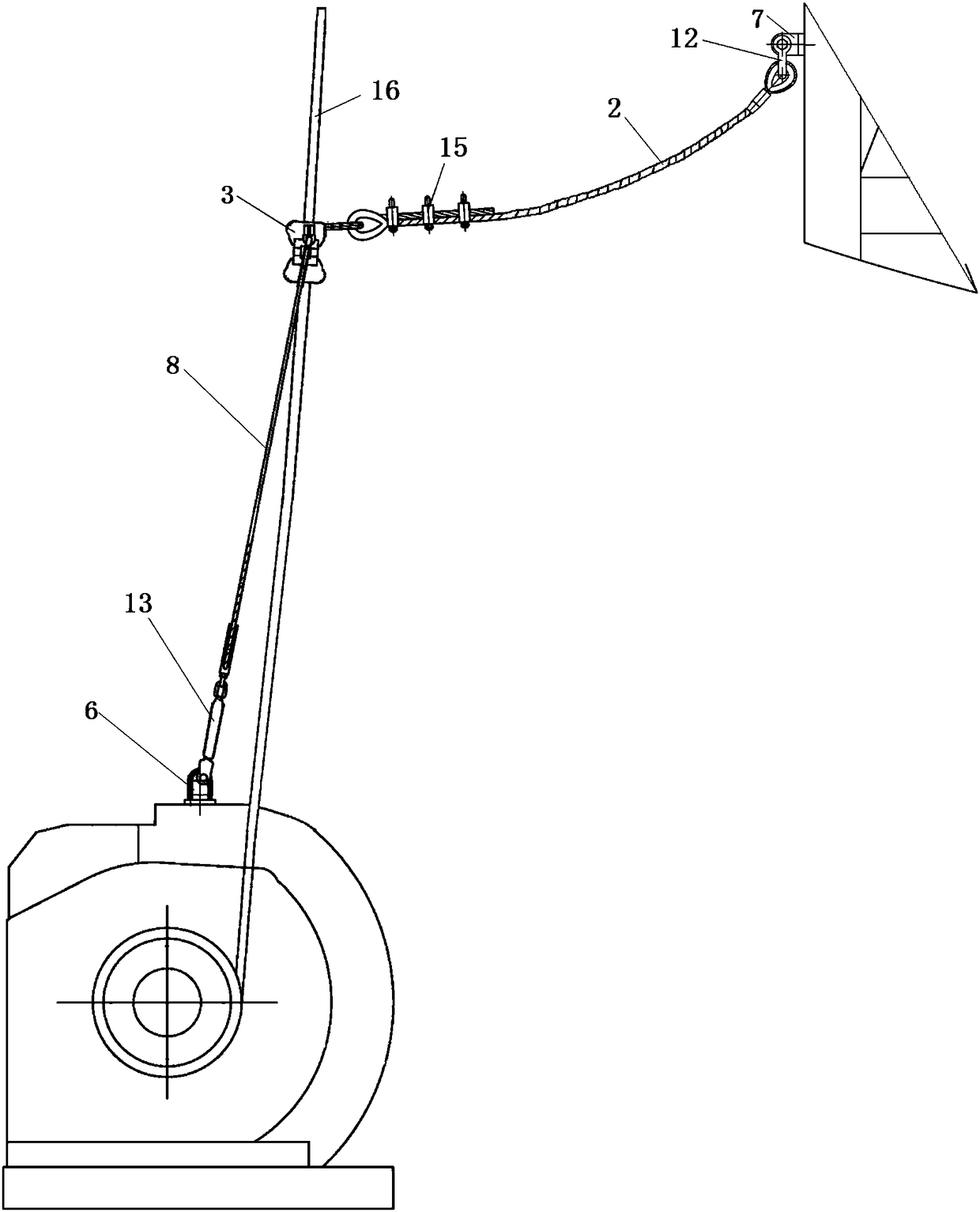

A rope-laying device for a follow-up winch

ActiveCN108341359BReduce swing rangeAchieve stabilityPortable liftingWinding mechanismsBlock and tackleEngineering

The invention discloses a servo winch rope aligning device. The servo winch rope aligning device comprises a steel wire rope a which is connected to the outer sides of three ling-ring-shaped single-wheel round head ring tackles in sequence in an inverted-triangle shape, the two ends of the steel wire rope a are connected to the two ends of a pulley block correspondingly, and the joints are fixed through a plurality of rope clips b; the ling-ring-shaped single-wheel round head ring tackle located at the bottom is buckled to one end of a rigging turnbuckle; bow shackles a are buckled on the pulley block, each bow shackle a is buckled with one end of a safety rope a, the middle of the safety rope a is buckled with one end of a safety rope b, and the other end of the safety rope b is connectedto a bow shackle b in a penetrating mode; the bow shackle b is buckled with a lug plate b; the joint between the safety rope a and the safety rope b is fixed through a plurality of rope clips b; anda fast rope is connected into a guide wheel set in a penetrating mode. According to the servo winch rope aligning device, the swinging range of a fast rope of a boring winch is decreased, the phenomenon that ropes are disordered or squeezing occurs in the drilling process is avoided, and the service life of the drilling steel wire rope is prolonged.

Owner:BAOJI PETROLEUM MASCH CO LTD

Servo winch rope aligning device

ActiveCN108341359AReduce swing rangeAchieve stabilityPortable liftingWinding mechanismsBlock and tackleEngineering

The invention discloses a servo winch rope aligning device. The servo winch rope aligning device comprises a steel wire rope a which is connected to the outer sides of three ling-ring-shaped single-wheel round head ring tackles in sequence in an inverted-triangle shape, the two ends of the steel wire rope a are connected to the two ends of a pulley block correspondingly, and the joints are fixed through a plurality of rope clips b; the ling-ring-shaped single-wheel round head ring tackle located at the bottom is buckled to one end of a rigging turnbuckle; bow shackles a are buckled on the pulley block, each bow shackle a is buckled with one end of a safety rope a, the middle of the safety rope a is buckled with one end of a safety rope b, and the other end of the safety rope b is connectedto a bow shackle b in a penetrating mode; the bow shackle b is buckled with a lug plate b; the joint between the safety rope a and the safety rope b is fixed through a plurality of rope clips b; anda fast rope is connected into a guide wheel set in a penetrating mode. According to the servo winch rope aligning device, the swinging range of a fast rope of a boring winch is decreased, the phenomenon that ropes are disordered or squeezing occurs in the drilling process is avoided, and the service life of the drilling steel wire rope is prolonged.

Owner:BAOJI PETROLEUM MASCH CO LTD

Eccentric shaft of side gauge device

InactiveCN102336056AImprove lubricationReduce frictionPrinting press partsNeedle roller bearingAgricultural engineering

The invention discloses an eccentric shaft of a side gauge device. The eccentric shaft comprises an eccentric shaft body, wherein a needle roller bearing is sleeved on the eccentric shaft body, and the inner diameter of the needle roller bearing is same as the external diameter of the eccentric shaft body. According to the invention, the needle roller bearing with the external diameter close to that of a copper bush is used, the inner diameter of the needle roller bearing is same as the external diameter of the eccentric shaft body, and the lubrication degree of the needle roller bearing is far higher than that of the copper bush, so that friction is reduced, service life is greatly prolonged, and pull accuracy of the side gauge device is also improved; in normal condition, the eccentric shaft can be contentiously used for more than half a year, and under a better lubrication condition, the eccentric shaft can definitely work for one year, so that maintenance cost and complicated dismounting and mounting work load are both reduced.

Owner:ZHEJIANG WELLVAST PACKING PRINTING PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com