Internal connecting type triple-connection structure of curtain wall keel

A technology for connecting structures and keels, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult to guarantee connection strength, poor force balance and stability, and difficult to hide connecting parts and screws, so as to reduce disassembly and assembly. Workload and accessory costs, high stability and reliability, and the effect of improving simplicity and sophistication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

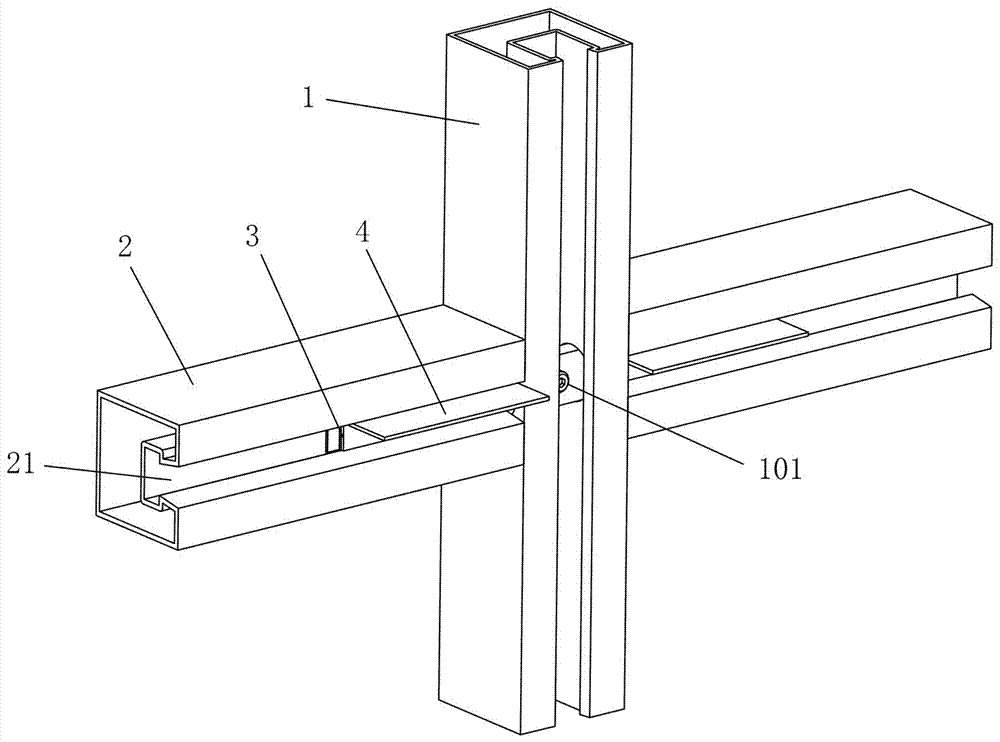

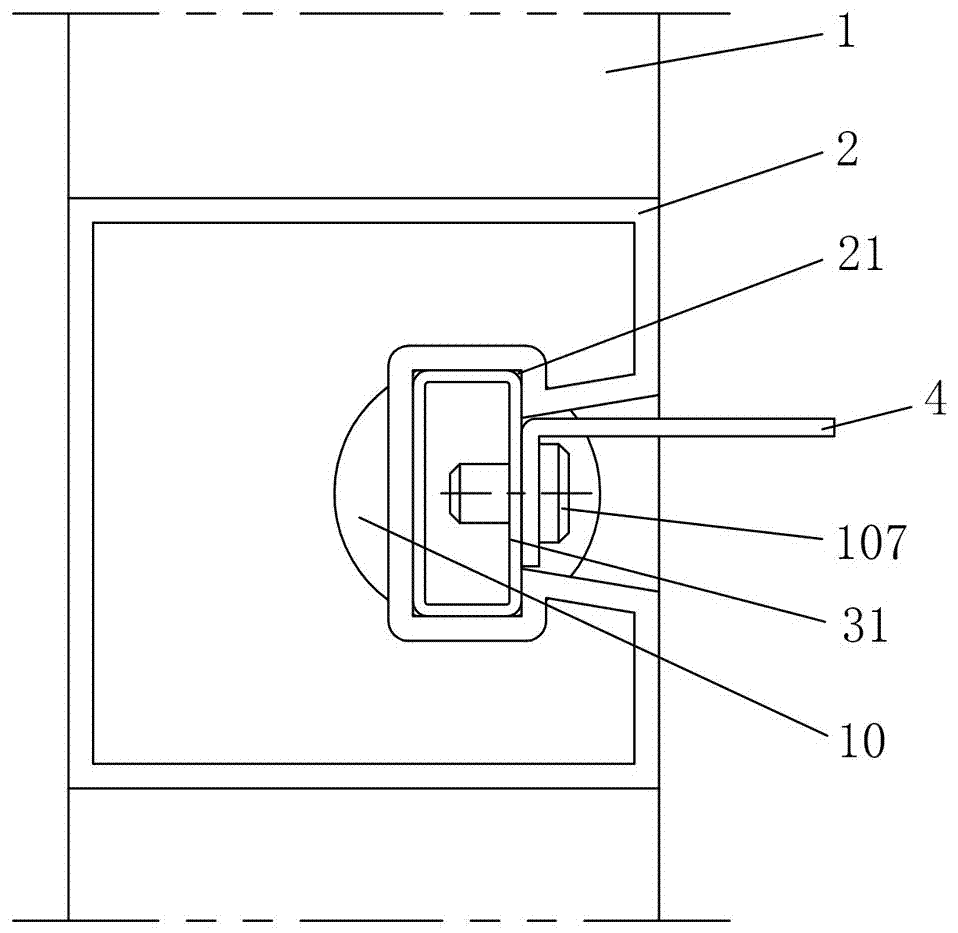

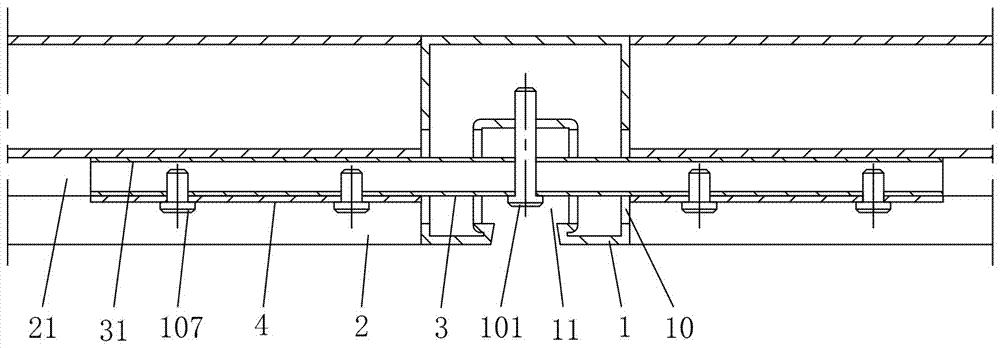

[0040] Such as Figure 1 to Figure 3 As shown, the internal triple connection structure of the curtain wall keel of this embodiment includes a vertical keel 1 and two horizontal keels 2 connected to both sides of the vertical keel 1 through a connecting assembly. The vertical keel 1 is provided with a through installation hole 10, The transverse keel 2 has a transverse inner expansion groove 21, and the connection assembly includes a sliding joint 3 that can pass through the through installation hole 10 and move along the transverse inner expansion groove 21. The sliding joint 3 is installed through the through installation hole 10 and can Rotating relative to the through installation hole 10, the sliding joint 3 has two connecting parts 31 that are respectively located in the transverse inner expansion grooves 21 of the two transverse keels 2 and only slide and fit with the transverse inner expansion grooves 21. The vertical keel 1 and the The sliding member 3 is fixedly conn...

Embodiment 2

[0046] The internal triple connection structure of the curtain wall keel of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 4 and Figure 5 As shown, the transverse keel 2 and the sliding joint 3 of this embodiment are also fixedly connected through the second fastening assembly, and the second fastening assembly is two fourth fastening screws 104, and each fourth fastening screw 104 is connected tightly at the same time. Fix the connecting part 31 of the holder 4 , the transverse keel 2 and the sliding joint 3 . Adding the second fastening component to connect the fastening transverse keel 2 and the sliding joint 3 can further improve the stability and reliability of the connection.

[0047] In this embodiment, the fourth fastening screw 104 is accommodated in the laterally expanded groove 21, the fourth fastening screw 104 is not exposed, and will not affect the installation of the curtain wall panel, and the curtain wa...

Embodiment 3

[0049] The internal triple connection structure of the curtain wall keel of this embodiment is basically the same as that of Embodiment 2, the main difference is that, as Figure 6 As shown, the vertical keel 1 of this embodiment does not have a vertically inwardly expanding groove 11, and the front of the vertical keel 1 is a plane. The first fastening component is a second fastening screw 102 , and the second fastening screw 102 is screwed and installed on the vertical keel 1 and presses the sliding joint 3 . The second fastening screw 102 in this embodiment does not perforate the sliding joint 3 , does not affect the strength of the sliding joint 3 , and the second fastening screw 102 is easier to install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com