Curtain wall keel connection structure based on inner expansion groove

A connection structure and connection mechanism technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as the influence of keel strength, a large number of connectors and screws, and damage, so as to improve the simplicity and delicacy of the appearance and improve the anti-bacteria Anti-corrosion ability, reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

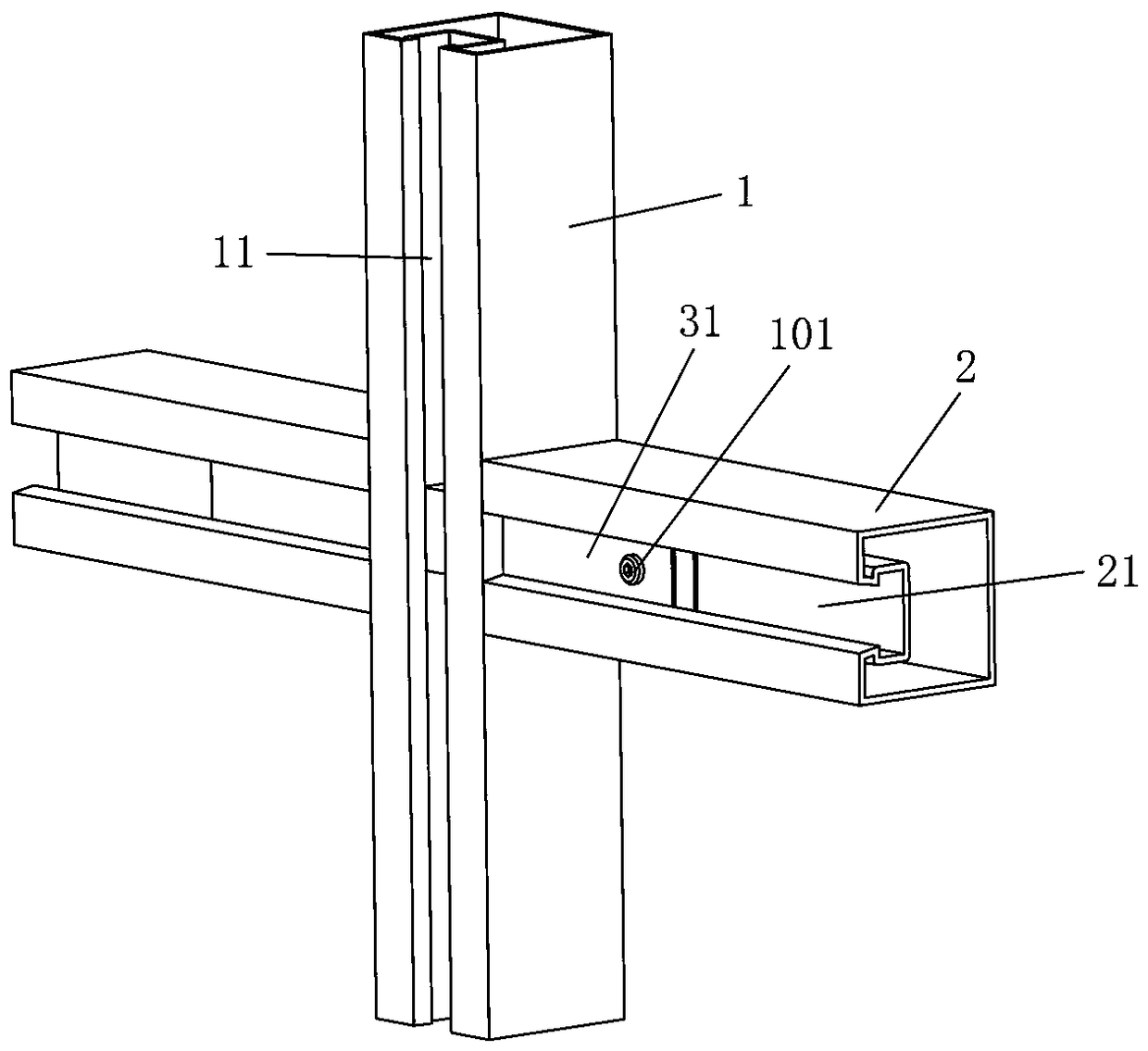

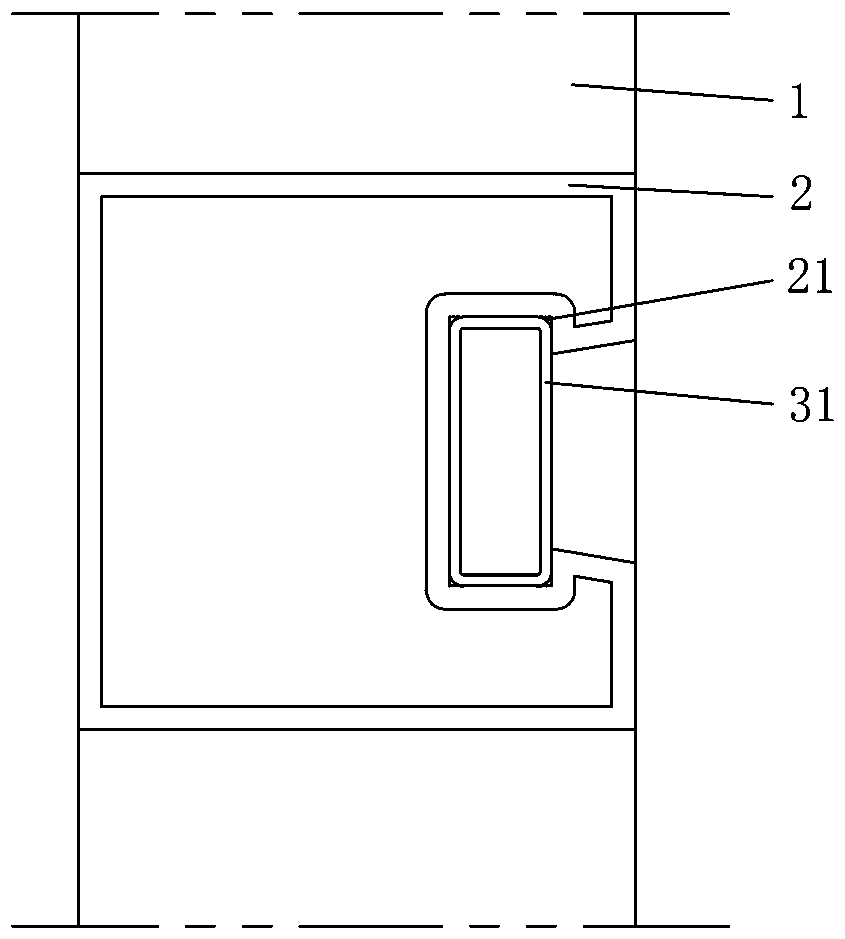

[0099] Such as Figure 1 to Figure 3 As shown, the curtain wall keel connection structure of this embodiment includes a vertical keel 1 and two horizontal keels 2 connected to both sides of the vertical keel 1 by connecting components. The vertical keel 1 is provided with a through installation hole 10, and the horizontal keel 2 has a horizontal The inner expansion groove 21, the transverse inner expansion groove 21 is opened on the front of the horizontal keel 2, and the connection assembly includes a sliding member 3 that can pass through the through mounting hole 10 and move along the lateral expansion groove 21, and the sliding member 3 penetrates Installed in the through mounting hole 10 and only slidably fits with the through mounting hole 10, the sliding member 3 has two lateral flared grooves 21 respectively located in the two horizontal keels 2 and only slides with the transverse flared groove 21 In the connecting portion 31, a first fastening component is provided betw...

Embodiment 2

[0104] The curtain wall keel connection structure of this embodiment is basically the same as that of embodiment 1, the main difference is that, as Figure 4 As shown, in this embodiment, only the first fastening component is provided between the vertical keel 1 and the sliding member 3, and the vertical keel 1 does not have a vertical inward expansion groove 11, and the front of the vertical keel 1 is flat. The first fastening component is a second fastening screw 102. The second fastening screw 102 is installed on the vertical keel 1 and presses the sliding part 3, through the friction between the second fastening screw 102 and the sliding part 3 Prevent the sliding member 3 from sliding. The number of screws used in this embodiment is less, the assembly and disassembly are more convenient and quicker, and the surface of the horizontal keel 2 does not require holes, which will not affect the strength of the horizontal keel 2, and the horizontal keel 2 has better rust resistanc...

Embodiment 3

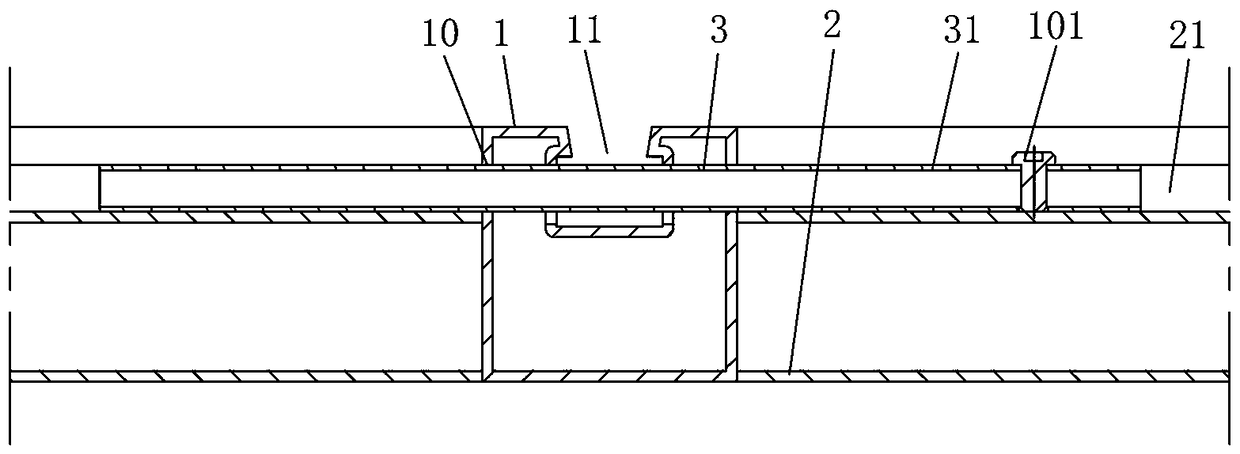

[0106] Such as Figure 5 to Figure 7 As shown, the curtain wall keel connection structure of this embodiment includes a vertical keel 1 and two horizontal keels 2 connected to both sides of the vertical keel 1 by connecting components. The vertical keel 1 is provided with a through installation hole 10, and the horizontal keel 2 has a horizontal The inner expansion groove 21, the connecting assembly includes a sliding member 3 that can pass through the through mounting hole 10 and move along the lateral expansion groove 21, the sliding member 3 is installed in the through mounting hole 10 and can be relative to the through mounting hole 10 rotates, the sliding member 3 has two connecting parts 31 respectively located in the lateral expansion grooves 21 of the two horizontal keels 2 and only slidingly fitted with the lateral expansion grooves 21. The vertical keel 1 and the sliding connection 3 pass The first fastening component is fixedly connected. The sliding member 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com