Patents

Literature

73results about How to "Installation will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Repair method of high-voltage transmission line and failure testing device thereof

InactiveCN101017190ARealize daily maintenanceGuaranteed uptimeTelevision system detailsElectric signal transmission systemsOnline testEngineering

This invention relates to one high voltage transmission test method and fault test device, which is fixed on remote helicopter for high voltage transmission wire for automatic recycle line to realize automatic fault test, wherein, it relates to one remote helicopter fixed GPS receiver, circuit trace system, high voltage circuit distance keeper, 3G real time transmission system, distance recorder and one hanging chamber with one portable test bench for recycle and to send the images through 3G into user terminal for online test.

Owner:杭州里肯科技有限公司

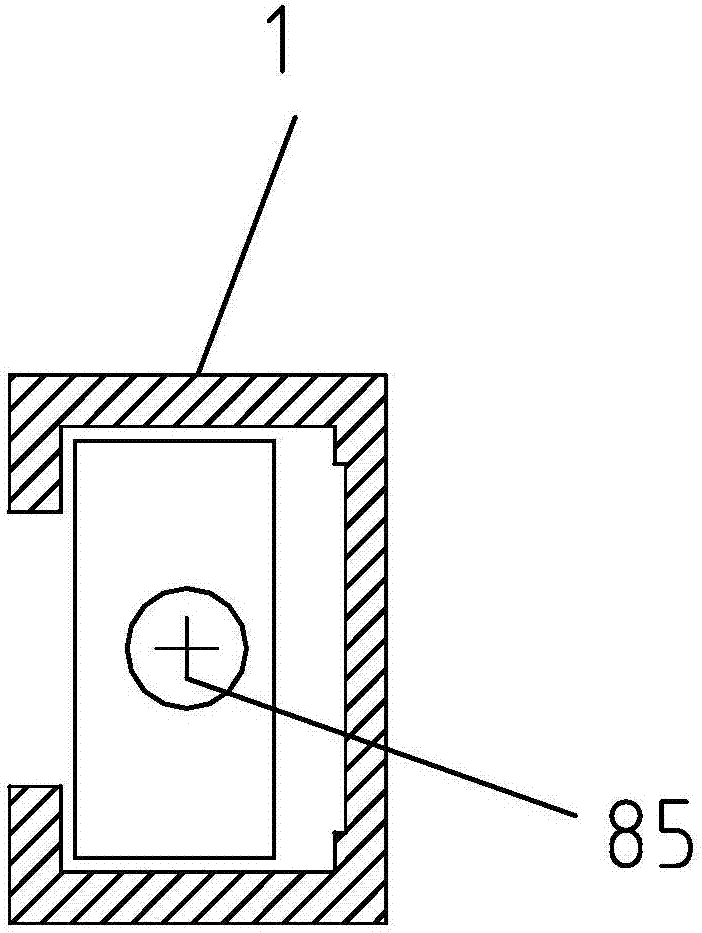

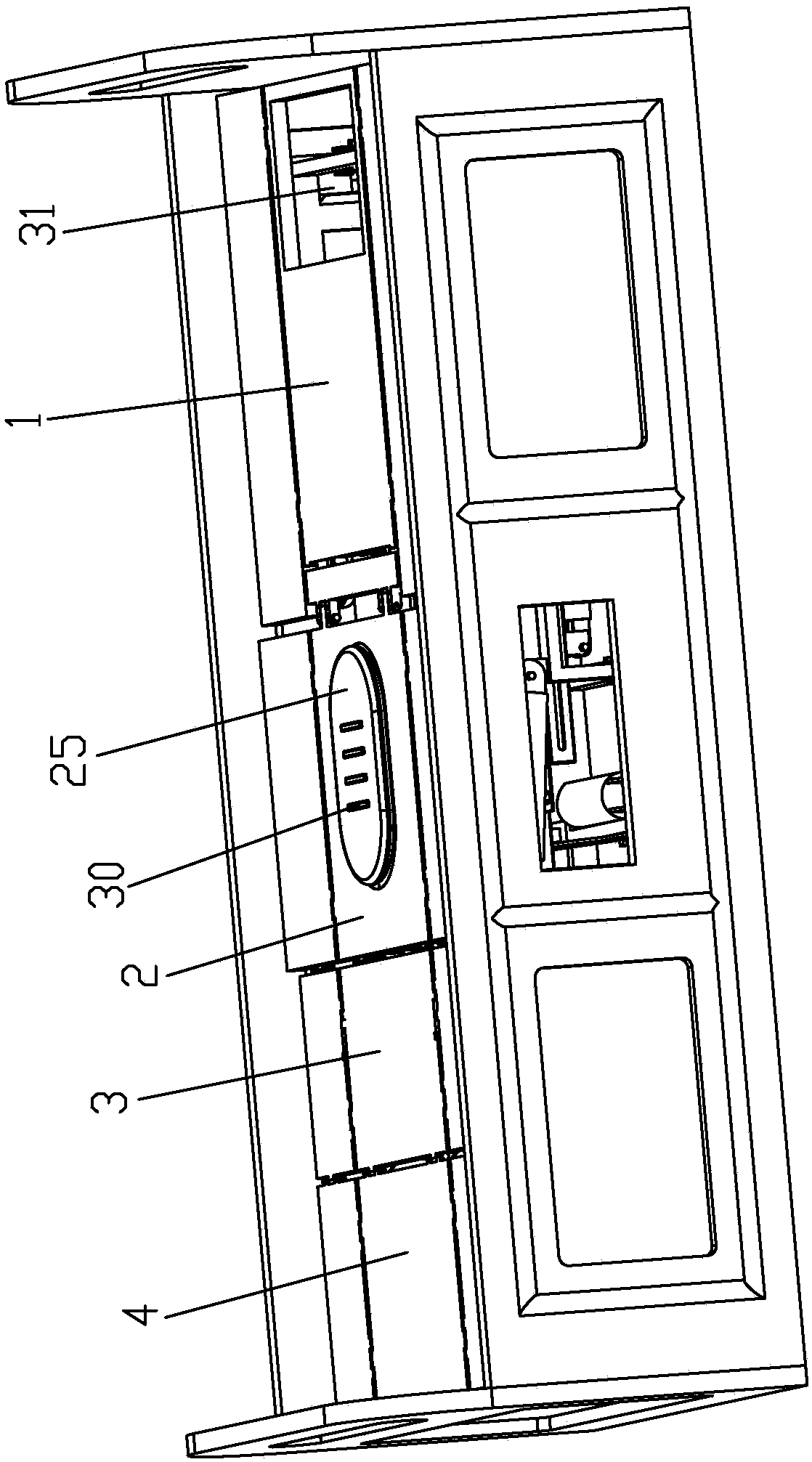

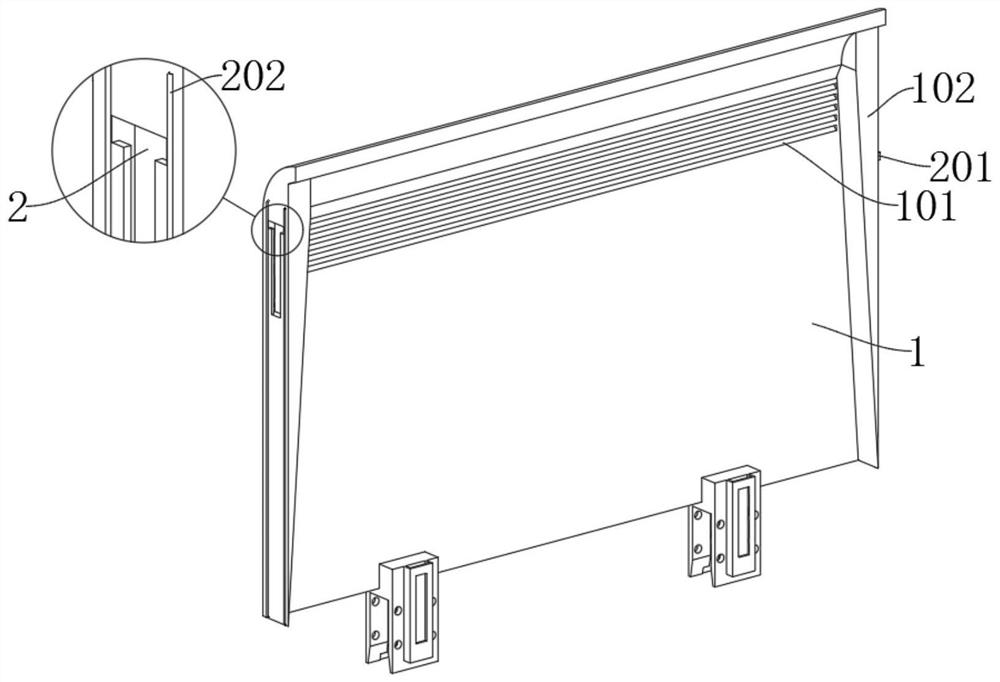

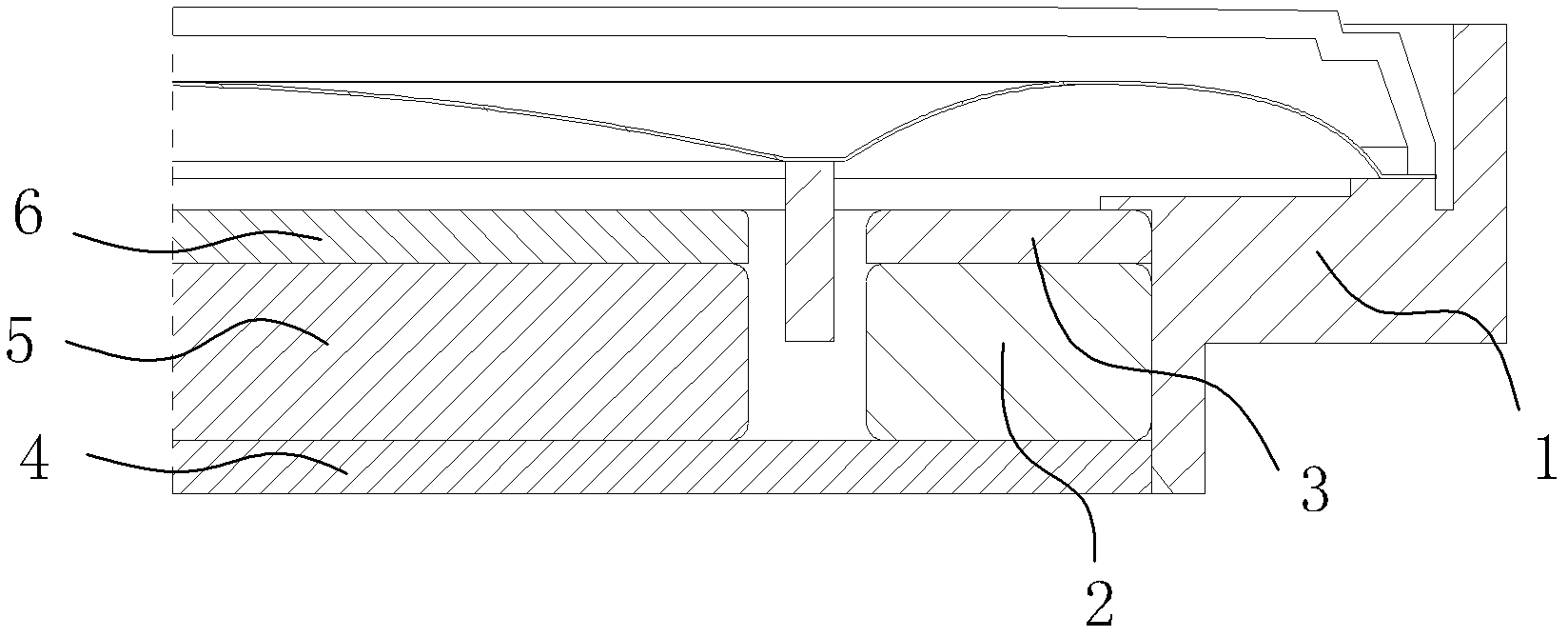

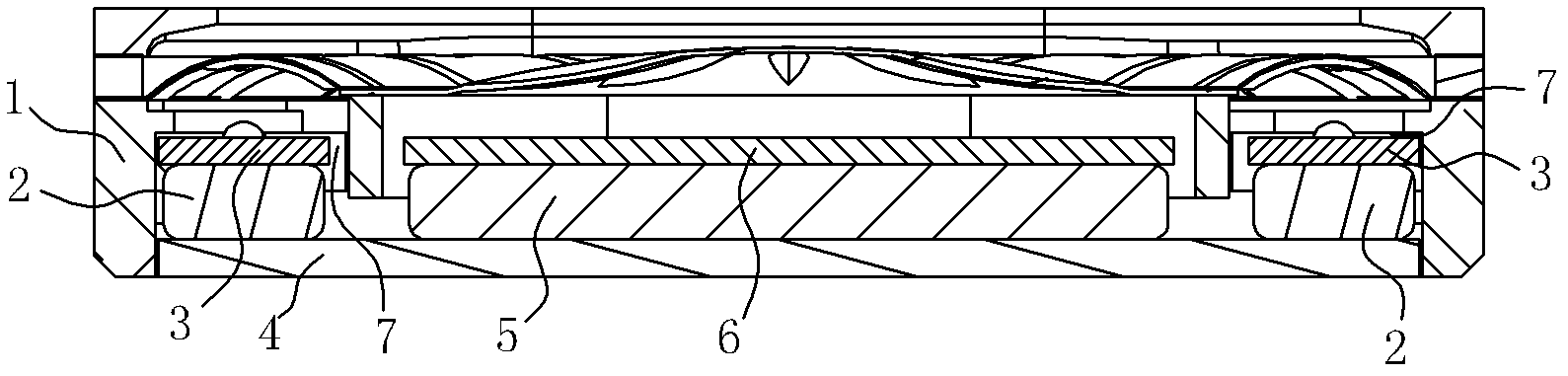

Window closing device and fireproof window containing window closing device

PendingCN107143267AIngenious structural designAchieve automatic shutdownFireproof doorsWing openersWindow openingThermal sensing

The invention relates to a window closing device. The window closing device comprises a first sliding groove arranged on a cross bar at the upper portion of a window opening fan and a sliding block cooperating with the first sliding groove. The sliding block is hinged to a sliding rod through a first tightness adjusting mechanism; a positioning unit is arranged in the first sliding groove; the positioning unit is connected with a second tightness adjusting mechanism; the second tightness adjusting mechanism is connected with a power mechanism through a connecting rod. The power mechanism comprises a fixing unit and a sliding unit; an elastic unit and a thermal sensing element are arranged between the fixing unit and the sliding unit; the sliding rod is connected with a closer arranged on a window frame. The invention also provides a fireproof window containing the window closing device. According to the window closing device, by arranging the first sliding groove and the sliding block cooperated with each other and the thermal sensing element, when the thermal sensing element is heated and broken, the sliding block drives the sliding rod to carry out the linkage, the sliding rod and the closer are cooperated with each other, and the window is opened and closed automatically in the case of fire; the window closing device is matched with the window closing device to realize real fireproof function. The window closing device is exquisite in structure design, does not affect the installation of other devices after the window closing device is installed, is relatively beautiful and strong in practicability.

Owner:青岛万和装饰门窗工程有限公司

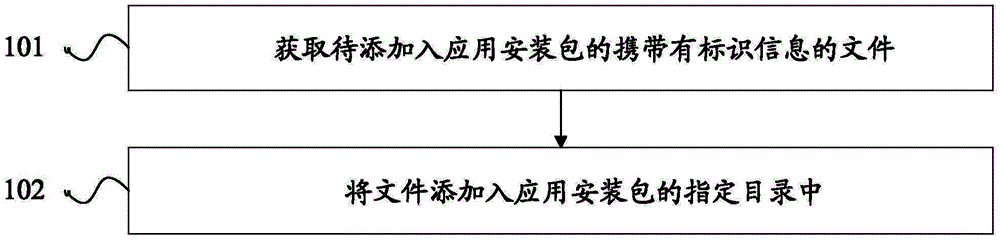

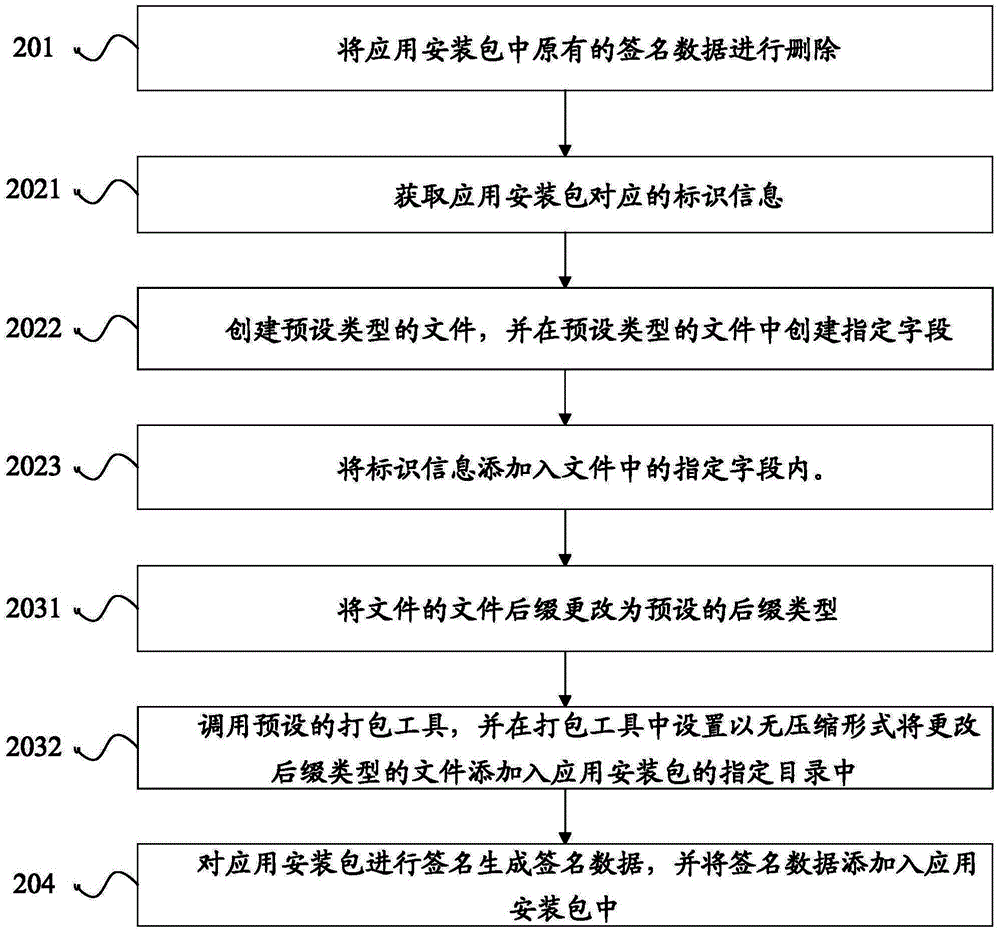

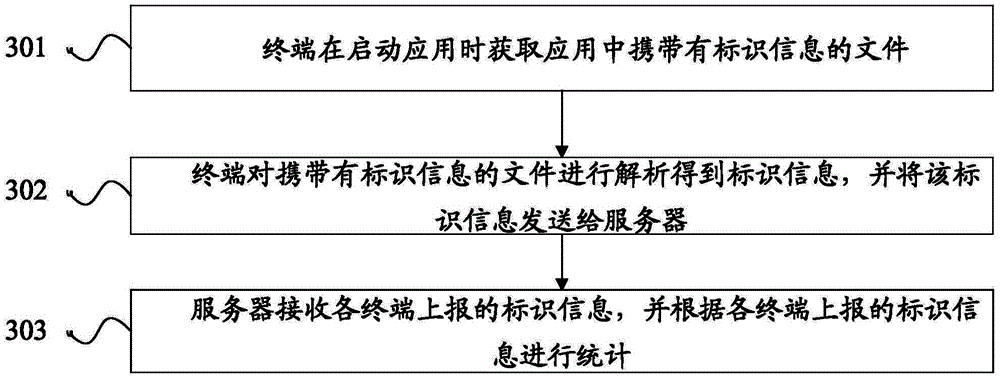

Method and device for adding information to application installation package

ActiveCN104090946ACause compatibility issuesInstallation will not affectFile/folder operationsSpecial data processing applicationsComputer engineering

The invention discloses a method and device for adding information to an application installation package, and belongs to the technical field of computers. The method comprises the following steps of obtaining a file which is to be added to the application installation package and carries the identification information and adding the file to a specified catalog of the application installation package. The file which needs to be added to the application installation package and carries the identification information is added to the specified catalog of the application installation package, wherein files in the specified catalog do not participate in resource numbering in a packaging process of the application installation package. The application installation package does not need to be recompiled when the identification information is added to the application installation package, and therefore files, participating in resource numbering, in the application installation package are not affected, no compatibility problem of the application installation package is caused, and application installation is not affected. Thus, in an application operating process, a terminal feeds data related to operating back to a server through the identification information added to the application installation package.

Owner:GUANGZHOU HUADUO NETWORK TECH

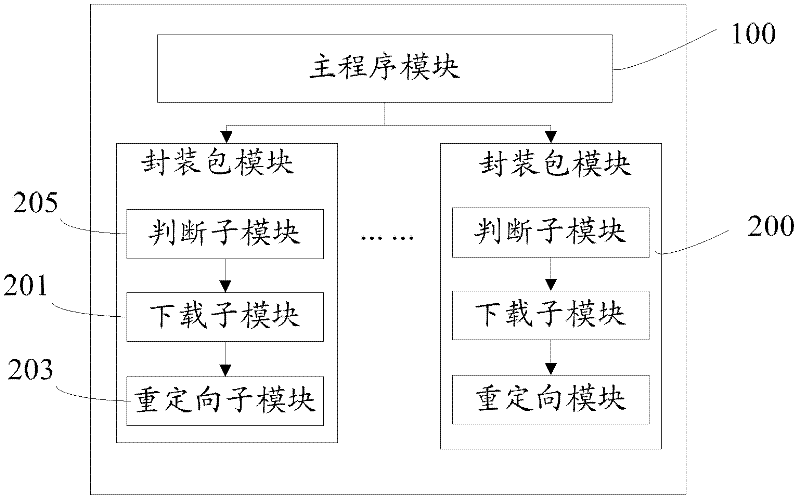

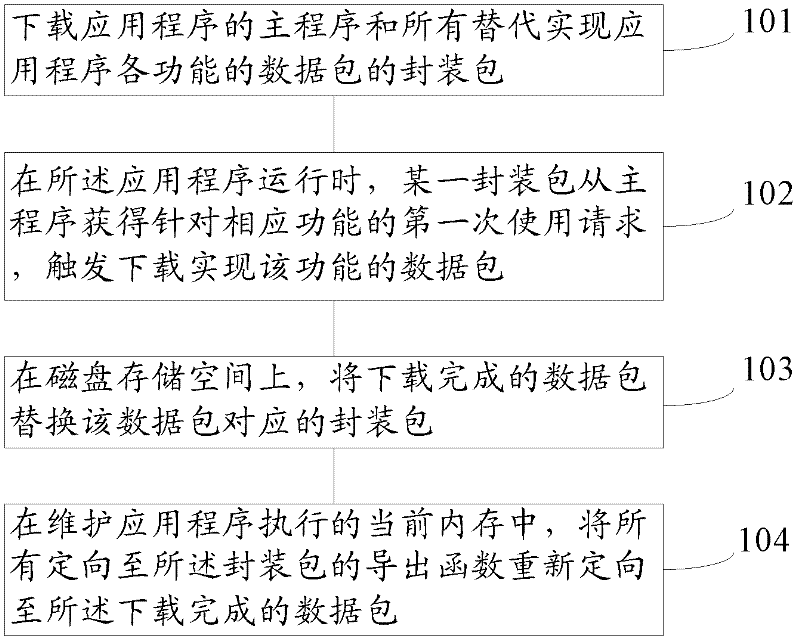

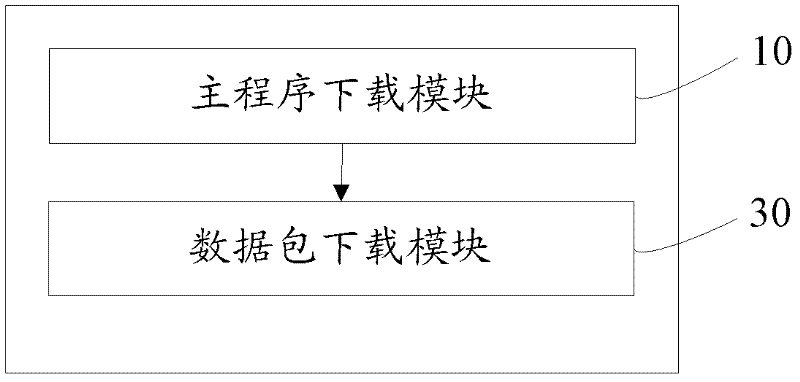

Data processing device, application program downloading method and device

ActiveCN102508677AInstallation will not affectReduce volumeProgram loading/initiatingNetwork packetComputer module

The invention provides a data processing device, which comprises a main program module and at least one package module. The main program module is used for controlling an integral data processing procedure, each package module corresponds to a data packet for realizing various function of the data processing procedure and further consists of a downloading sub-module and a redirection sub-module, the downloading sub-modules are used for downloading the data packet modules corresponding to the package modules and replacing the package modules corresponding to data packet modules with the downloaded data packet modules on a memory space of a disk, and the redirection sub-modules are used for redirecting all the export functions, which are oriented from the main program module to the package modules, to the downloaded data packet modules in current mapping executed for maintaining an application program. The invention further provides an application program downloading method and a device. The data processing device, the application program downloading method and the device can solve the problem that installation of a large-size application program is affected due to long downloading consumed time.

Owner:三六零数字安全科技集团有限公司

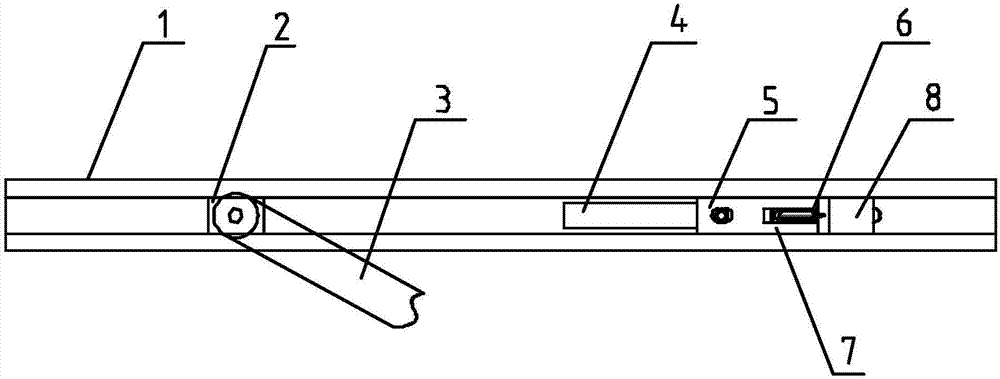

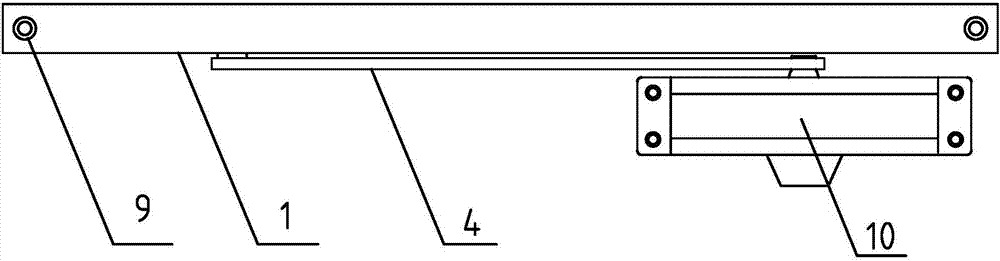

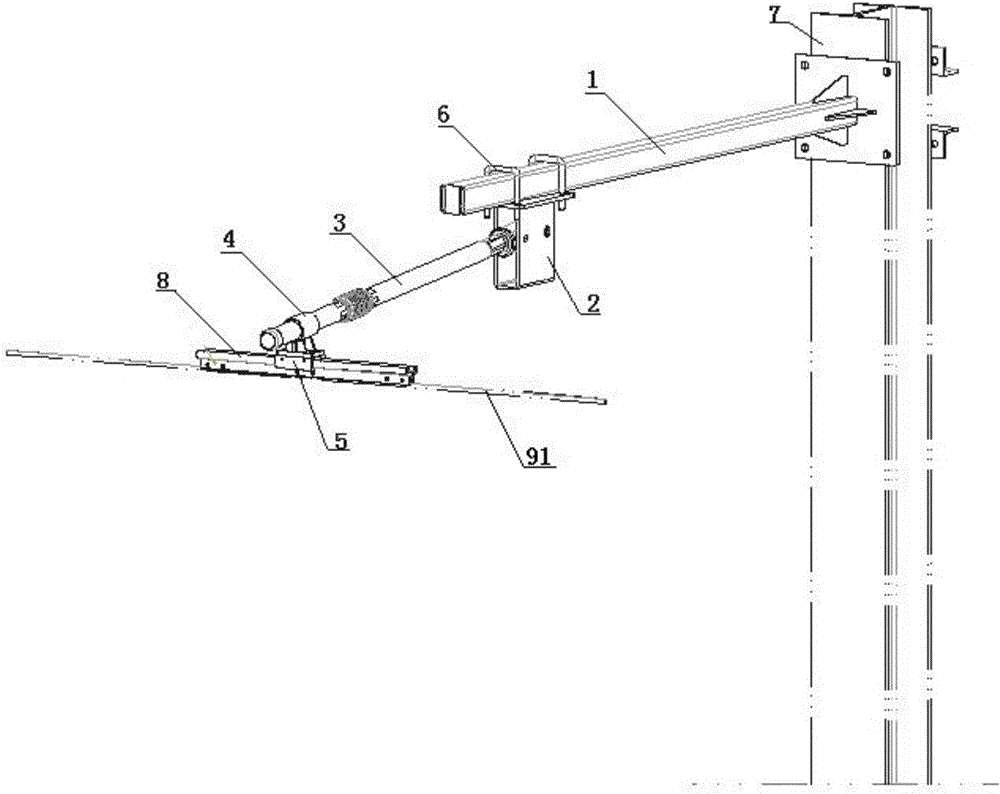

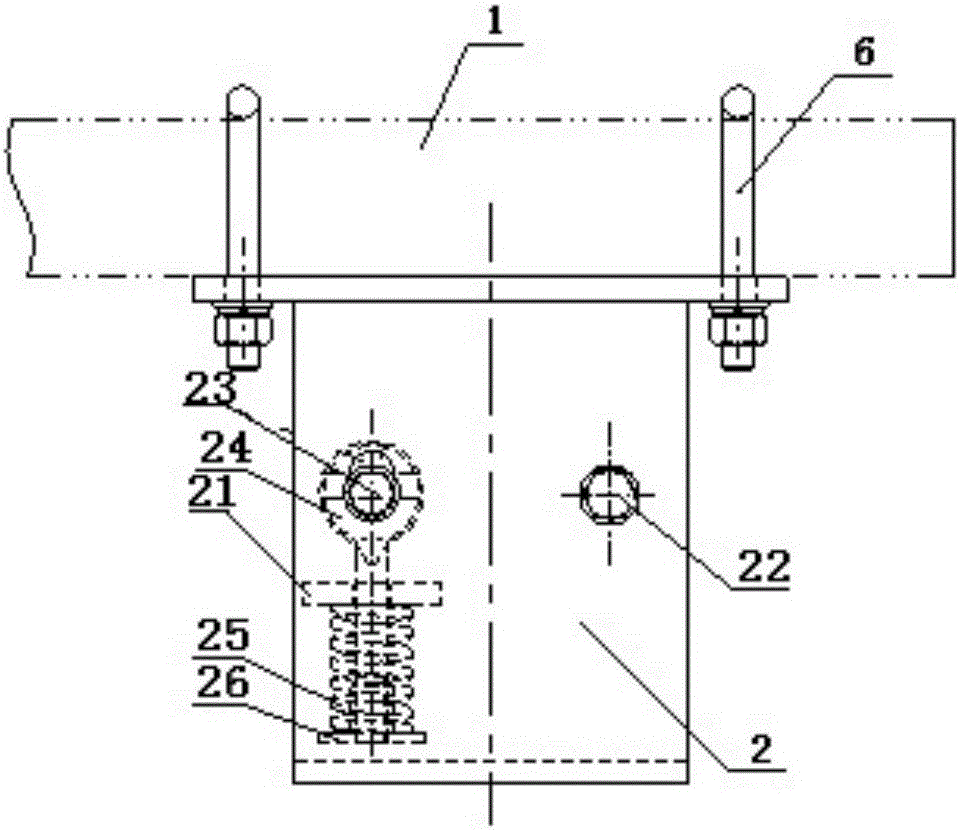

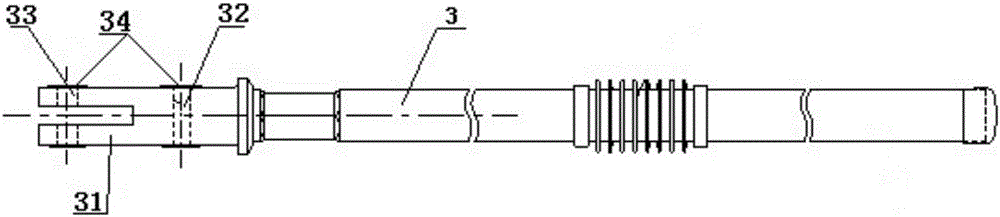

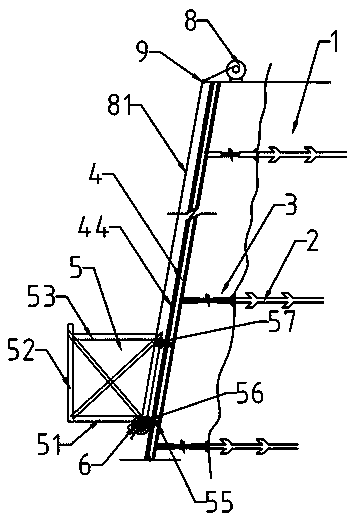

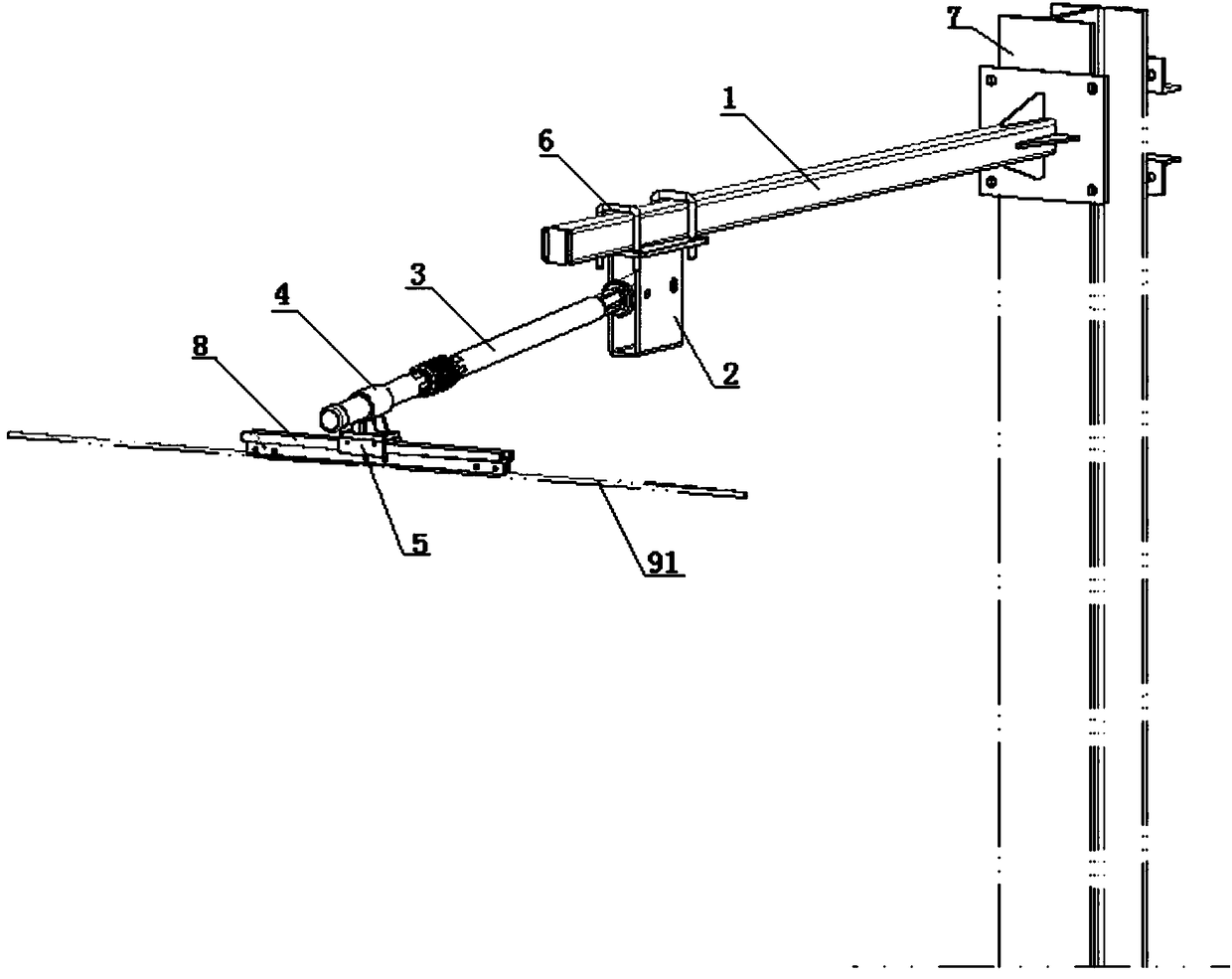

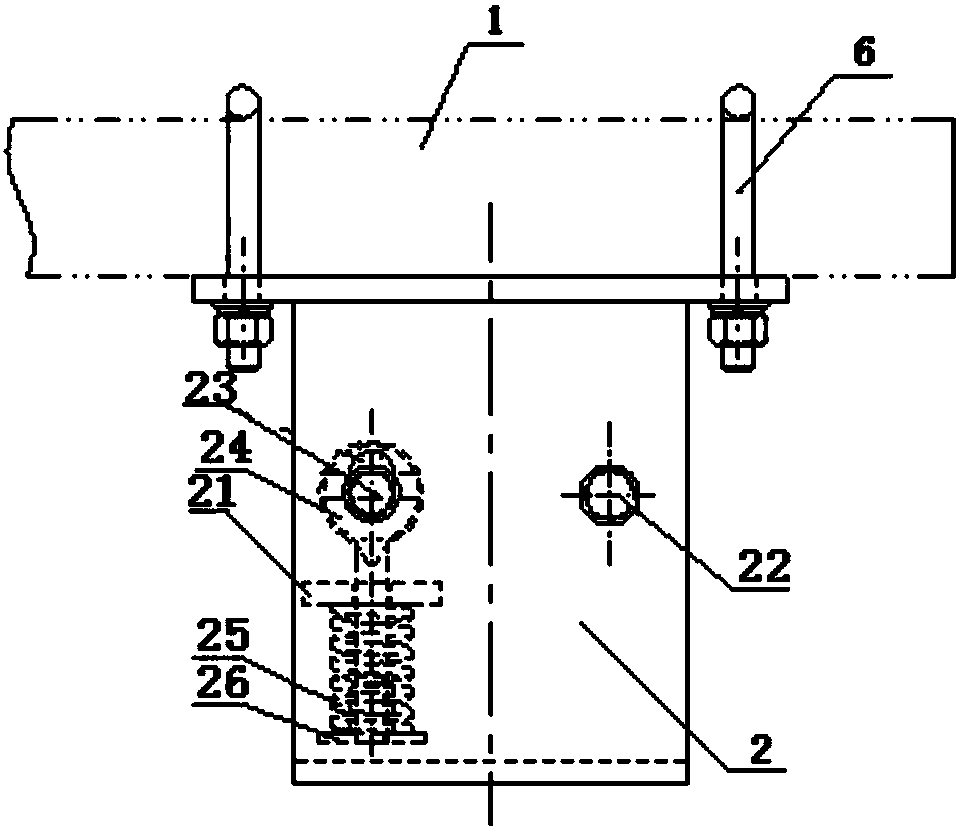

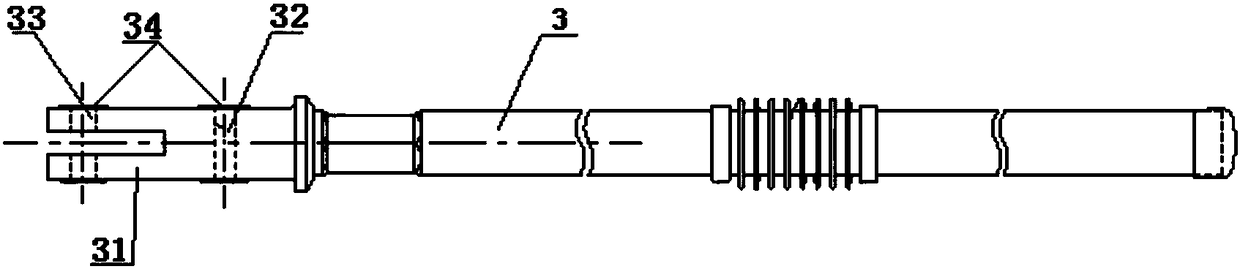

Tramcar contact line sliding type elastic suspension device

ActiveCN105730282AImprove space utilizationMeet the requirements of landscapingTrolley linesEngineeringContact line

The invention discloses a tramcar contact line sliding type elastic suspension device. The tramcar contact line sliding type elastic suspension device comprises a rigid cantilever. The rigid cantilever is of a square tube structure, the inner end of the rigid cantilever is fixed to a supporting column, and a positioning supporting seat is fixed to the outer end of the rigid cantilever through U-shaped bolts. An insulation positioning tube is elastically hinged to the positioning supporting seat. A holder is fixed to the outer end of the insulation positioning tube. A sliding block is horizontally fixed to the lower portion of the holder. A horizontal sliding rail is installed on the sliding block. Groove clamping plates are arranged on the lower portion of the horizontal sliding rail. The problems that existing contact line suspension devices are complex in structure and large in occupied space are solved, and the tramcar contact line sliding type elastic suspension device has the characteristics of being simple in structure, light, handy, high in space utilization rate and the like.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

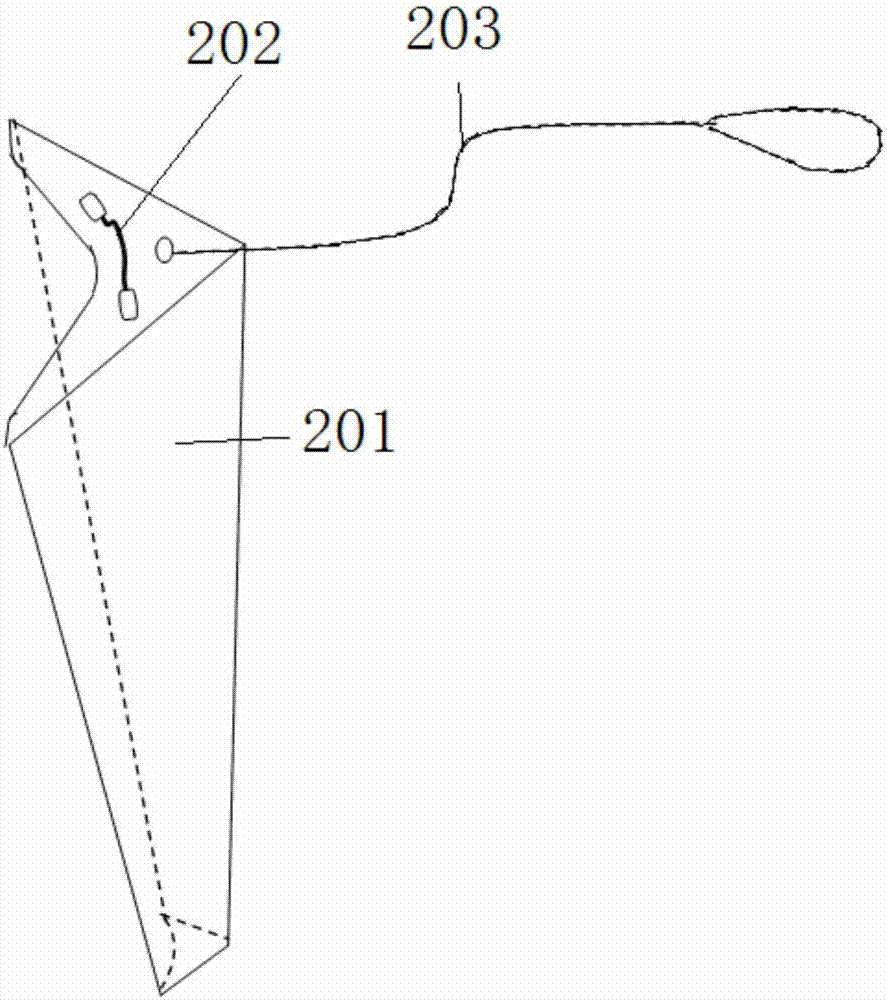

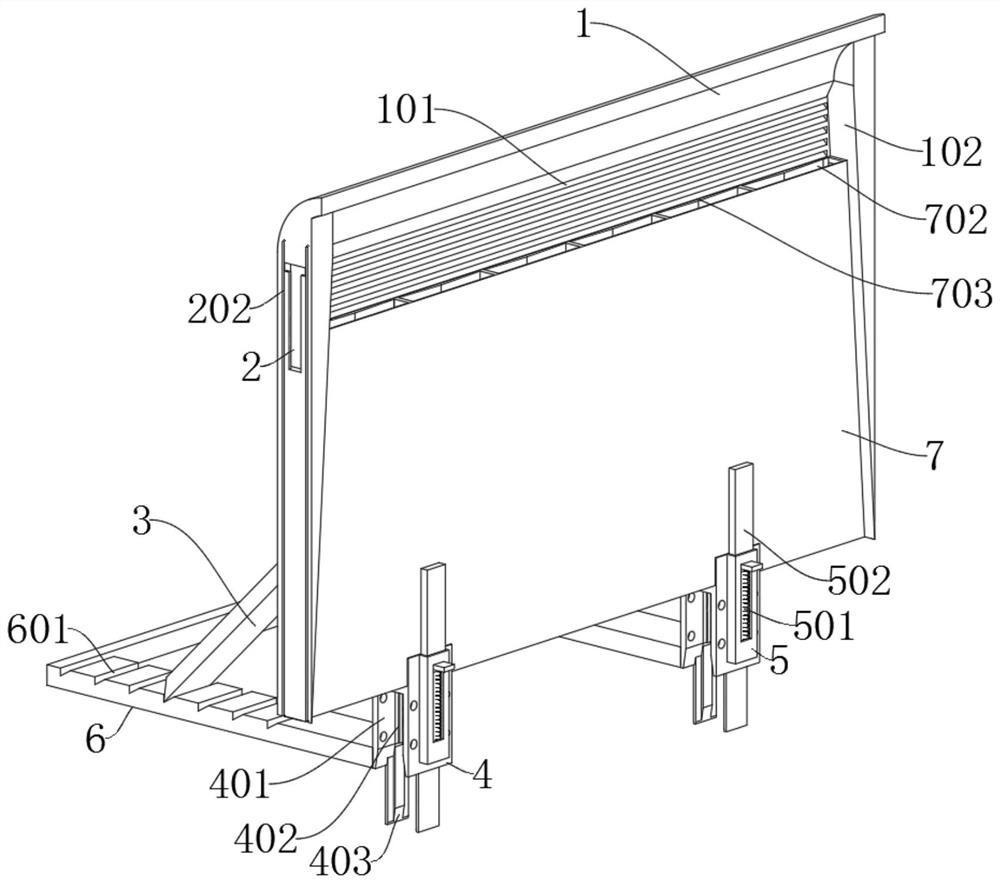

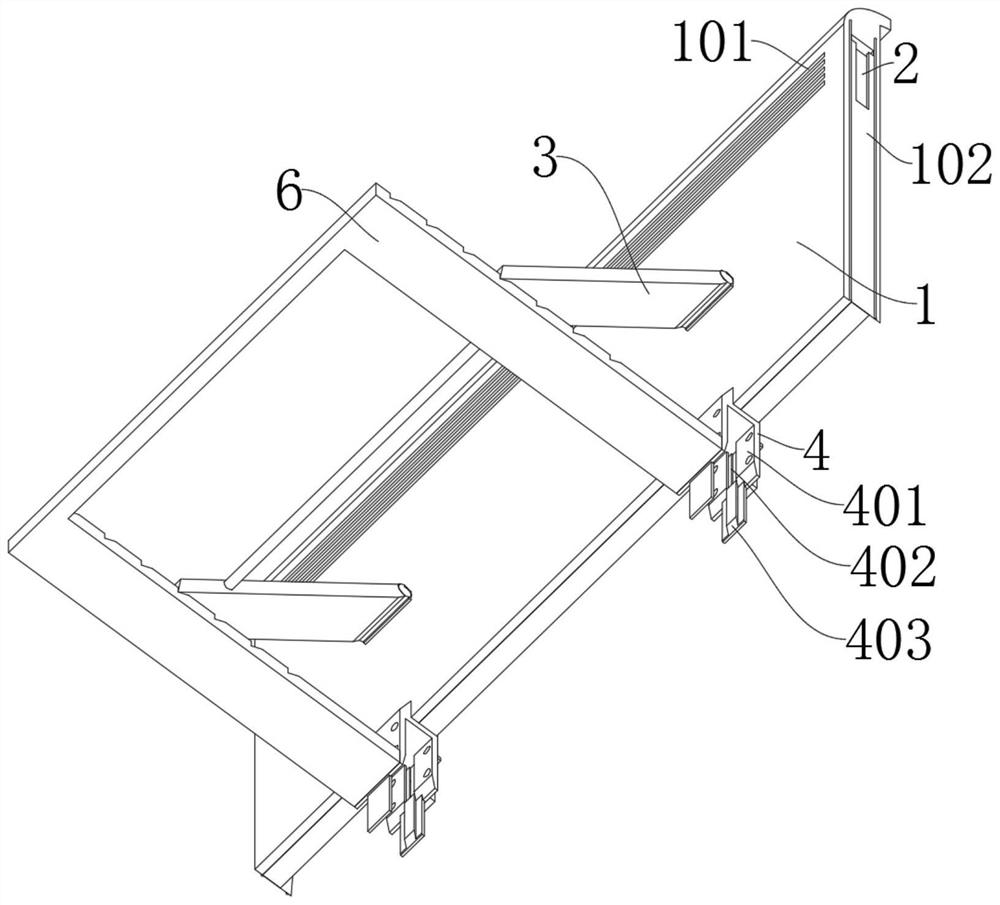

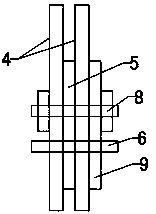

Auxiliary operating platform rack for supporting high and steep side slope and mounting method of auxiliary operating platform rack

PendingCN110004952AInstallation will not affectThe connection structure is stableExcavationsBulkheads/pilesEngineering

The invention discloses an auxiliary operating platform rack for supporting a high and steep side slope and a mounting method of the auxiliary operating platform rack. The auxiliary operating platformrack includes rails arranged in the width direction of the side slope at intervals and mounted outside a side slope soil layer, the auxiliary operating platform rack is characterized in that an operating carriage provided with rollers at the lower end is arranged on each rail, and the operating carriages can slide up and down in the length direction of the rails and locate; and a plurality of regulating brackets fixedly connected with the rails are arranged at the lower end of each rail in the length direction of the rails at intervals, the regulating brackets can shrink upward and can be fixed in the length direction, and the outer ends of the regulating brackets are fixedly connected with an anchor plate for connecting with anchor rods. The obtained auxiliary operating platform rack forsupporting the high and steep side slope and the mounting method of the auxiliary operating platform rack can be applied to irregular high and steep side slope mounting, the mounting structure is stable and firm, the operating platform rack is stable in operation and can transport materials, and extremely high practicability is provided.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

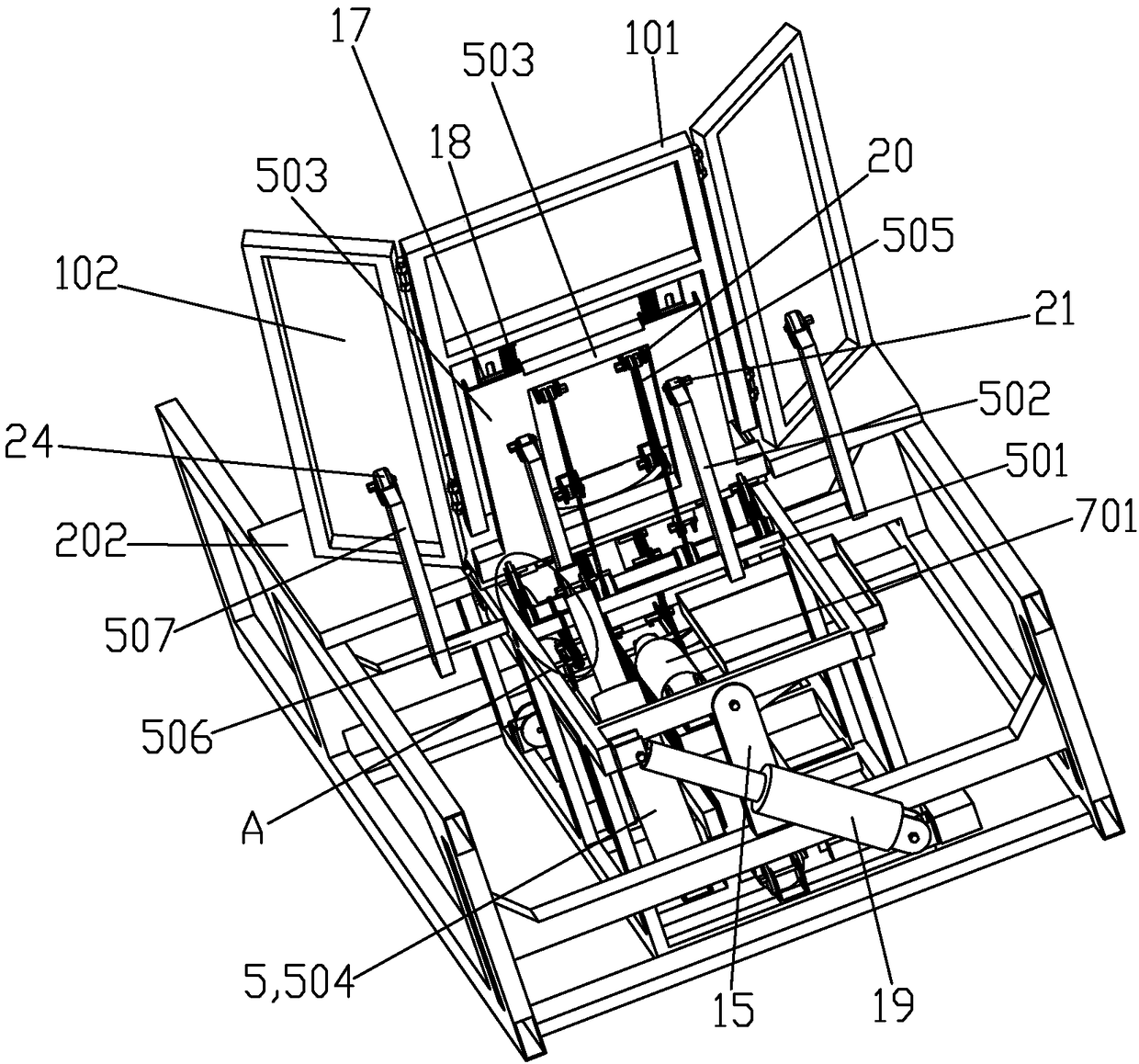

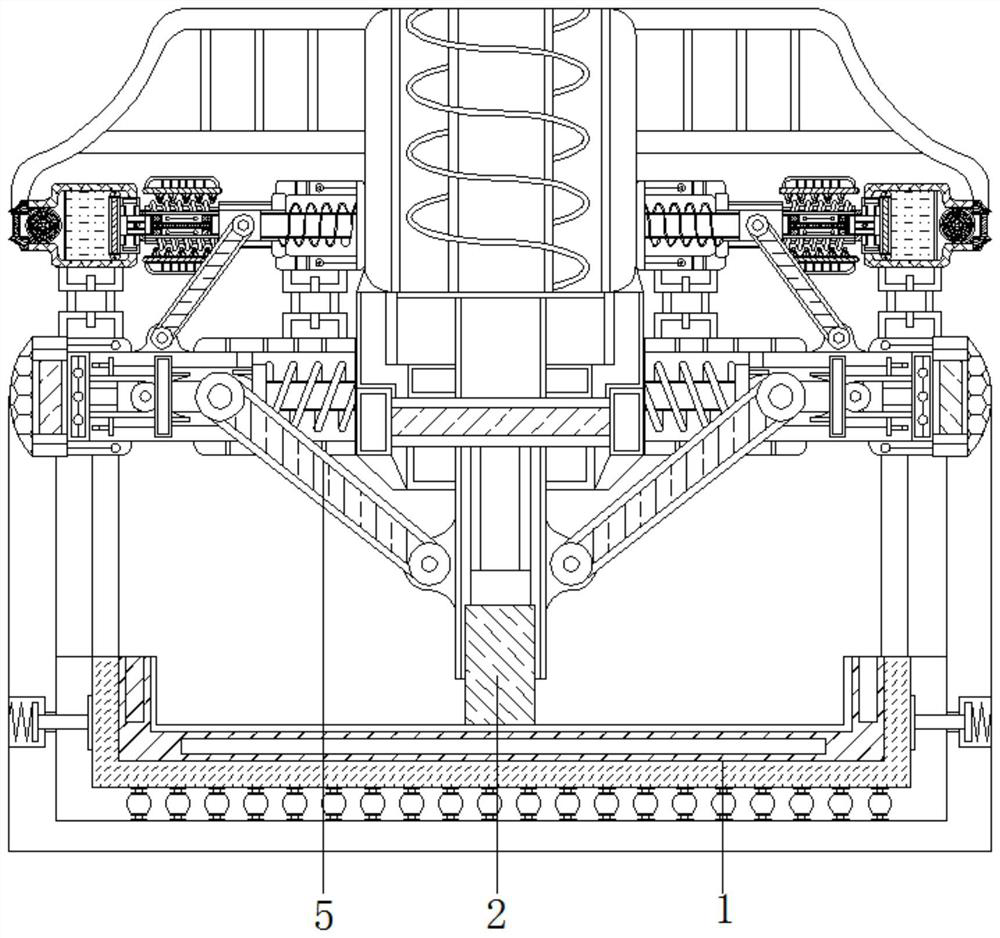

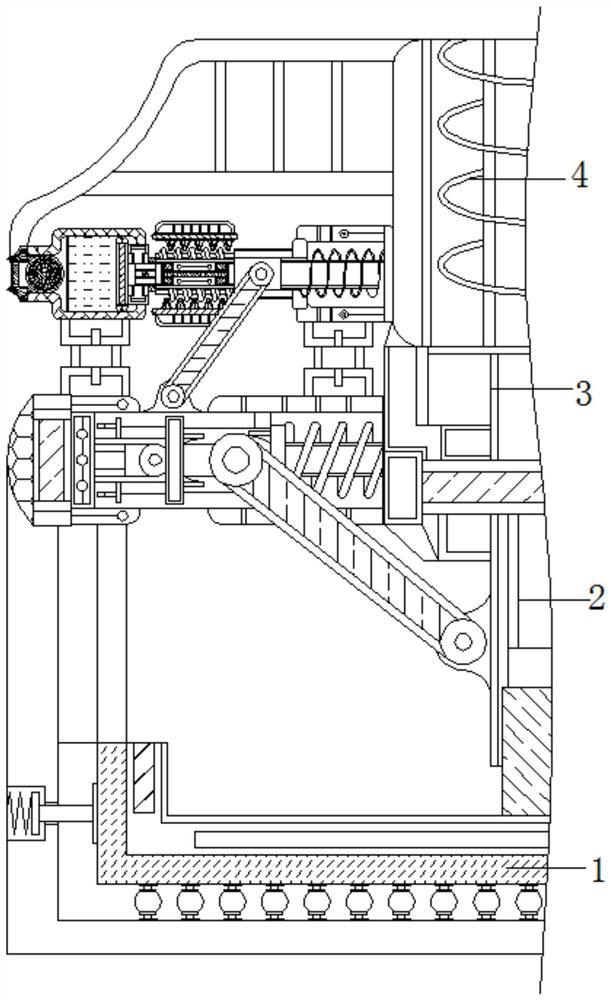

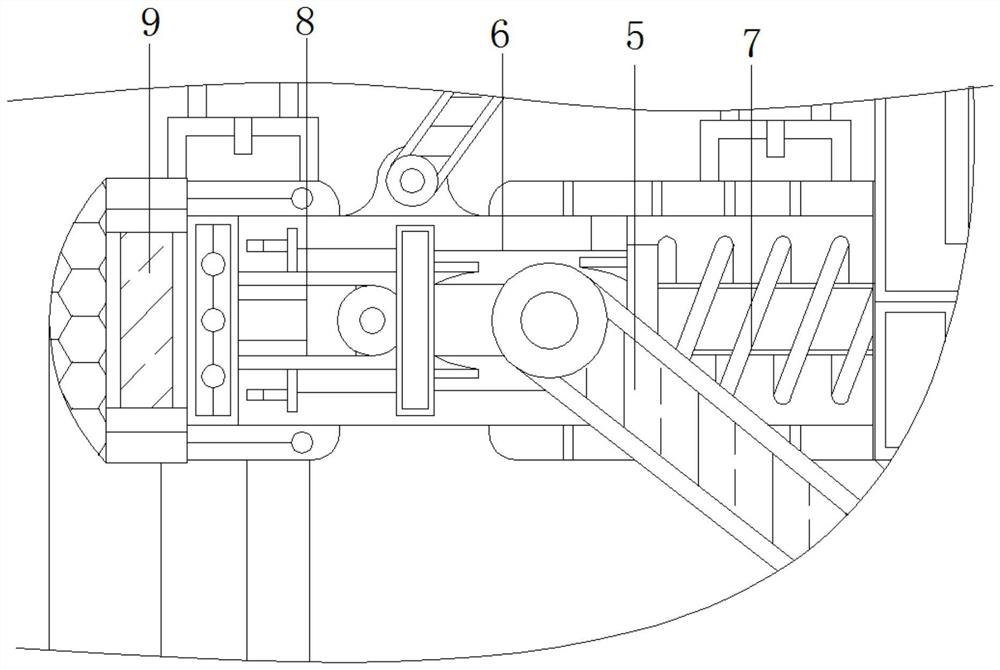

Multifunctional nursing bed and working method thereof

PendingCN108542646AEasy to wash your hairEasy to take a bathNursing bedsAmbulance serviceEngineeringHead of bed

The invention discloses a multifunctional nursing bed and a working method thereof. By means of the technical scheme, the multifunctional nursing bed is characterized by comprising a bed frame, a bedboard is arranged on the bed frame, the bed board sequentially comprises a back board, a middle board, a leg board and a foot board from the bed head to the bed tail, the two outer sides of the back board and the two outer sides of the middle board are all arranged on the bed frame, one end of the leg board is hinged to the middle board, the other end of the leg board is hinged to the foot board,a first driving device for driving the back board to turn up towards the bed tail is arranged on the lower side of the bed board, and a second driving device for driving the foot board to rise and fall is arranged on the lower side of the bed board. The multifunctional nursing bed integrates the functions of being easy to clean after defecation and beneficial for head washing, bathing, side turning, urine wetness sensing, foot washing, back rising, leg lifting, leg lowering, moving and the like for a patient, and various structural configurations are reasonable and compact.

Owner:中山市恒文床业科技有限公司

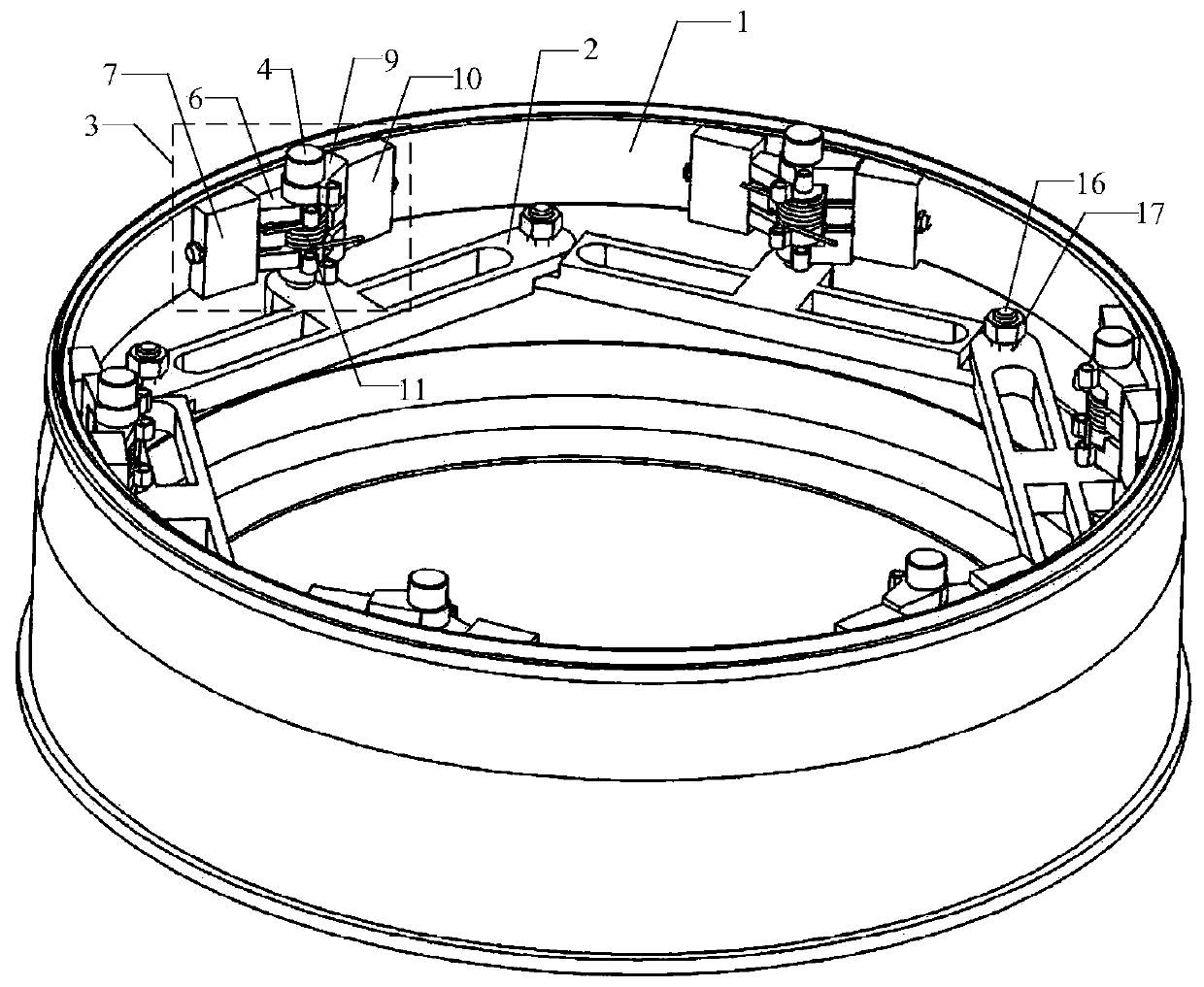

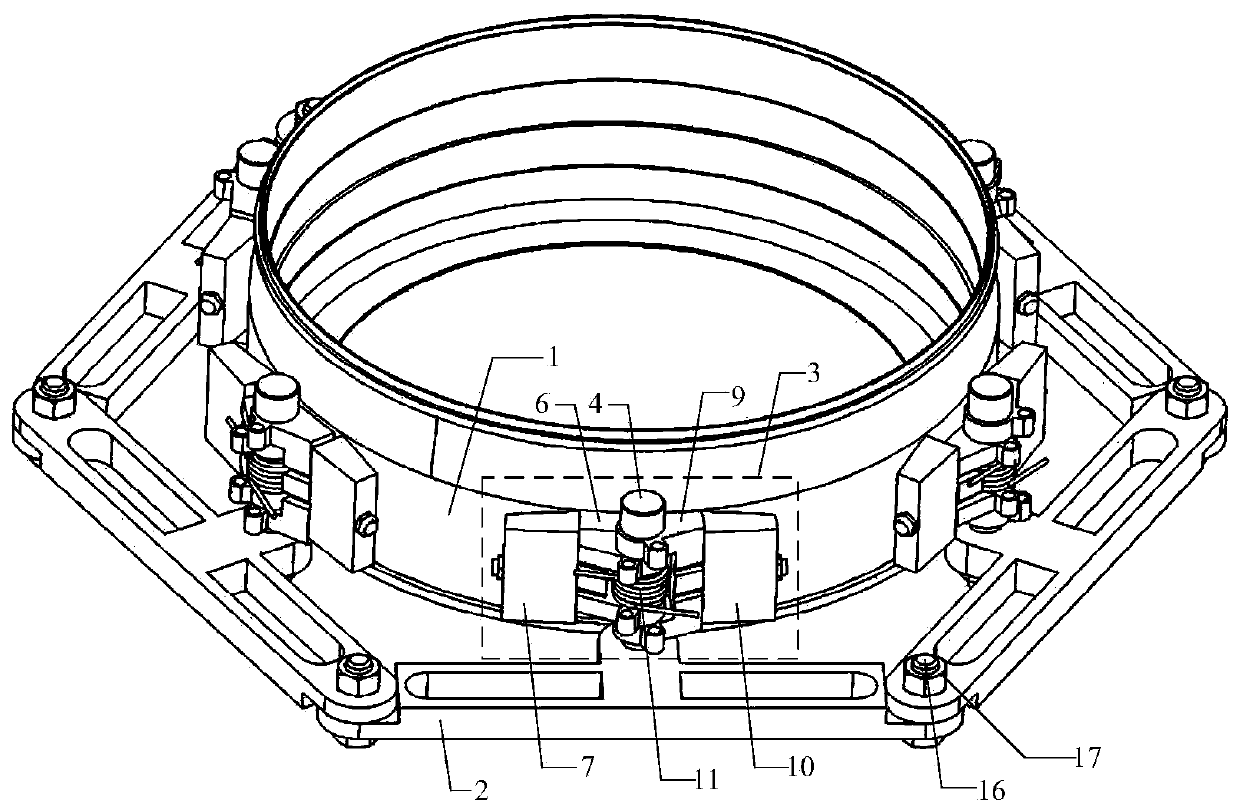

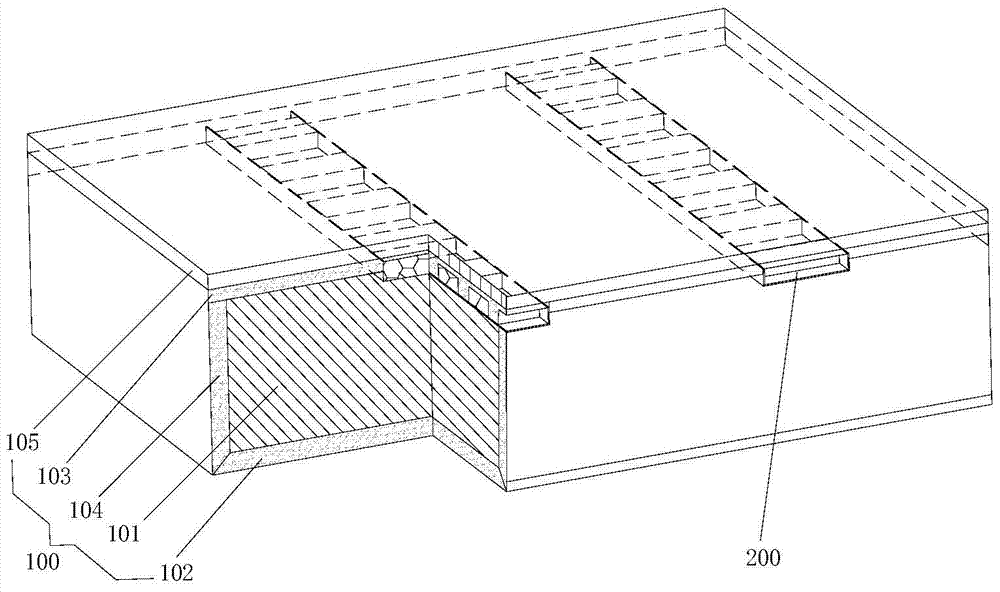

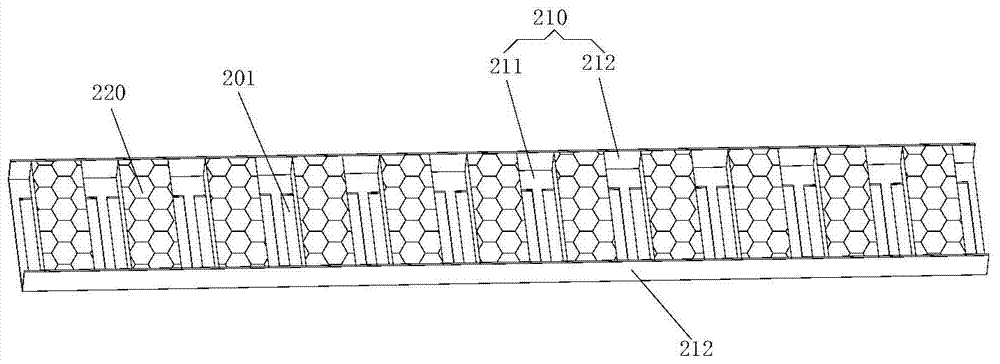

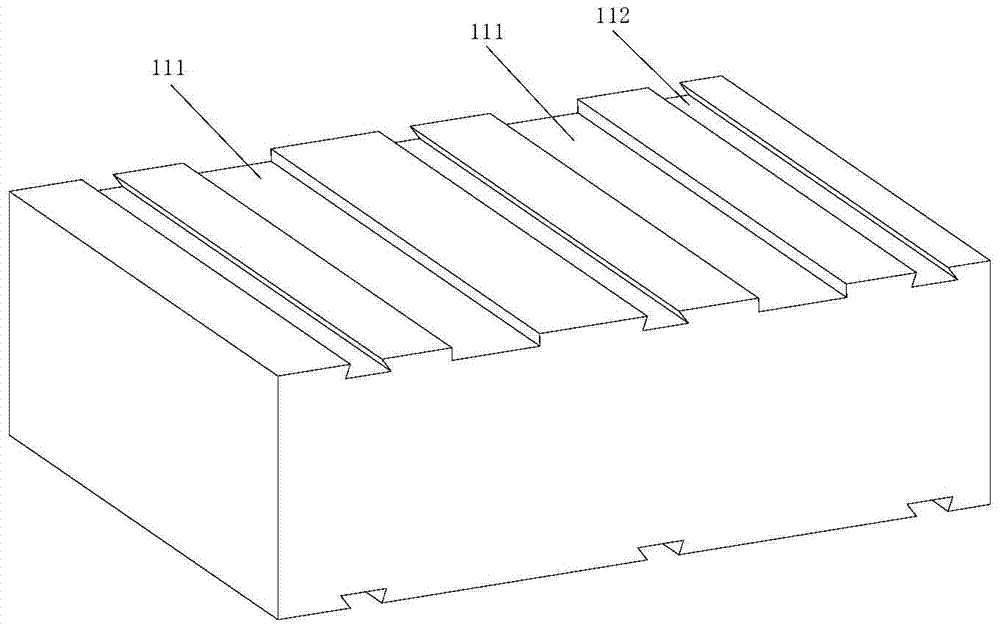

Auxiliary clamp for inhabiting cutting machining vibration of thin-walled casing

InactiveCN111113080AReduce vibrationImprove machining accuracyWork clamping meansPositioning apparatusMachining vibrationsSurface mounting

The invention discloses an auxiliary clamp for inhibiting cutting machining vibration of a thin-walled casing. The vibration of the thin-walled casing in a machining process can be effectively inhibited by fixing the auxiliary clamp to the inner wall or the outer wall of the thin-walled casing through the cooperation of a spring unit group and a hexagonal frame, so that the machining precision ofthe thin-walled casing is improved; the practicability is high, and the auxiliary clamp is fixed to the inner wall or the outer wall of the thin-walled casing according to the difference of the machining surfaces of the thin-walled casing; the auxiliary clamp can be adjusted correspondingly along with the change of the application environment by only changing the length of a connecting rod for thin-walled casings with different sizes, so that the application range is wide; a machine tool is not required to be improved, the auxiliary clamp is easy to use and low in cost; the auxiliary clamp iseasy to mount without the help of other power devices, and is suitable for different machining processes; the auxiliary clamp is simple in structure, and cannot affect the machining of various characteristic surfaces of the thin-walled casing; and enough knife feeding and retracting space is reversed even when the surface mounted with the auxiliary clamp is machined, so that as many characteristicsurfaces as possible can be machined in one mounting, and the mounting frequency is reduced.

Owner:BEIHANG UNIV +1

Steel bending equipment for steel machining

InactiveCN112139303AImprove fluencyEasy to wipeShaping toolsMetal-working feeding devicesStructural engineeringManufacturing engineering

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

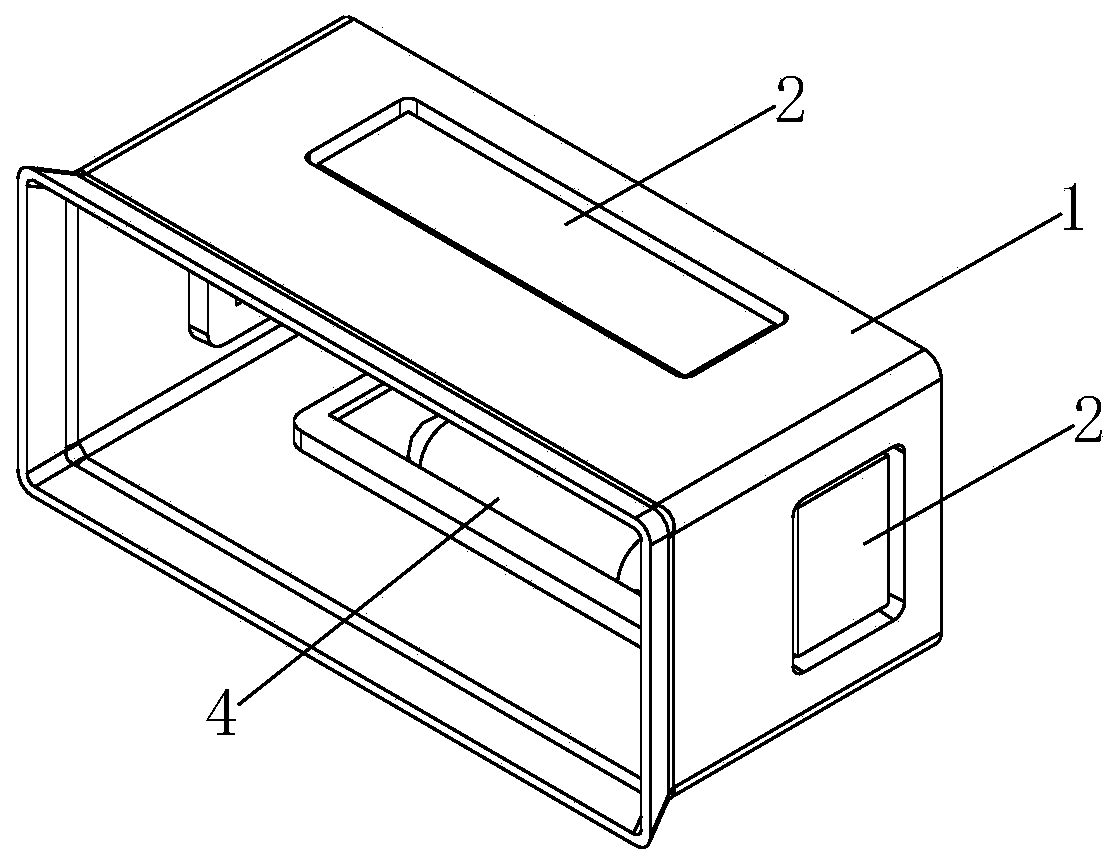

Ultraviolet sterilization and disinfection device

PendingCN111361395AEasy to installDoes not affect normal dockingAir-treating devicesVehicle heating/cooling devicesEngineeringLED lamp

The invention discloses an ultraviolet sterilization and disinfection device. The device comprises a mirror surface support of a frame structure, a PCB arranged inwards is arranged on the side wall ofthe mirror surface support, UVC LED lamp beads are installed on the PCB, and the UVC LED lamp beads are covered with a lens. The PCB arranged inwards is additionally arranged on the side wall of themirror surface support, and the UVC LED lamp beads are mounted on the PCB, so that the sterilization and disinfection device can be conveniently inserted into the interface of an air duct without influencing normal butt joint between the air ducts, repeated mold opening of an air duct system due to configuration difference is reduced, and the cost is reduced; ultraviolet rays emitted by the UVC LED lamp beads are irradiated to air flowing through the air duct, and DNA or RNA molecular structures in bacteria and viruses are destroyed by short waves of the ultraviolet rays to cause death of growth cells or regeneration cells, so that the effects of sterilization and disinfection are achieved, and sterile air is continuously output; and the lens enables the UVC LEDs to emit light more uniformly through an optical refraction principle, so that the sterilization and disinfection effects are improved. The device is suitable for automobiles.

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

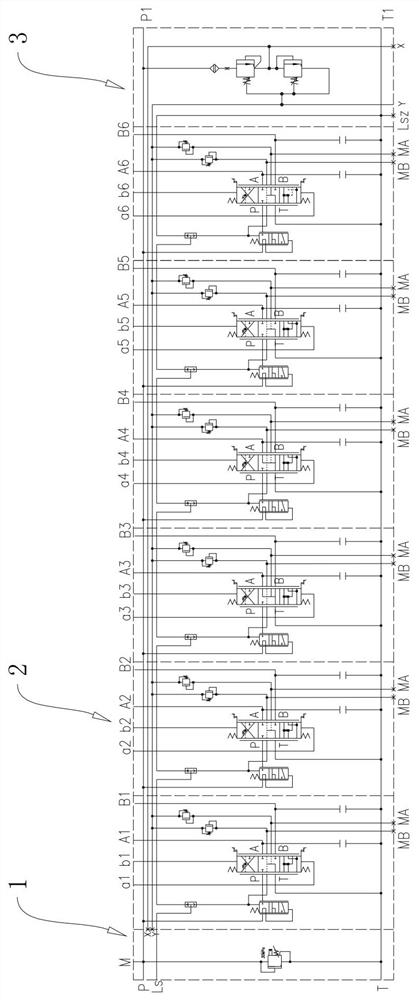

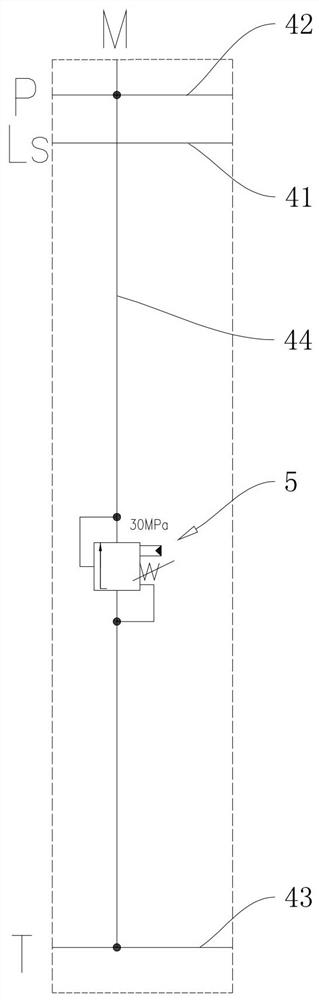

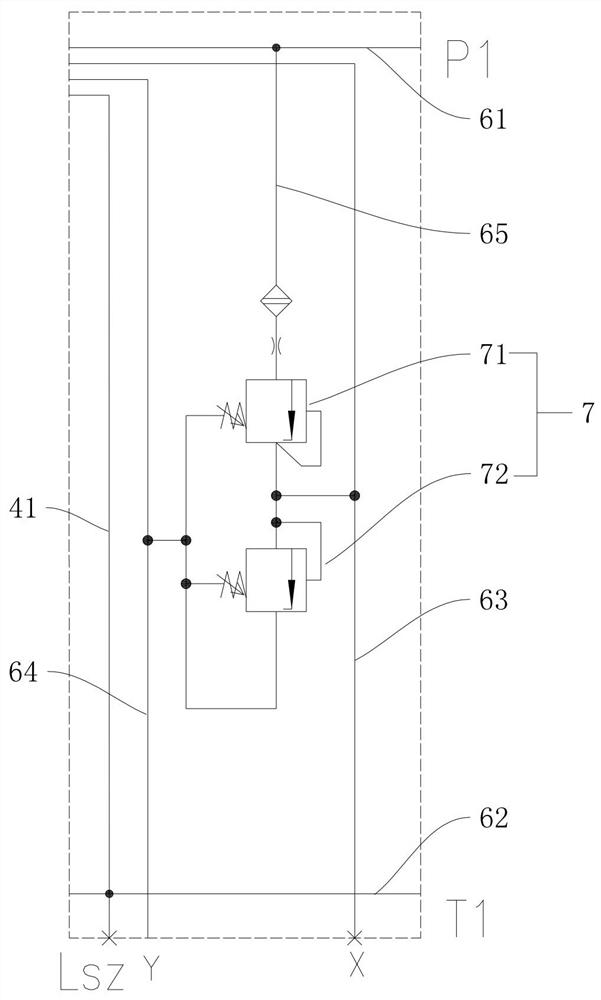

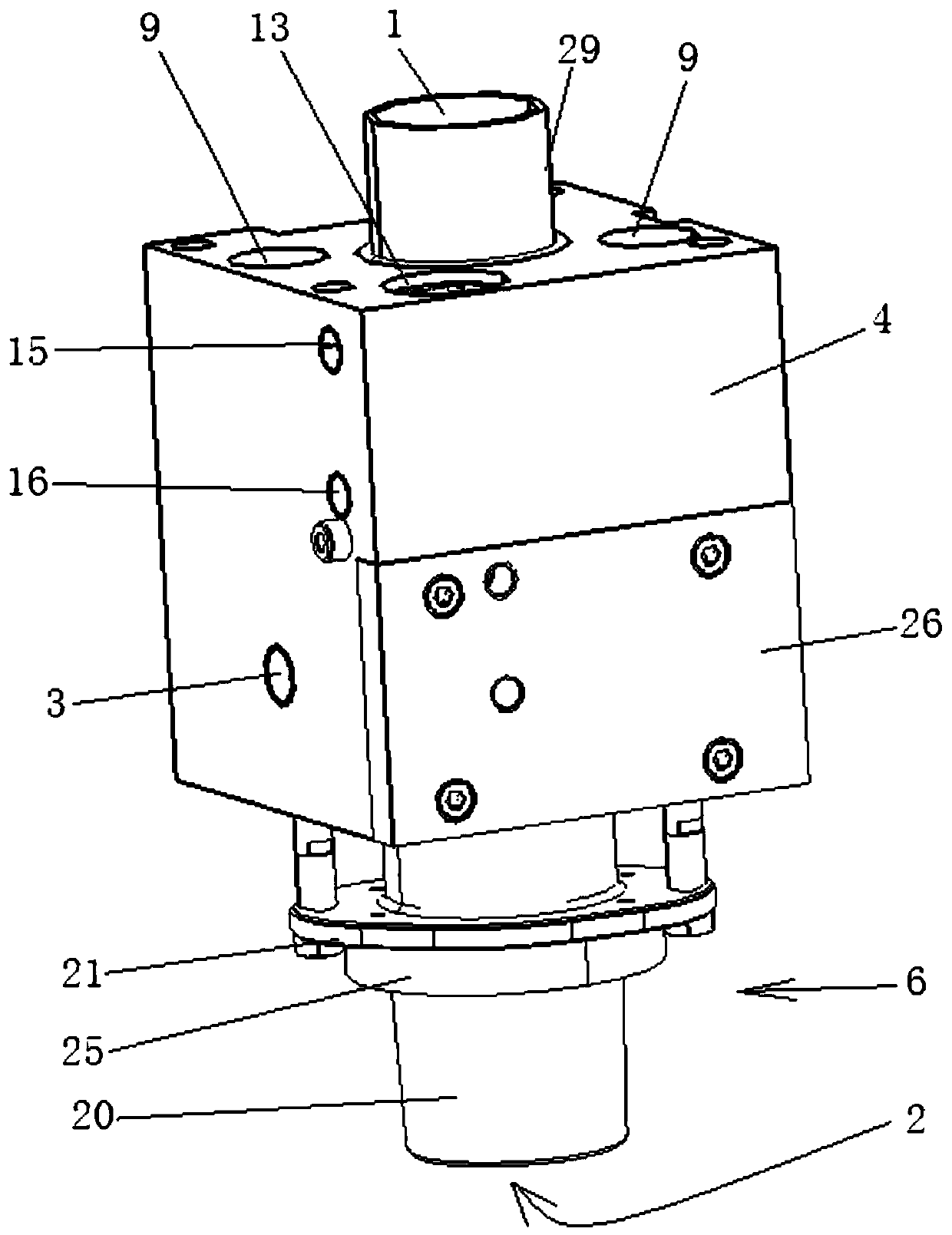

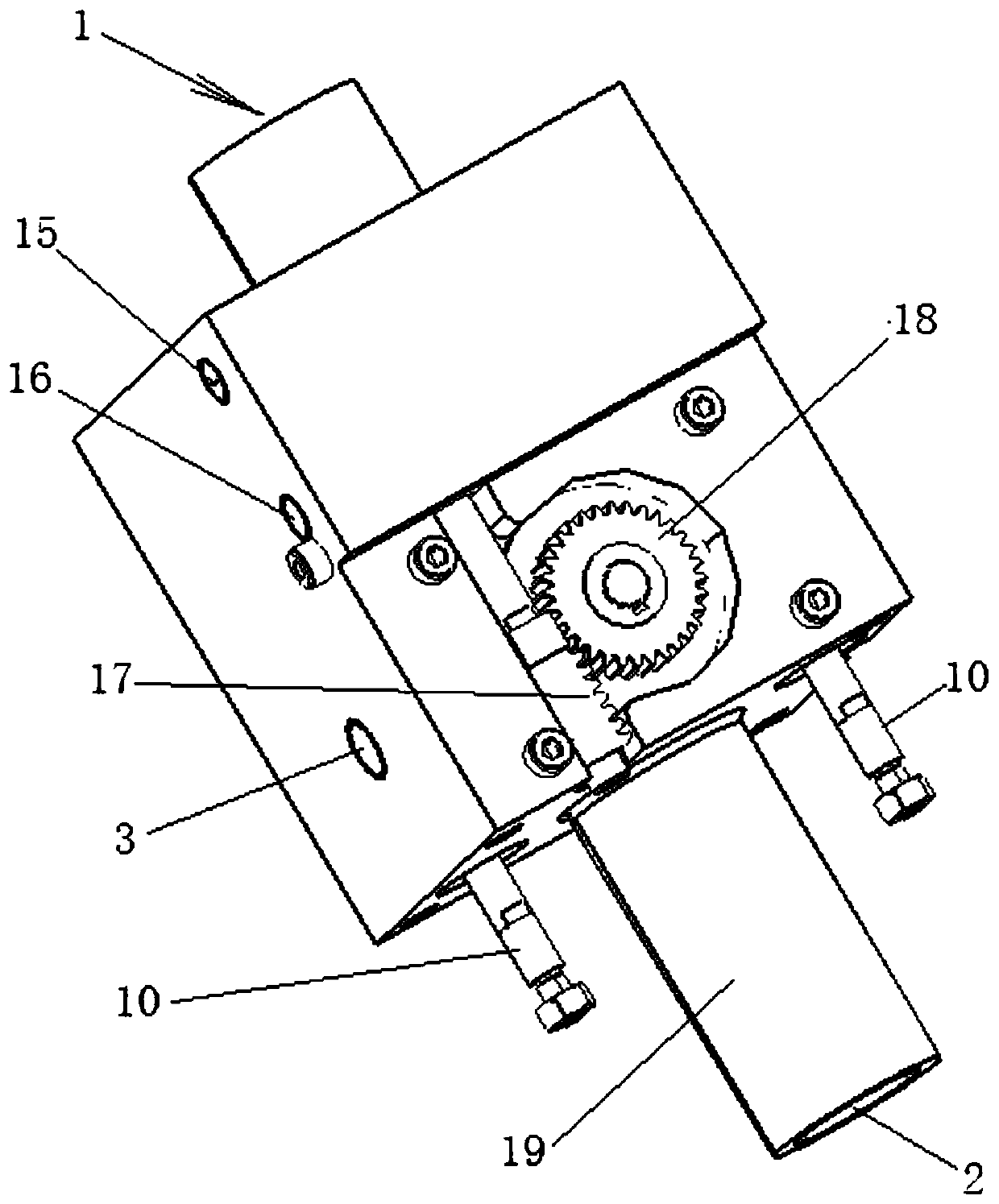

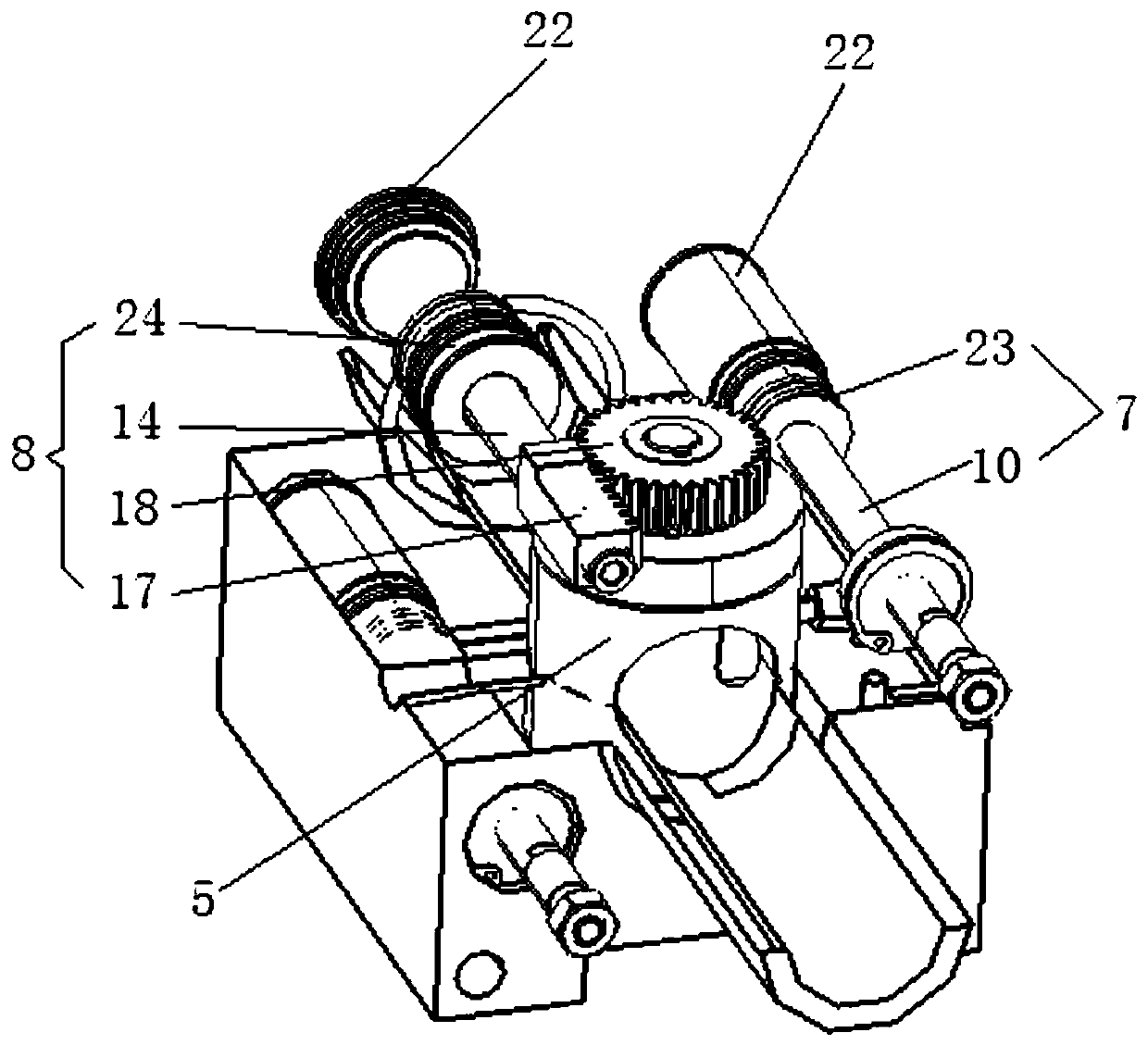

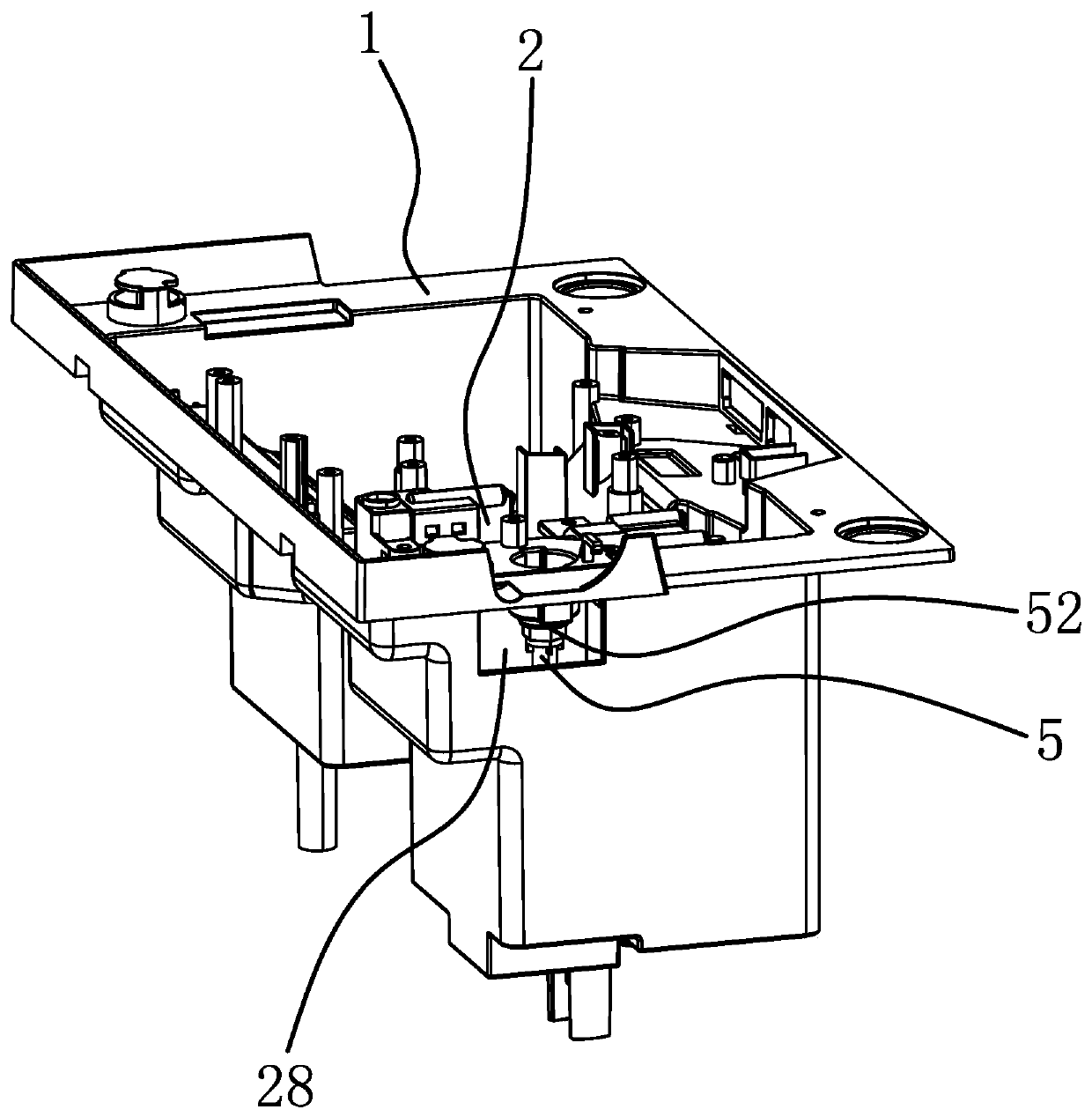

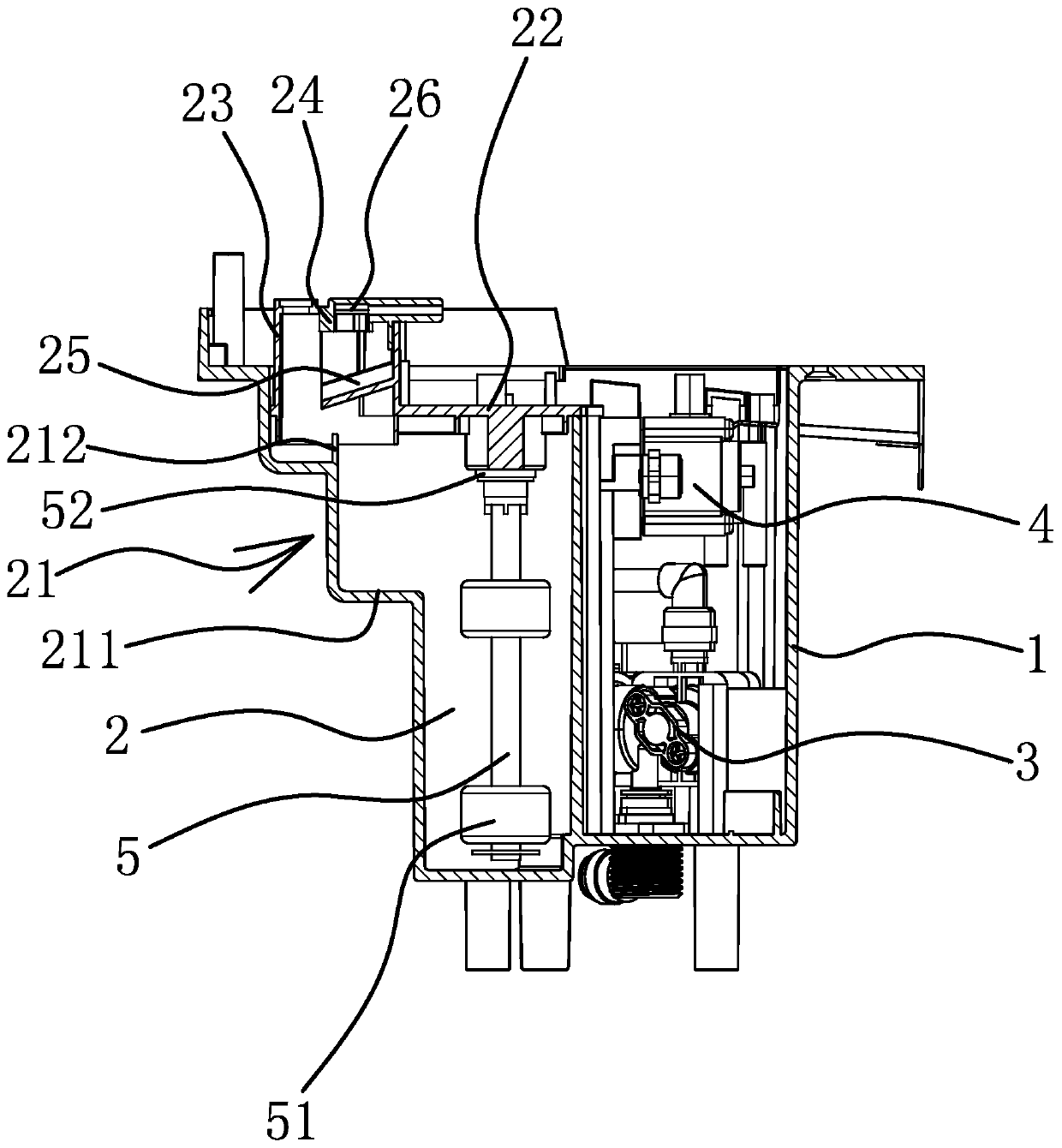

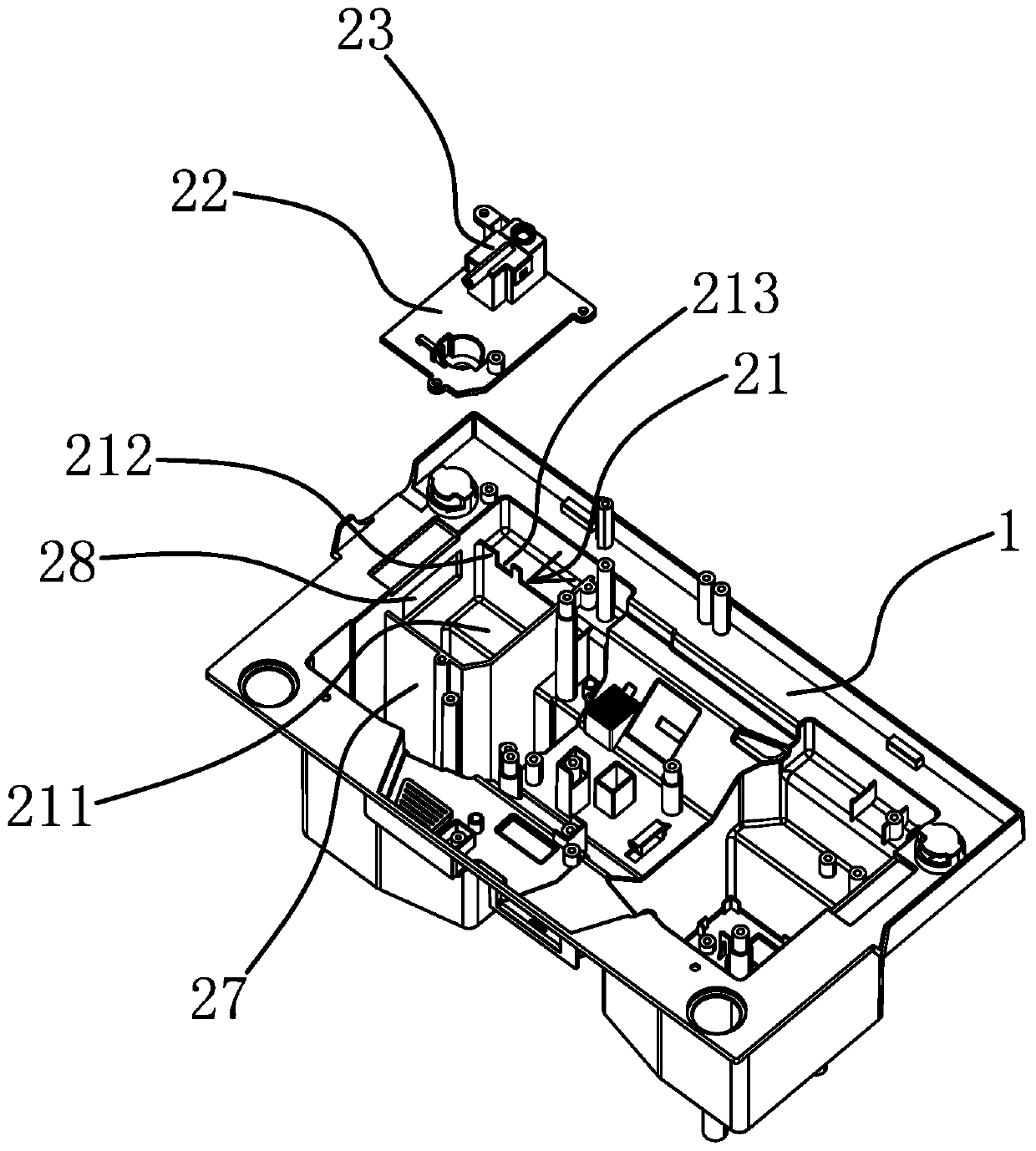

A load-sensing multi-way valve

ActiveCN113669323BReduce sizeNot easy to be damaged by collisionServomotor componentsInlet valveOil intake

Owner:宁波市博尔法液压有限公司

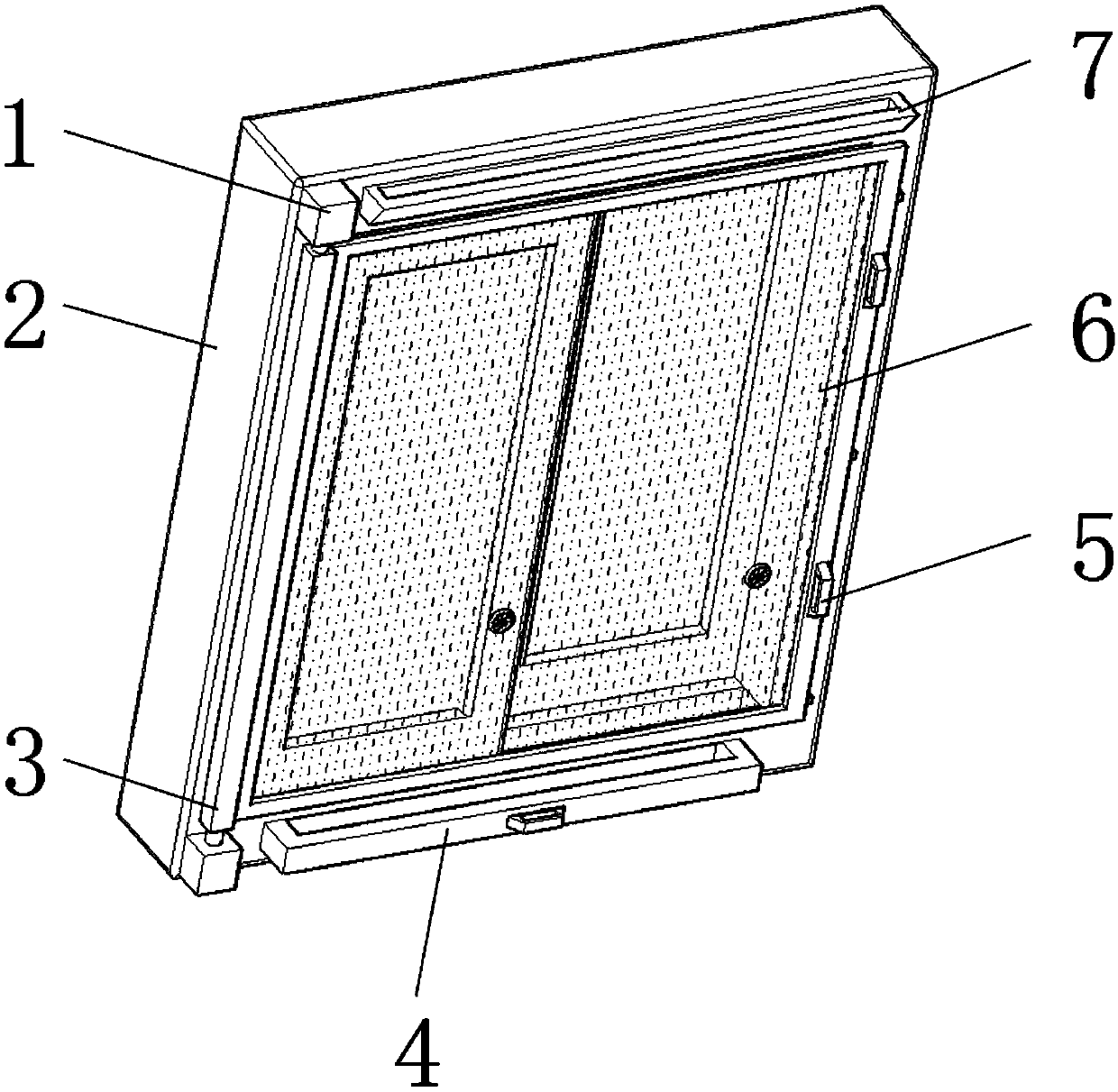

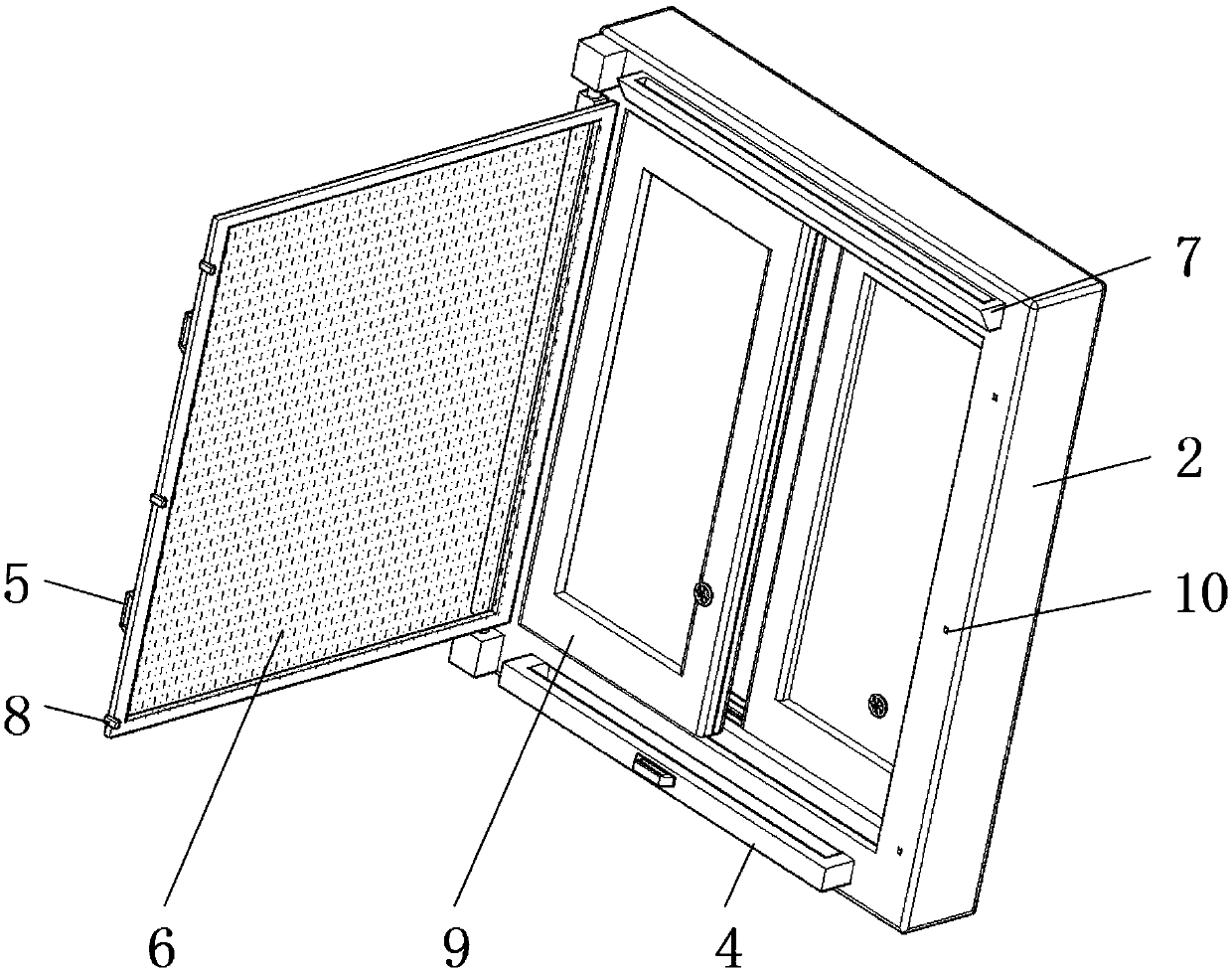

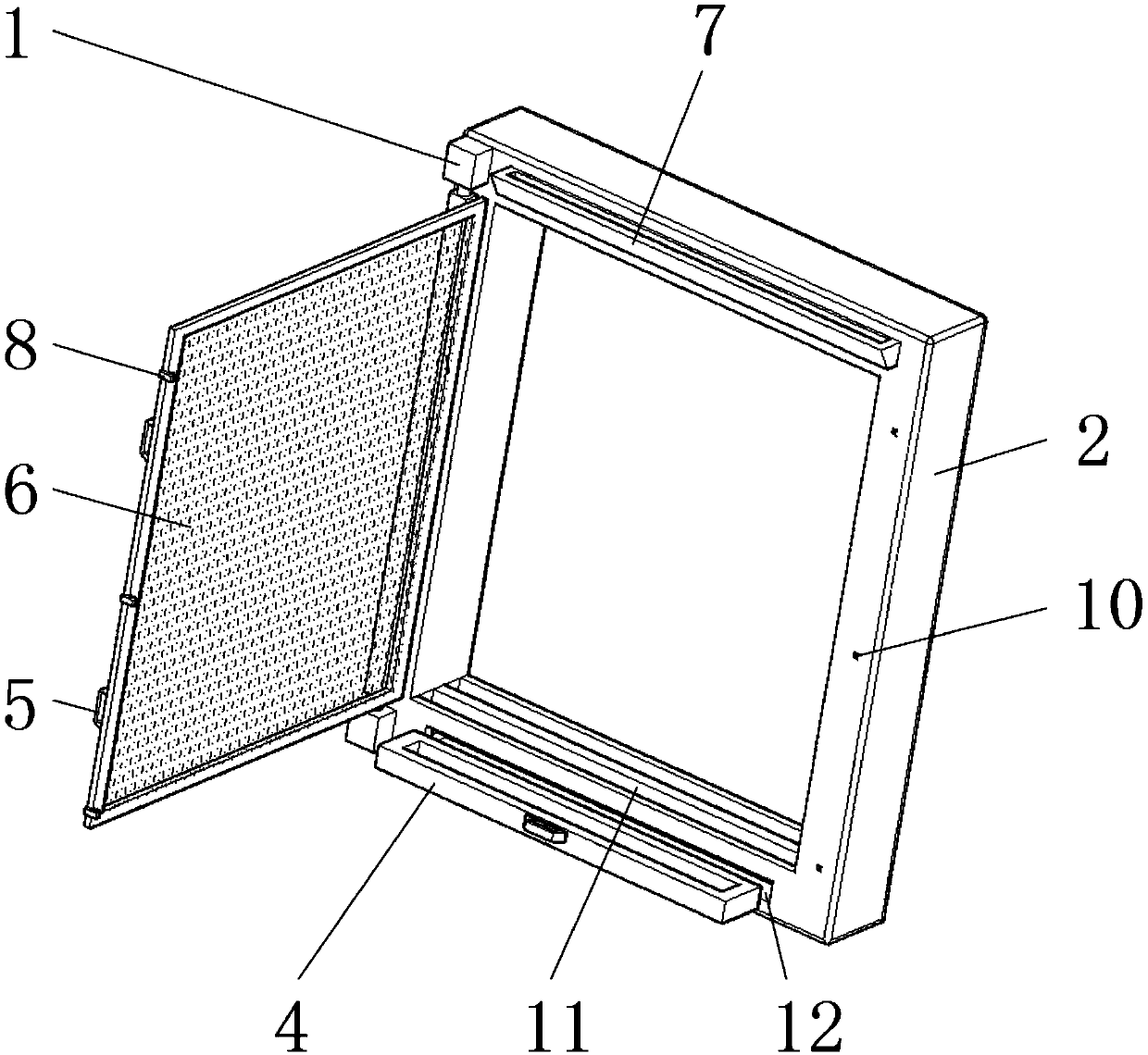

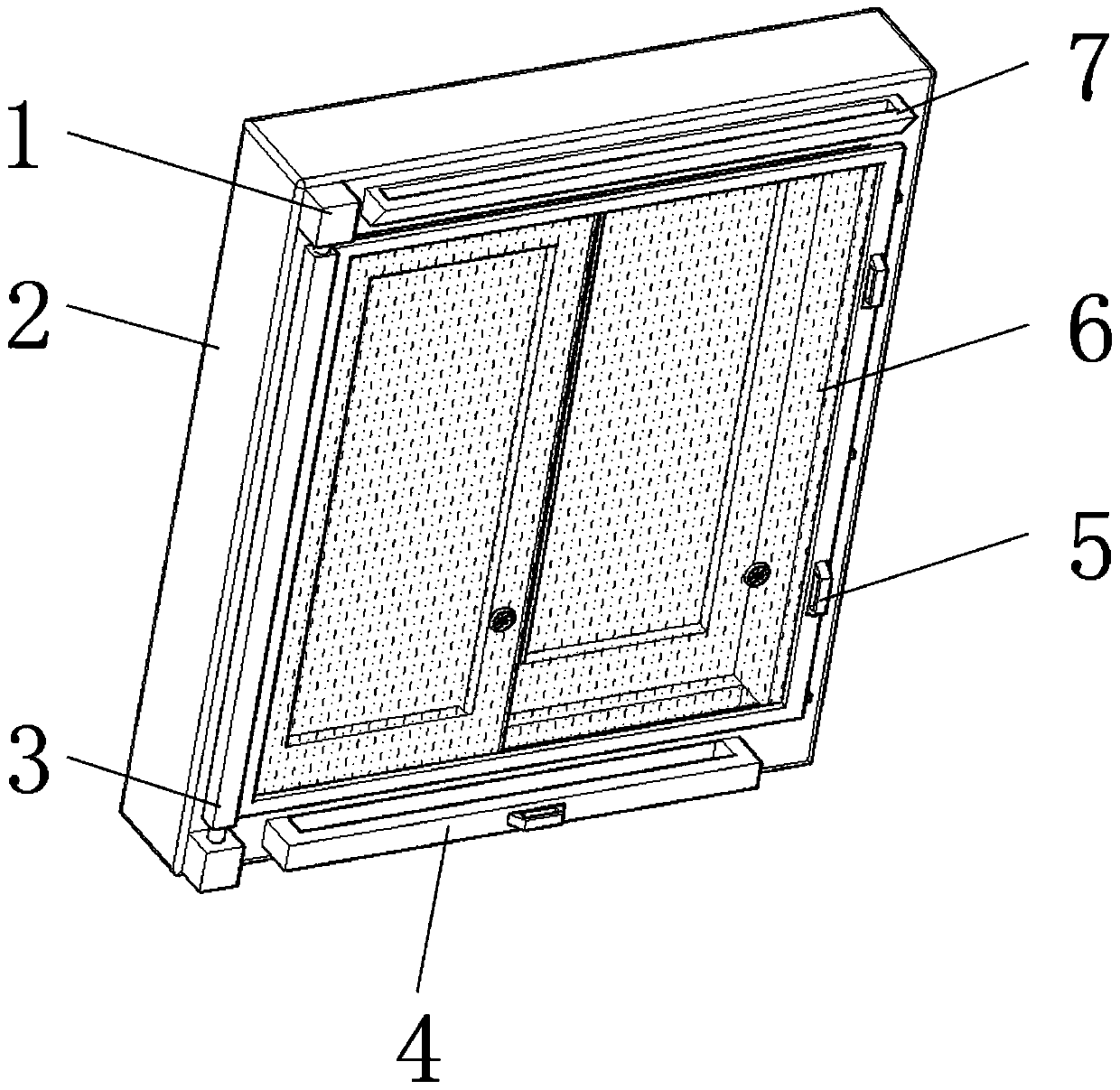

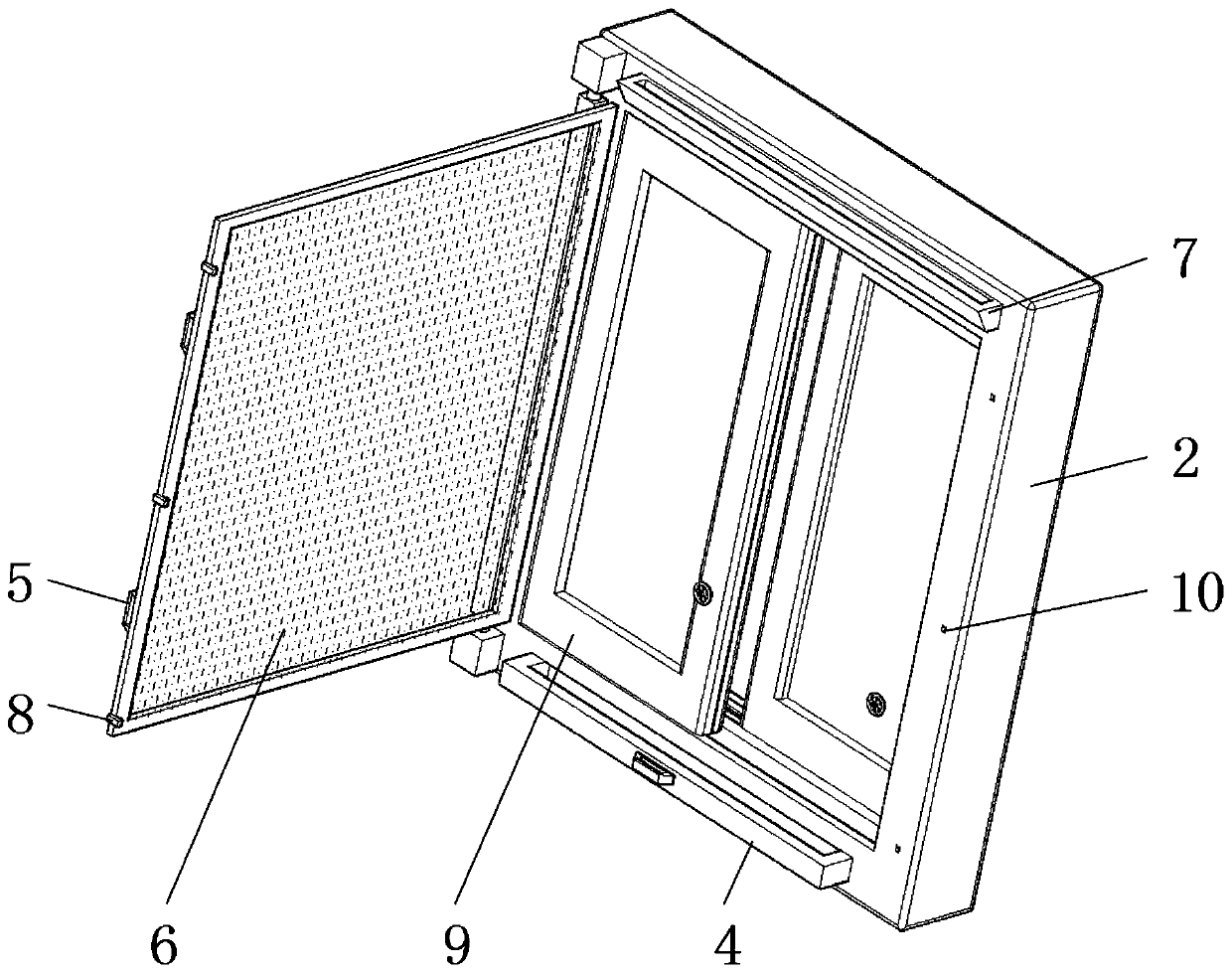

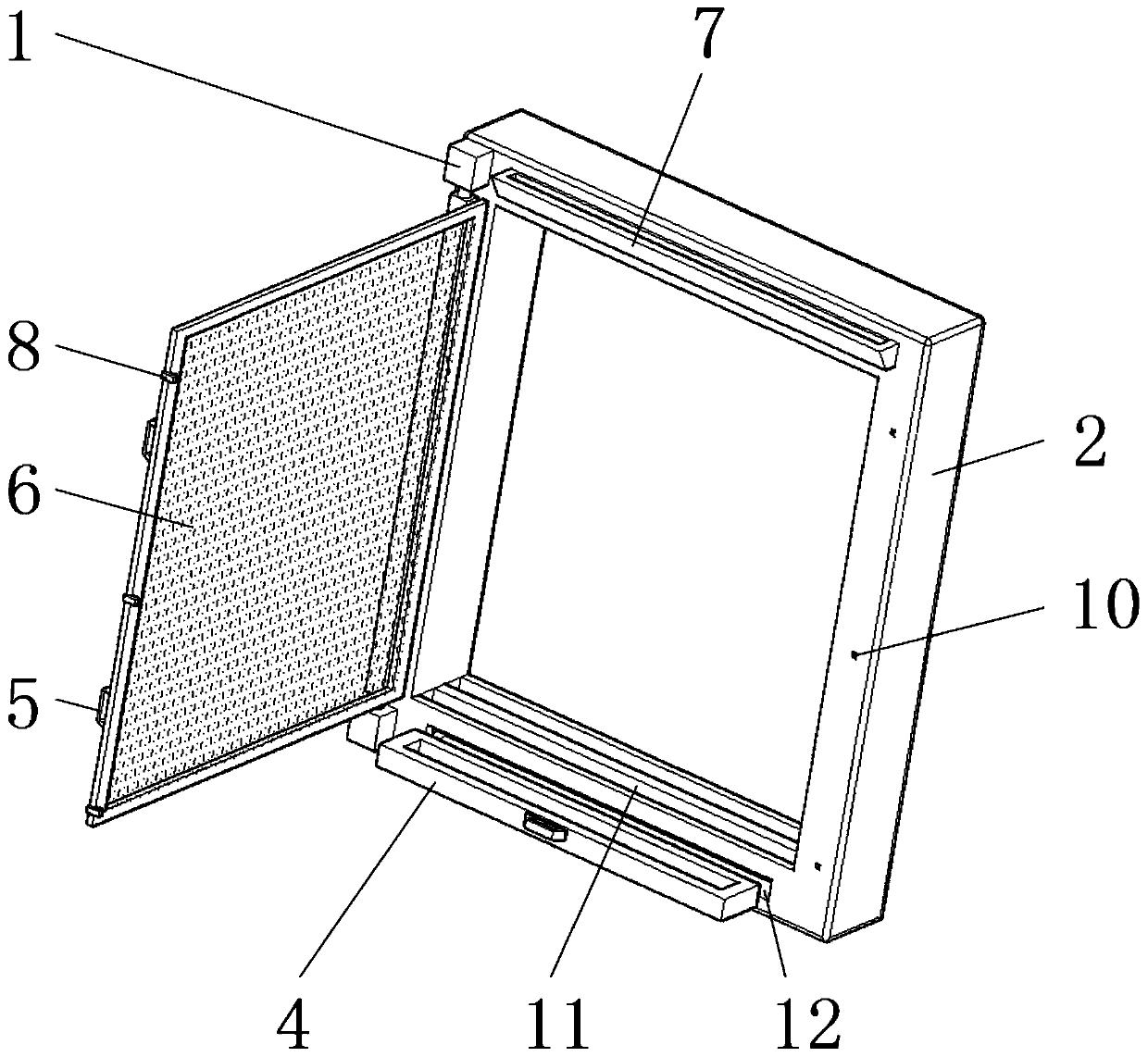

Dust-proof window quick and convenient to clean

ActiveCN109611003ALateral forces in the same directionNo inclinationInsect protectionWindow cleanersEngineering

Owner:方之航

Sand ejection nozzle

The invention relates to the technical field of formative technology equipment of precoated sand and discloses a sand ejection nozzle which comprises a three-way valve body equipped with a sand inletchannel, a sand outlet channel and a sand return channel as well as a rotary valve core which is disposed inside the three-way valve body, located at an intersection part of the sand inlet channel, the sand outlet channel and the sand return channel and used for channel rotation, wherein a movable sand outlet pipe assembly is connected to an outlet of the sand outlet channel; a straight-line motion execution element and a rotation motion execution element are disposed on the three-way valve body respectively; the straight-line motion execution element is connected to the movable sand outlet pipe assembly; and the rotary motion execution element is connected to the rotary valve code. The sand ejection nozzle disclosed by the invention has the advantages that the automation degree of precoated sand shaping is increased; and reliability of a sand ejection operation is enhanced.

Owner:江阴市惠尔信精密装备股份有限公司

Sliding Elastic Suspension Device for Tram Contact Line

ActiveCN105730282BImprove space utilizationMeet the requirements of landscapingTrolley linesEngineeringContact line

The invention discloses a tramcar contact line sliding type elastic suspension device. The tramcar contact line sliding type elastic suspension device comprises a rigid cantilever. The rigid cantilever is of a square tube structure, the inner end of the rigid cantilever is fixed to a supporting column, and a positioning supporting seat is fixed to the outer end of the rigid cantilever through U-shaped bolts. An insulation positioning tube is elastically hinged to the positioning supporting seat. A holder is fixed to the outer end of the insulation positioning tube. A sliding block is horizontally fixed to the lower portion of the holder. A horizontal sliding rail is installed on the sliding block. Groove clamping plates are arranged on the lower portion of the horizontal sliding rail. The problems that existing contact line suspension devices are complex in structure and large in occupied space are solved, and the tramcar contact line sliding type elastic suspension device has the characteristics of being simple in structure, light, handy, high in space utilization rate and the like.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

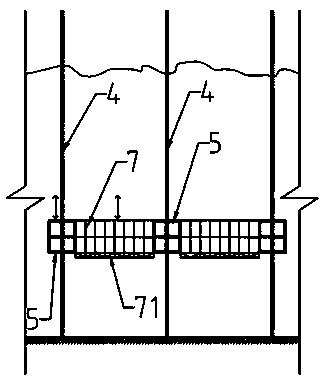

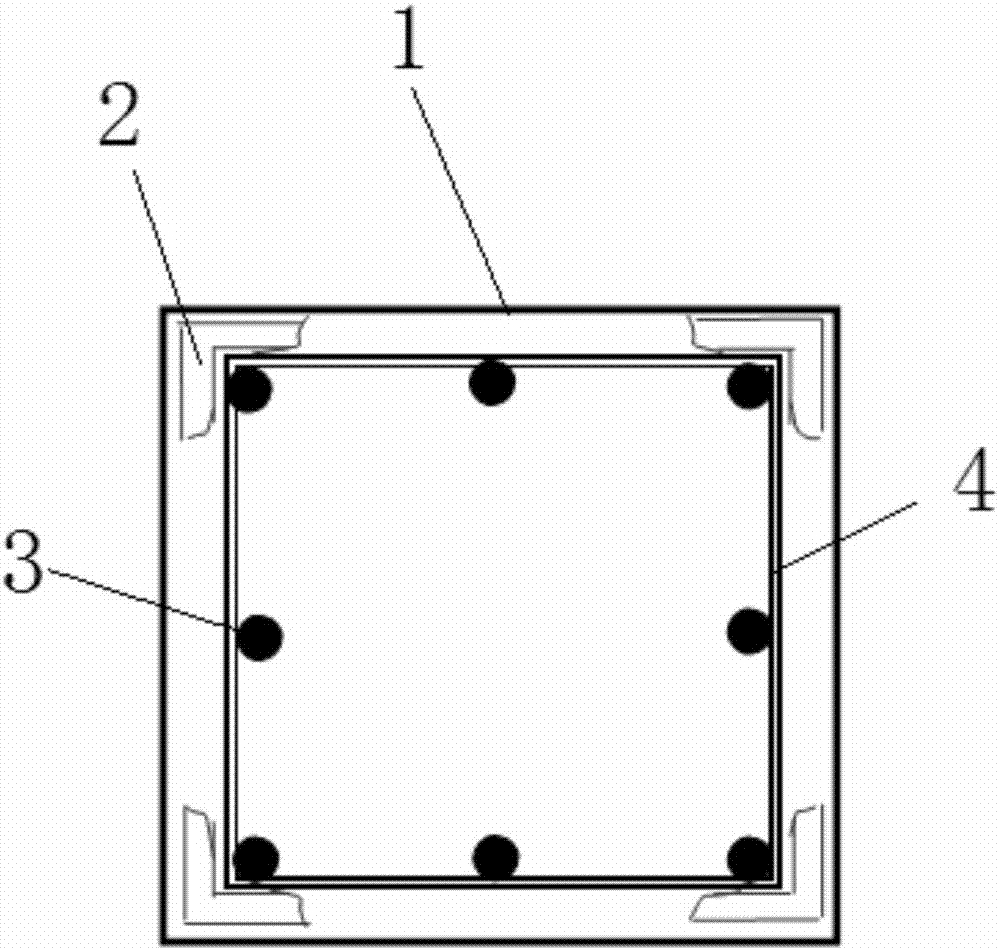

Control device for concrete protective layer

PendingCN107288146AGuaranteed standard distanceUniform distance on all sidesFoundation engineeringArchitectural engineeringRebar

A control device for a concrete protective layer is characterized in that the control device for the concrete protective layer comprises a reinforcement cage, wedges special for controlling the protective layer, reinforcement stand column main reinforcements and an inner formwork. The reinforcement cage is of a cuboid columnar structure and is internally provided with the inner formwork, the inner formwork is internally provided with the multiple reinforcement stand column main reinforcements, and the transverse distance is 50-150 mm; and the wedges special for controlling the protective layer are arranged at the four corners between the reinforcement cage and the inner formwork. The control device has the advantages that the wedges special for controlling the protective layer can control the inner formwork and the reinforcement cage and are provided with thick upper portions and thin lower portions, and the control device achieves the following functions that the design of the standard distance over the protective layer can be ensured, the evenness of the distances of the four surfaces of the protective layer can be ensured, it can be ensured that the special wedges cannot displace and fall down in the construction process, after the special wedges are installed, the heights of the upper surfaces of the wedges cannot exceed the upper edge of a foundation formwork, and installation of a foundation bolt support cannot be affected.

Owner:BENXI POWER SUPPLY COMPANY OF STATE GRID LIAONINGELECTRIC POWER SUPPLY +1

Environment-friendly sound absorption and noise reduction barrier based on municipal bridge

InactiveCN111851335AInsertion does not affectAvoid breakingNoise reduction constructionThick lineClassical mechanics

The invention provides an environment-friendly sound absorption and noise reduction barrier based on a municipal bridge, relates to the technical field of noise reduction barriers, and aims at solvingproblems that when an existing bridge sound absorption and noise reduction barrier is used and encounters strong wind, thick lines are prone to loosening, an automatic auxiliary fixing structure doesnot exist after loosening, and the noise reduction barrier cannot be automatically reinforced. The barrier comprises a main body and a side groove. The main body is a plate-shaped structure, and a top end of the main body is an arc-shaped structure. The side groove is formed in the left end of the main body, and the connector at the right end of the side groove is arranged at the right end of themain body; a supporting plate is located at the rear end of the main body; a bottom piece is used for being mounted at the bottom of the main body; and the main body can be connected with a bridge guardrail through the bottom piece during mounting. And when the device is used for a long time and blown by strong wind to shake back and forth, a gap can be formed between the bottom piece and the guardrail so that a fixing piece is not fixed with the guardrail, is in contact with a limiting position, and downwards moves and extends under the action of a gravity.

Owner:厦门市晶锐永兴塑胶有限公司

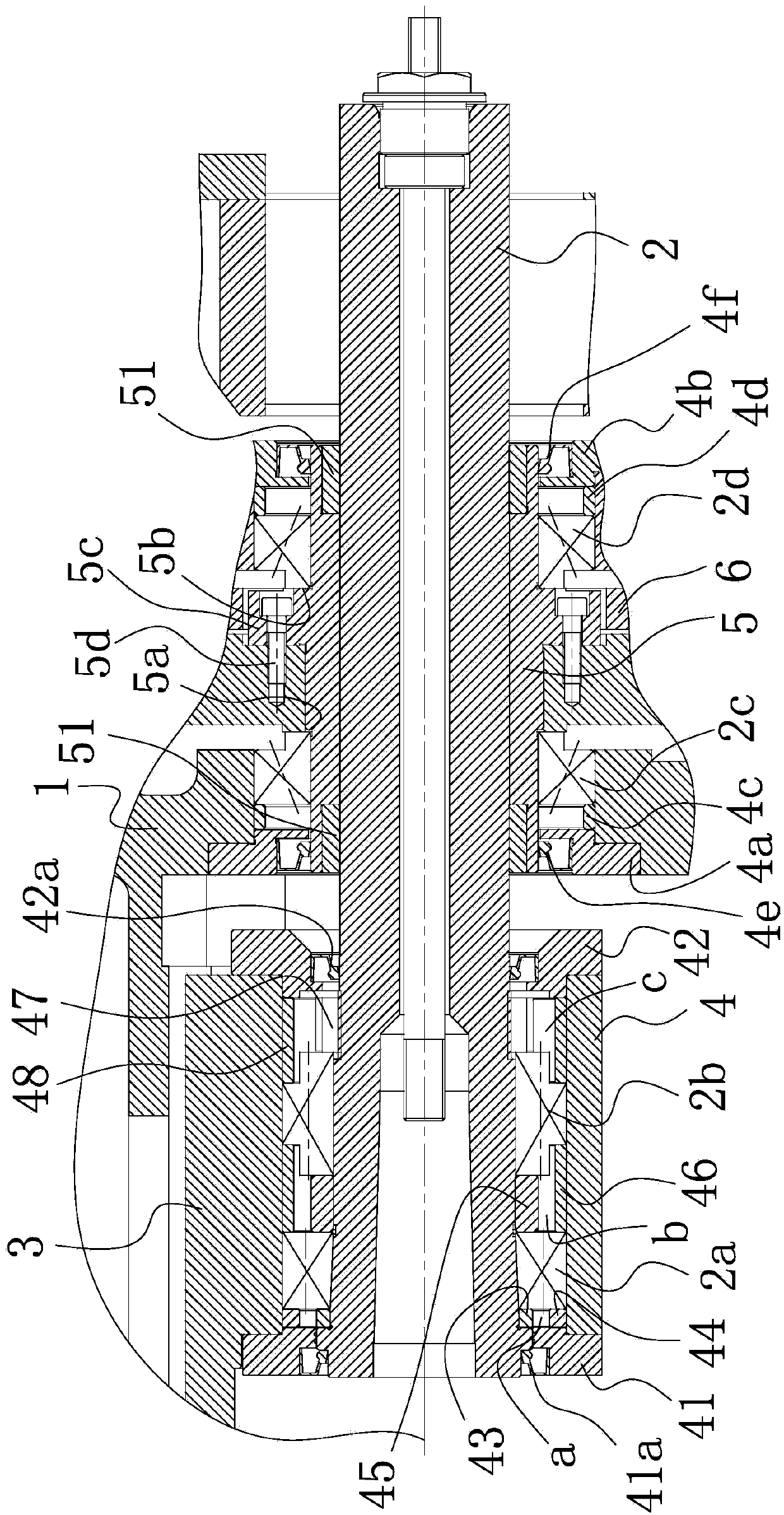

Hobbing cutter main shaft mechanism of CNC gear hobbing machine

InactiveCN103990818AReasonable designImprove structural strengthLarge fixed membersHobbingEngineering

The invention belongs to the technical field of gear hobbing machines, and particularly relates to a hobbing cutter main shaft mechanism of a CNC gear hobbing machine. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine solves the technical problems that practicability is poor in the prior art and the like. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine comprises a cutter rest shell and hobbing cutter main shaft which is arranged in the cutter rest shell in a penetrating mode and can rotate relative to the cutter rest shell, the front end of the hobbing cutter main shaft is inserted into the cutter rest shell and is arranged in a suspending mode, the tail end of the hobbing cutter main shaft penetrates through the cutter rest shell and extends out of the cutter rest shell, a first rolling structure is arranged between the cutter rest shell and the hobbing cutter main shaft, a supporting plate fixedly connected with the cutter rest shell is arranged in the cutter rest shell and is provided with a barrel-shaped locating body which is fixedly connected with the supporting plate and arranged on the periphery of the suspended end of the hobbing cutter main shaft in a sleeved mode, a second rolling structure is arranged between the hobbing cutter main shaft and the barrel-shaped locating body, and an axial locating mechanism used for preventing axial float of the hobbing cuter is further arranged between the hobbing cutter main shaft and the barrel-shaped locating body. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine has the advantages of being high in structural intensity, rigidity and practicability during interrupted cutting.

Owner:浙江嘉力宝精机股份有限公司

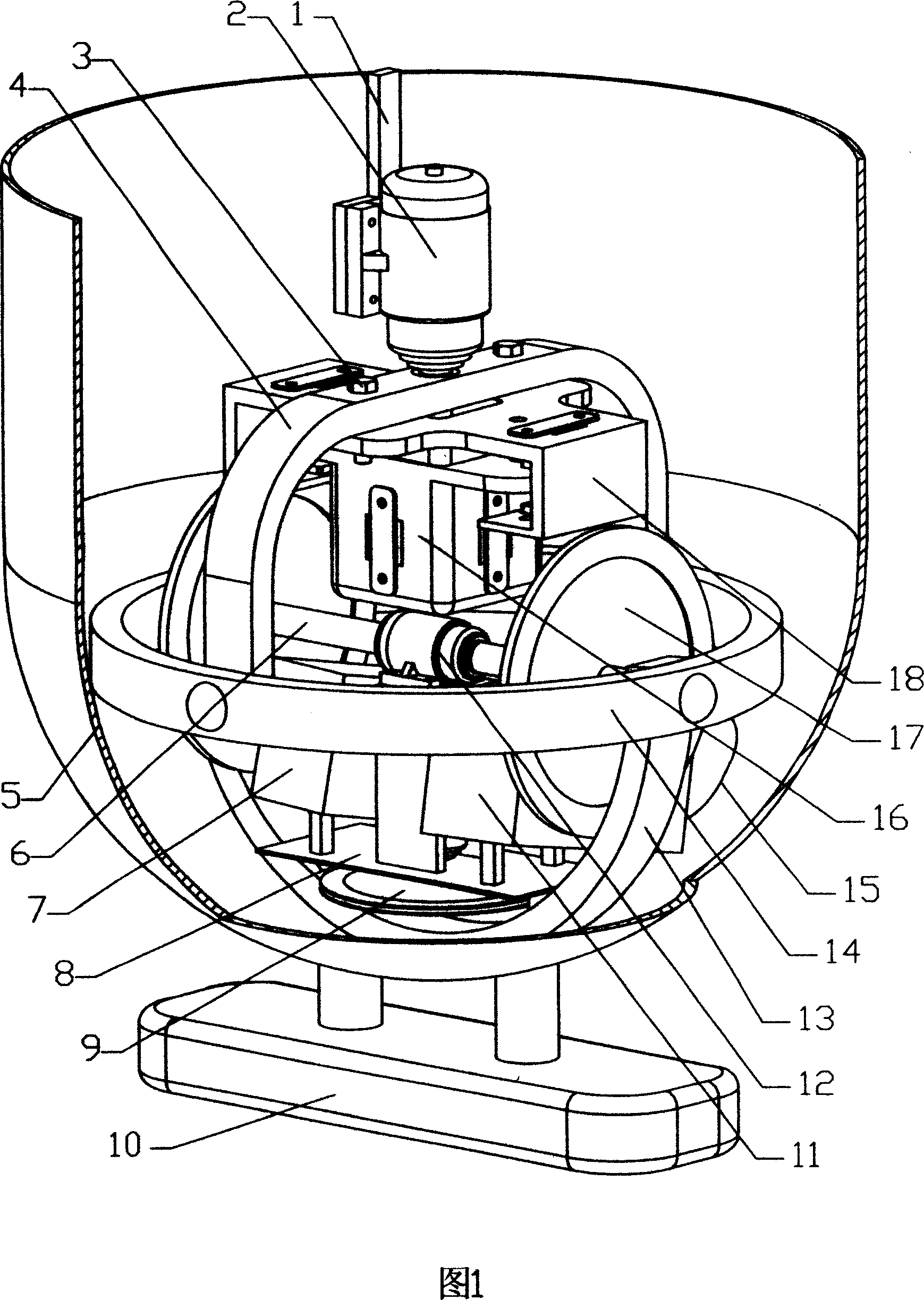

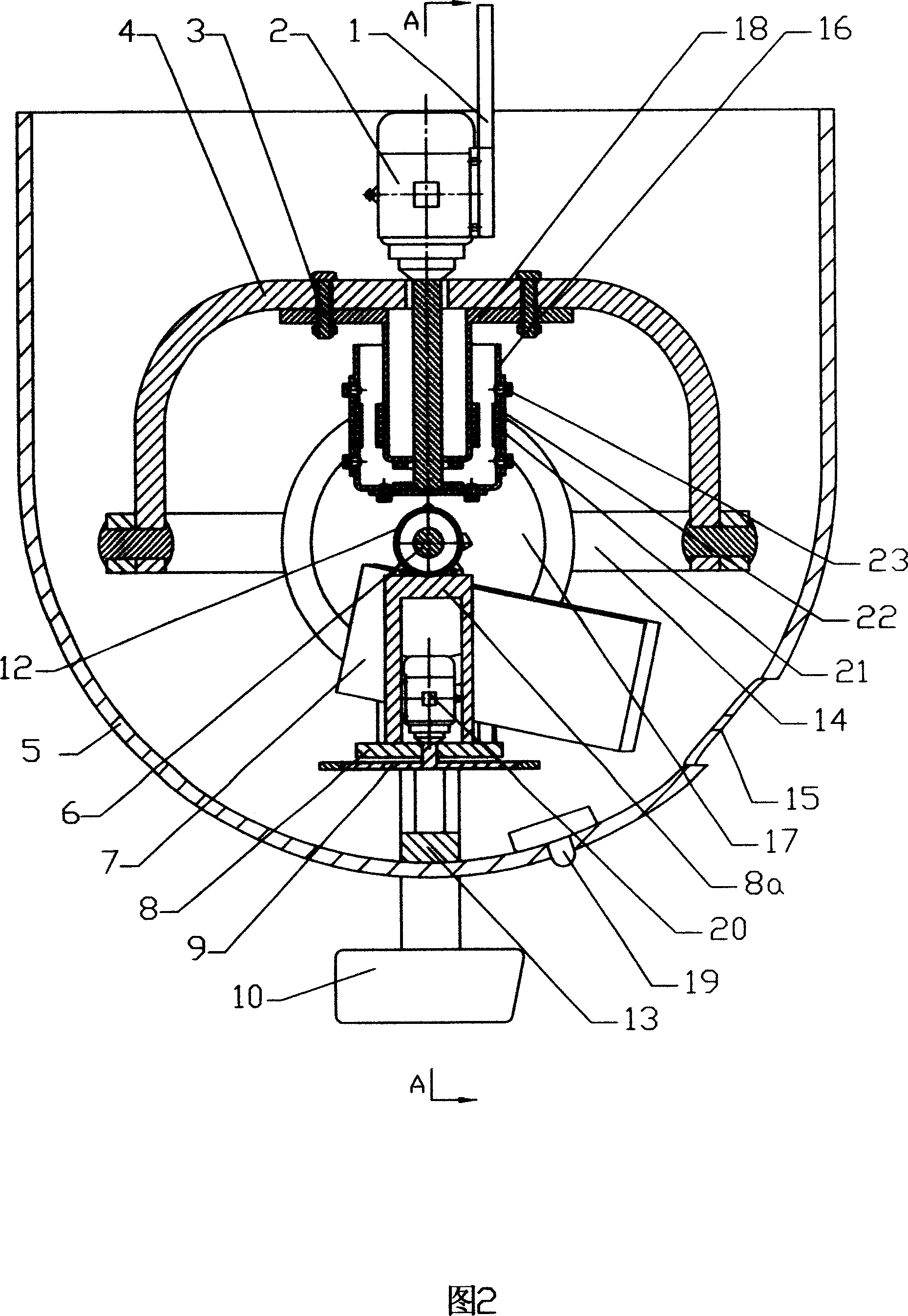

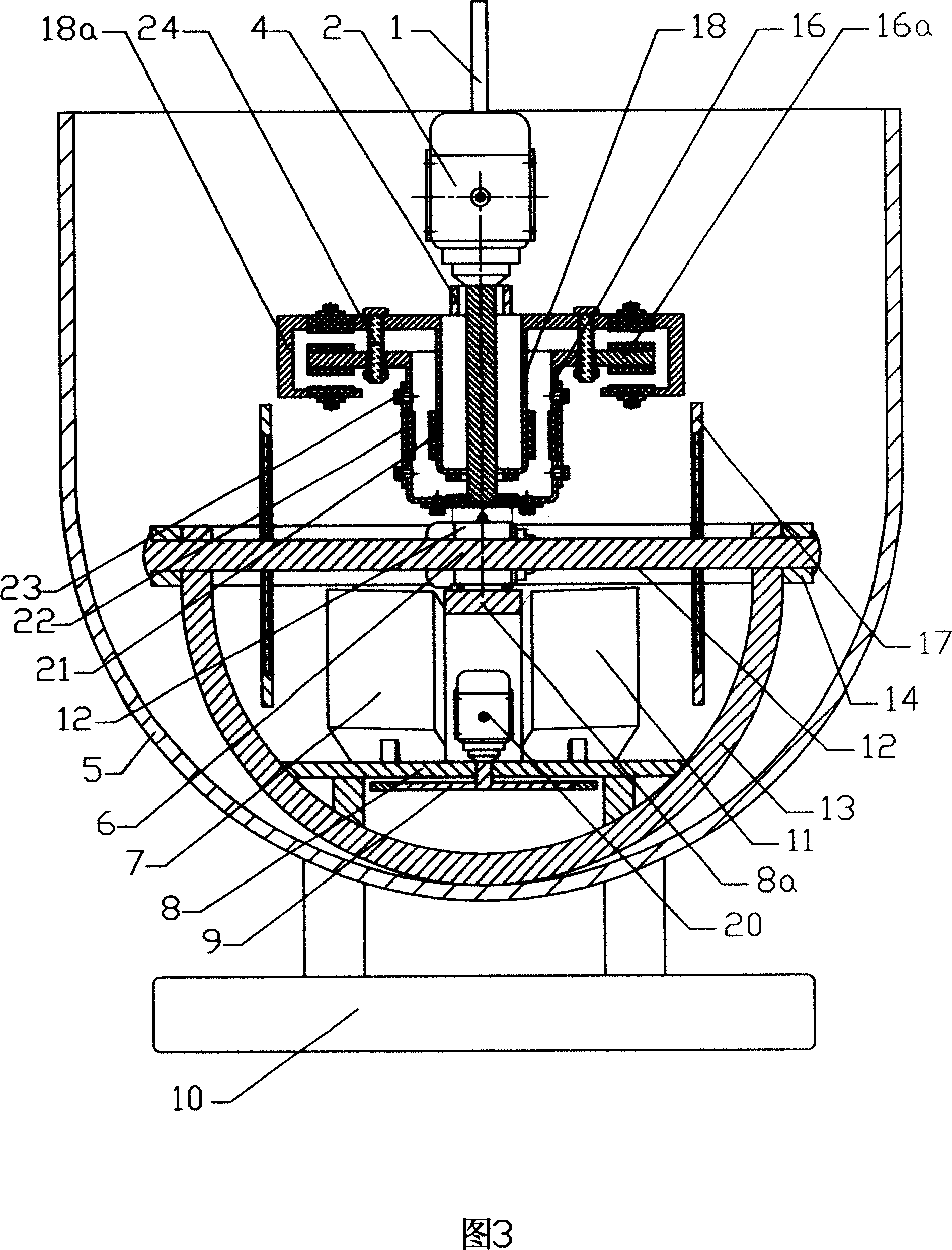

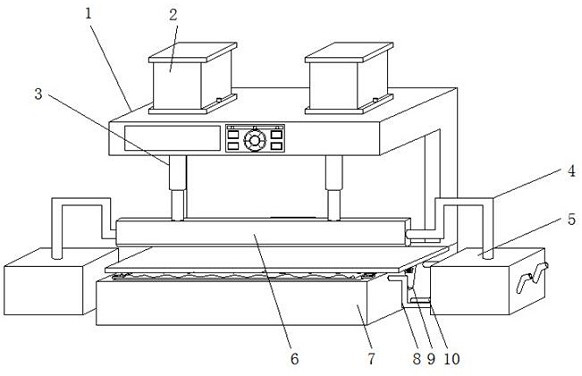

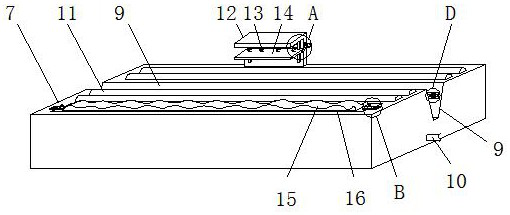

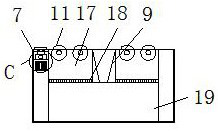

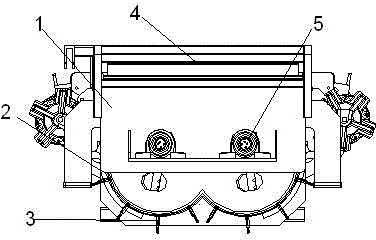

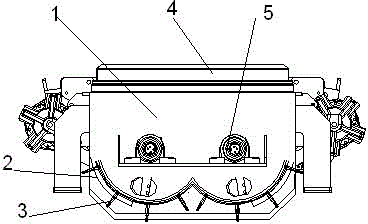

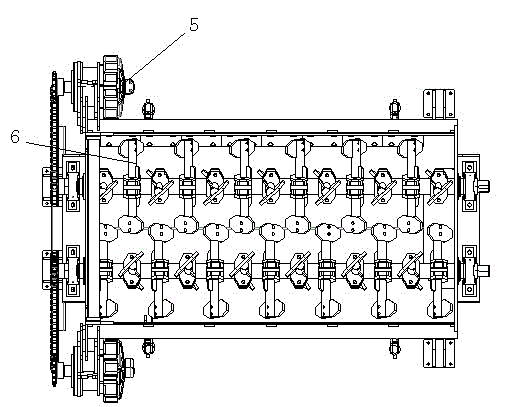

Fuel gas and electricity hybrid heated asphalt mixture sliding type stirring device and working process thereof

The invention relates to a fuel gas and electricity hybrid heated asphalt mixture sliding type stirring device and a working process thereof. The stirring device disclosed by the invention is characterized in that (1) an electric heater for conductive preheating is adopted at the bottom of a cylinder body, so that asphalt at the bottom of the cylinder body is not stuck to the cylinder body; meanwhile, an infrared heater is adopted on the top of the cylinder body, and the heating effect of the asphalt is ensured by using the permeability of the infrared heater; (2) the electric heater is flat and is small in size and suitable for being installed at the bottom of the cylinder body, and the stirring device adopts a nested installation manner, so that the whole structure is compact and the overall installation of the stirring device is not affected; (3) the lower part of the cylinder body can ascend and descend, so that the asphalt residue can be conveniently cleaned as long as the bottom of the cylinder body declines.

Owner:JIANGSU AOXIN SCI & TECH

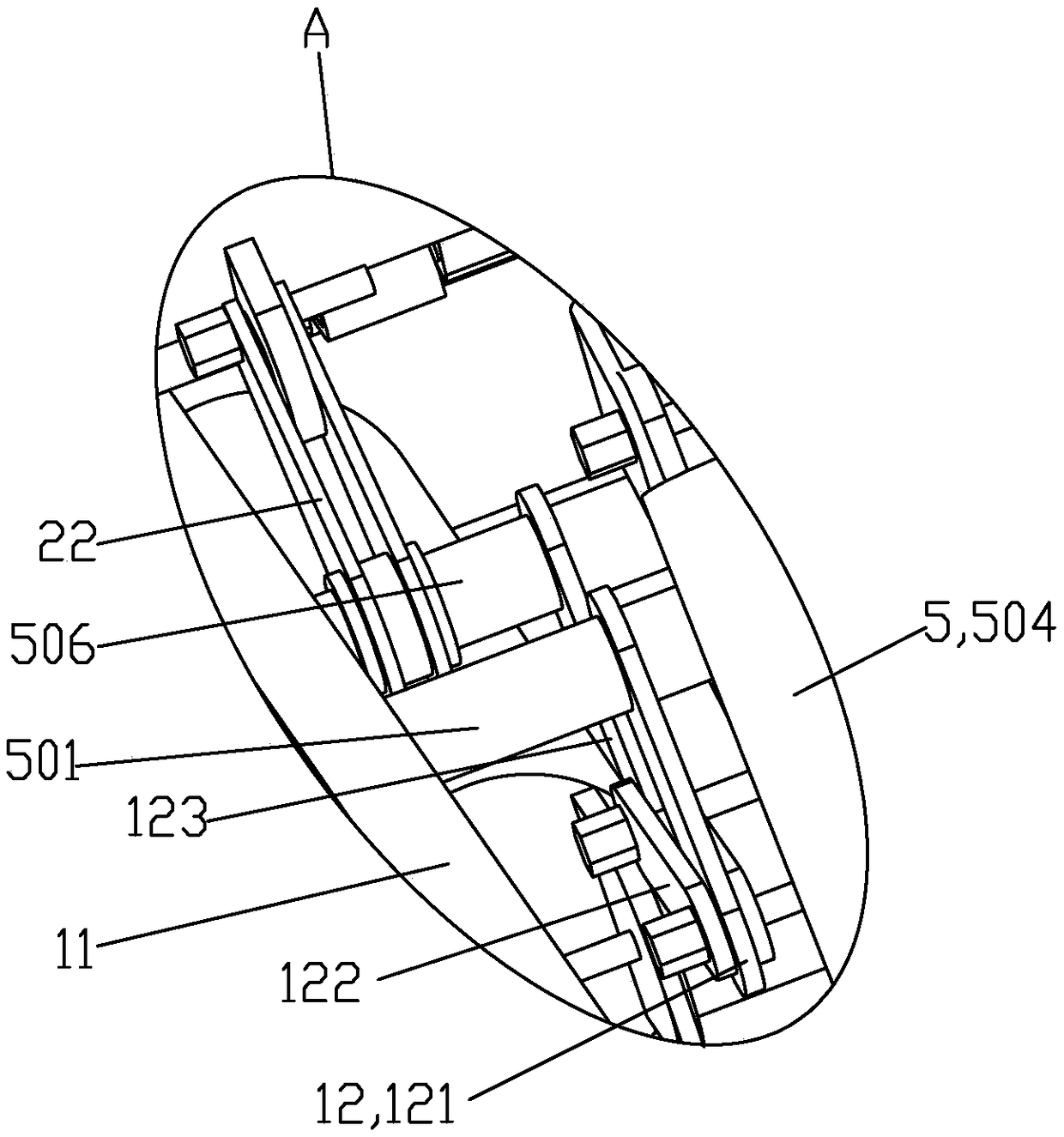

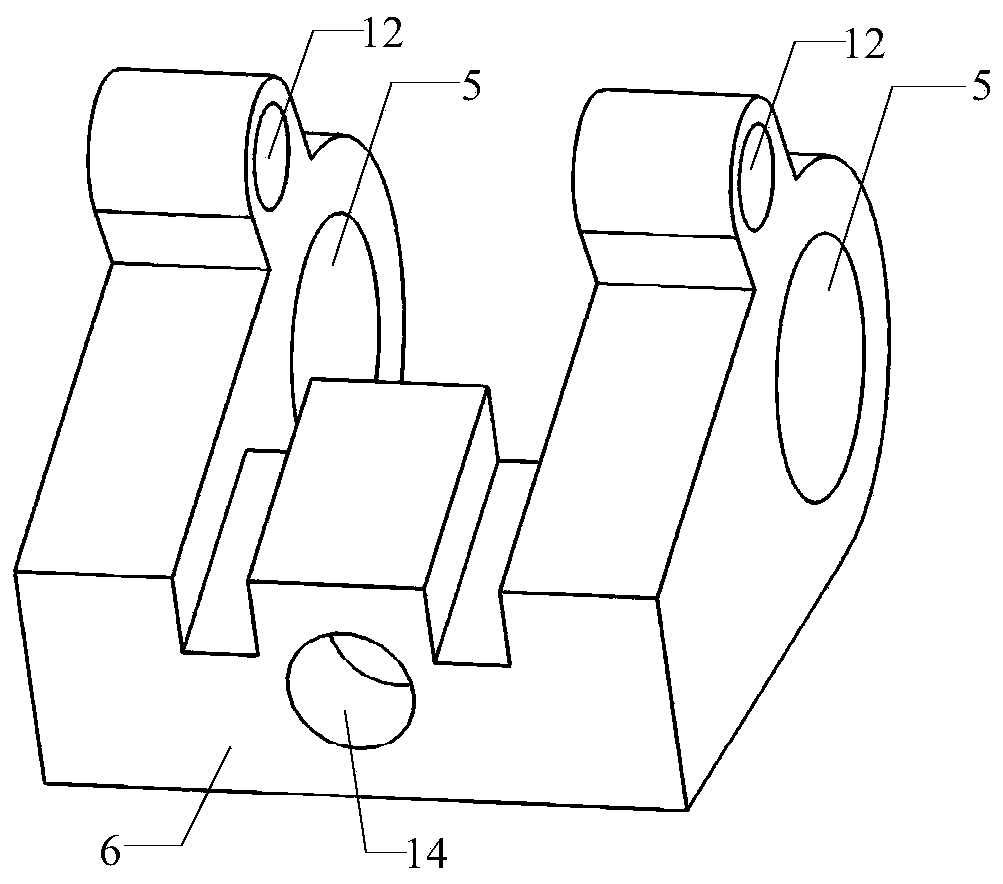

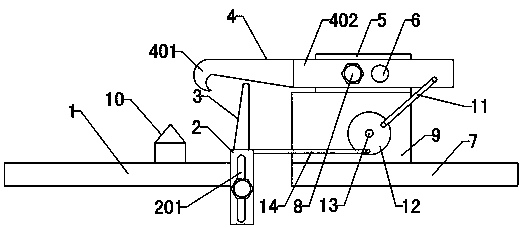

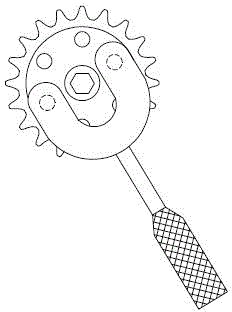

Rapier loom weft scissors

The invention discloses rapier loom weft scissors, and belongs to the technical field of rapier loom accessories. The weft scissors are characterized in that a weft hook knife (4) is rotationally arranged on a hook knife mounting frame (9) through a hook knife rotating shaft (6); a rotating wheel (12) rotationally arranged in the vertical direction is disposed on one side face of the hook knife mounting frame (9), and a push rod (11) and a pull rod (14) are hinged to the end face of the rotating wheel (12) separately; the rotating wheel (12) is hinged to the tail portion of the weft hook knife(4) through the push rod (11), and the rotating wheel (12) is fixedly connected with one side of a cutter (3) through the pull rod (14). The push rod and the pull rod which are hinged to the rotatingwheel can be matched with the cutter to move back and forth to synchronously push the head portion of the weft hook knife to swing upwards or sink downwards, and the cutter and the weft hook knife are coordinating in action, so that the weft cutting time and frequency are controlled in a specific position and time, and the weft breaking phenomenon is avoided. The installation height and inclination angle of the cutter can be adjusted freely according to needs, and the cutter can be conveniently replaced in time.

Owner:SHANDONG XINLI ENVIRONMENTAL PROTECTION MATERIAL

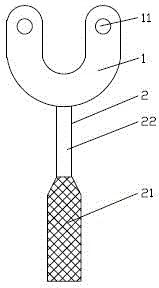

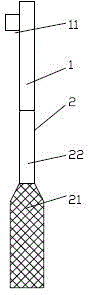

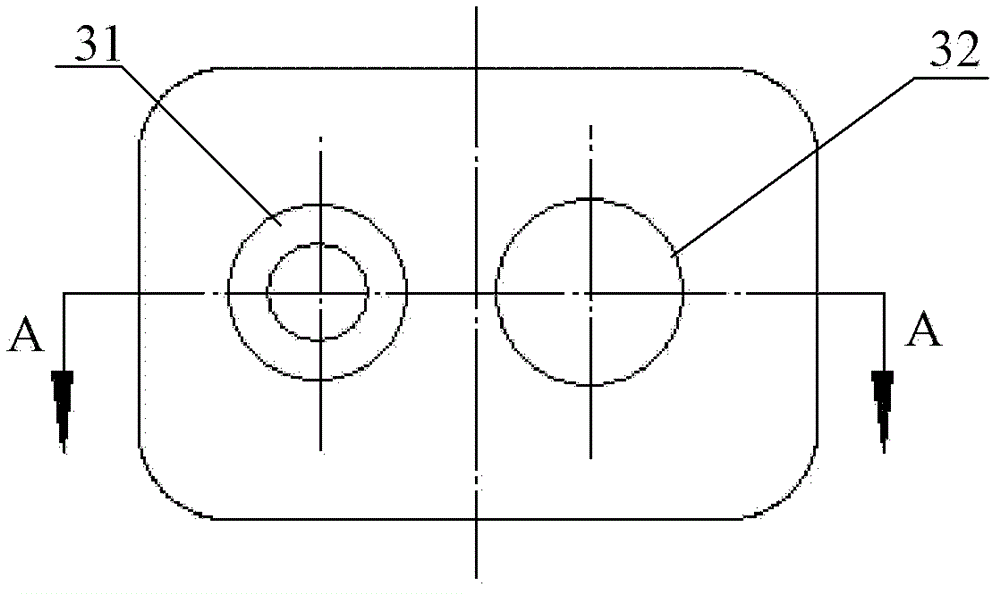

Anti-rotation tool for chain wheel

InactiveCN104440714AGuaranteed anti-rotation fixationInstallation will not affectWork holdersMetal-working hand toolsSprocketEngineering

The invention discloses an anti-rotation tool for a chain wheel, and belongs to the technical field of engine tools. The anti-rotation tool comprises a U-shaped tool plate, wherein positioning pins matched with chain wheel process holes are arranged on two straight arms of the U-shaped tool plate respectively; the distance between the two straight arms of the U-shaped tool plate is greater than the maximum size of the head of a mounting bolt of a center hole of the chain wheel; a cylindrical handle is welded at the sealed end of the U-shaped tool plate, and is divided into a handheld knurled section and a smooth section; the smooth section is connected with the U-shaped tool plate. According to the anti-rotation tool, anti-rotation fixation is ensured, and meanwhile, influence on the mounting of a center bolt is eliminated; during mounting, the handheld knurled section of the handle is handheld, so that the influence of slip on mounting is avoided, and reliability and effectiveness are achieved.

Owner:刘兴永

Equipment for automatically detecting aperture and assisting in mounting for mounting pressure sensor

InactiveCN112857662AInstallation will not affectEasy to installForce measurementFluid pressure measurementStructural engineeringMechanical engineering

The invention relates to the technical field of pressure sensors, and discloses equipment for automatically detecting aperture and assisting in mounting for mounting a pressure sensor. The equipment comprises an installation seat, the top of the installation seat is movably connected with a transmission rod, the top of the transmission rod is movably connected with a supporting seat, the top of the supporting seat is movably connected with a detection spring, the left side of the transmission rod is movably connected with a push rod, the top of the push rod is movably connected with a push block, the right side of the push block is movably connected with an extension spring, and an action is exerted on the supporting seat through a threaded hole, so that the detection spring is compressed to drive the transmission rod to move; the movement of the transmission rod pulls the push rod, and the movement of the push rod drives two clamp blocks to move relative to each other; when the hole diameter of the threaded hole is small, the pressure applied to the detection spring is increased, then the movement distance of the clamp blocks is increased, the two clamp blocks make contact with the diameter of the threaded hole at the moment to stop installation of the equipment, and therefore the effect of automatically detecting whether the installation hole diameter is qualified or not is achieved.

Owner:李伟军

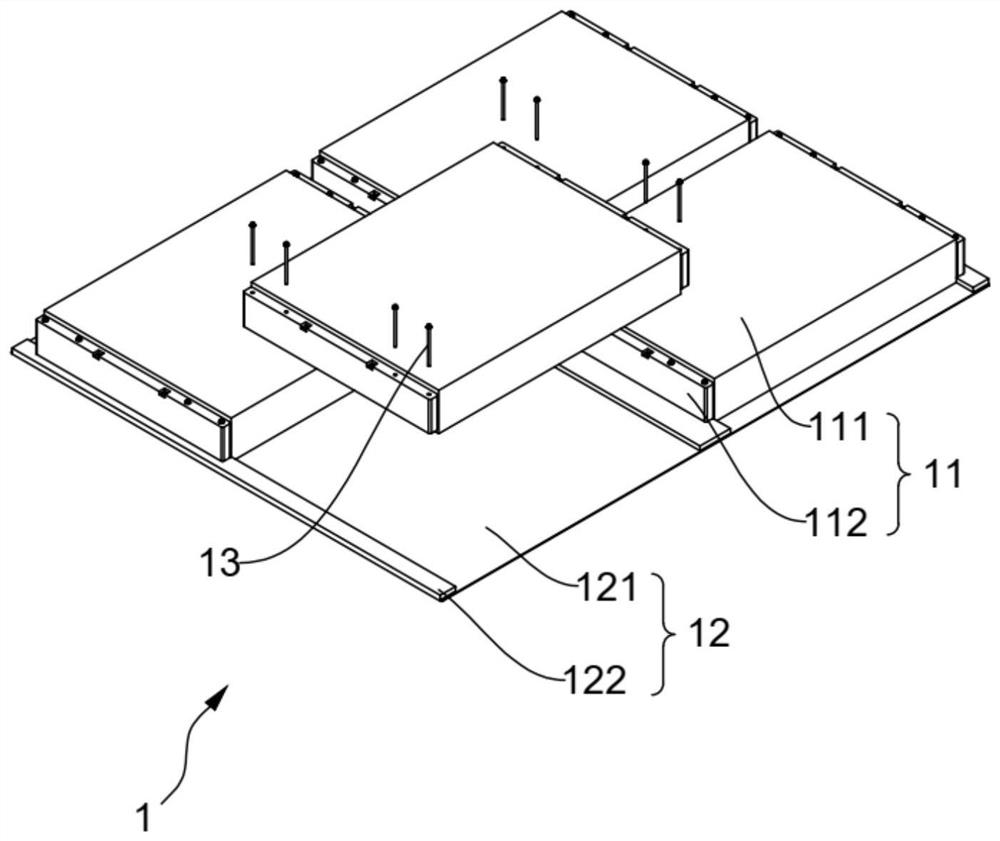

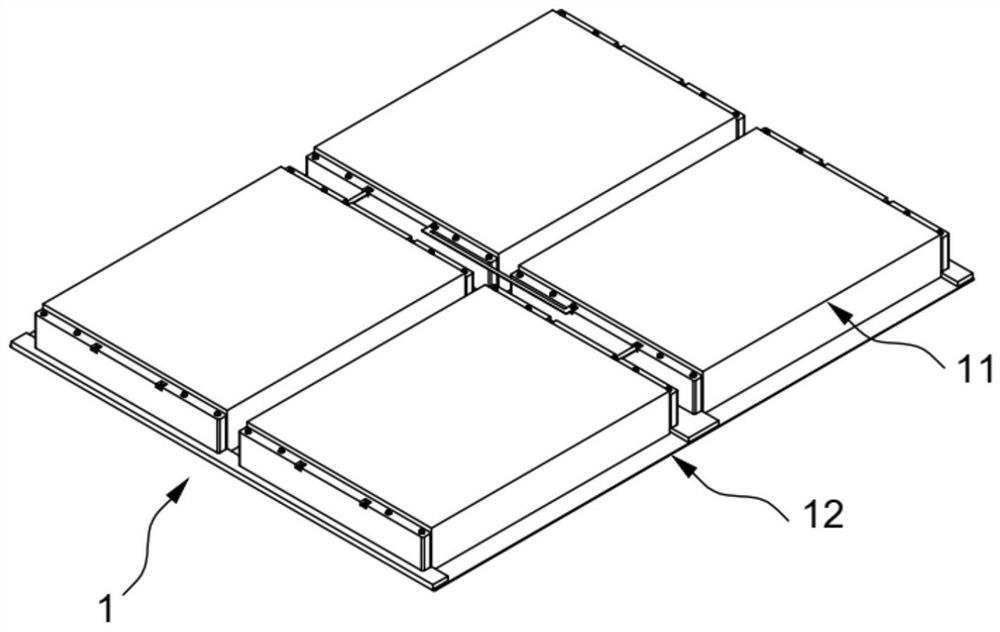

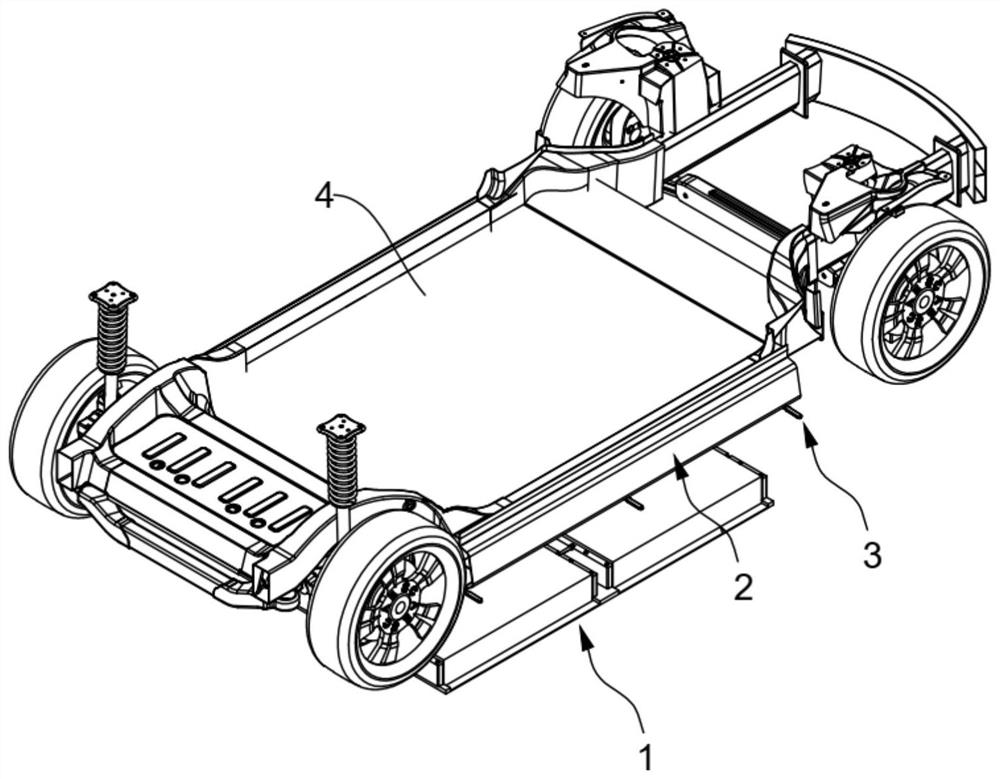

Battery pack, battery pack mounting structure and battery pack mounting method

InactiveCN113067089AEasy to installThe situation that affects the seriesCell component detailsVehicle frameElectrical battery

The invention relates to the technical field of electric vehicles, and particularly discloses a battery pack, a battery pack mounting structure and a battery pack mounting method. The battery pack comprises a plurality of battery modules, wherein each battery module comprises a battery body and an end plate, and the two ends of each battery body are connected with the end plates respectively; and a bottom plate assembly which comprises a bottom plate and a plurality of mounting plates arranged on the bottom plate at intervals, wherein the end plates are connected with the mounting plates, and the battery bodies are arranged between every two adjacent mounting plates. The battery pack mounting structure comprises a frame which comprises a frame body, wherein the frame body forms an accommodating cavity for accommodating a battery pack; and a locking mechanism which is connected to the frame body, wherein the locking mechanism can be switched between an avoiding state and a locking state for locking the battery pack, and when the locking mechanism is in the avoiding state, the battery pack can be installed on the frame from bottom to top. According to the battery pack, the battery pack mounting structure and the battery pack mounting method provided by the invention, the problem that the battery module is damaged due to the fact that high-temperature welding slag falls onto the battery module in the process of welding the upper cover can be solved.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

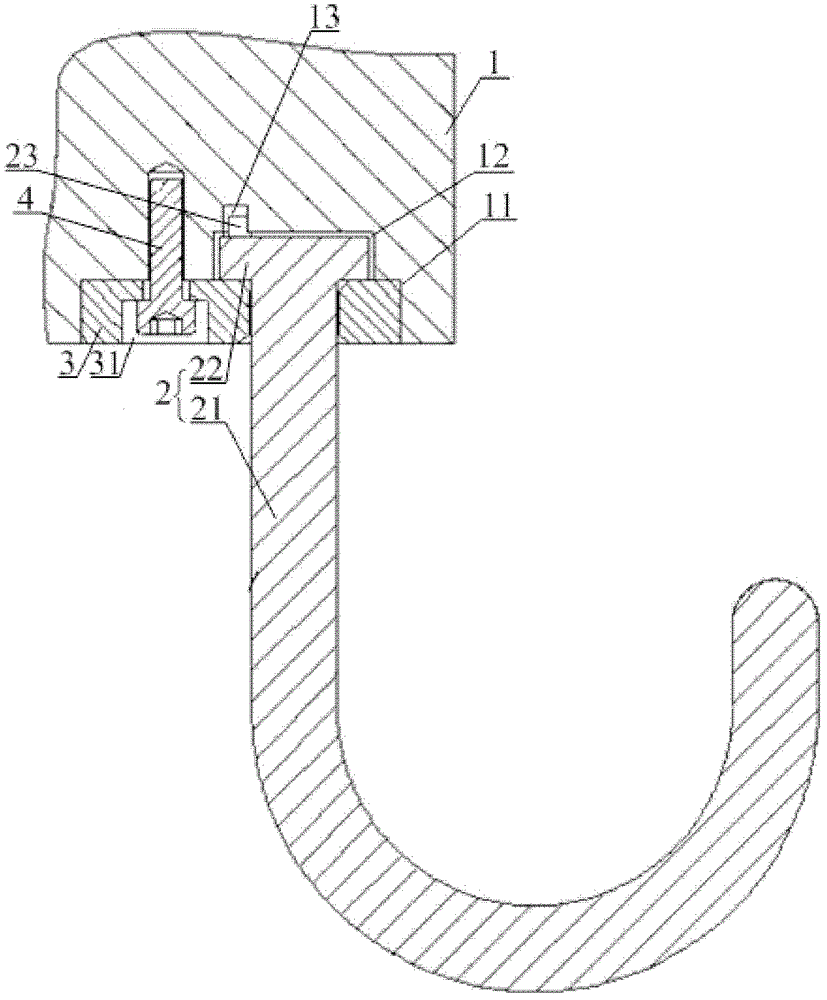

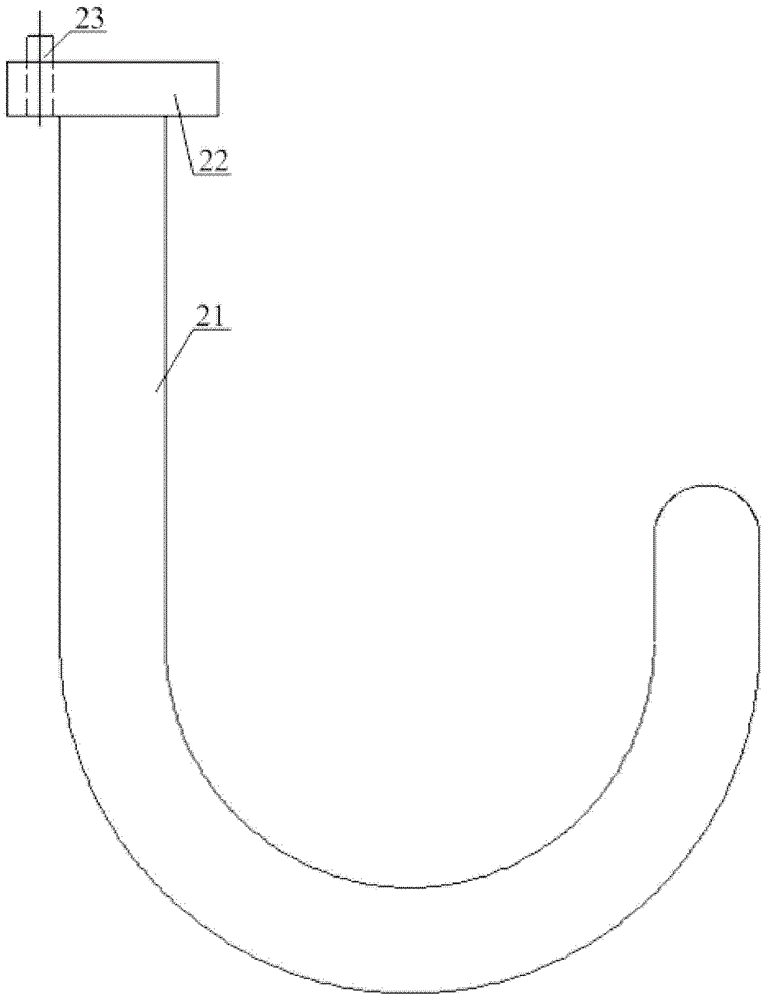

Limit hook device

Owner:BEIJING AEONMED

Cuttable thermal insulation and fireproof decorative board and preparation method thereof

ActiveCN105544914BLower prefab size categoryImprove prefabrication efficiencyCovering/liningsNatural mineral layered productsThermal insulationEngineering management

The invention discloses a thermal-insulation fireproof decorative board capable of being cut and a preparation method thereof. The thermal-insulation fireproof decorative board capable of being cut comprises a thermal-insulation fireproof board body and a connecting belt embedded in the thermal-insulation fireproof board body, the connecting belt penetrates the two opposite side faces of the thermal-insulation fireproof board body, and the connecting belt is used for being connected with a connecting piece for installation. The decorative board can be cut freely, and installation is not affected.

Owner:CABR TECH CO LTD

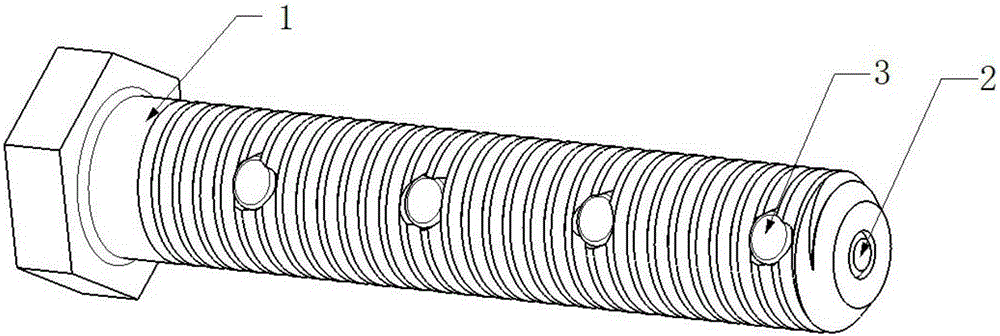

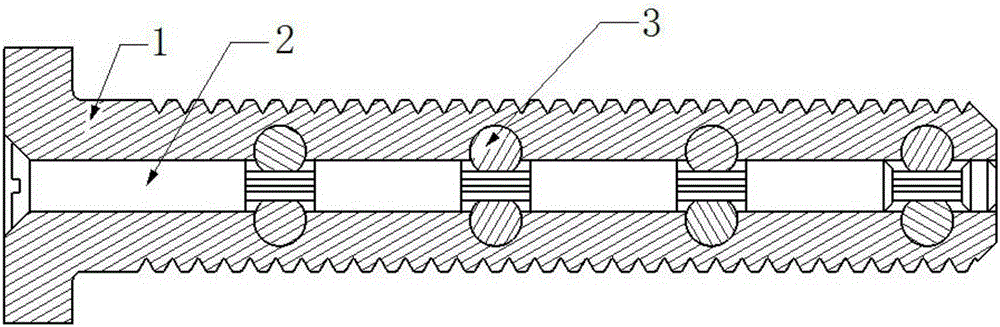

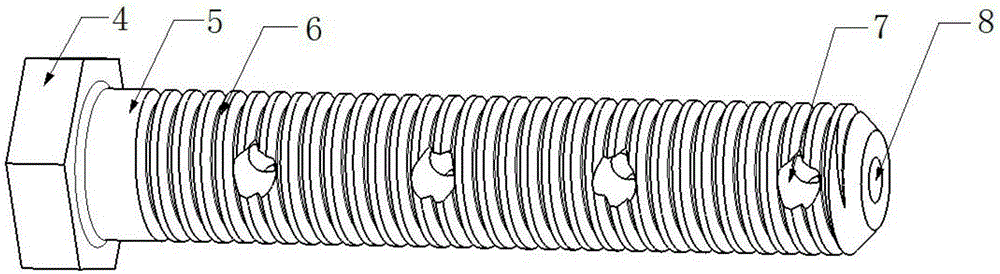

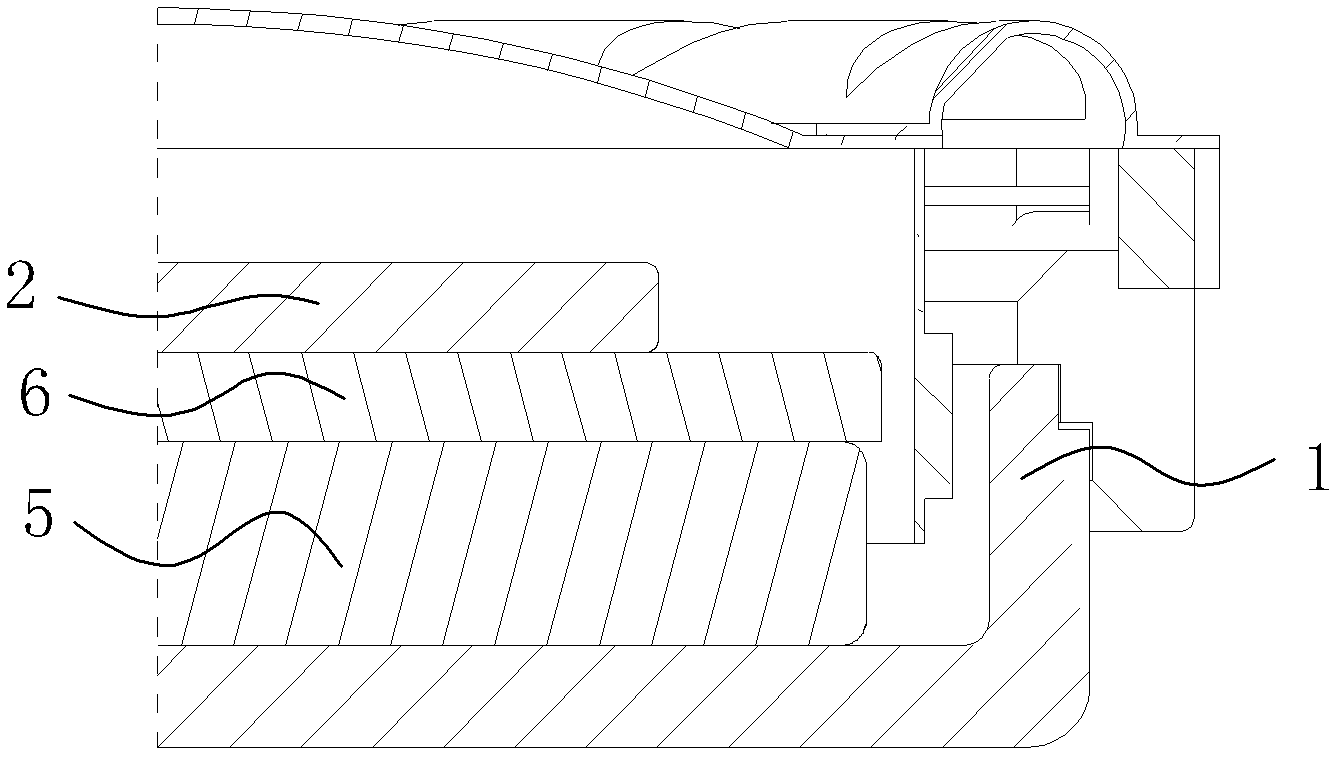

Multi-interlayer detachable pin locking thread assembly for blind hole and locking method

ActiveCN105422594AReasonable structural designImplement a locking structureNutsBoltsEngineeringMechanical engineering

The invention relates to a multi-interlayer detachable pin locking thread assembly for a blind hole. The multi-interlayer detachable pin locking thread assembly for the blind hole comprises a screw located outside and an adjustment pin located inside, wherein an axial throughout adjustment pin hole is formed in the center of the screw, and the adjustment pin is located in the adjustment pin hole; the adjustment pin comprises an adjustment rod, an adjustment end socket is arranged at one end of the adjustment rod, and a stop tail is arranged at the other end of the adjustment rod; a plurality of adjustment tooth posts are arranged on a rod body of the adjustment rod at intervals; a groove for containing the adjustment end socket of the adjustment pin is formed in the outer end of the adjustment pin hole in a flaring mode, and the stop tail blocks the other end of the adjustment pin hole; a plurality of groups of stop pin holes are formed inside the screw in the axial direction, the number of the groups is equal to the number of the adjustment tooth posts, and the outer ends of the stop pin holes are communicated with the outside; stop pins are arranged in the multiple groups of stop pin holes; each stop pin comprises a pin rod, adjustment teeth are arranged on the outer wall of each pin rod and connected with the corresponding adjustment tooth post in an engaged mode, and the stop pins stretch out and draw back in the respective stop pin holes when the adjustment pin rotates. The invention further relates to a locking method.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

A kind of pin connection pin press-in welding method of pcb board

ActiveCN103533779BIncrease installation spaceInstallation will not affectPrinted circuit assemblingWork in processEngineering

The invention discloses a PIN connection pin pressed welding method for a PCB (Printed Circuit Board) board, which comprises the following steps of: A, forming a PIN hole on a PCB bare board; B, correspondingly pressing a PIN connection pin into the PIN hole and enabling the length of an exposed part of the PIN pin cap to be not over 0.2mm; C, forming a mesh opening 0.2mm to 0.8mm away from the PIN pin cap in the PCB bare board; D, installing an electronic component on the PCB bare board to form a PCB board semi-finished product; E, carrying out reflow soldering on the PCB board semi-finished product and welding the PIN pin cap and the PCB together. According to the invention, after the pressure generated when the PIN connection pin is pressed into the PCB board is released by the formed mesh opening, the electronic component is installed, and thus, the pressure is timely released and the installed electronic component has no stress damage risk; the minimum spacing between the PIN connection pin and the electronic component can reach 1mm, so that the installation space of the electronic component is greatly promoted.

Owner:SHENZHEN HUICHEN ELECTRONICS

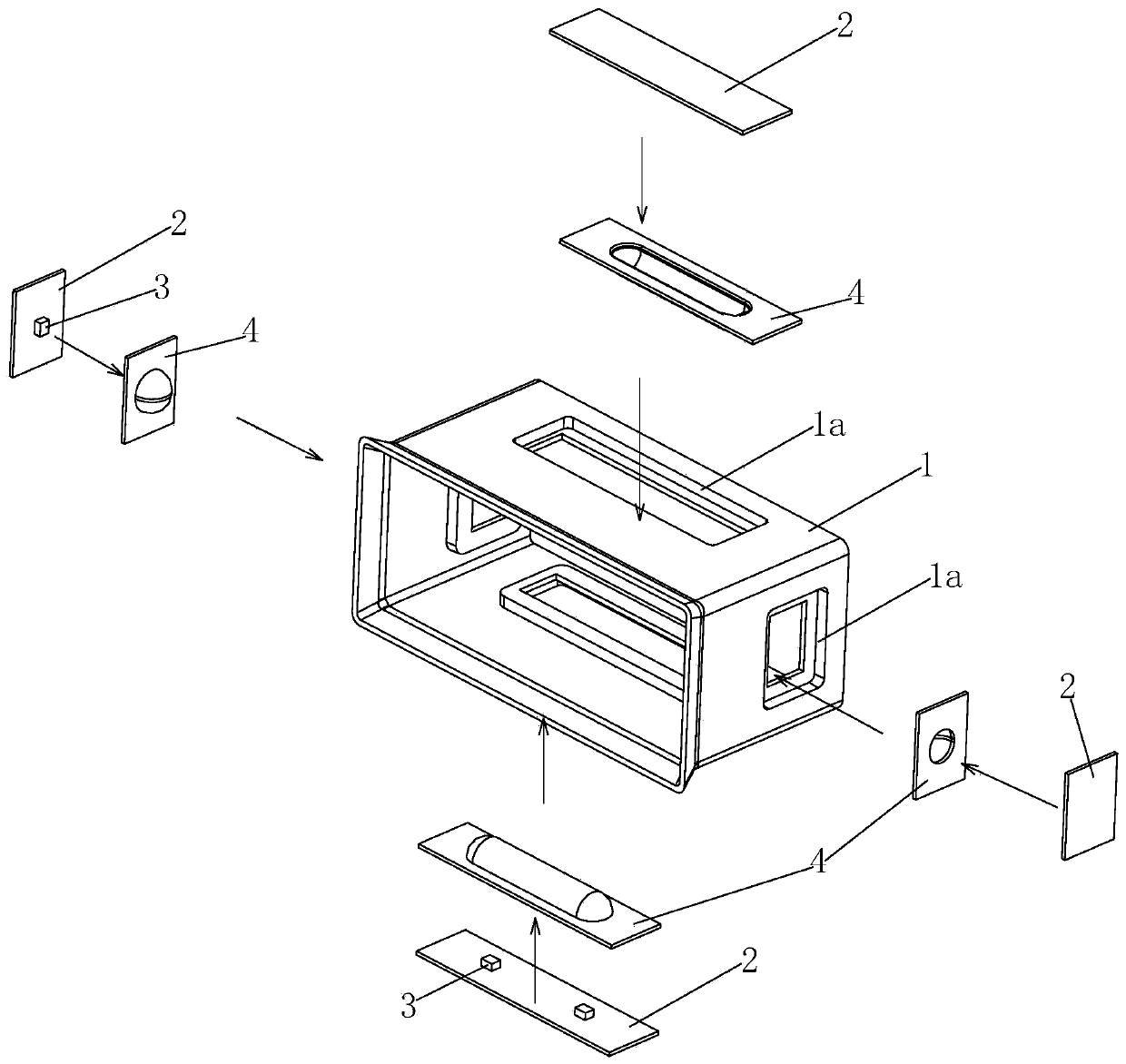

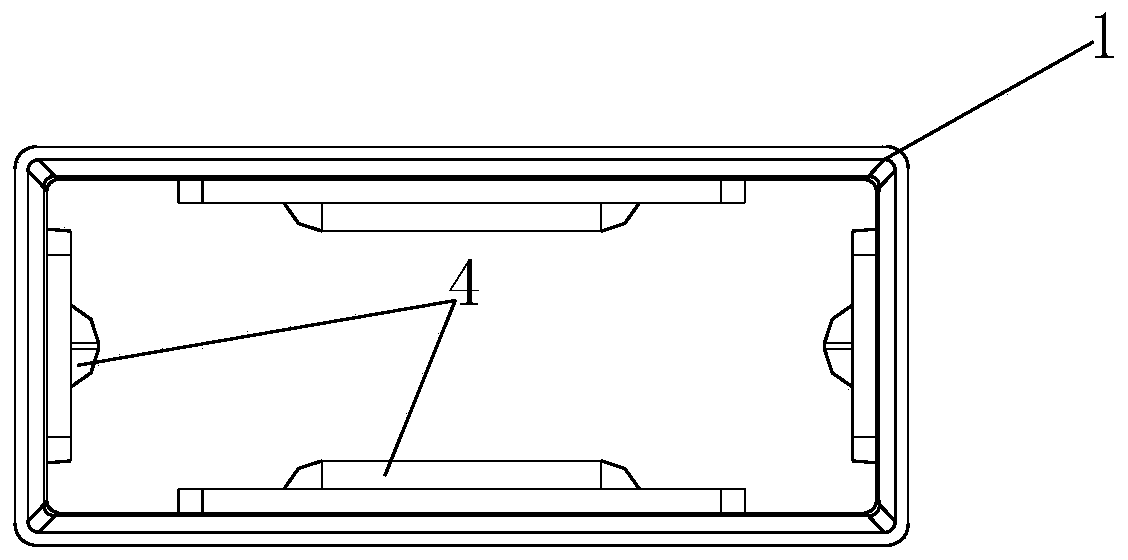

Auxiliary magnetic structure of loudspeaker and assembling method of auxiliary magnetic structure

InactiveCN102647653AInstallation impactInstallation will not affectElectrical transducersMagnetic polesEngineering

Disclosed are an auxiliary magnetic structure of a loudspeaker and an assembling method of the auxiliary magnetic structure. The structure comprises a hollow frame, a lower piece, a primary magnet, an auxiliary magnet, a primary magnet pole piece and an auxiliary magnet piece, wherein the lower piece is arranged at the bottom of the frame, the primary magnet and the auxiliary magnet are arranged on the lower piece, the primary magnetic pole piece is arranged on the primary magnet and an auxiliary magnetic pole piece arranged on the auxiliary magnet. The auxiliary magnetic structure and the assembling method of the auxiliary magnetic structure are applicable to the light and thin loudspeaker and the primary magnet and the auxiliary magnet are convenient to install.

Owner:MERRY ELECTRONICS SUZHOU

A dust-proof window that is easy to clean

ActiveCN109611003BLateral forces in the same directionNo inclinationInsect protectionWindow cleanersEngineeringStructural engineering

Owner:方之航

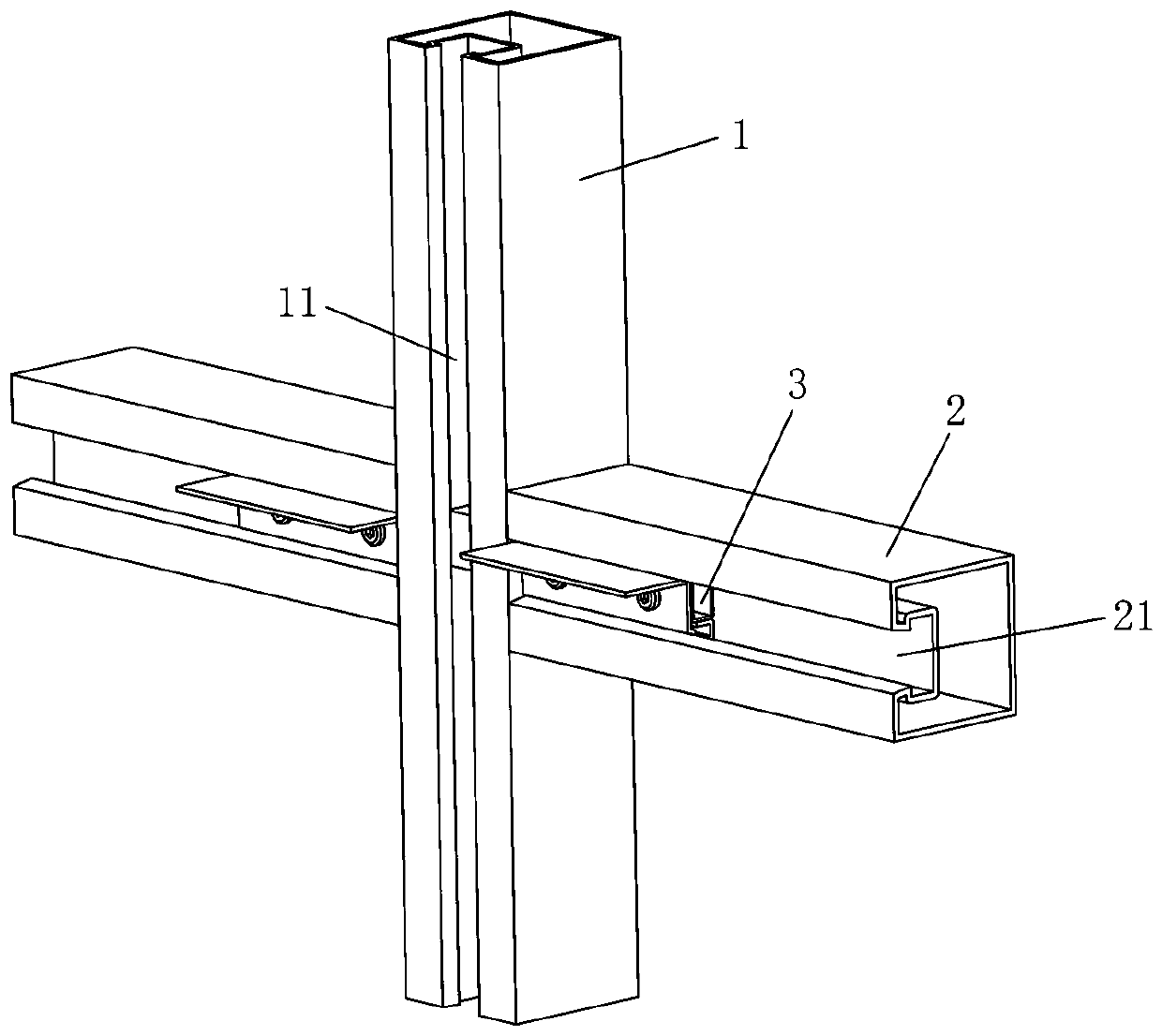

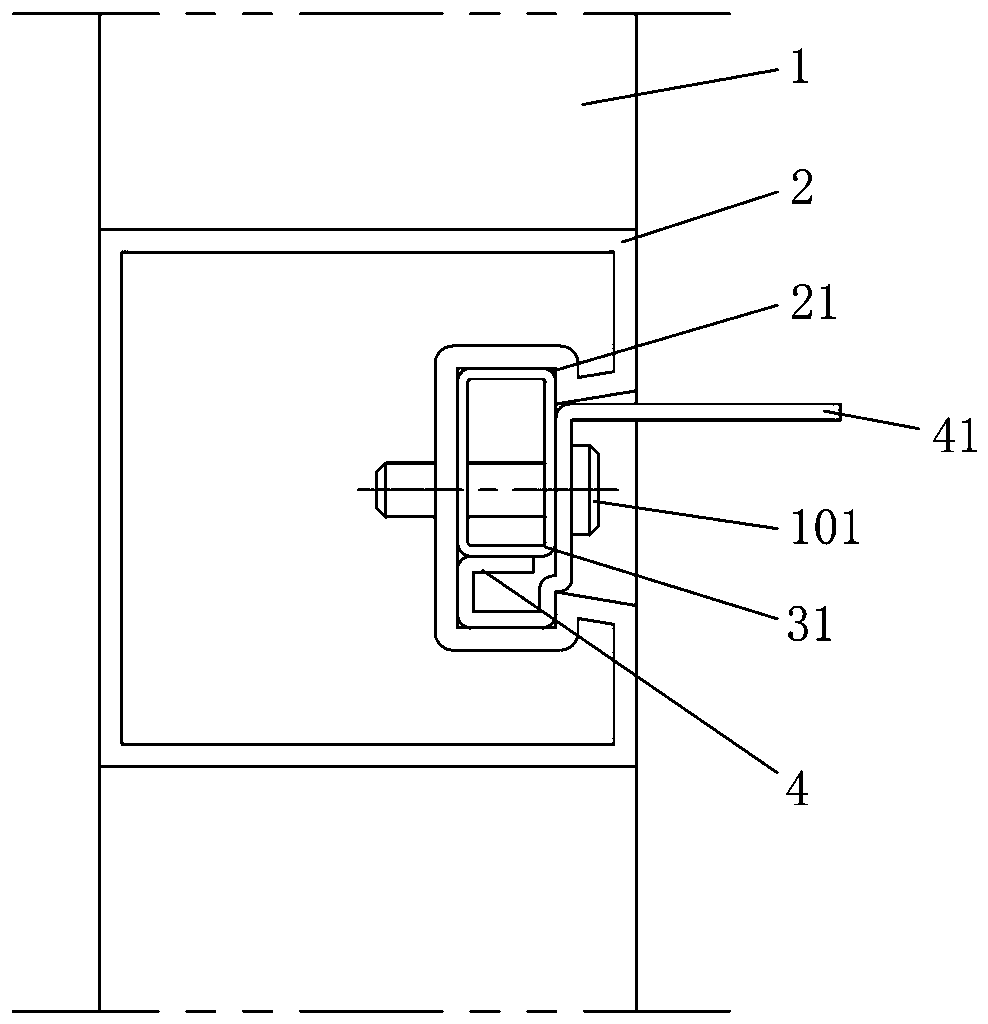

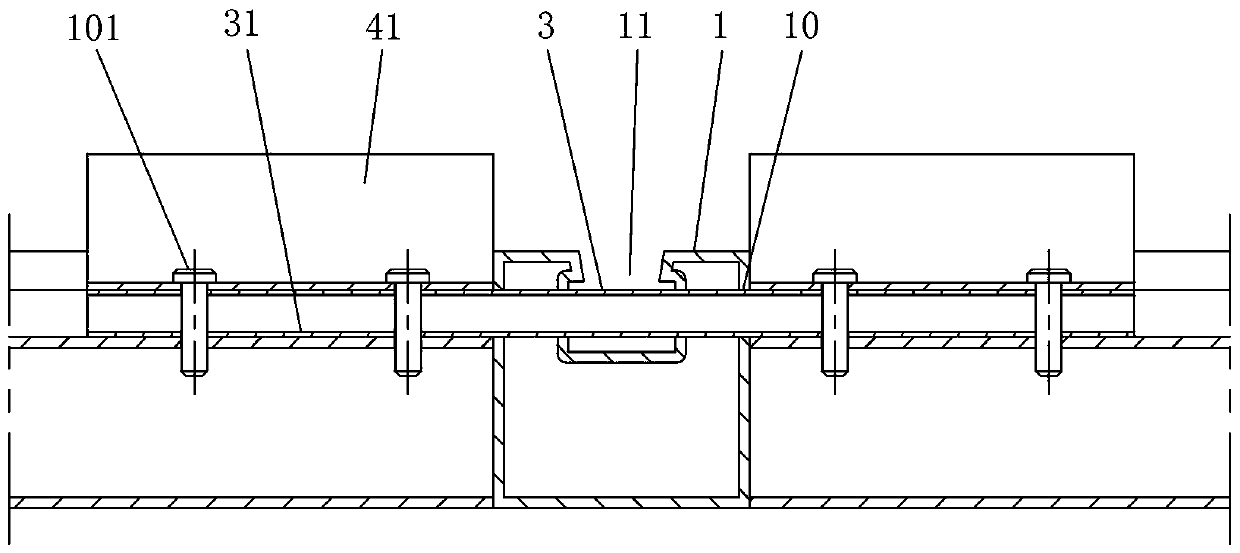

An internally connected curtain wall keel triple connection structure

ActiveCN106948526BImprove simplicity and refinementRestricted degrees of freedomWallsConnection typeKeel

The invention discloses an intra-connection type curtain wall keel triple connection structure. The intra-connection type curtain wall keel triple connection structure comprises a vertical keel and two transverse keels connected to the two sides of the vertical keel through connection assemblies; the vertical keel is provided with a through mounting hole; the transverse keels are provided with transverse inner-expanded grooves; each connection assembly comprises a slide-connection part capable of penetrating through the through mounting hole and moving along the corresponding transverse inner-expanded groove; each slide-connection part is installed in the through mounting hole in a penetrating mode and is only in sliding fit with the through mounting hole; each slide-connection part is provided with two connection portions which are located in the transverse inner-expanded grooves of the two transverse keels and capable of rotating relative to the transverse inner-expanded grooves; and every two connection portions are fixedly connected with the two transverse keels through first fastening assemblies correspondingly. The intra-connection type curtain wall keel triple connection structure has the advantages of being easy and convenient to mount and dismount, high in connection strength, stability and reliability, low in cost, capable of advantageously improving appearance conciseness and refinement of a curtain wall, and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

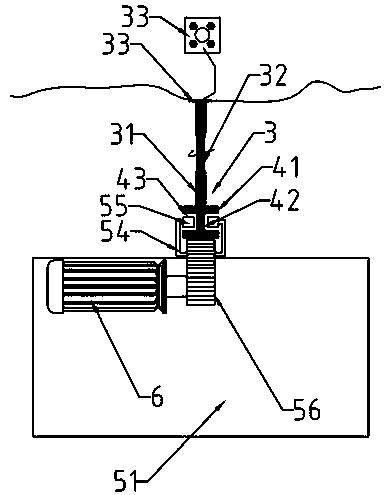

Intelligent toilet flushing structure

PendingCN111236379ARealize physical anti-siphonPlay the role of partitionLavatory sanitoryToilet flushingMechanical engineering

The invention provides an intelligent toilet flushing structure, and belongs to the technical field of toilets. The intelligent toilet flushing structure solves the problem that an existing intelligent pedestal pan flushing structure has a siphonage phenomenon. The intelligent toilet flushing structure comprises a mounting frame fixed in a toilet main body, a water tank arranged in the mounting frame, a first driver and a second driver, the water inlet end of the first driver is connected with the outside; the water outlet end of the first driver is connected with the top of the water tank, the water inlet end of the second driver is connected with the bottom of the water tank, the water outlet end of the second driver is used for being connected with a flushing pipe, and an overflow portis formed in the side portion of the box body and located between the water outlet end of the first driver and the water inlet end of the second driver in the vertical direction. The intelligent toilet flushing structure is provided.

Owner:ZHEJIANG TEJJER INTELLIGENT SANITARY WARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com