Rapier loom weft scissors

A technology of rapier looms and weft yarns, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inaccurate shearing time, increase maintenance costs, affect the accuracy of weft insertion, and avoid weft breakage. , to avoid the effect of weft breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

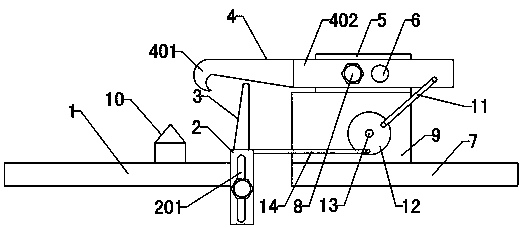

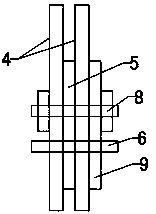

[0018] Figure 1~2 The preferred embodiment of the invention, below in conjunction with the attached Figure 1~2 The present invention will be further described.

[0019] Refer to attached Figure 1~2 : A kind of weft scissors of rapier loom, comprising relatively installed cutter 3 and weft hook cutter 4, the lower part of the cutter 3 is installed on the outside of the weft sley 1 near the chest beam through the cutter positioning adjustment slide seat 2 On the side, the weft yarn hook knife 4 is installed on the loom breast beam 7 by the hook knife mounting frame 9, and the weft yarn hook knife 4 is installed on the hook knife mounting frame 9 by the hook knife rotating shaft 13 rotation; A runner 12 arranged to rotate in the vertical direction is provided, and the end faces of the runner 12 are respectively hinged with a push rod 11 and a pull rod 14, and the tail of the weft hook knife 4 is hinged through the push rod 11, and one side of the cutter 3 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com