Quick cutting-off deslagging valve

A technology of quick cut-off and slag discharge valve, applied in sliding valve, valve details, valve device and other directions, can solve the problems of lack of strength, cutting performance, unable to re-establish the seal, wear of the sealing structure, etc., to shorten the opening and closing time of the valve , high-intensity, fast opening and closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

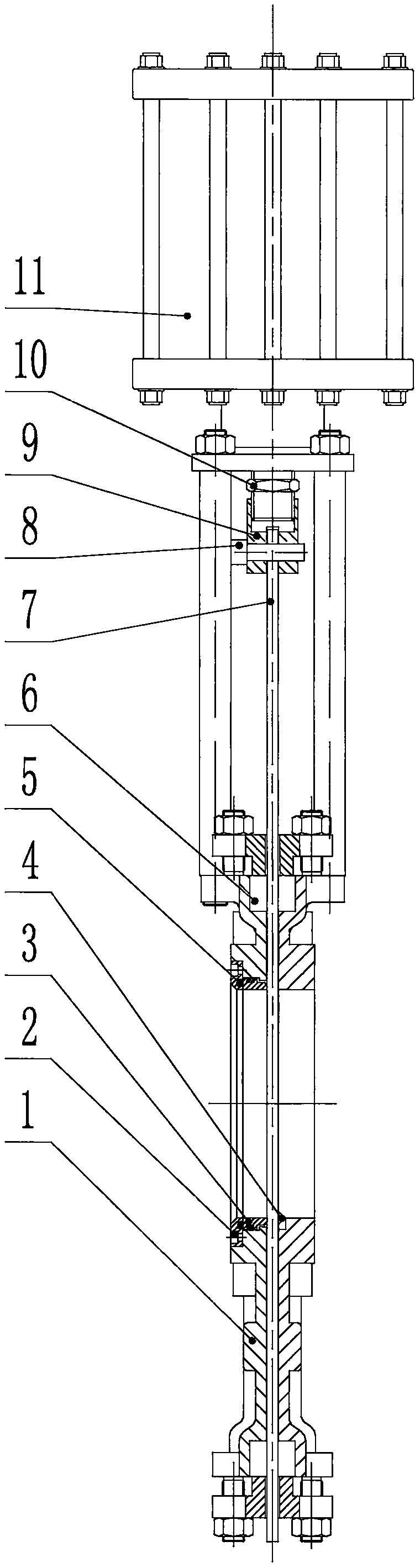

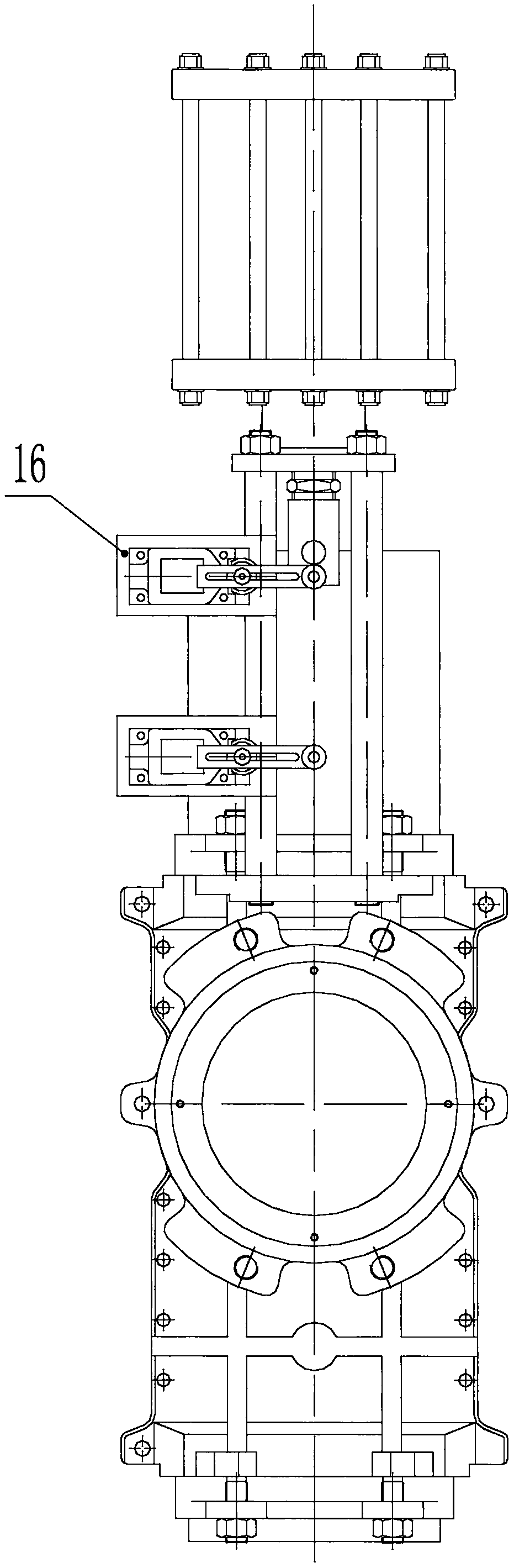

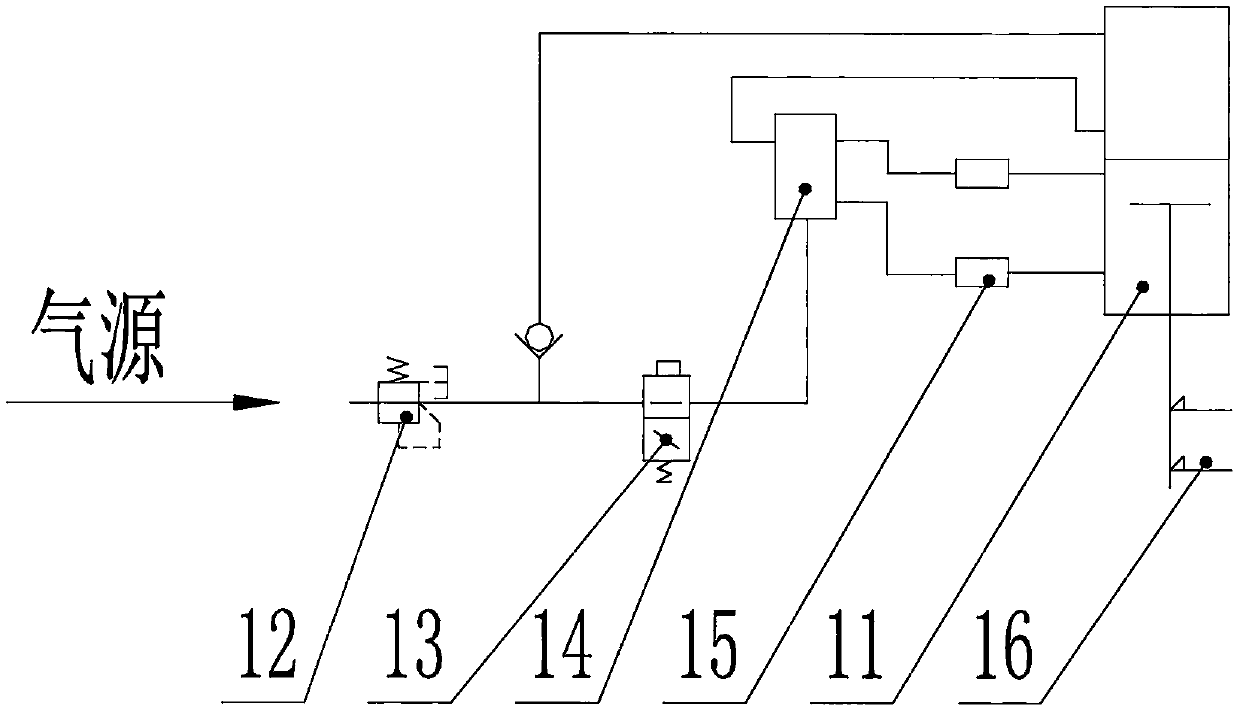

[0034] see Figure 1 ~ Figure 2 , in this embodiment, a fast cut-off slag discharge valve includes a valve body 1, a gate knife 4, a gate plate 7 and a cylinder assembly 11, a gate knife 4 is installed inside the valve body 1, and the gate knife 4 is fixed by a hexagon socket head cap screw On body 1 on the outlet side, see Figure 4-6 As shown, the inside of the switch knife 4 is arc-shaped and equipped with a blade. The switch knife 4 is made of high-alloy structural steel 40MnVB, which has high strength and good cutting performance, and can well realize the cutting function. The valve body 1 shown in the figure Two gate knives 4 are arranged symmetrically on the exit side, and a gate plate 7 is arranged inside the exit surrounded by the gate knife 4. The surface of the gate plate 7 is sprayed with high-nickel alloy and / or carbonitriding to improve the overall hardness of the gate plate 7 And wear resistance, improve the service life of the valve.

[0035] Due to the speci...

Embodiment 2

[0043] see Figure 1-7 As shown, a slag discharge conveying pipeline includes the quick shut-off slag discharge valve described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com