Fuel gas and electricity hybrid heated asphalt mixture sliding type stirring device and working process thereof

A technology of asphalt mixture and electric heating device, which is applied to roads, road repair, roads, etc., can solve the problems of poor heating penetration, difficult to clean, poor economy, etc., and achieves the effect of ensuring heating effect, convenient cleaning and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

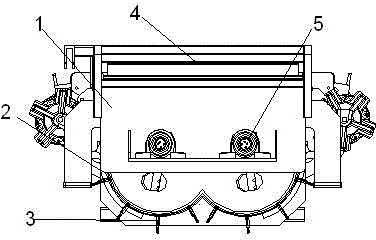

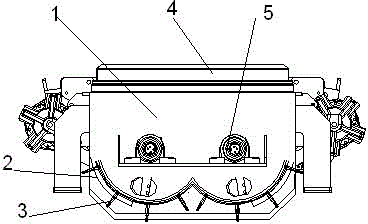

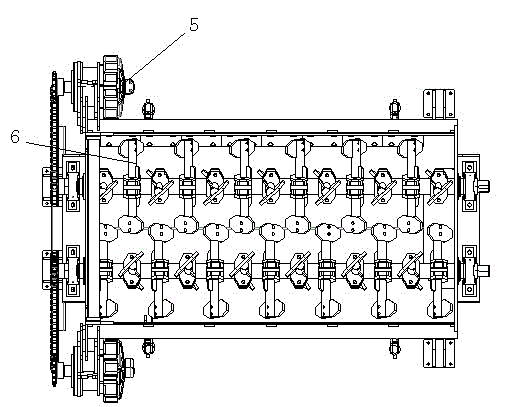

[0031] The core of the invention is to provide an asphalt mixing material mixing device heated by gas and electricity. The device adopts four main parts: 1. Bottom electric heating device 3, which is installed at the bottom of the cylinder body 1, is used for heating the bottom of the cylinder; its working process is to start the engine first, drive the hydraulic pump, and open the oil output ratio of the hydraulic pump through electronic control The solenoid valve is used to drive the hydraulic motor, and the hydraulic motor drives the generator; at the same time, the hydraulic motor has a speed sensor, which feeds back the measured speed to the controller, and the controller adjusts the duty ratio of the proportional solenoid valve in real time, thereby controlling the hydraulic motor. The amount of oil input ensures that the generator works at a fixed speed and the voltage of the generator is stable; finally, the switch of the electric heating device 3 is turned on, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com