Method for manufacturing high tension coil of resin pouring dry type coiling iron core transformer and high tension coil manufactured through method

A resin casting, high-voltage coil technology is applied in the field of transformer manufacturing, which can solve the problems of high-voltage coil manufacturing. , to achieve the effect of being conducive to large-scale use and promotion, easy bending, and simple mold making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

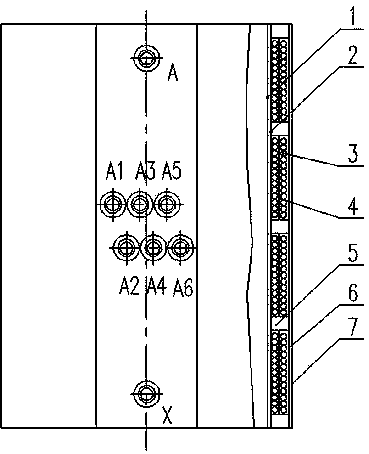

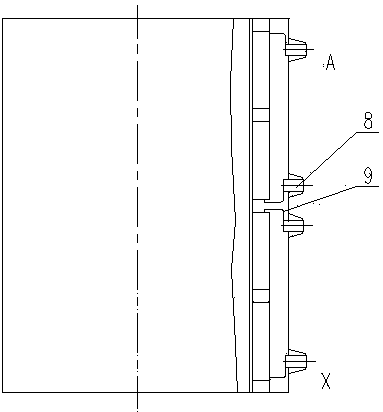

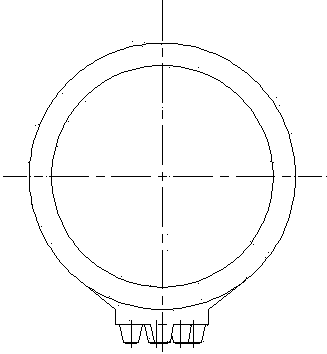

[0025] Such as Figure 1-7 As shown, the invention provides a method for manufacturing a high voltage coil of a resin cast dry-type wound core transformer. First, a set of coil winding mold and a set of resin casting mold are prefabricated. The coil winding mold includes a core tube composed of a plurality of tiles, upper and lower end plates 12 located at both ends of the core tube, and upper and lower end plates 12. The opposite surface is provided with a groove for clamping the core tube, the opposite surface is equipped with a transmission ring gear, and the upper end plate 12 is provided with a pouring port and an exhaust hole. The resin casting mold includes an inner mold and an outer mold. The inner mold is the above-mentioned coil winding mold. The outer mold includes a wiring panel module and a notch ring module. The two modules are combined to form a circle; the high-voltage coil is made according to the following steps:

[0026] (1) Wrap a circle of glass cloth boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com