Automation device for spray-polishing of wooden door oil paint

A technology of automation equipment and wooden doors, applied in spray booths, spray devices, coatings, etc., can solve the problems of poor spray quality, endangering the health of operators, and low production efficiency, so as to achieve good spray quality, eliminate potential safety hazards, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

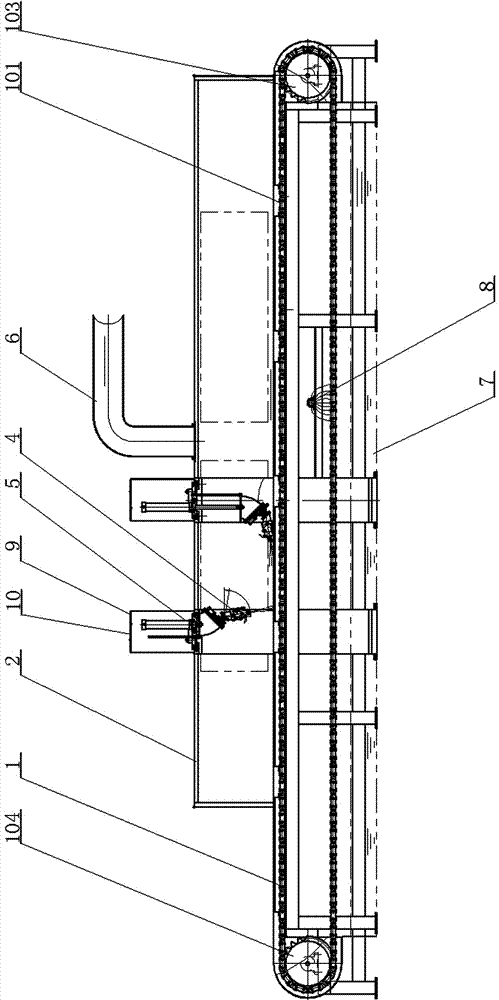

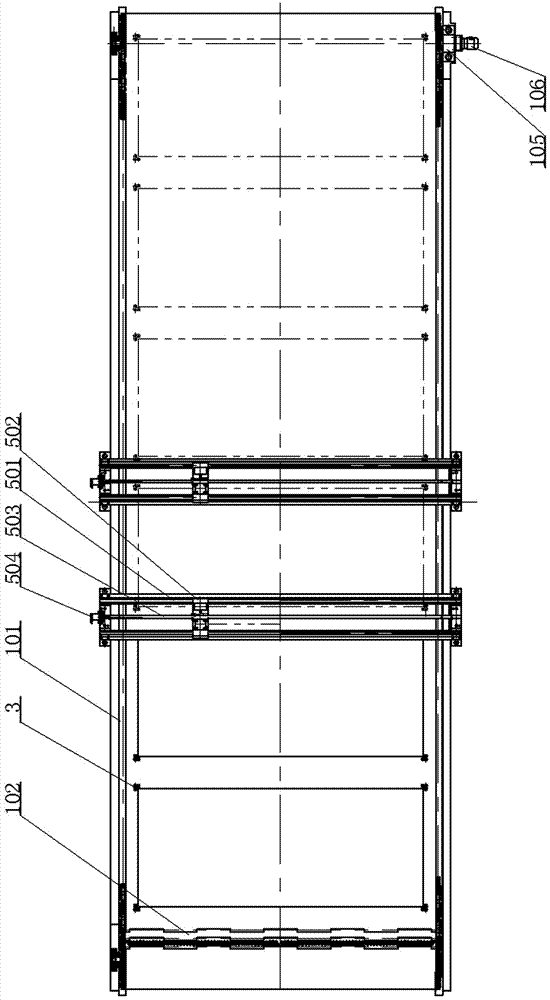

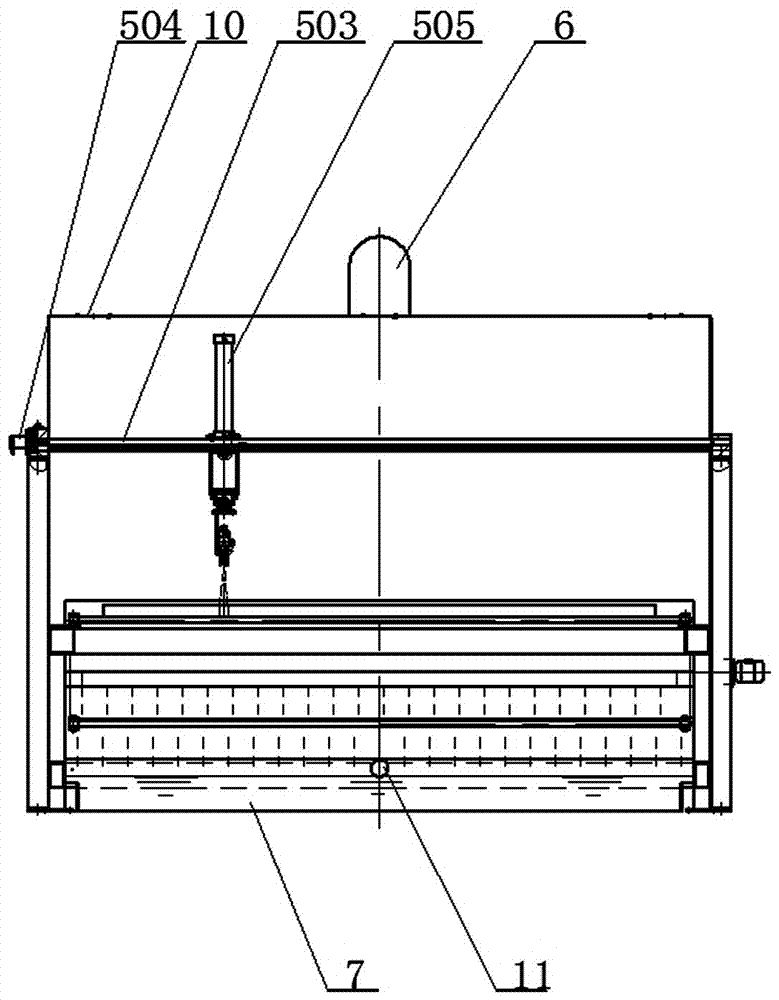

[0016] Depend on Figure 1 to Figure 5 As shown, a wooden door paint spraying automation equipment includes a chain-rail conveying device 1 and a spraying room 2, the upper side of the chain-rail conveying device 1 passes through the spraying chamber 2, and the chain-rail conveying device 1 is provided with The wooden door positioning part 3, the spraying room 2 is provided with a spraying station, and two symmetrical spray guns 4 are respectively arranged above the spraying room 2 on both sides of the corresponding spraying station, and the spraying gun 4 is connected with the pneumatic spraying machine, and the spraying gun 4 is installed On the spray gun drive mechanism 5, the spray gun drive mechanism 5 includes a transverse track 501, a transverse slide seat 502, a ball screw 503, a transverse servo motor 504, a lift cylinder 505, a curved plate 506, a rotary seat 507 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com