Sand ejection nozzle

A sand injection nozzle and sand feeding technology, which is applied in the field of sand injection nozzles, can solve the problems of accelerated sand injection nozzle sealing buffer ring wear, air or sand leakage between the nozzle and the sand injection plate, and reliability decline, and achieves convenient installation and connection. The overall structure Effect of compactness and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

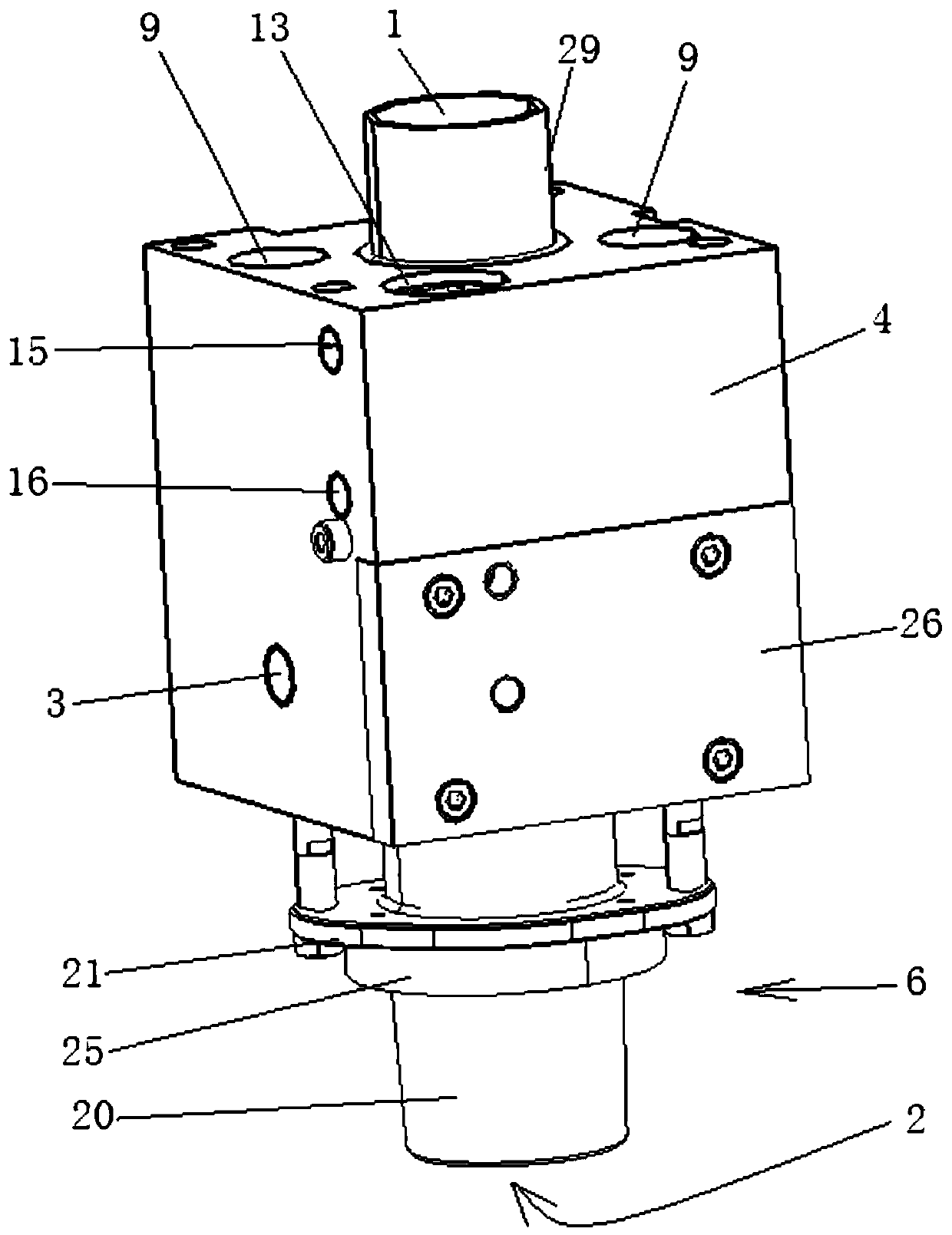

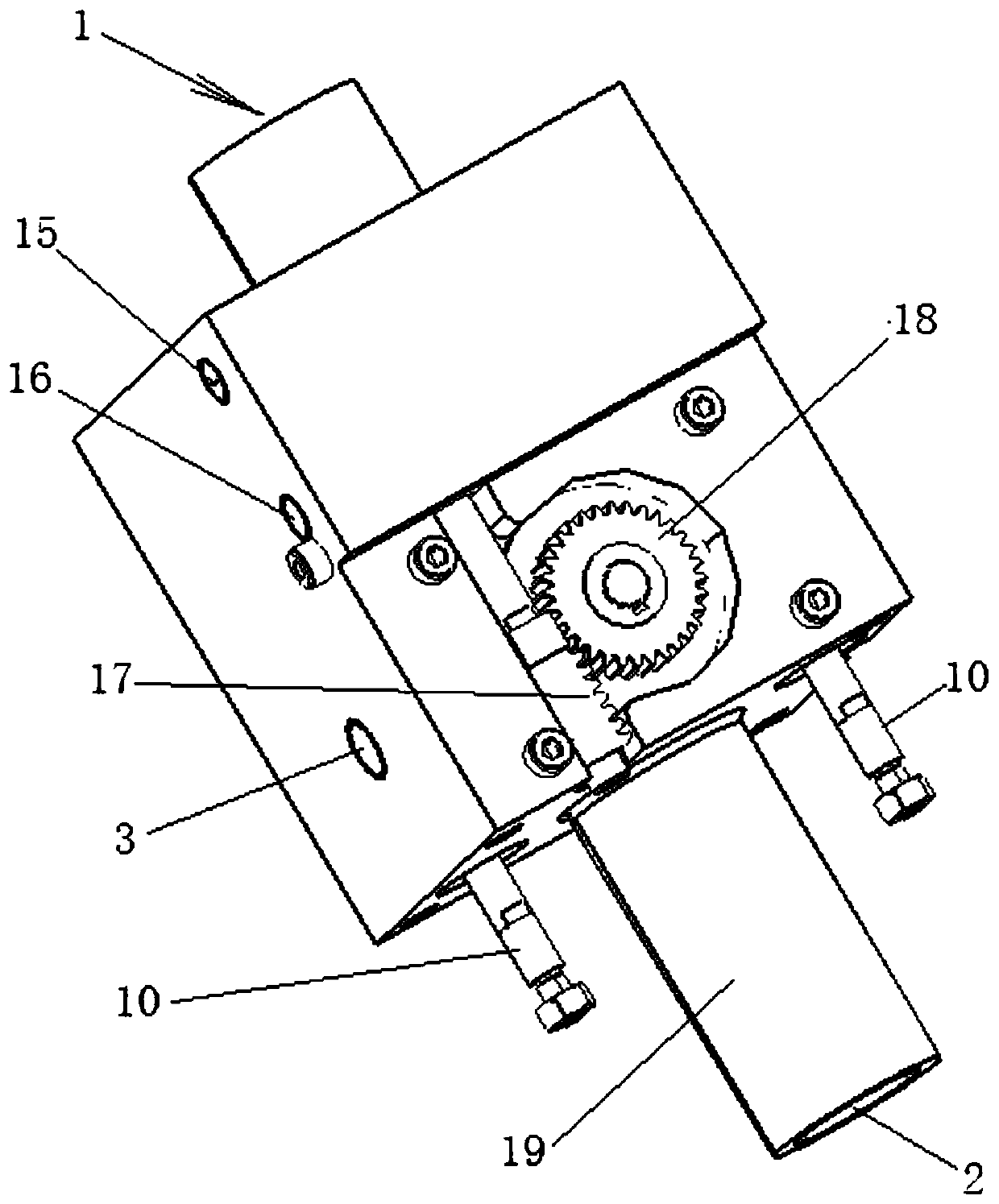

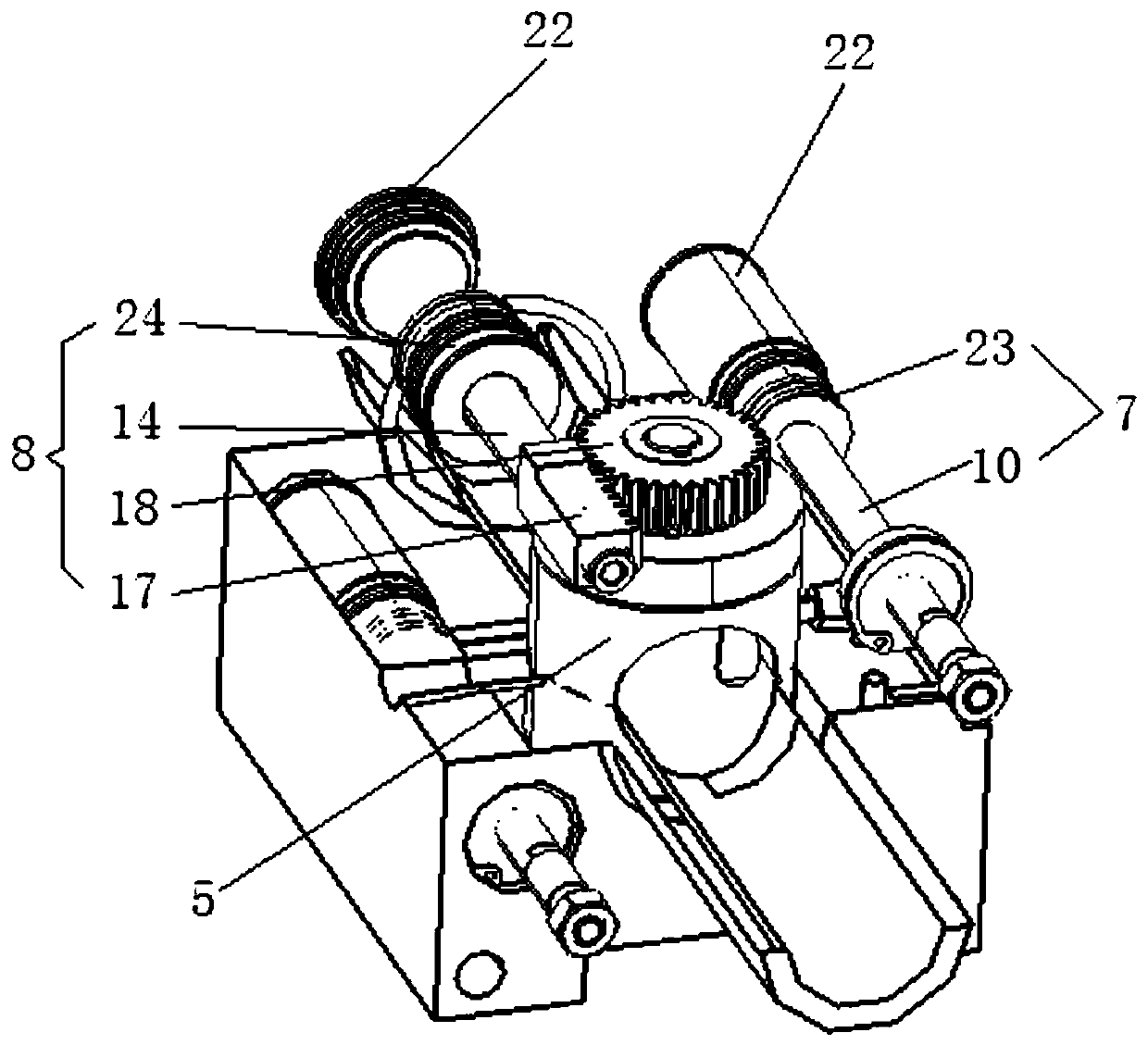

[0041] Such as Figures 1 to 6 Shown is an embodiment of a sand shooting nozzle of the present invention, including a three-way valve body 4 with a sand inlet channel 1, a sand outlet channel 2 and a sand return channel 3, which is arranged inside the three-way valve body 4 and located at the The sand inlet channel 1, the sand outlet channel 2 and the sand return channel 3 intersections are used for the rotary valve core 5 for channel switching. The outlet of the sand outlet channel 2 is connected with a mobile sand outlet pipe assembly 6. The three The valve body 4 is respectively provided with a linear motion actuator 7 and a rotary motion actuator 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com