Installation device for U-shaped grooved plates of strip-shaped bubble cap tray

An installation device and U-shaped groove technology, which is applied in the field of acetylene partial oxidation of natural gas, can solve the problems of poor sealing effect, difficult construction, and easy leakage, so as to improve the efficiency of disassembly and assembly construction and reduce the disassembly and assembly of trays Work load, effect of reducing leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

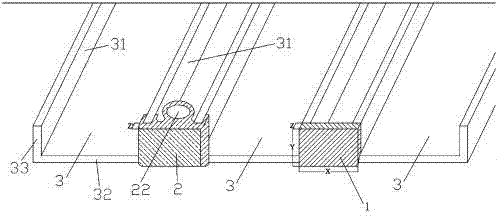

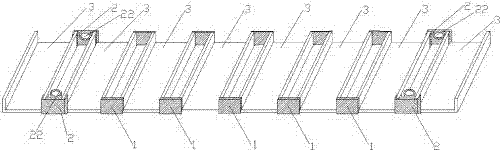

[0019] A device for installing U-shaped groove plates of a strip-shaped bubble-cap tray, comprising a first end plug 1 and a second end plug 2, 5 to 8 U-shaped groove plates 3 form a group, and the U-shaped groove plates 3 in the group Use the first end plug 1 to connect; between groups use the second end plug 2 to connect. Such as figure 1 shown.

[0020] The first end plug 1 is a rectangular block, and the end plug 1 is welded on the outer side of the U-shaped groove plate to connect adjacent U-shaped groove plates. The length X of the first end plug 1 is the distance between two adjacent U-shaped groove plates plus the thickness of the U-shaped side of one side of the two adjacent U-shaped groove plates; the height Y of the first end plug 1 is the U shape of the U-shaped groove plate The height of the side; the thickness Z of the first end plug 1 is 2-5 mm, preferably 3 mm. Such as figure 2 shown.

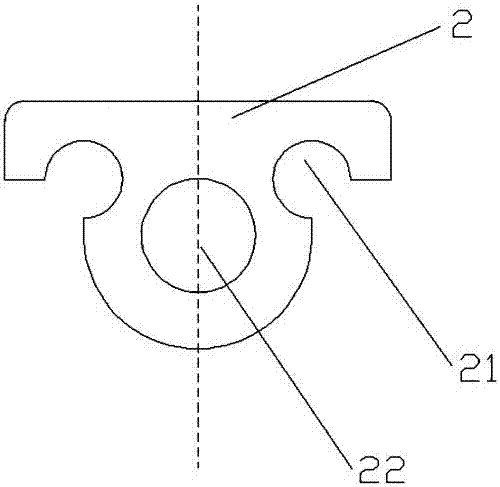

[0021] The second end plug 2 is provided with a center hole 22 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com