A rope-laying device for a follow-up winch

A winch and rope arranging technology, applied in the direction of hoisting device, portable lifting device, clockwork mechanism, etc., can solve the problem of large swing range of fast rope, reduce personnel or property loss, achieve stability, disassembly and assembly The effect of less work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

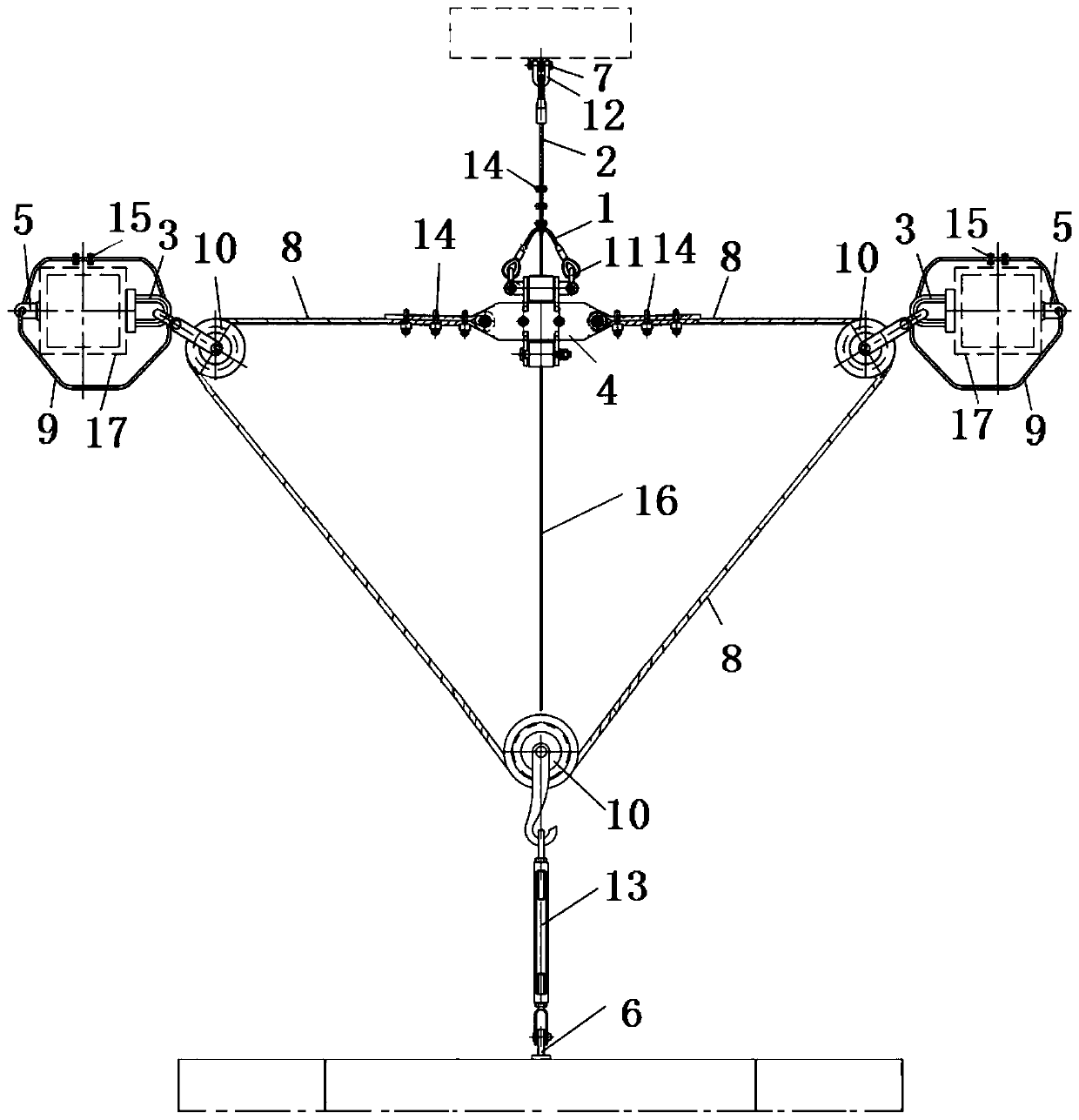

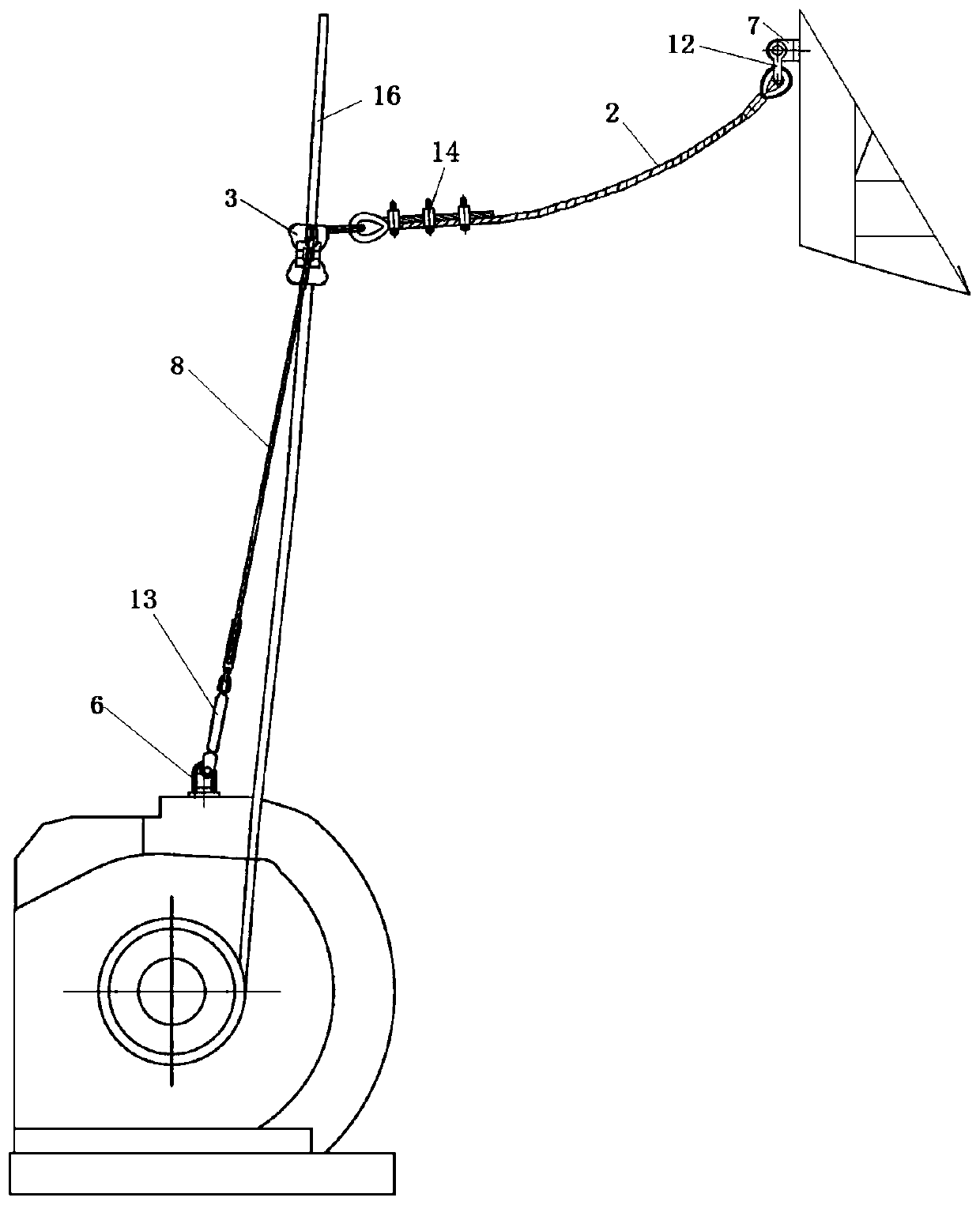

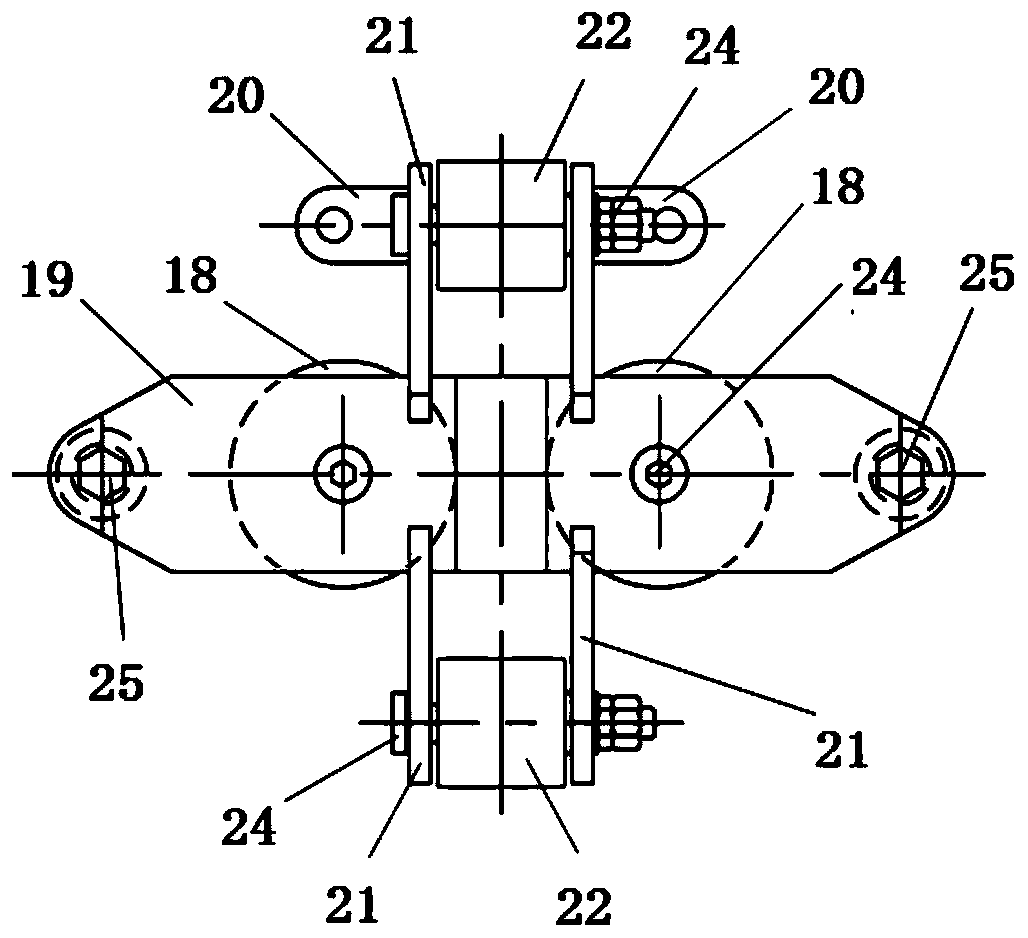

[0019] The present invention is a kind of follower winch rowing device, such as figure 1 and figure 2 As shown, including the steel wire rope a8, the steel wire rope a8 is in the shape of an inverted triangle, and is successively threaded on the outside of three ring-type single-wheel round-toe ring blocks 10, and the two ends of the steel wire rope a8 are respectively threaded on the two ends of the guide wheel group 4, using several ropes The clip a14 is fixed, the ring-type single-wheel round head ring block 10 at the bottom is fastened to one end of the rigging turnbuckle 13, the guide wheel group 4 is fastened to the bow-shaped shackle a11, and each bow-shaped shackle a11 is buckled. Connect one end of the safety rope a1, the middle part of the safety rope a1 is fastened to one end of the safety rope b2, the other end of the safety rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com