adjustable guide

An adjustable and guarded technology, applied in the direction of guiding/positioning/aligning devices, etc., can solve the problems of time-consuming, labor-intensive operators, etc., to improve work efficiency, reduce the workload of disassembly and assembly, and ensure stable rolling. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

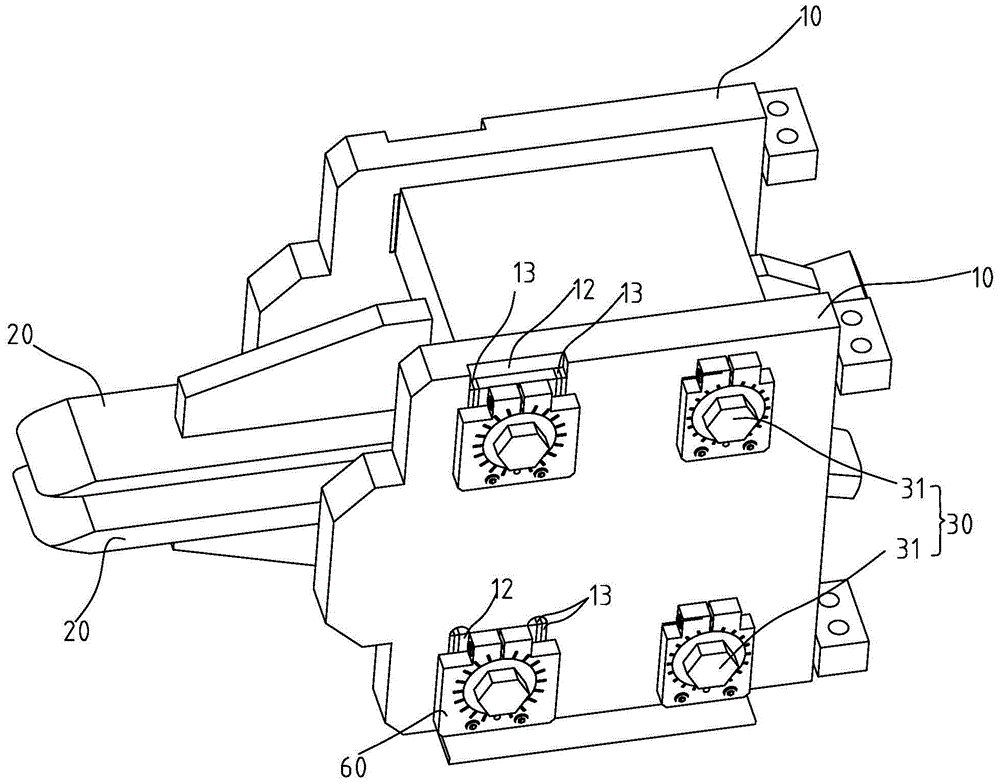

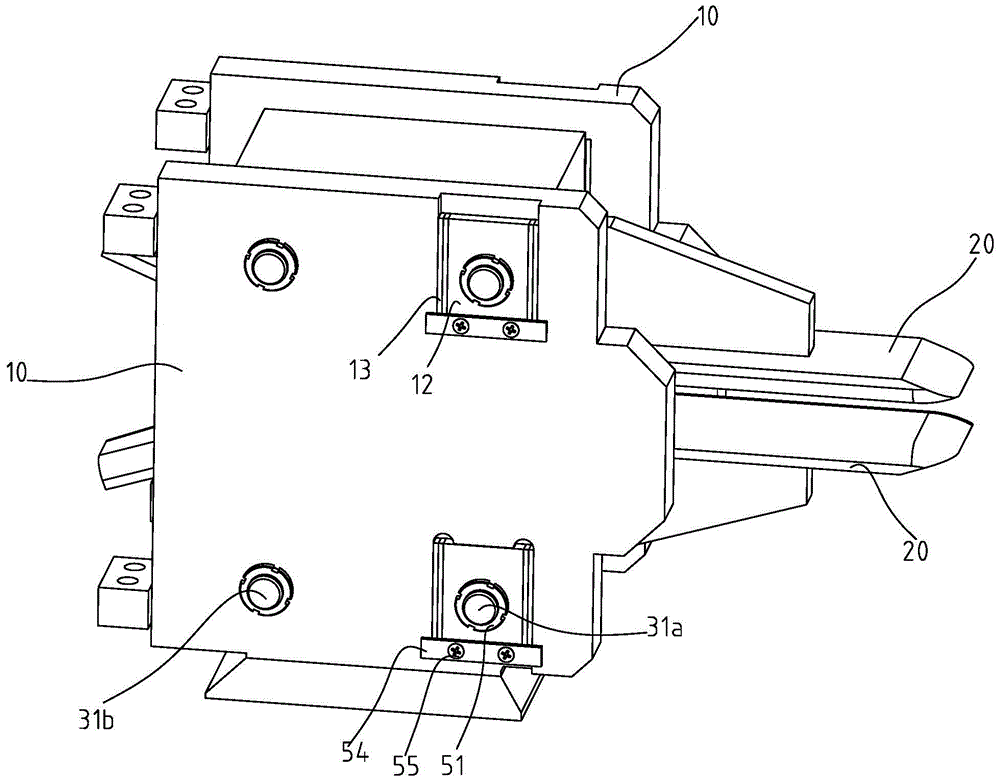

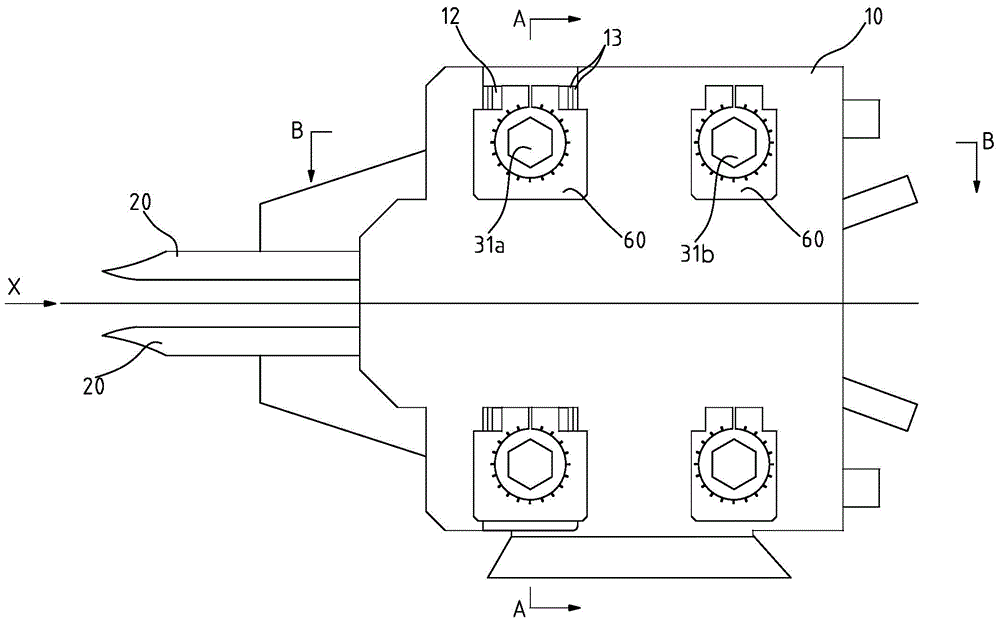

[0024] An adjustable guide body, including a vertically arranged guide body 10 and two correspondingly arranged upper and lower guard boards 20, the said guide body 10 is provided with two pieces and is located on the left and right sides of the two guard boards 20 , the connecting shaft group 30 arranged horizontally and perpendicular to the guiding body 10 is connected between the two guide bodies 10, the connecting shaft group 30 is composed of two connecting shafts 31 arranged in parallel up and down, the two guard boards 20 Respectively fixed on the corresponding connecting shaft 31, two guide bodies 10 and two guard boards 20 enclose a guide path for materials to pass through; the guide body 10 is provided with hole cores arranged along the axis direction of the connecting shaft 31 The square hole 11 is provided with a square briquetting block 12 in the square hole 11, and the middle part of the briquetting block 12 is provided with a middle hole 121 for the connecting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com