Beam-column type support and method for constructing multi-section adjacent bridges using same

A beam-column and bridge technology, which is applied to the preparation and construction of pillars and building components on site, and can solve the problems of long cycle time, troublesome disassembly, handling and assembly, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

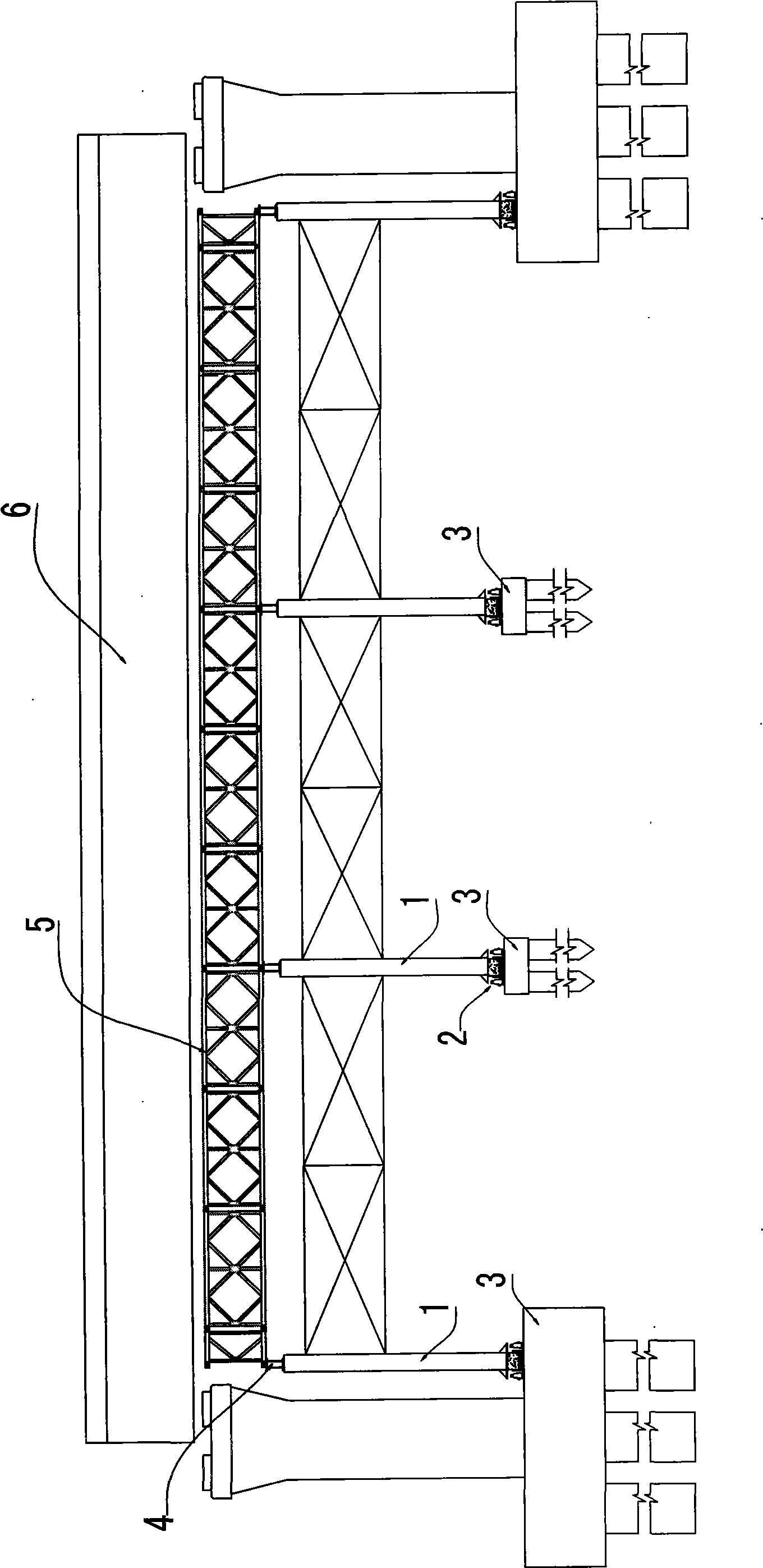

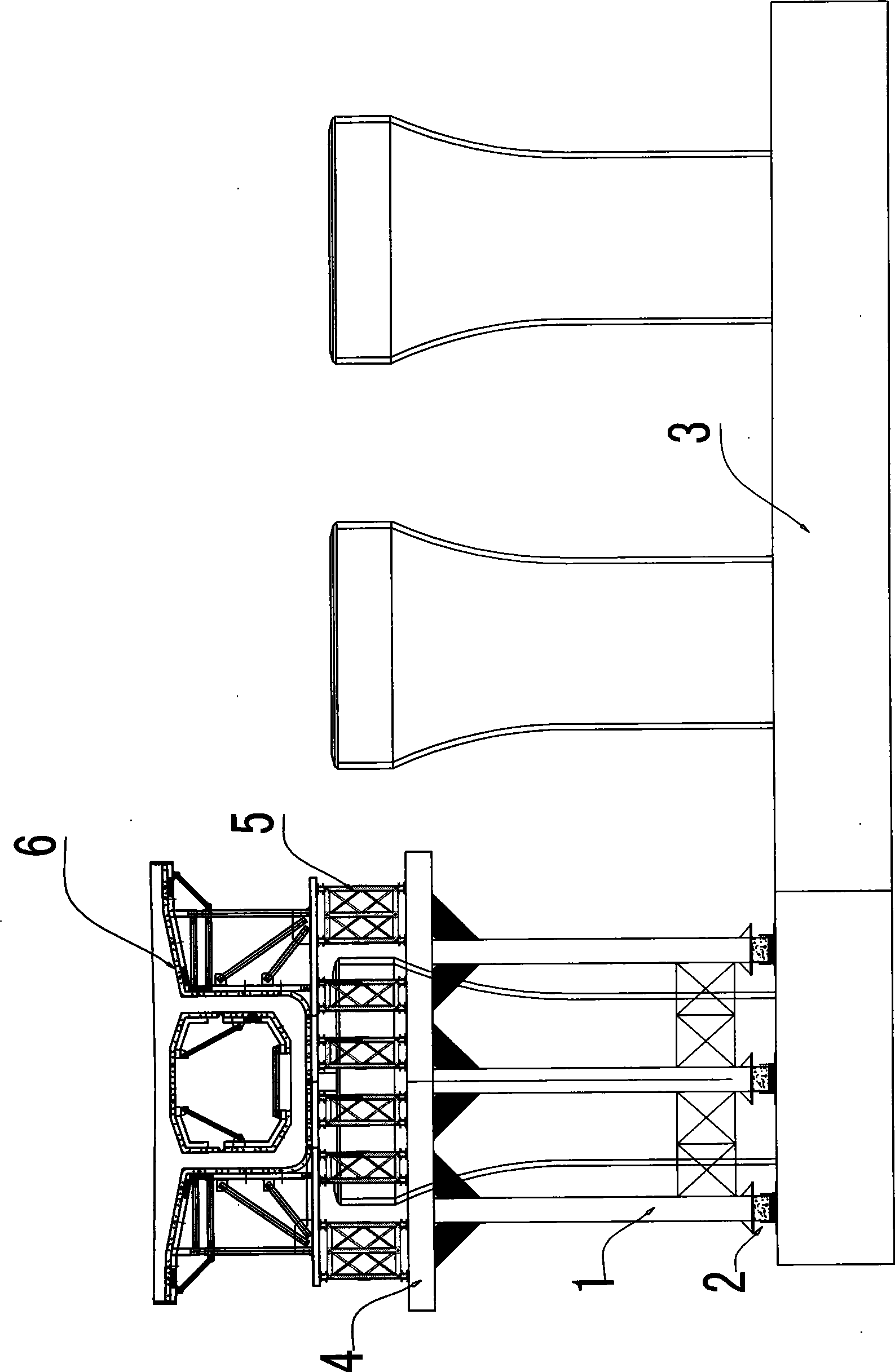

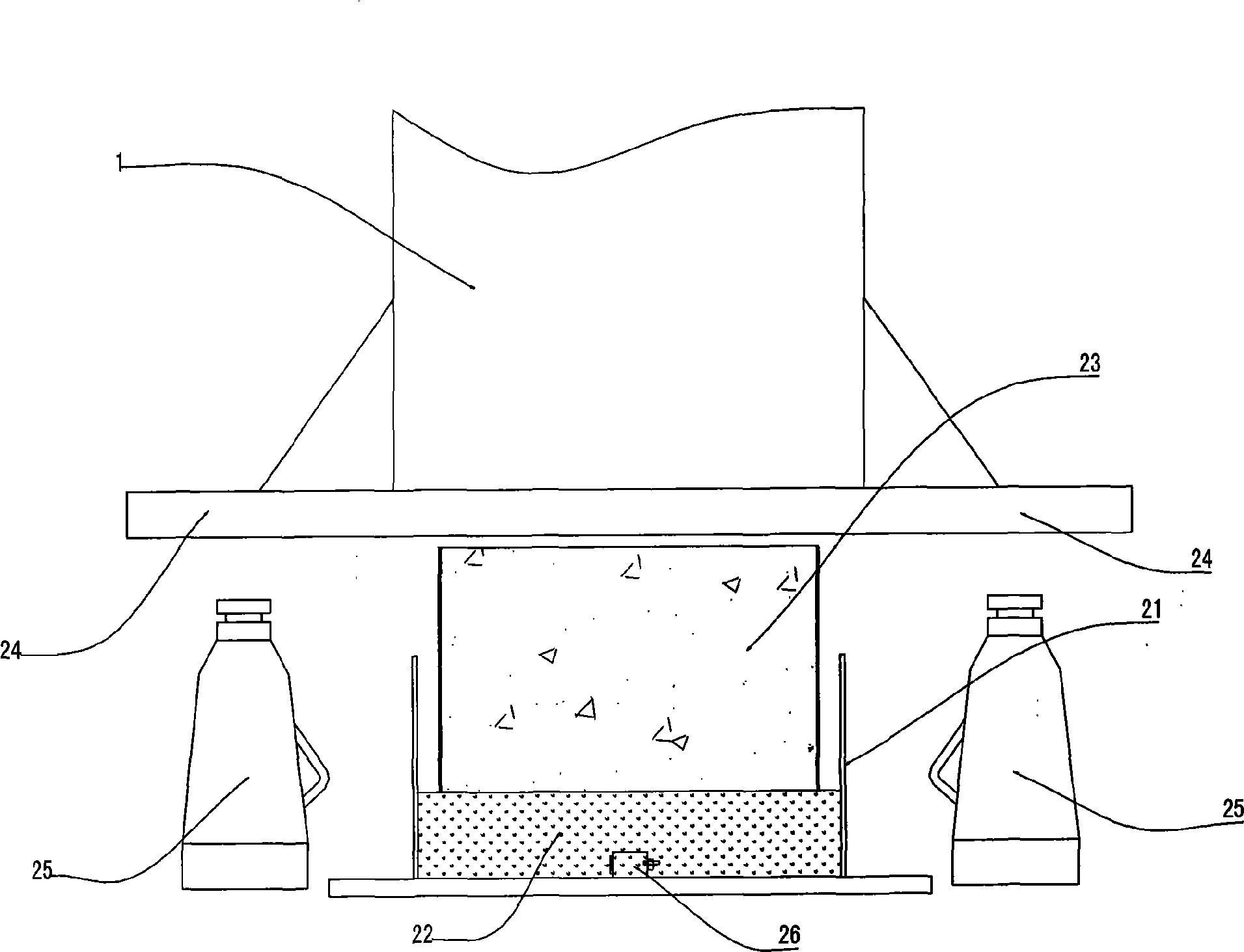

[0023] A beam-column support such as figure 1 , figure 2 , including a plurality of rows of columns 1, each column sits on the base part 3 for supporting it at the bottom through a liftable drop frame device 2, and the drop frame device is a sand bucket 21 with an openable and closed sand discharge port at the bottom, such as image 3 , the top of the sand bucket is open, sand 22 is housed in it, and there is a briquetting block 23 at the bottom of the column, which is placed in the sand bucket through the briquetting block and pressed on the sand in the sand bucket, and the bottom of the column is located at the position above the sand bucket. A flange 24 protrudes outward, and a hydraulic cylinder 25 is installed on the base part below the flange. The falling frame device can also be other widely used existing falling frame structures, which are prior art. The top of the column is equipped with a beam 4 and a longitudinal beam 5 to support the bridge mold 6 above it. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com