Internal connecting type double-connection structure of curtain wall keel

A technology for connecting structures and keels, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of easy looseness, failure safety, poor force balance and stability, and a large number of connectors and screws, etc., to improve simplicity Delicacy and anti-rust ability, high stability and reliability, and the effect of reducing the workload of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

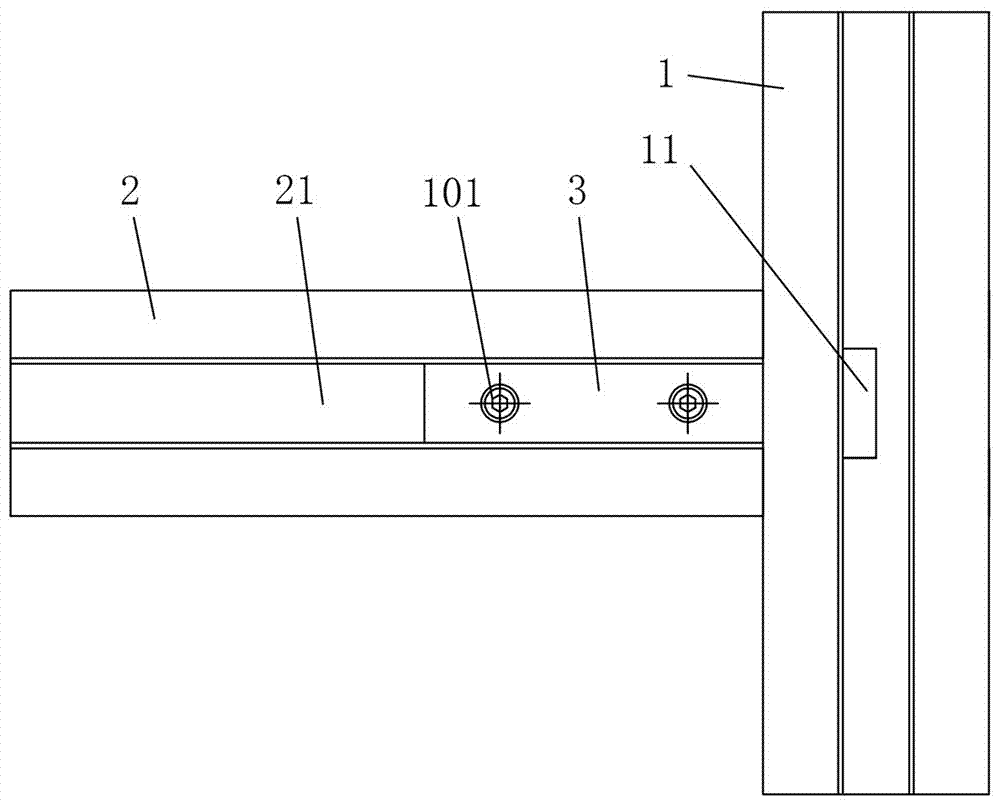

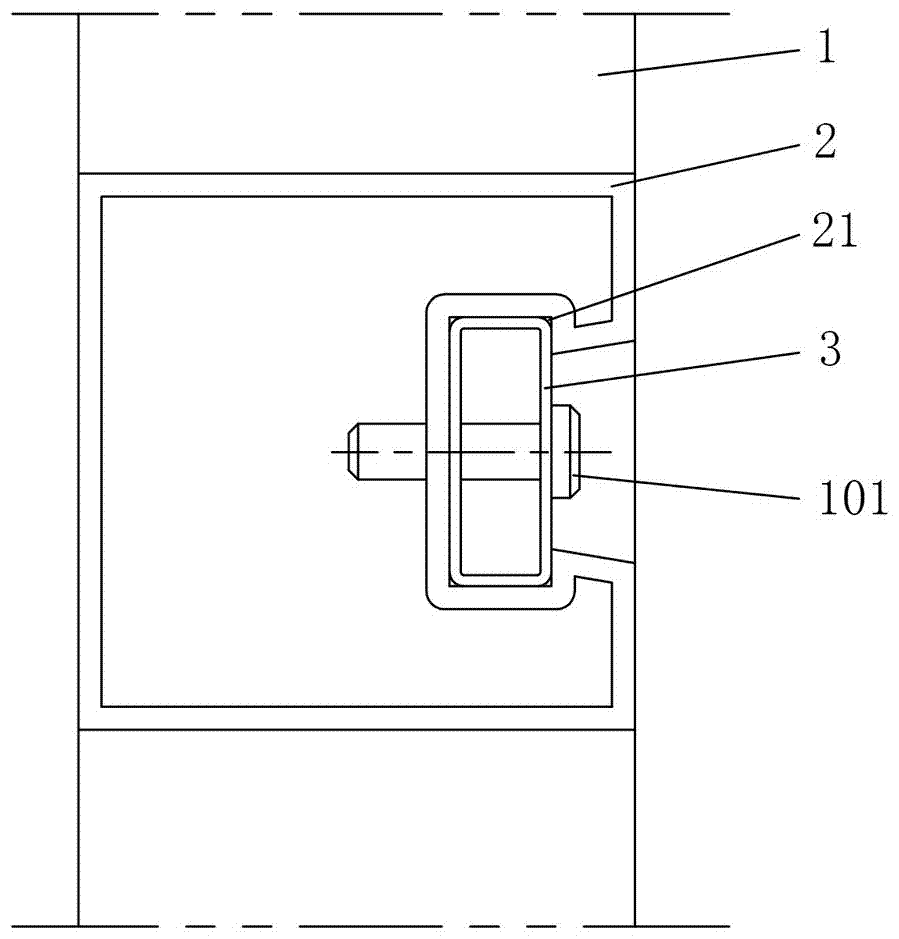

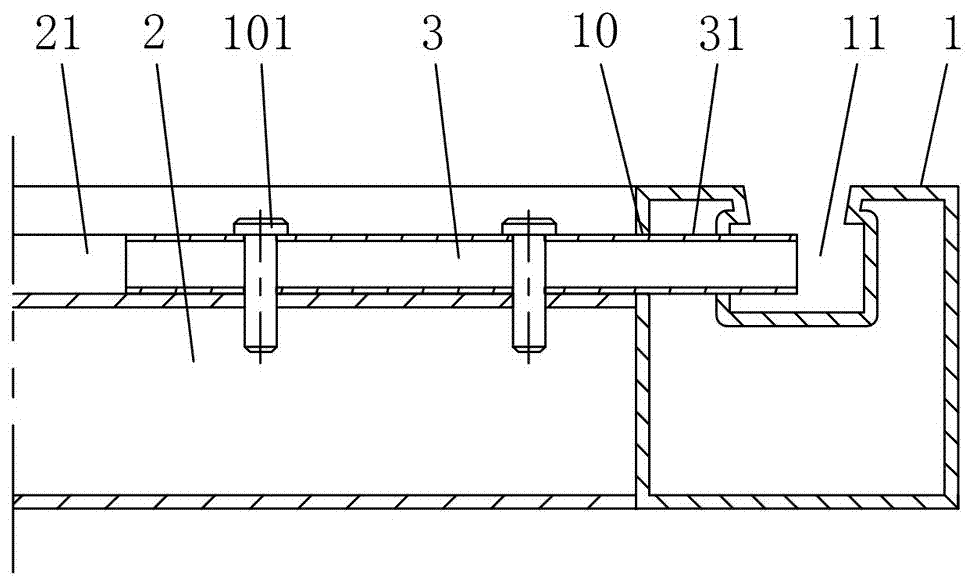

[0037] Such as Figure 1 to Figure 3 As shown, the curtain wall keel internal connection type double connection structure of this embodiment includes a vertical keel 1 and a horizontal keel 2 connected to one side of the vertical keel 1 through a connecting component. The horizontal keel 2 has a laterally expanded groove 21, and the connecting component It includes a connecting piece 3 that is located in the transverse inner expansion groove 21 and can move along the transverse inner expansion groove 21. The connecting piece 3 has an insertion part 31 that is inserted into the vertical keel 1 and only slides with the vertical keel 1. The horizontal keel 2 It is fixedly connected with the connecting piece 3 through the first fastening component. The vertical keel 1 of this embodiment is provided with an insertion hole 10, the insertion hole 10 is a rectangular hole, the connector 3 is a rectangular pipe, one end of which is inserted into the rectangular hole as the insertion pa...

Embodiment 2

[0042] The curtain wall keel internal connection double connection structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 4 As shown, the first fastening component in this embodiment is a second fastening screw 102 , and the second fastening screw 102 is threadedly mounted on the connecting member 3 and compresses the transverse keel 2 .

[0043] The second fastening screw 102 of this embodiment does not perforate the transverse keel 2 , which can reduce the impact on the strength of the transverse keel 2 , improve the anti-rust ability of the transverse keel 2 , and the installation difficulty of the second fastening screw 102 is small.

Embodiment 3

[0045] The curtain wall keel internal connection double connection structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 5 As shown, the present embodiment is also provided with a supporting member 4 for supporting the curtain wall panel to facilitate the installation of the curtain wall panel. The supporting member 4 is fixedly connected with the transverse keel 2 and the connecting member 3 through the first fastening assembly, specifically, The first fastening screw 101 simultaneously connects the fastening holder 4 , the connecting piece 3 and the transverse keel 2 .

[0046] The first fastening screw 101 of this embodiment simultaneously connects the fastening holder 4 , the connecting piece 3 and the transverse keel 2 , which can save the number of fasteners, reduce costs and simplify installation. In other embodiments, the supporting part 4 can also be connected with the connecting part 3 as one piece, or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com