Fixing bottom case of LED display screen module

A technology of LED display screen and fixing part, which is applied to instruments, identification devices, etc., can solve the problems of affecting production efficiency, large amount of screws, difficult operation, etc., and achieves the effect of uniform distribution of nuts, small number of nuts, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

[0020] In the present invention, in the absence of a contrary statement, the used orientation words such as "up and down" usually refer to the direction shown in the drawings, or refer to the vertical, vertical or gravity direction Similarly, for the convenience of understanding and description, "left and right" usually refer to the left and right shown in the drawings; The words are not used to limit the invention.

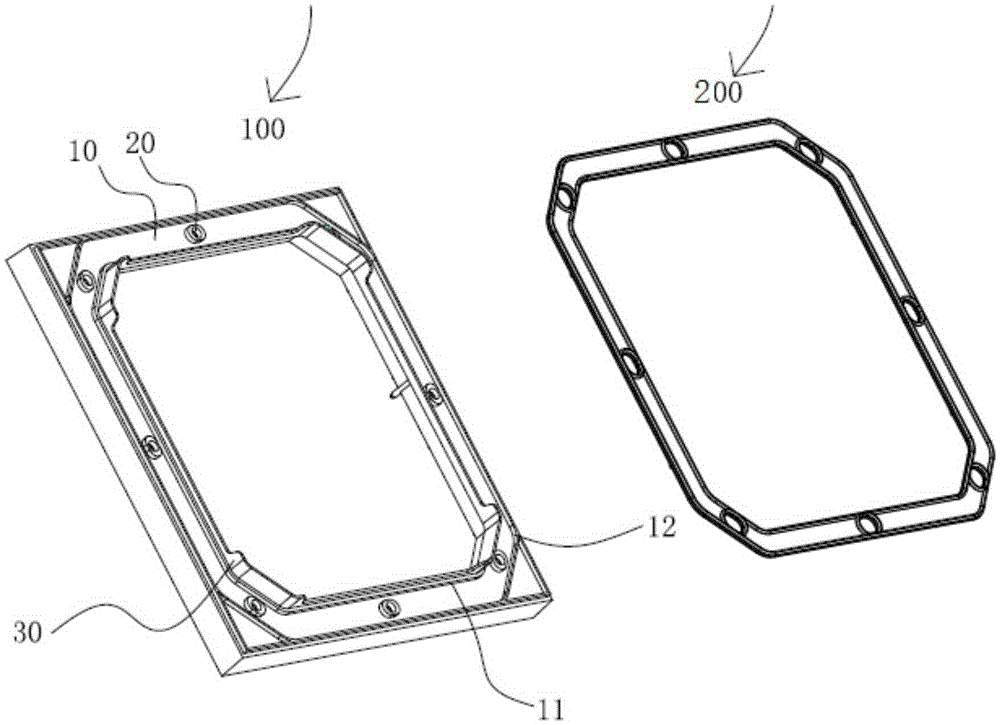

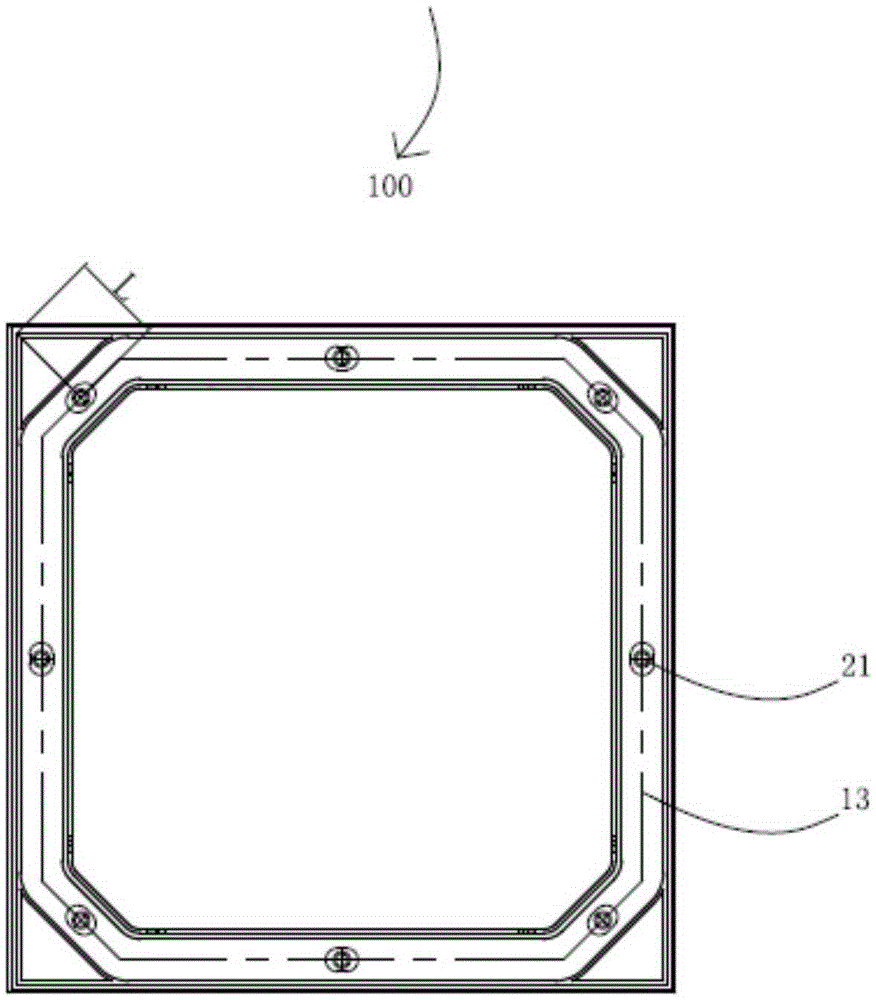

[0021] Such as figure 1 , figure 2 As shown, the present invention proposes a fixed bottom case 100 for an LED display module, which includes a sealing groove 10 disposed on the edge of the upper surface of the fixed bottom case 100 and a fixing portion 20 disposed in the sealing groove 10. The fixing part 20 is used for fixing the LED display module and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com