High strength concave type ceiling keel

A high-strength, concave-shaped technology, applied to ceilings, building components, buildings, etc., can solve the problems of poor joint shape and low structural strength, and achieve the effects of small protrusion height, good decorative effect, and improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

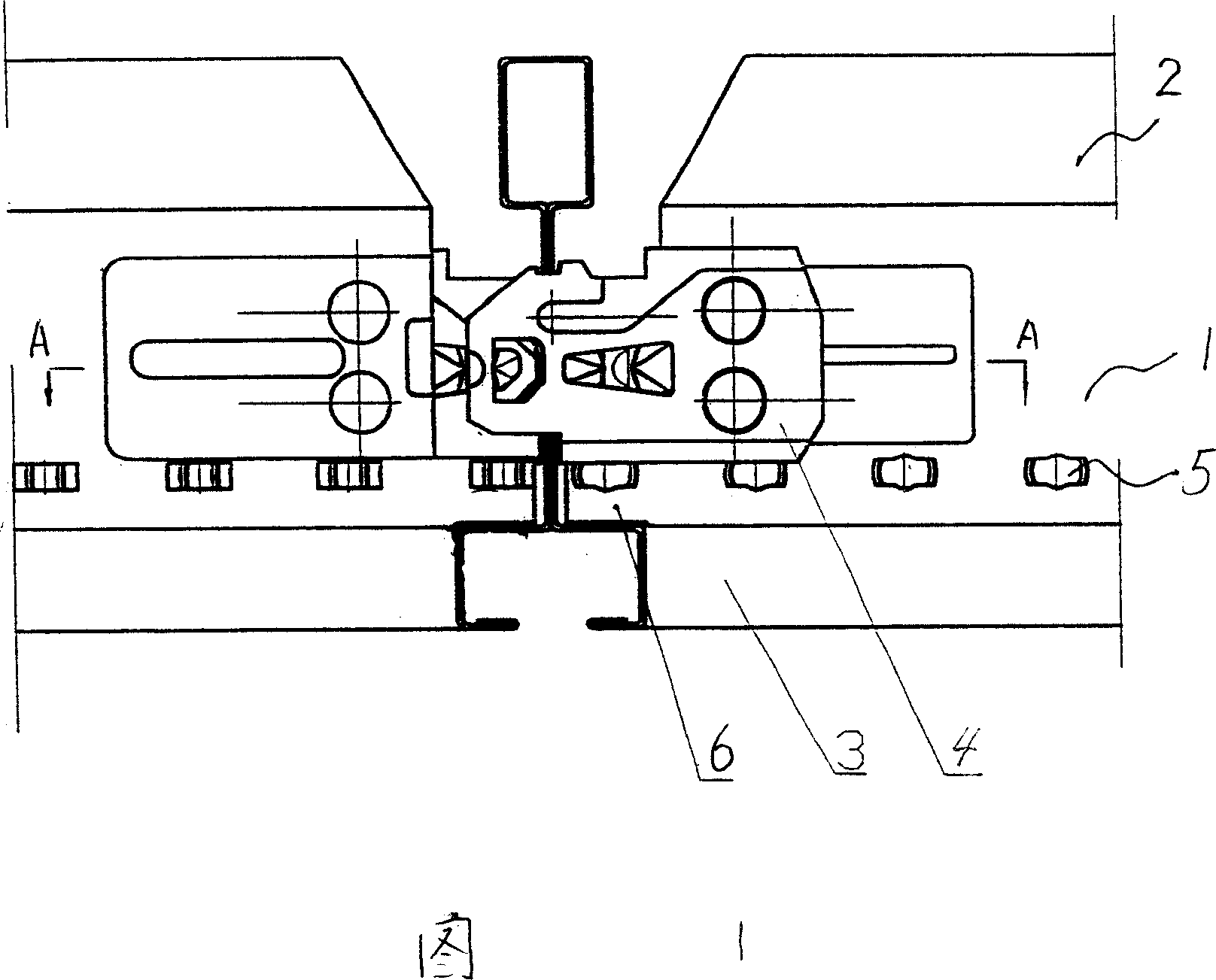

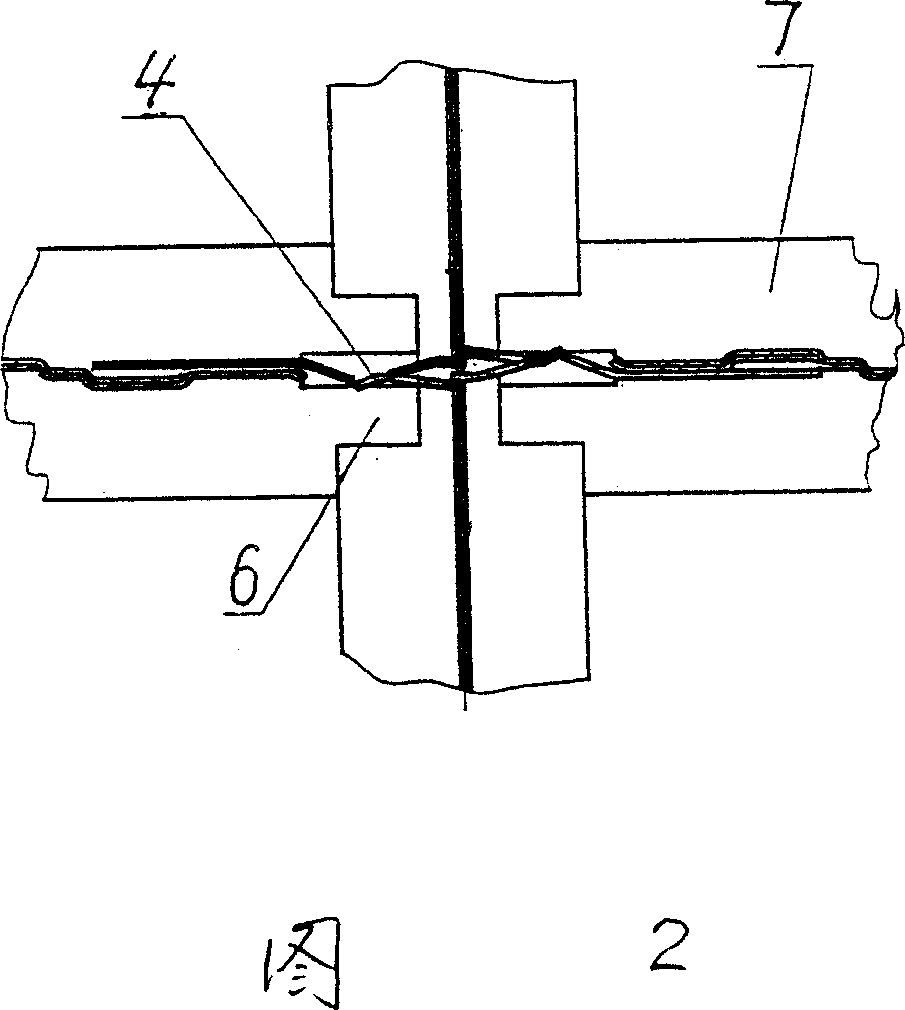

[0021] As shown in Figures 1 and 2: the main keel can be the same as the prior art, and the auxiliary keel is also made of a metal plate folded and pressed together with the prior art. It has a rib plate 1, an upper edge 2 and a lower edge 3, and the rib plate There are ends 4 at both ends of 1, and there are a plurality of occlusal points 5 on the rib plate 1, and at both ends of the rib plate 1 and the lower edge 3, there are lap plates 6 for lapping on the main keel, and the lap plates 6 are in the form of L-shaped, one side is located on the inner top surface 7 of the lower edge 3 , and the other side is located on the rib 1 between the end 4 and the lower edge 3 .

Embodiment 2

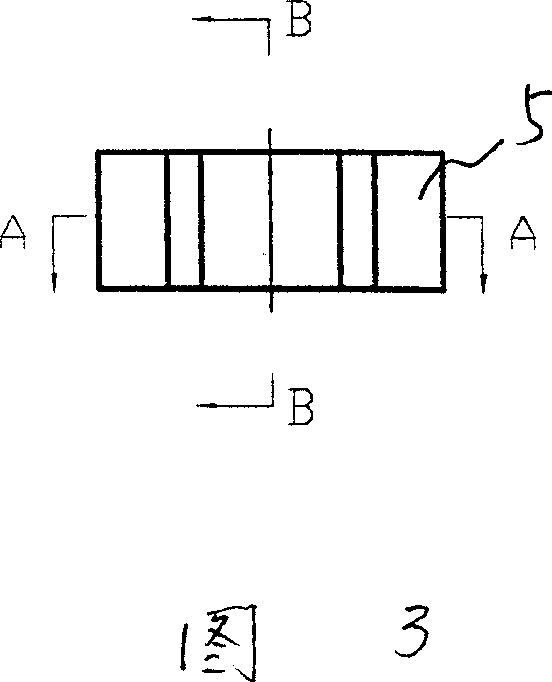

[0023] Others are the same as in Embodiment 1, except that a plurality of occlusal points 5 are in a row. As shown in Figures 3, 4, and 5: the occlusal point 5 is formed by shearing, pressing, stretching, and rolling processes, and its plane protrusion height is 1.57 mm, which is located 10 mm above the bottom edge of the lower edge 3 .

Embodiment 3

[0025] Others are the same as embodiment 1 or embodiment 2, but the end 4 is made of 0Cr18Ni9 / SUS304 stainless alloy steel strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com