Special movable device for barrel cutting

A special device and cylinder technology, which is applied in the field of carding machines, can solve the problems of rough surface, unevenness of the cylinder, and insufficient precision of mechanical manufacturing, so as to reduce the grinding time, reduce the workload, prolong the grinding cycle and needle The effect of cloth service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

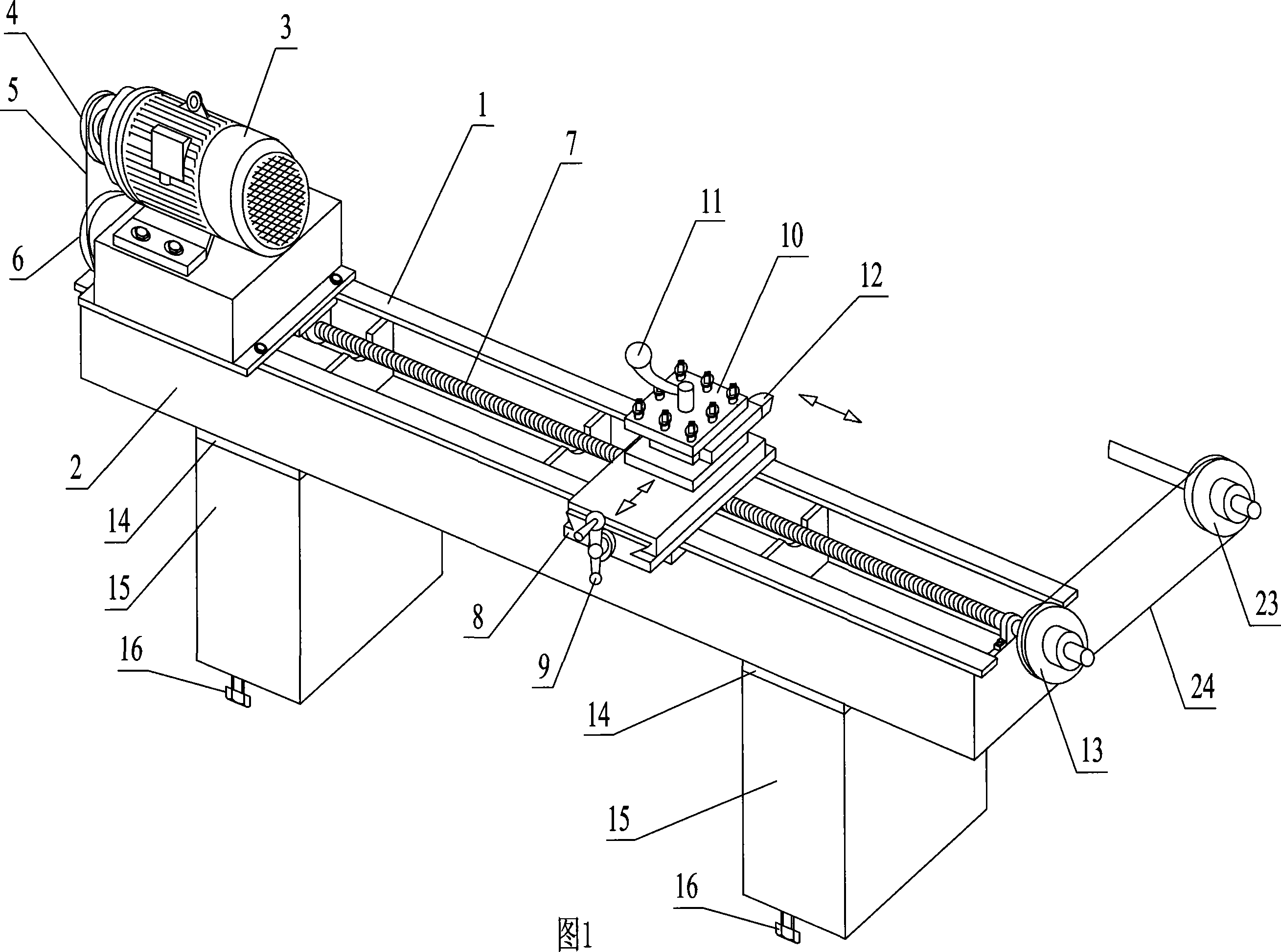

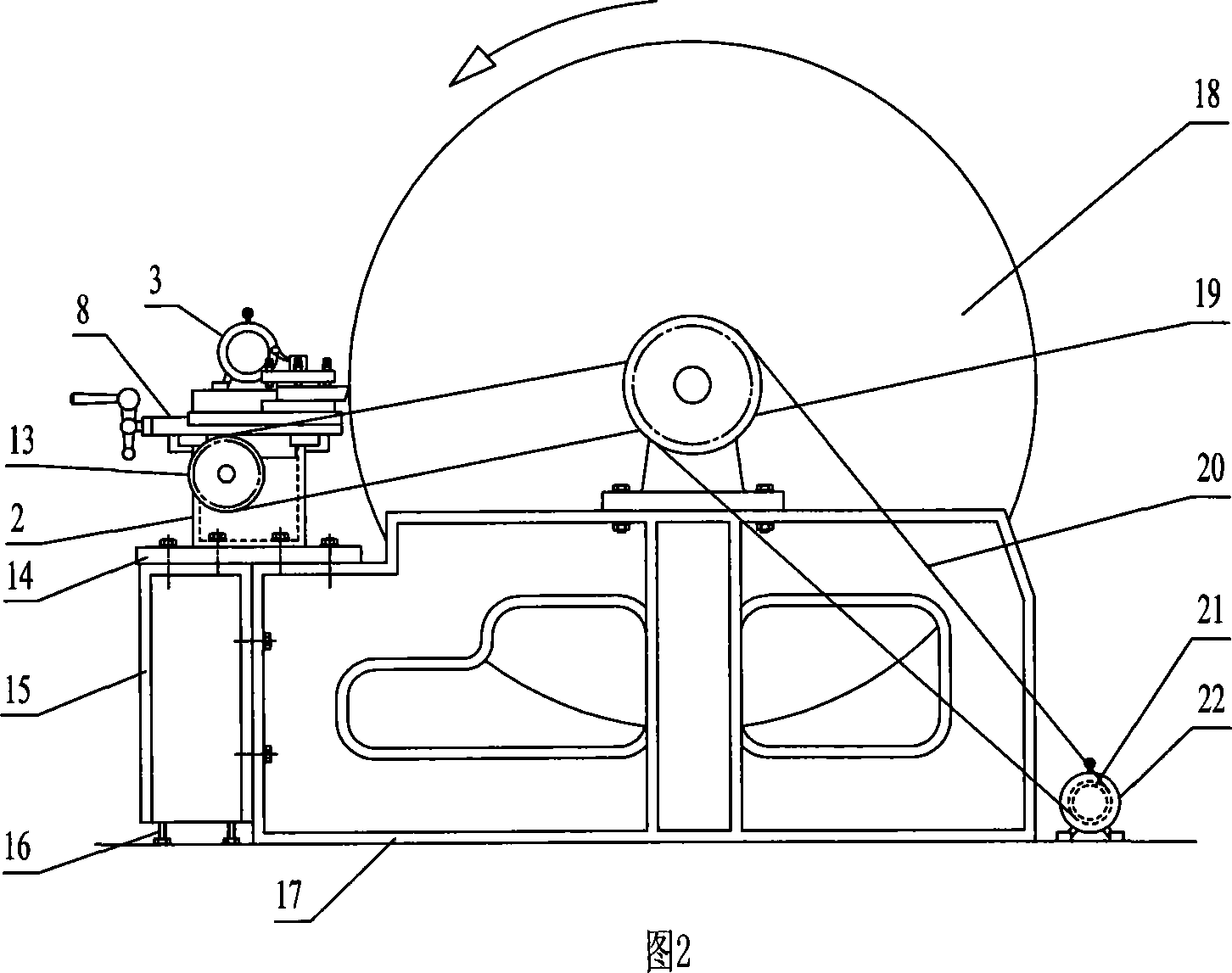

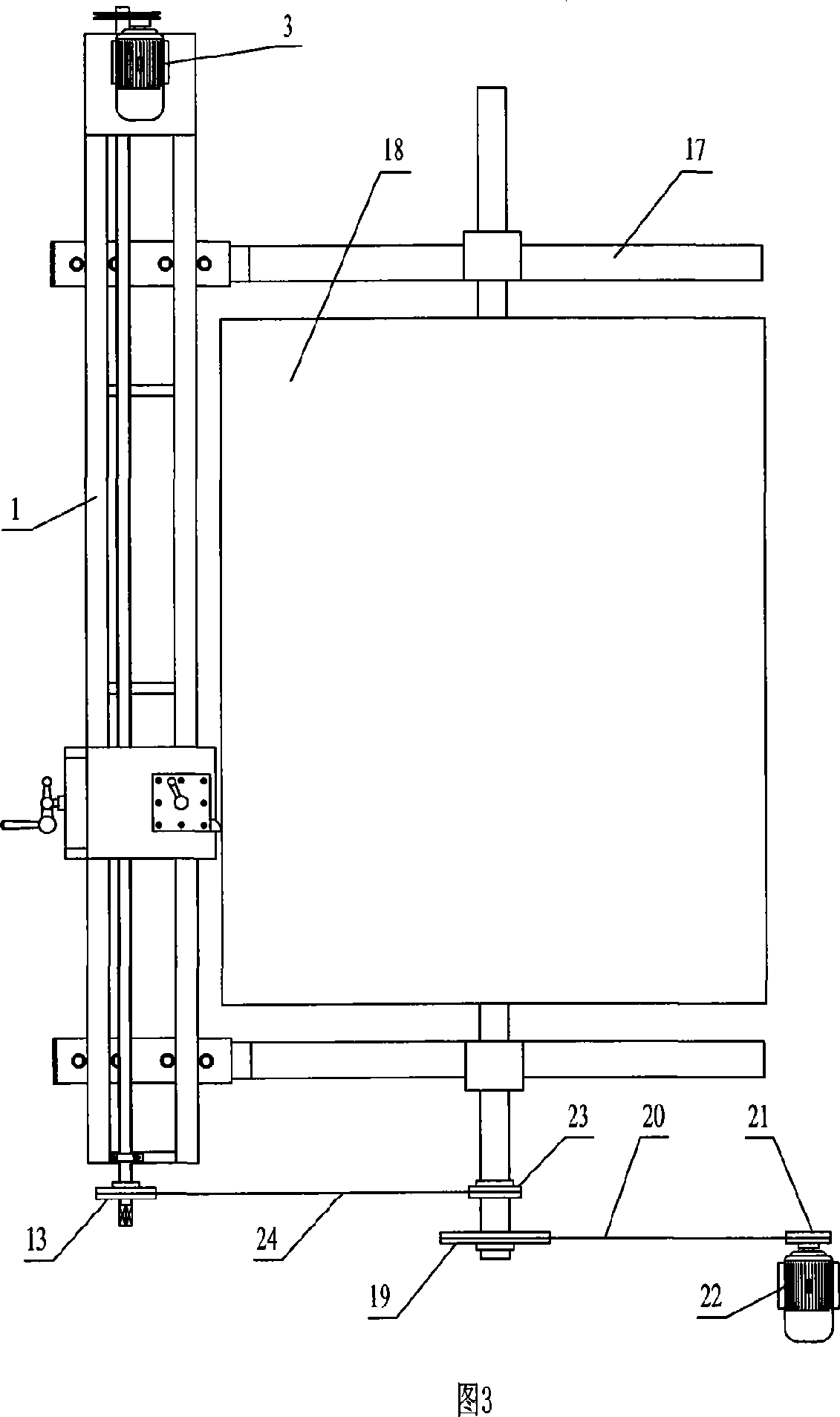

[0012] As shown in Figure 1, the special device for movable cylinder cutting of the present invention includes a guide rail backing plate 14 installed upwards on the lifting seat 15, a frame 2 with a guide rail 1, and the bottom end of the lifting seat 15 is provided with an adjustable lift. device, and the adjustable lifting device is a lifting screw 16. A variable frequency motor 3 with a belt pulley 4 is installed at the left end of the guide rail 1 . Screw rod 7 with belt pulley 6 and sprocket 13 on the left and right ends is installed in the frame 2, belt pulley 6 is connected with belt pulley 4 through V-belt 5, and sprocket 13 is installed on the cylinder body 18 to be cut by chain 24. The sprocket 23 on the shaft is connected. A supporting plate 8 that can slide left and right along the guide rail 1 is installed on the screw rod 7. A knife holder 10 that is regulated by a rocker handle 9 to move back and forth is installed on the supporting plate 8. A knife head 12 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com