Box type substation

A technology of box-type substation and box-type transformer, which is applied in substation/power distribution device casing, substation/switch layout details, substation/switchgear board/panel/desk, etc., which can solve the problem of increasing space and occupying area, Low space utilization rate, low operating efficiency and other issues, to achieve the effect of reducing the workload of disassembly and assembly, high space utilization rate, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

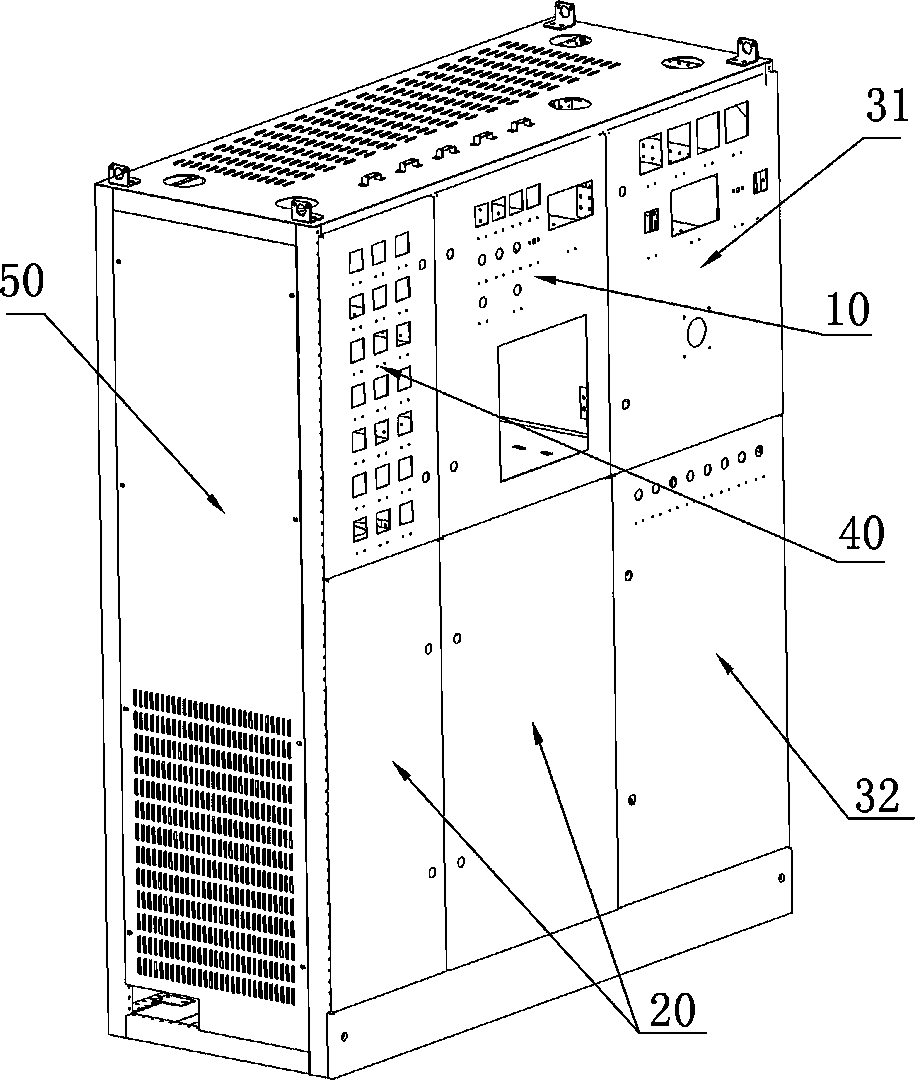

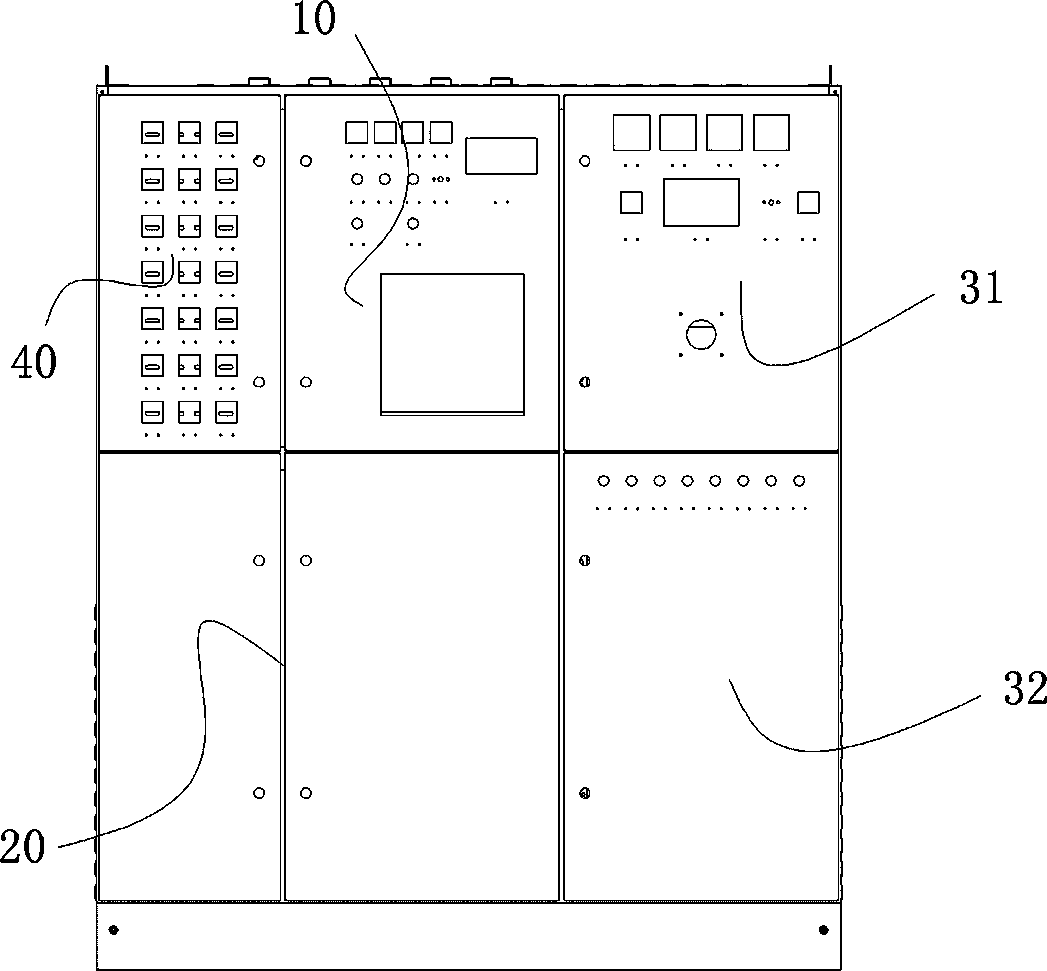

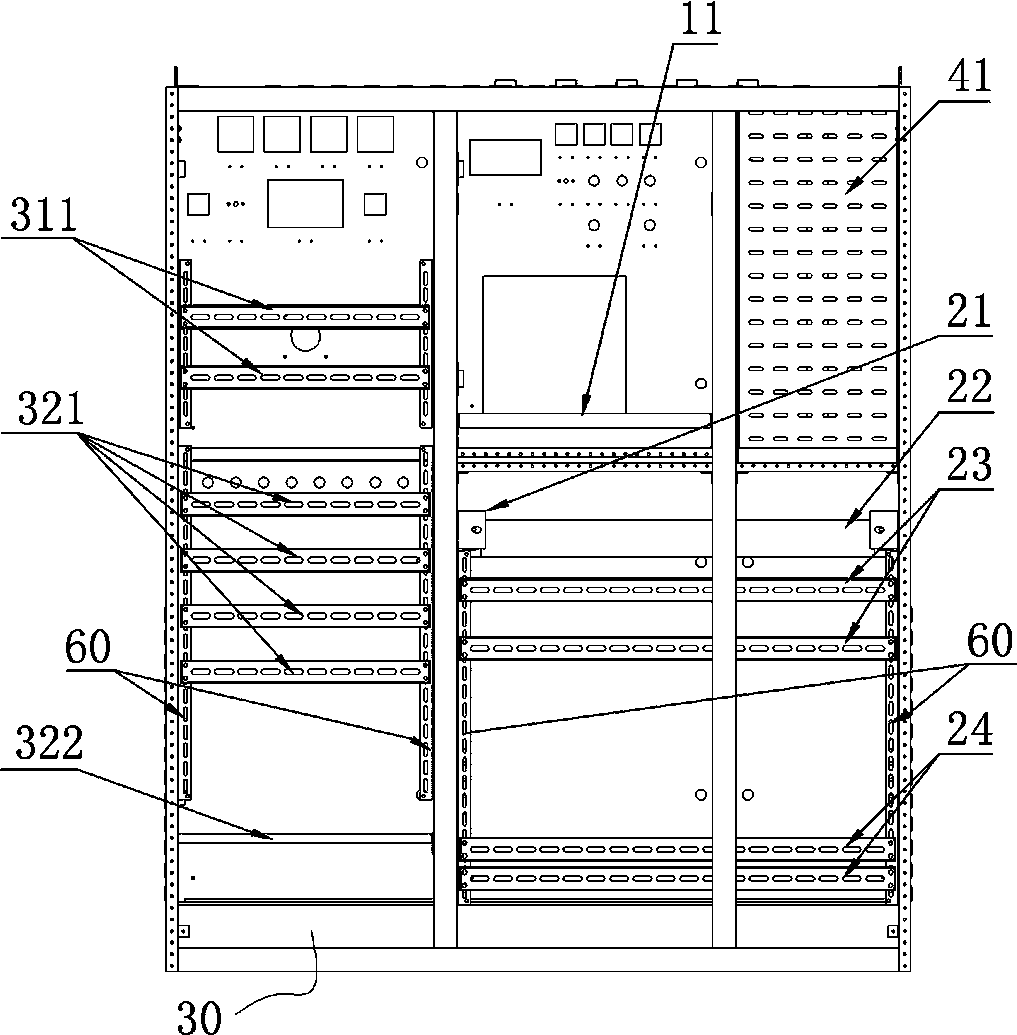

[0023] An embodiment of the low-voltage cabinet of the box-type substation in the present invention is as follows Figure 1~Figure 6 As shown, it is a low-voltage cabinet with the existing C profile as the skeleton, and the cabinet body is assembled through a bolt combination structure. The back of the low-voltage cabinet is open to form a structure without a rear door, and it is a structure without a bottom plate with an open bottom. Side protective partitions 50 are provided on both lateral sides of the cabinet body, and the inside of the cabinet body includes incoming line unit 10 , feeder line unit 20 , capacitance compensation unit 30 and secondary instrument unit 40 separated from each other by corresponding partition boards. The low-voltage cabinet adopts a structure without a bottom plate, which shares the bottom plate with the box-type transformer, and relies on the bottom plate of the box-type transformer for protection, which can save materials and reduce assembly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com