Detachable type wire withdrawing spool spindle of water tank drawing mill

A technology of water tank wire drawing machine and I-shaped wheel, which is applied in the field of metal wire processing equipment, can solve problems such as production inconvenience, and achieve the effect of reducing production costs and reducing the workload of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

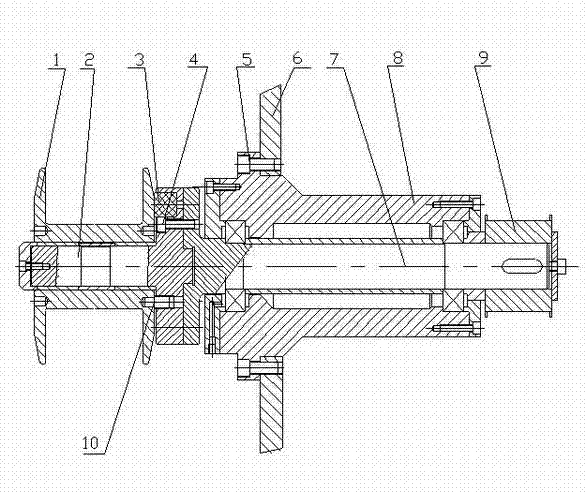

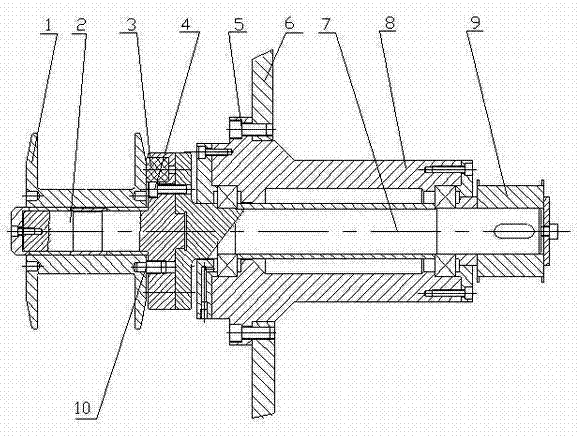

[0011] Such as figure 1 As shown, the detachable take-up I-wheel main shaft of the water tank drawing machine includes a front shaft (2) and a rear shaft (7). The front shaft (2) and the rear shaft (7) are provided with a boss and six There are two light holes, grooves and six screw holes are provided on the shaft end where the rear axle (7) contacts the front axle (2), and the boss of the front axle (2) is installed in the groove of the rear axle (7), It is fastened by six connecting screws (4); the spool (1) and the front axle (2) are equipped with shift pins (10) and fixed by eight magnets (3); the rear axle sleeve (8) is fixed by six Only the fastening screw (5) is fixed on the box body (6), the rear axle (7) is fixed in the rear axle sleeve (8), and the pulley (9) is installed at the end of the rear axle (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com