Assembling auxiliary device for large-scale vertical HVPE reaction chamber

An assembly-assisted, vertical technology, applied in the direction of chemical reactive gas, single crystal growth, crystal growth, etc., can solve the problems of complex component structure, affecting the service life of components, frequent disassembly and assembly, etc., to achieve high precision, improve Assembly efficiency, the effect of reducing the workload of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

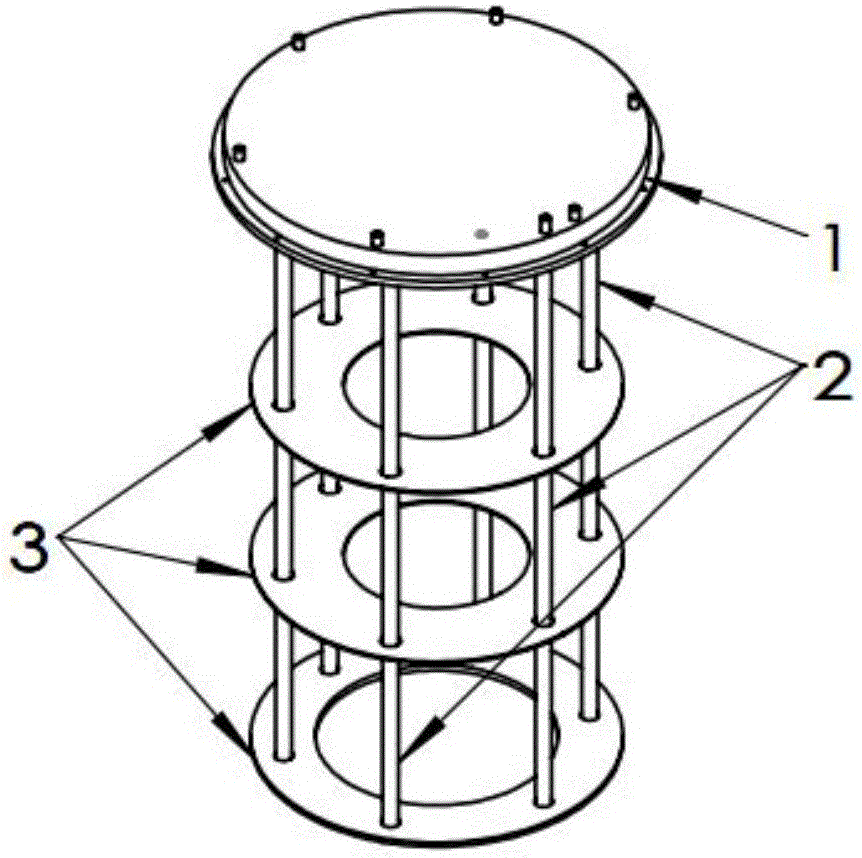

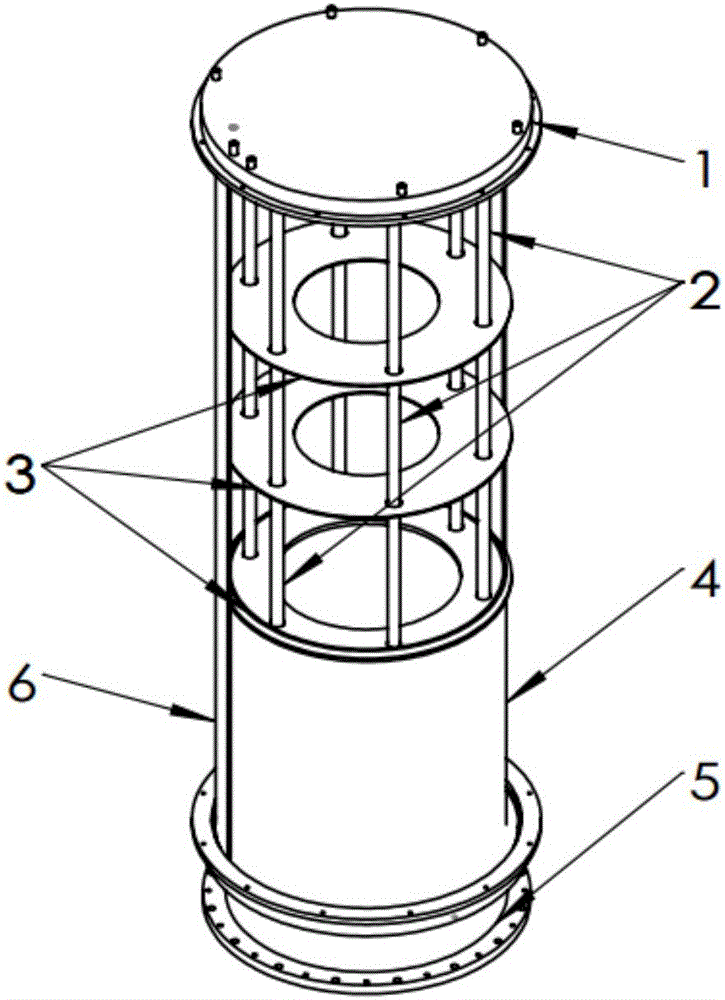

[0018] In this example, if figure 1 As shown, there are 6 hoisting load-bearing columns 2, all of which adopt a cylindrical structure; there are 3 precision-adjusting load-bearing plates 3, all of which are ring structures, and are arranged between the inner and outer edges of the plates. The 6 fixed round holes for installation can be inserted into the 6 hoisting load-bearing columns 2 correspondingly to form a stable connection with them, and the fixed connection method adopts the form of nut locking.

[0019] In order to ensure that the frame can withstand the high temperature working environment of 1300K, and it is not easy to volatilize and has a certain rigidity, the hoisting load-bearing column 2 and the precision adjustment load-bearing plate 3 are all made of high-purity molybdenum material, and the top flange 1, its environment The temperature is relatively low, and 316L stainless steel can be used.

[0020] The specific assembly of the auxiliary device is as follow...

Embodiment 2

[0023] In this example, if figure 1 As shown, there are 6 hoisting load-bearing columns 2, all of which adopt a cylindrical structure; there are 3 precision-adjusting load-bearing plates 3, all of which are ring structures, and are arranged between the inner and outer edges of the plates. The 6 fixed round holes for installation can be inserted into the 6 hoisting load-bearing columns 2 correspondingly to form a stable connection with them, and the fixed connection method adopts the form of nut locking.

[0024] In order to ensure that the frame can withstand the high temperature working environment of 1300K, and it is not easy to volatilize and has a certain rigidity, the hoisting load-bearing column 2 and the precision-adjusted load-bearing plate 3 are all made of high-purity tungsten material, and the top flange 1, its environment The temperature is relatively low, and 316L stainless steel can be used.

[0025]The specific assembly of the auxiliary device is as follows: ad...

Embodiment 3

[0028] In this embodiment, when a certain part in the B area of the large vertical HVPE reaction chamber is worn out and needs to be replaced and maintained, the auxiliary frame is first removed as a whole together with the A area of the large vertical HVPE reaction chamber; after that, the jacket is disassembled Pipe 6 and load-bearing pipe 4 can disassemble and replace the consumable parts in area B; after the replacement is completed, follow the reverse direction of the disassembly process, first install the components in area B and fix them with the bottom flange 5, and install the load-bearing The tube 4 and the outer tube 6; finally, the frame of the auxiliary device together with the parts in the A area are hoisted and moved to the load-bearing part as a whole, and the two major areas of A and B are connected, and finally the large vertical HVPE reaction chamber is completed the overall assembly.

[0029] Because in the process of disassembly, replacement and reasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com