Maintenance method and device for slewing bearing part of gantry crane

A technology of portal cranes and slewing bearings, which is applied to feeding devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of long maintenance time, increase processing costs, and affect on-site production, so as to reduce the workload of disassembly and assembly, reduce The cost of storage and the effect of shortening the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

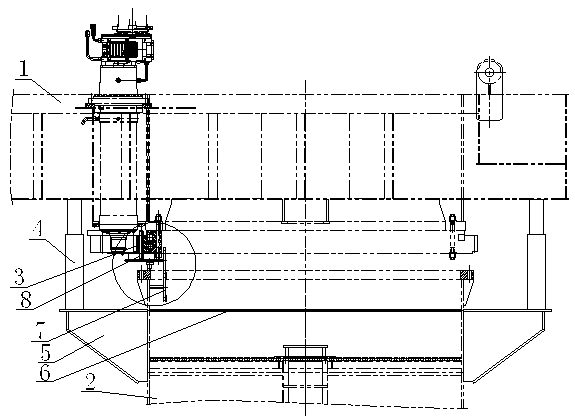

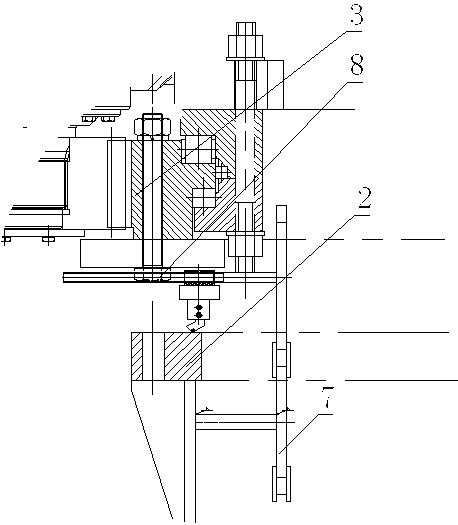

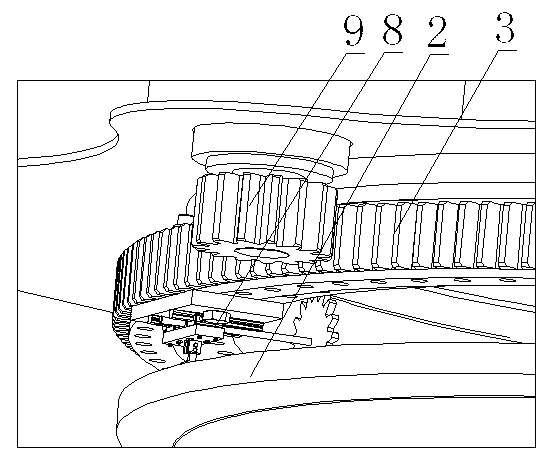

[0027] Such as Figure 1 to Figure 6 In the maintenance device for the slewing bearing part of the portal crane shown, four jacking supports 5 are welded in a cross direction on the outer surface of the cylindrical body 2 of the portal crane; The inner side of the cylindrical body 2 is welded with annular reinforcing ribs 6, and a plurality of jacks 4 are placed between each jacking support 5 and the lower plane of the turntable 1 of the portal crane, and the total jacking force of the jacks 4 must be greater than that of the portal crane. The gravity of the part above the slewing bearing. When it is necessary to cut the slewing bearing surface of the cylindrical body 2, a maintenance and processing device 8 needs to be installed. Please combine Figure 5 , the maintenance processing device 8 includes a connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com