Coolant purging device and purging method for battery assembly testing

A battery assembly and cooling liquid technology, which is applied in the field of cooling liquid purging devices for battery assembly testing, can solve the problems of increased processing cost, inability to reuse, and troublesome recycling and processing, and achieves convenient management, simple structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

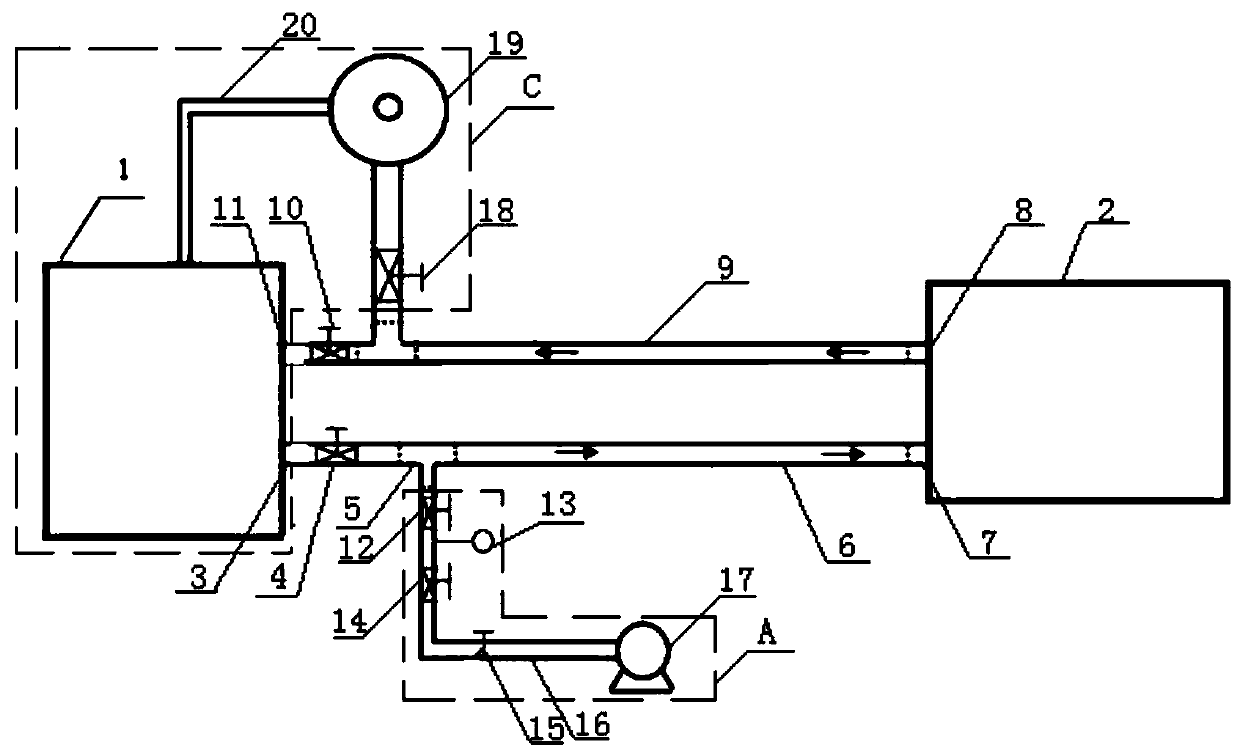

[0027] The structural features of each part of the present invention will be described in detail below, and if there is a description to the direction (up, down, left, right, front, back), it is based on figure 2 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto. The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

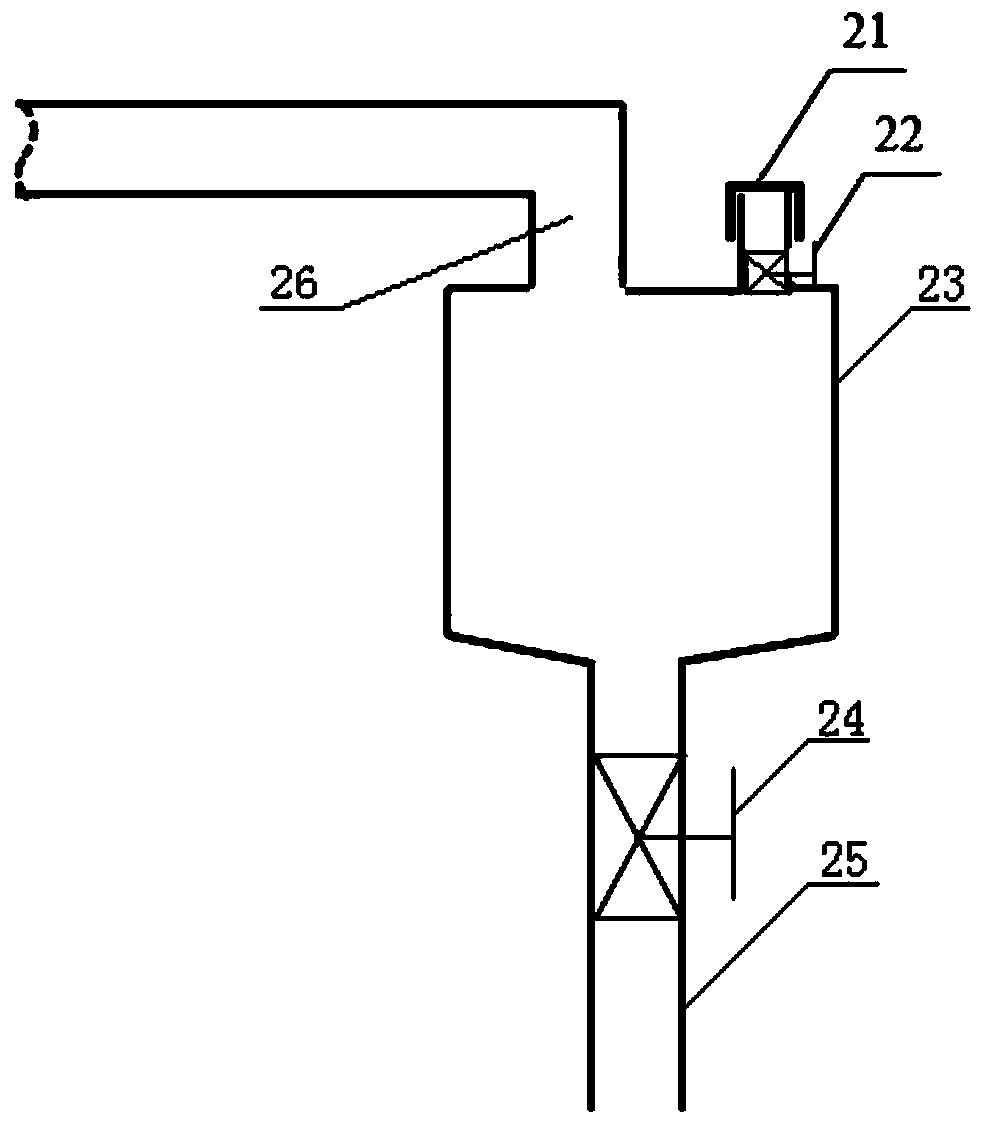

[0028] see figure 1 As shown, this embodiment discloses a cooling liquid purge device for battery assembly testing, including a battery assembly 2, a compressed gas control unit A for purge cooling liquid, and a liquid storage unit for recovering circulating cooling liquid C. The battery assembly 2 and the liquid storage unit C are connected through the coolant outlet pipe 9 and the coolant inlet pipe 6 ; the compressed gas control unit A is connected to the coolant inlet pipe 6 .

[0029] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com