A fuel cell air system control method

A technology of air system and control method, which is applied in the direction of fuel cells, electrical components, circuits, etc., can solve problems such as violation of the demand for rapid discharge, and achieve the effect of optimizing output performance

Active Publication Date: 2022-06-03

上海申风投资管理有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

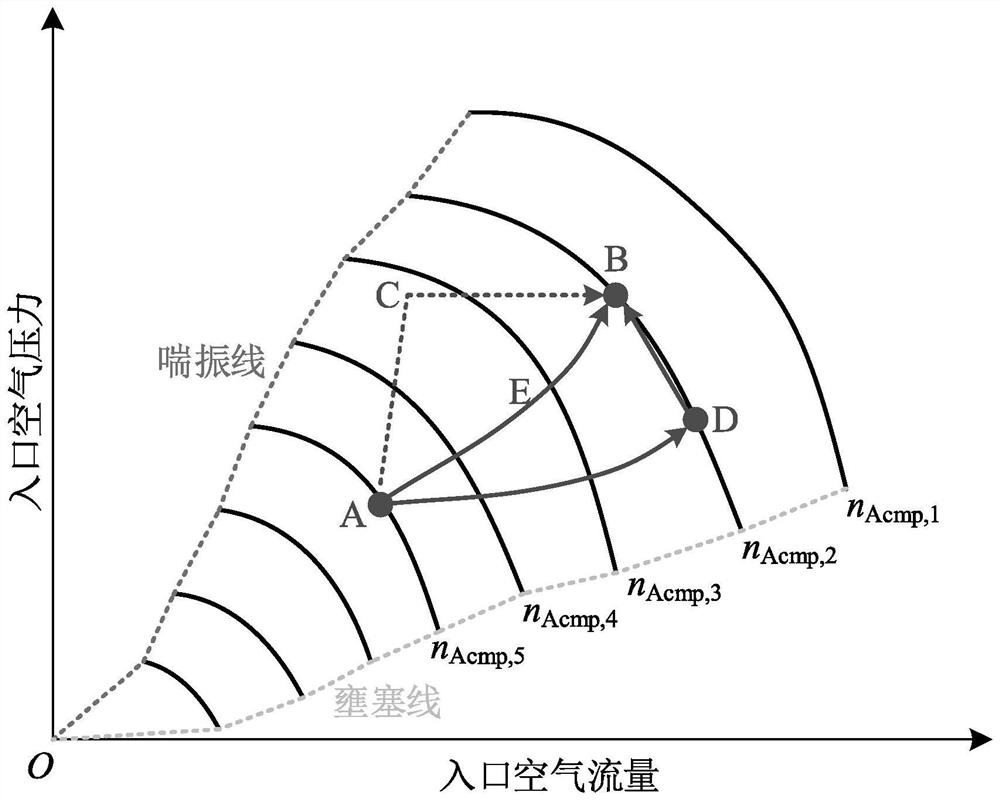

To meet the demand for rapid discharge of water generated by the electrochemical reaction of the fuel cell stack, it is necessary to increase the air flow rate at the inlet of the fuel cell stack and reduce the air pressure at the inlet of the fuel cell stack. Inlet air flow increases, as figure 1 The middle curve trajectory A→C→B violates the requirement of rapid discharge of water generated by the electrochemical reaction of the fuel cell stack

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

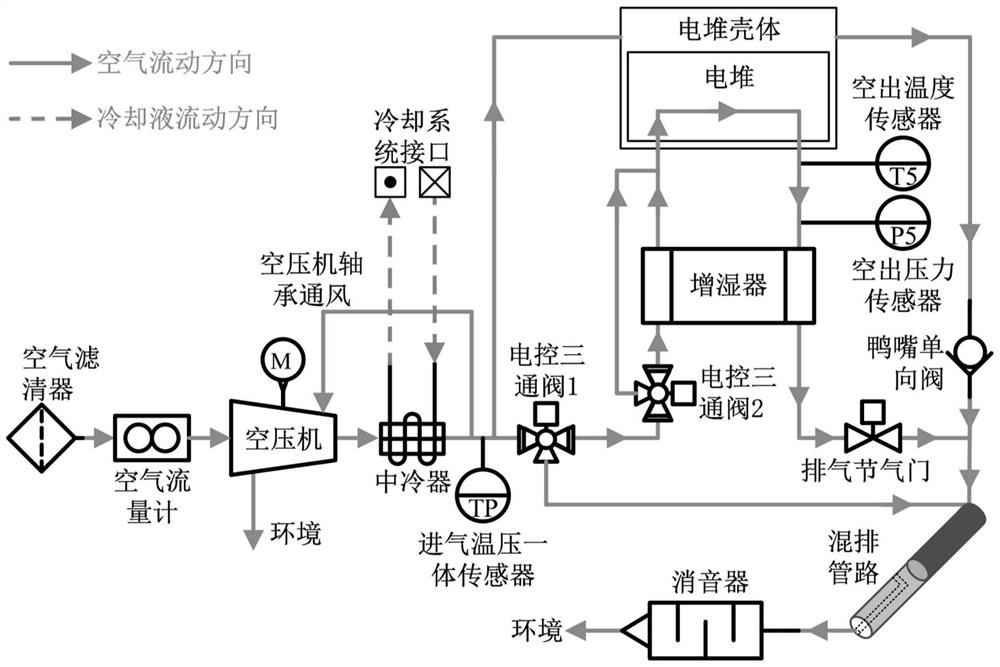

[0020] As shown in FIG. 1, the fuel cell air system control method, in this embodiment, includes a fuel cell stack according to the

[0034] A proton exchange membrane fuel cell is an electrochemical reaction device. Hydrogen is more common in the field of transportation

[0037] The specific embodiments described herein are merely illustrative of the spirit of the invention. The technical field to which the present invention belongs

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

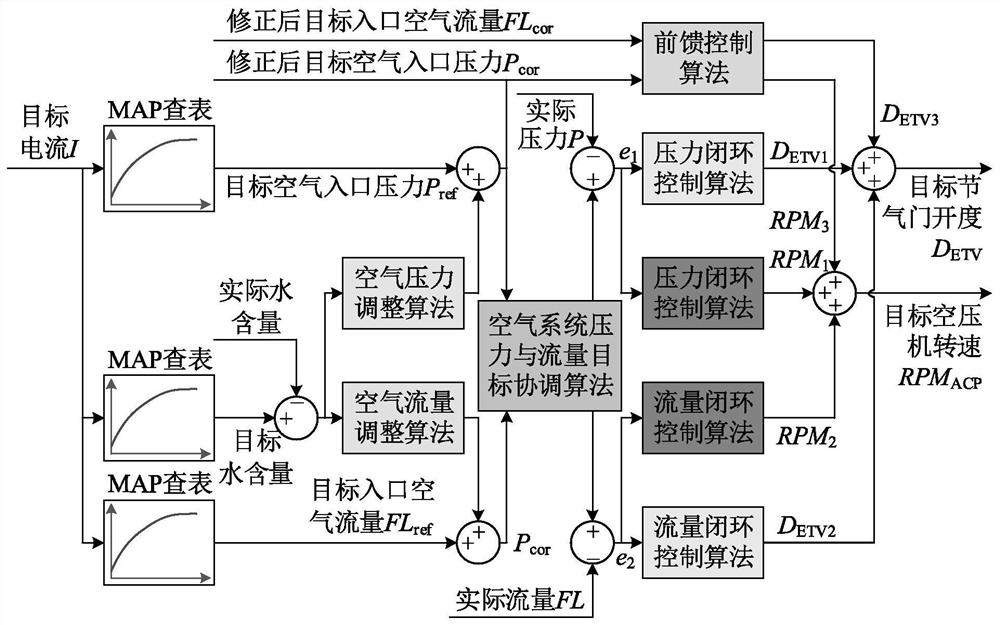

The invention provides a fuel cell air system control method, which belongs to the technical field of fuel cells. It solves the technical problems such as the low discharge rate of the water generated by the electrochemical reaction of the existing fuel cell stack. The fuel cell air system control method is characterized in that it includes obtaining the target inlet air flow rate FLref, the target air inlet pressure Pref and the target water content of the fuel cell stack according to the fuel cell stack output current I look-up table; according to the target water content and the actual water content Content difference, execute the air pressure adjustment algorithm, air flow adjustment algorithm, and correct the target inlet air flow and target air inlet pressure. The invention has the advantages of high discharge speed of the water generated by the electrochemical reaction of the fuel cell stack during the large-scale loading process.

Description

A kind of fuel cell air system control method technical field The invention belongs to the technical field of fuel cells, relate to a kind of control method, especially a kind of fuel cell air system system control method. Background technique Hydrogen proton exchange membrane fuel cells are widely used due to their high efficiency, no pollution, low operating temperature, low noise and other advantages. Used in the field of transportation, especially buses, logistics vehicles, heavy trucks, etc. The on-board fuel cell system must meet the According to the customer's requirements for the power performance of the whole vehicle, that is, the output power from idle speed is increased to the peak output power in a short time, then the fuel The fuel cell stack in a fuel cell system must ramp up from idle output current to peak output current in the same time, i.e. Amplitude loading. During the large loading process, the electrochemical reaction of the fuel cell stack ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M8/04992

CPCH01M8/04992Y02E60/50

Inventor 张大陆阮磊范立宁

Owner 上海申风投资管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com