Antifreezing liquefied gas spraying device

A kind of injection device, technology of liquefied gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

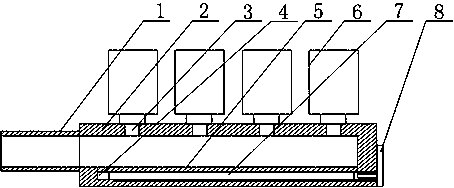

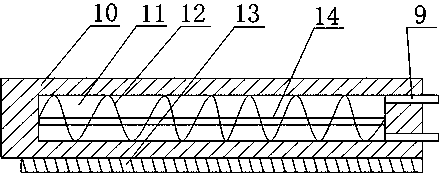

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes an air intake pipe 1 and a hollow pipe 2 communicating with it. A plurality of injection holes 3 are opened on the upper end of the hollow pipe 2, and a solenoid valve 6 is correspondingly installed on the injection holes 3. The inner wall of the hollow tube 2 is provided with a groove 4 with a superior arc in section, and the injection hole 3 is facing the groove 4, and a plurality of electric heating tubes 7 are arranged side by side in the groove 4, and the electric heating tubes 7, a guide block 13 is installed at the bottom, and a guide groove matching with the guide block 13 is opened at the bottom of the groove 4. The electric heating tube 7 includes a tube body 10, an insulating material 11 filled inside the tube body 10, and a tube The heating wire 12 inside the body 10, the end of the heating wire 12 is connected with a terminal 9, the end of the groove 4 away from the intake pipe 1 has a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com