Fuel gas injection method for dual-fuel vehicle

An injection method and dual-fuel technology, applied in the direction of charging system, combustion engine, internal combustion piston engine, etc., can solve the problems that affect the normal use of the gas system, the difficulty of opening the gas injection rail, and increase the difficulty of maintenance, so as to reduce heat loss. Dispersion, stable placement, and low heating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

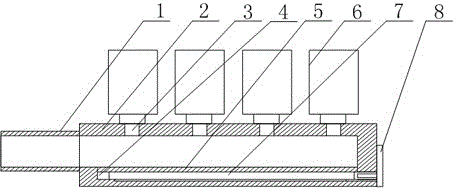

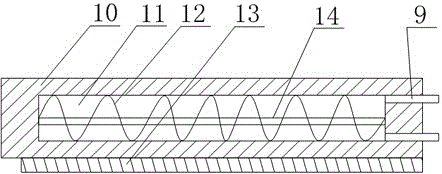

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes an air intake pipe 1 and a hollow pipe 2 communicating with it. A plurality of injection holes 3 are opened on the upper end of the hollow pipe 2, and a solenoid valve 6 is correspondingly installed on the injection holes 3. The inner wall of the hollow tube 2 is provided with a groove 4 with a superior arc in section, and the injection hole 3 is facing the groove 4, and a plurality of electric heating tubes 7 are arranged side by side in the groove 4, and the electric heating tubes 7, a guide block 13 is installed at the bottom, and a guide groove matching with the guide block 13 is opened at the bottom of the groove 4. The electric heating tube 7 includes a tube body 10, an insulating material 11 filled inside the tube body 10, and a tube The heating wire 12 inside the body 10, the end of the heating wire 12 is connected with a terminal 9, the end of the groove 4 away from the intake pipe 1 has a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com