Liquid atomization device

A liquid atomization and liquid storage technology, applied in the direction of liquid injection device, injection device, etc., can solve the problems of insufficient odor, large oil consumption, liquid pollution, etc., and achieve the improvement of atomization fineness and atomization fineness. , the effect of slowing down the flow rate of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

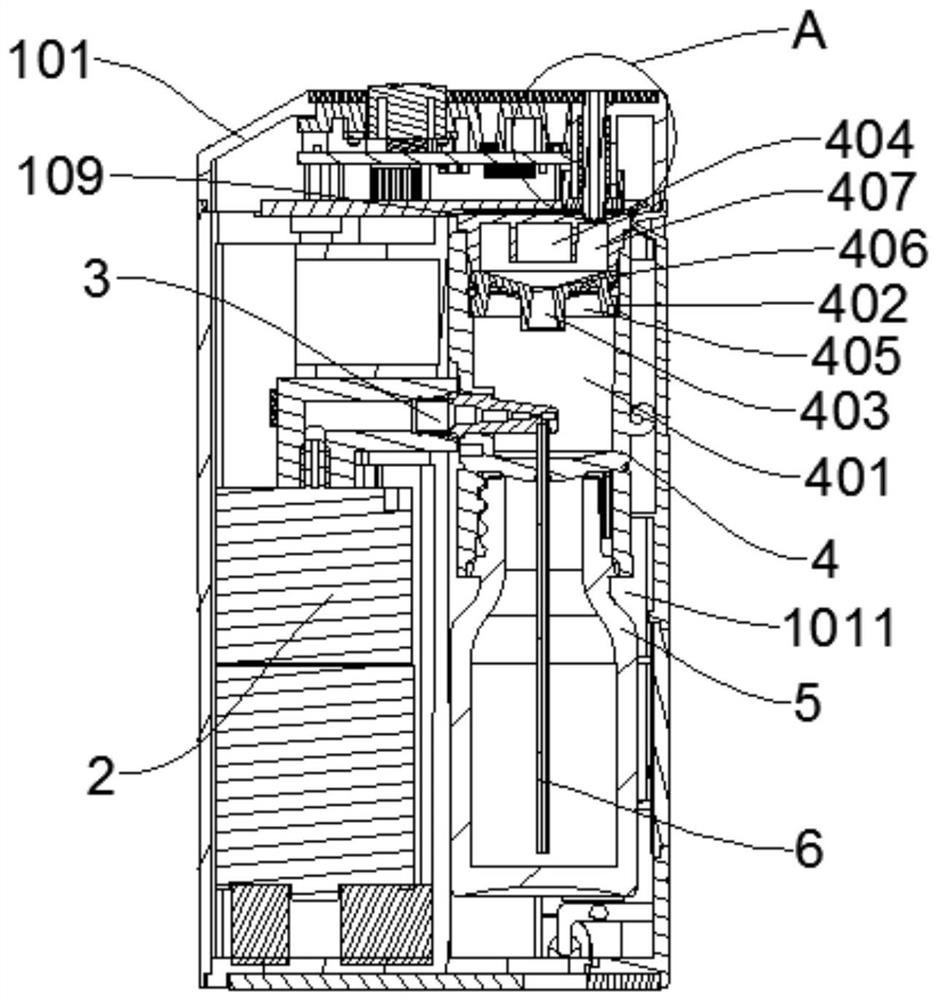

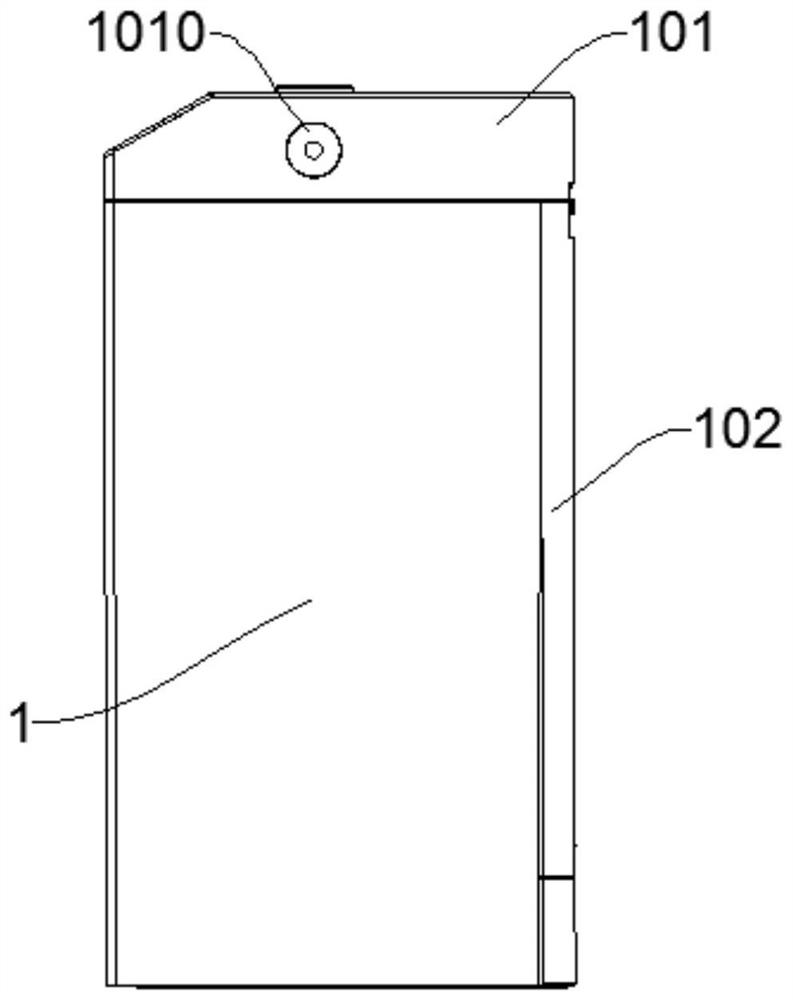

[0040] The reference signs in the drawings of the specification include: housing 1, air pump 2, spray core 3, liquid storage cap 4, liquid storage bottle 5, suction tube 6;

[0041] Upper cover 101, flip cover 102, second air outlet 103, exhaust pipe 104, fourth groove 105, first protrusion 106, spring 107, sealing plug 108, second protrusion 109, magnetic suction interface 1010, storage room 1011 ;

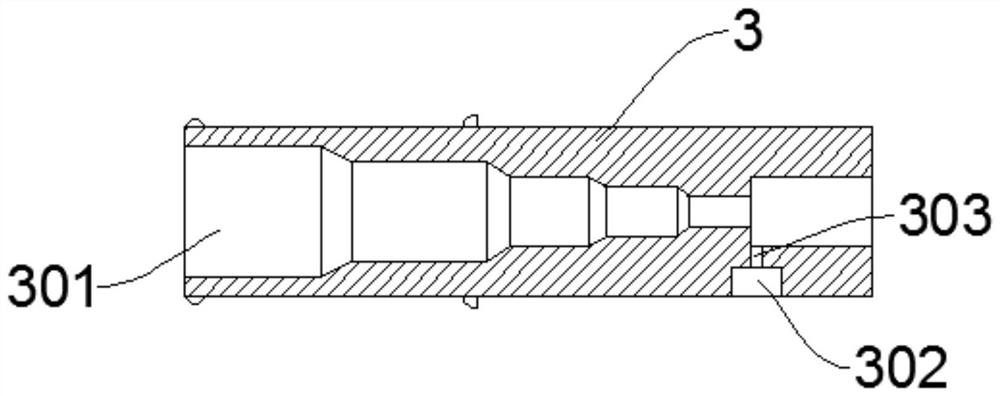

[0042] The first gas channel 301, the third groove 302, the through hole 303;

[0043] The second gas channel 401, the baffle plate 402, the first groove 403, the second groove 404, the first annular groove 405, the gas through hole 406, the second annular groove 407, the first gas outlet 408, the honeycomb groove Groove 409, fifth groove 4010, fitting groove 4011, sixth groove 4012, internal thread 4013, eighth groove 4014, V-shaped shrapnel 4015, fixed shrapnel 4016, non-return shrapnel 4017;

[0044] The liquid storage bottle body 501 , the liquid storage bottle mouth 502 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com