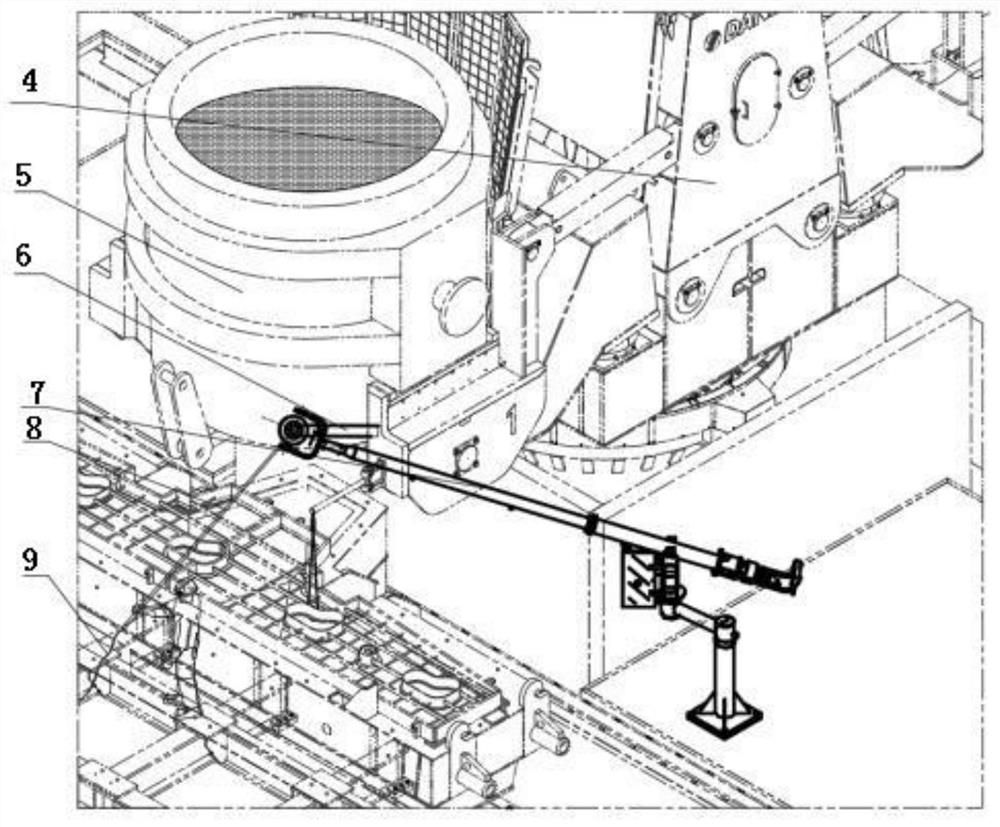

Continuous casting ladle long nozzle residual steel cleaning equipment and using method thereof

A technology for cleaning equipment and long nozzles, which is applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. It can solve problems such as affecting the smooth flow of molten steel, narrowing the long nozzle, and damaging the long nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

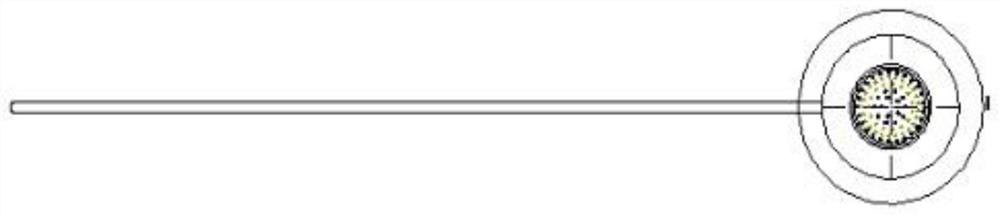

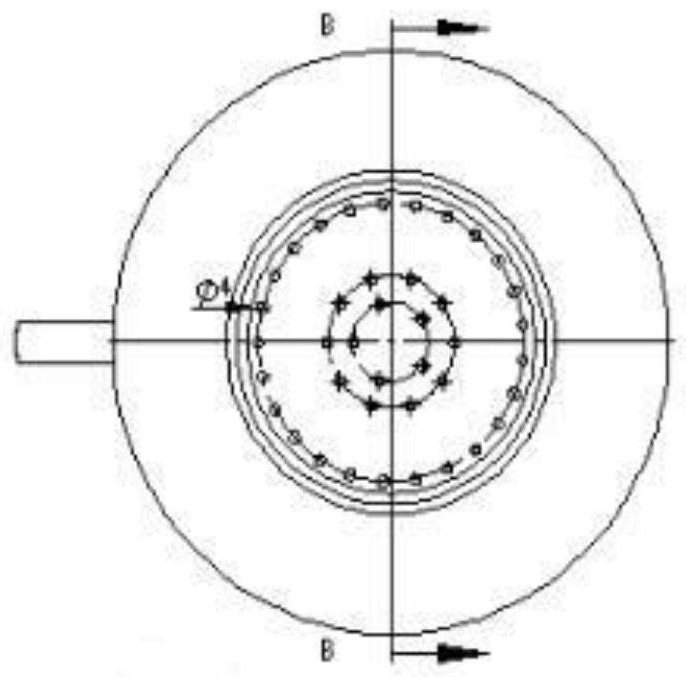

[0023] Example 1: Outer diameter of the inlet end of the shroud inner diameter of entrance When the inlet slope is 8° (the angle between the oblique line and the vertical direction), the outer diameter of the pressure plate of the shroud purging device used Nozzle outer diameter The nozzle slope is 8°, made of stainless steel, and the hand-held stainless steel pipe is a 4-point steel pipe with a length of 1400mm.

Embodiment 2

[0024] Example 2: Outer diameter of the inlet end of the shroud inner diameter of entrance When the inlet slope is 8° (the angle between the oblique line and the vertical direction), the outer diameter of the pressure plate of the shroud purging device used Nozzle outer diameter The nozzle slope is 8°, made of stainless steel, and the hand-held stainless steel pipe is a 4-point steel pipe with a length of 1400mm.

[0025] According to the actual needs of production, there is a device that can conveniently and quickly clean and purge the residual steel in the long nozzle within the time interval of switching the ladle, so as to realize the timely cleaning of the residual steel in the long nozzle, prolong the service life of the nozzle, and effectively improve the efficiency of continuous casting. The repeated use of the shroud reduces the consumption of the shroud, and it is estimated that the annual cost of the ladle shroud will be reduced by about 300,000 yuan.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com