Patents

Literature

30results about How to "Incomplete cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

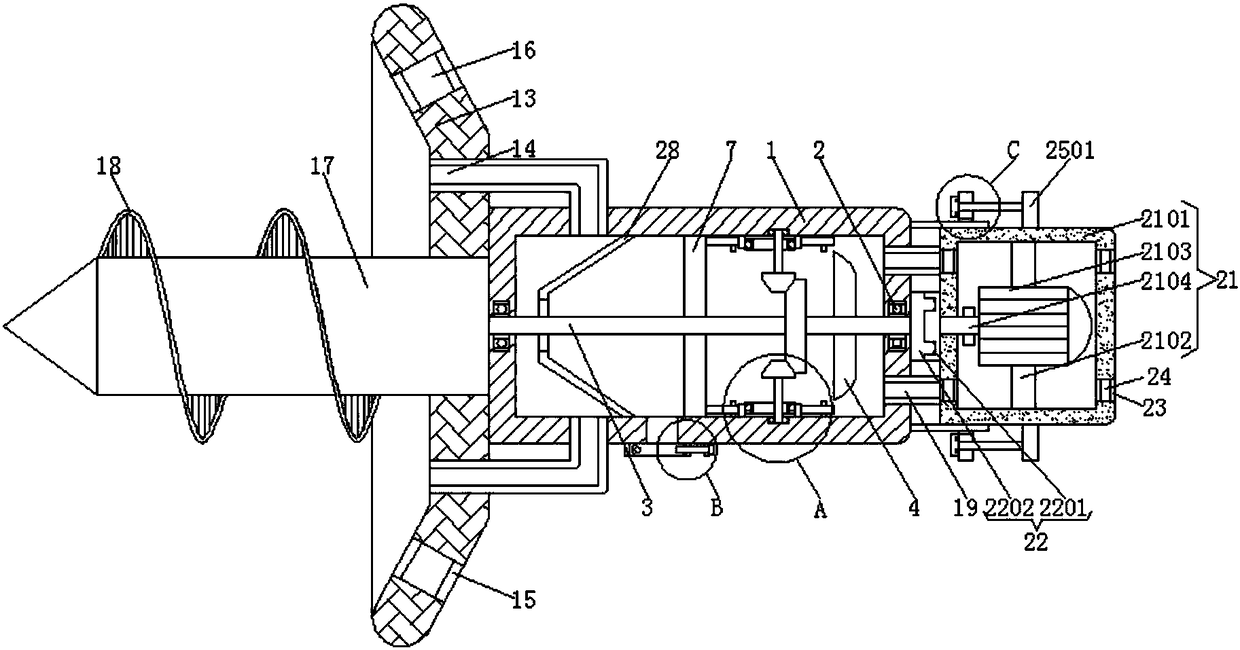

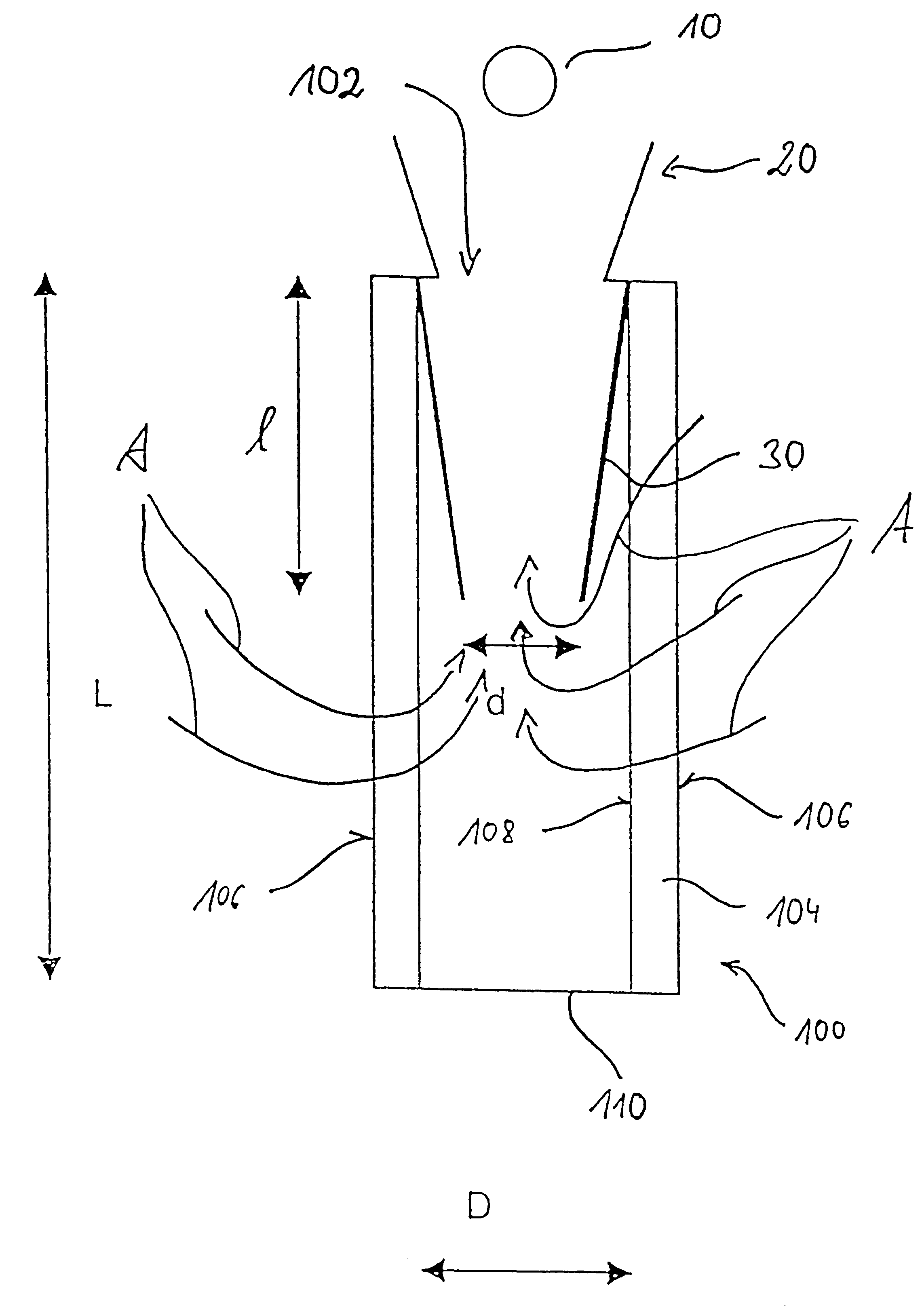

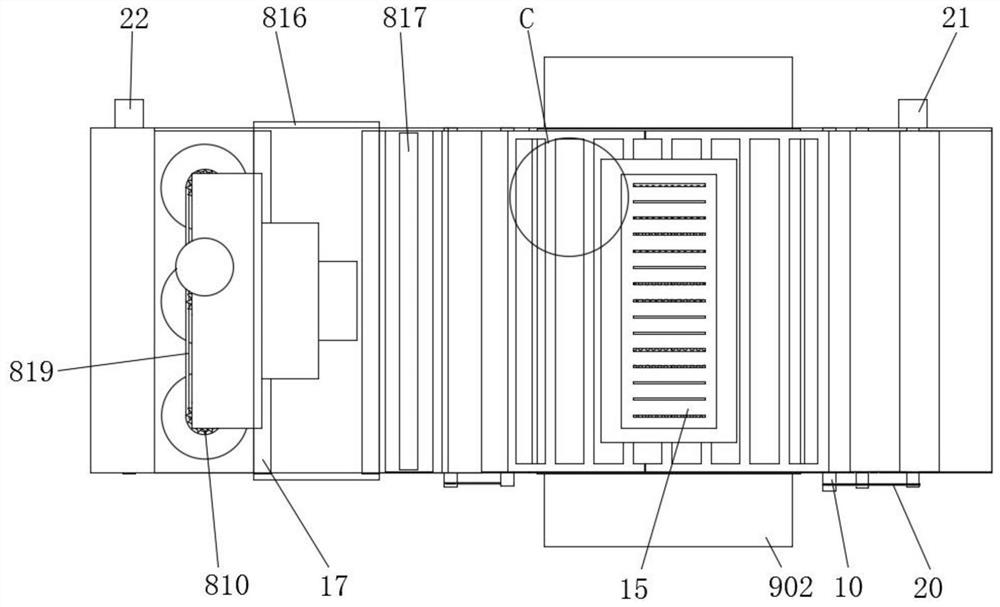

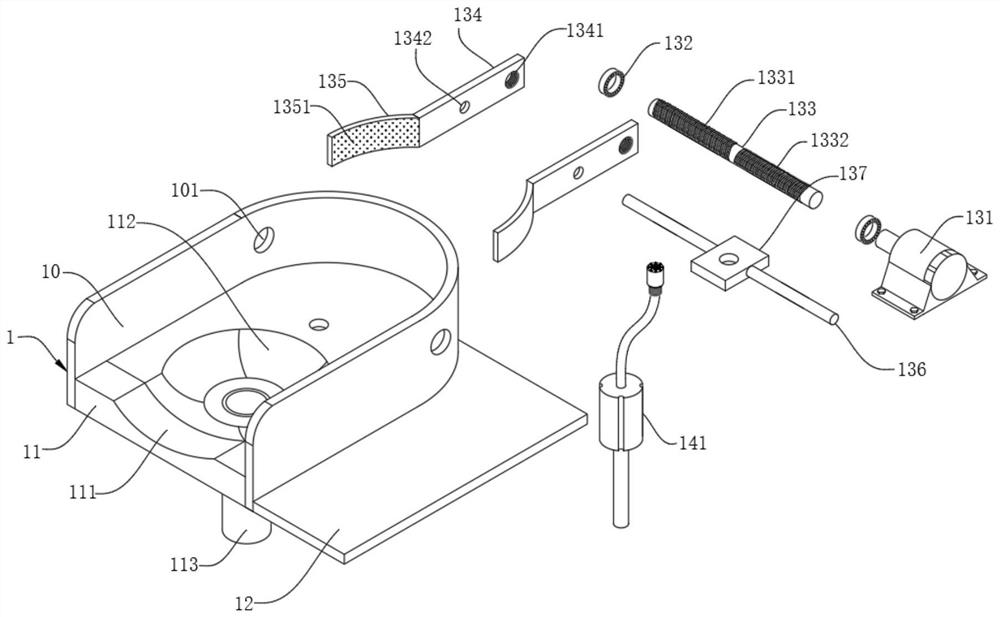

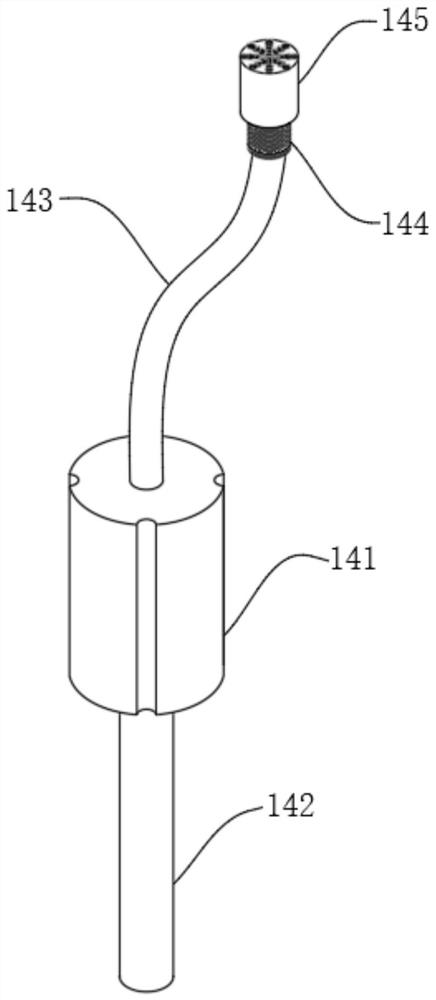

Anti-diffusion tunnel surrounding rock blasting hole slag removal device

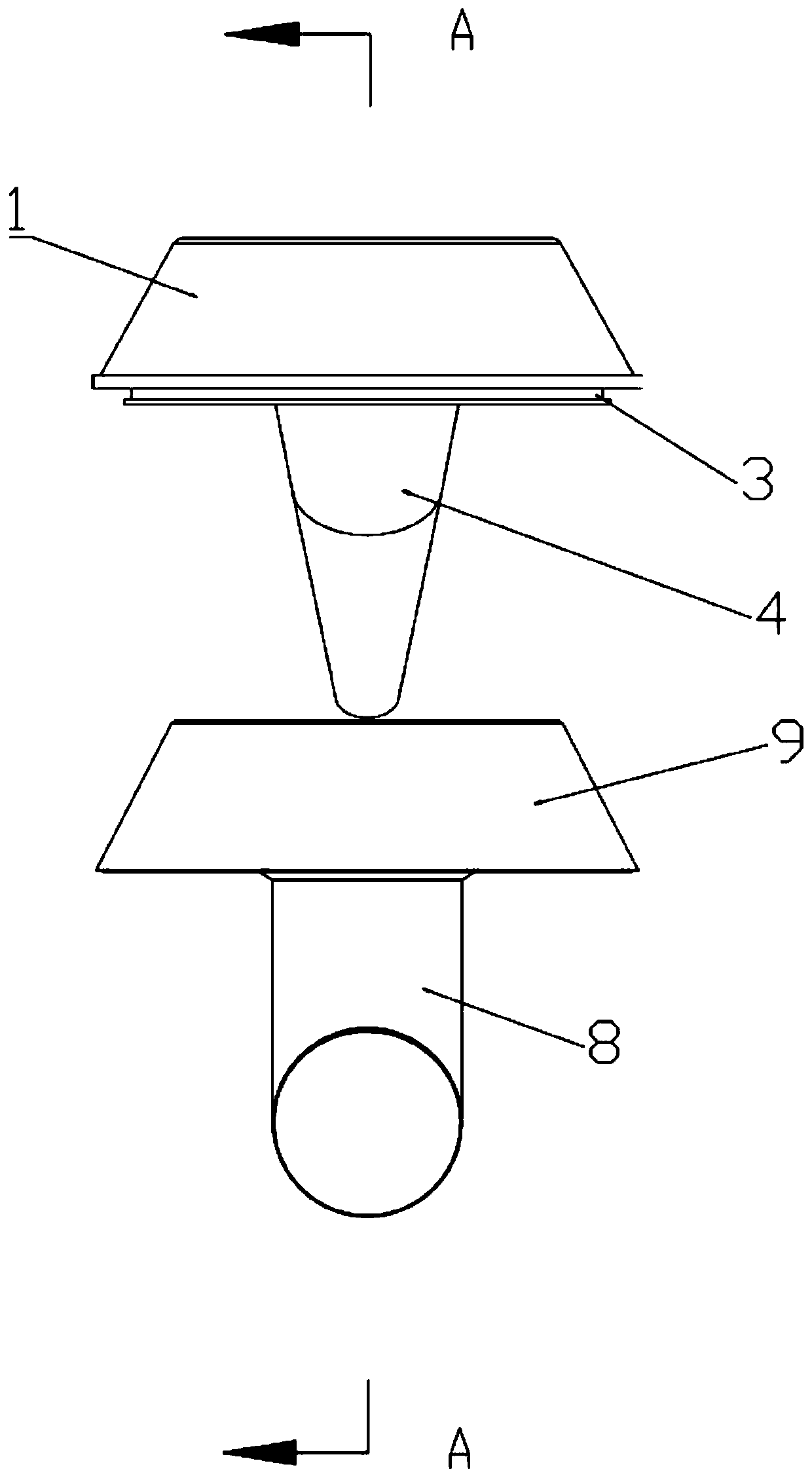

The invention discloses an anti-diffusion tunnel surrounding rock blasting hole slag removal device, and relates to the technical field of tunnel construction. The anti-diffusion tunnel surrounding rock blasting hole slag removal device comprises a box body; first ball bearings are fixedly connected into the left side and the right side of the box body; a first rotary shaft is fixedly connected tothe inner walls of the first ball bearings, and the right side of the surface of the first rotary shaft is fixedly connected with fan blades; and a first conical fluted disc is fixedly connected to the position, located on the left sides of the fan blades, of the surface of the first rotary shaft. According to the anti-diffusion tunnel surrounding rock blasting hole slag removal device, negativepressure forms in the box body through rotation of the fan blades, waste slag removed from blasting holes is collected into the box body through a first pipeline and prevented from being diffused intothe other blasting holes, and accordingly, the problems that a slag removal device on the market at present cannot collect waste slag removed from blasting holes, the waste slag removed from the blasting holes are prone to being diffused into the cleaned blasting holes, and then, the blasting holes are not thoroughly cleaned are effectively solved.

Owner:广德昊宇新型材料有限公司

Cleaning device

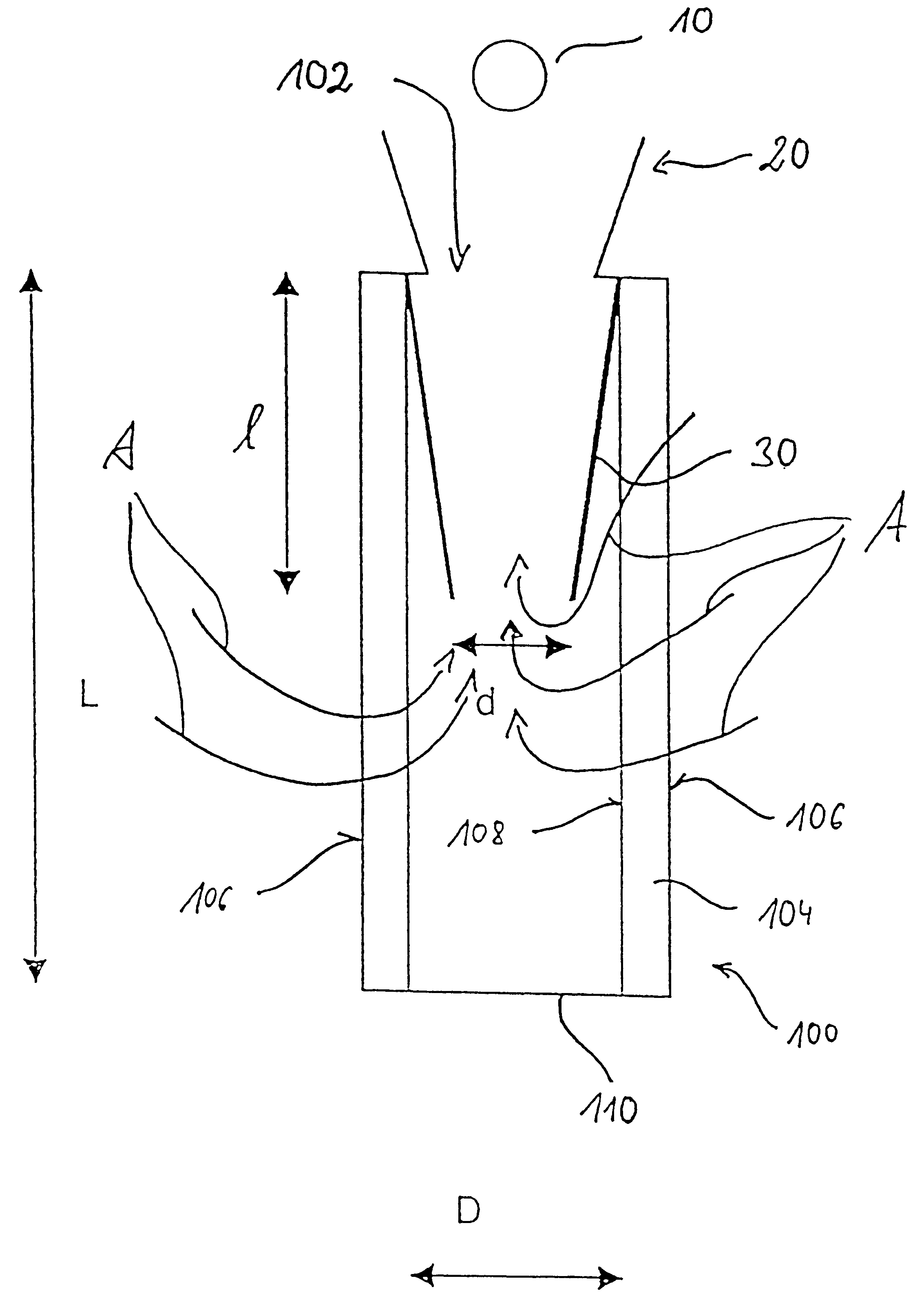

InactiveUS6554138B1Lower overall flow resistanceQuickly degree of soilingDispersed particle filtrationTransportation and packagingFiltrationBiomedical engineering

The invention relates to a device for cleaning the filter surface of a filter element, through which the liquid to be filtered flows, during a filtration operation using a pressurised cleaning fluid. According to an improvement of the invention, a distribution device is provided which delivers an essentially even pressure distribution of the cleaning fluid over the entire area of the filter surface to be cleaned.

Owner:DISA IND

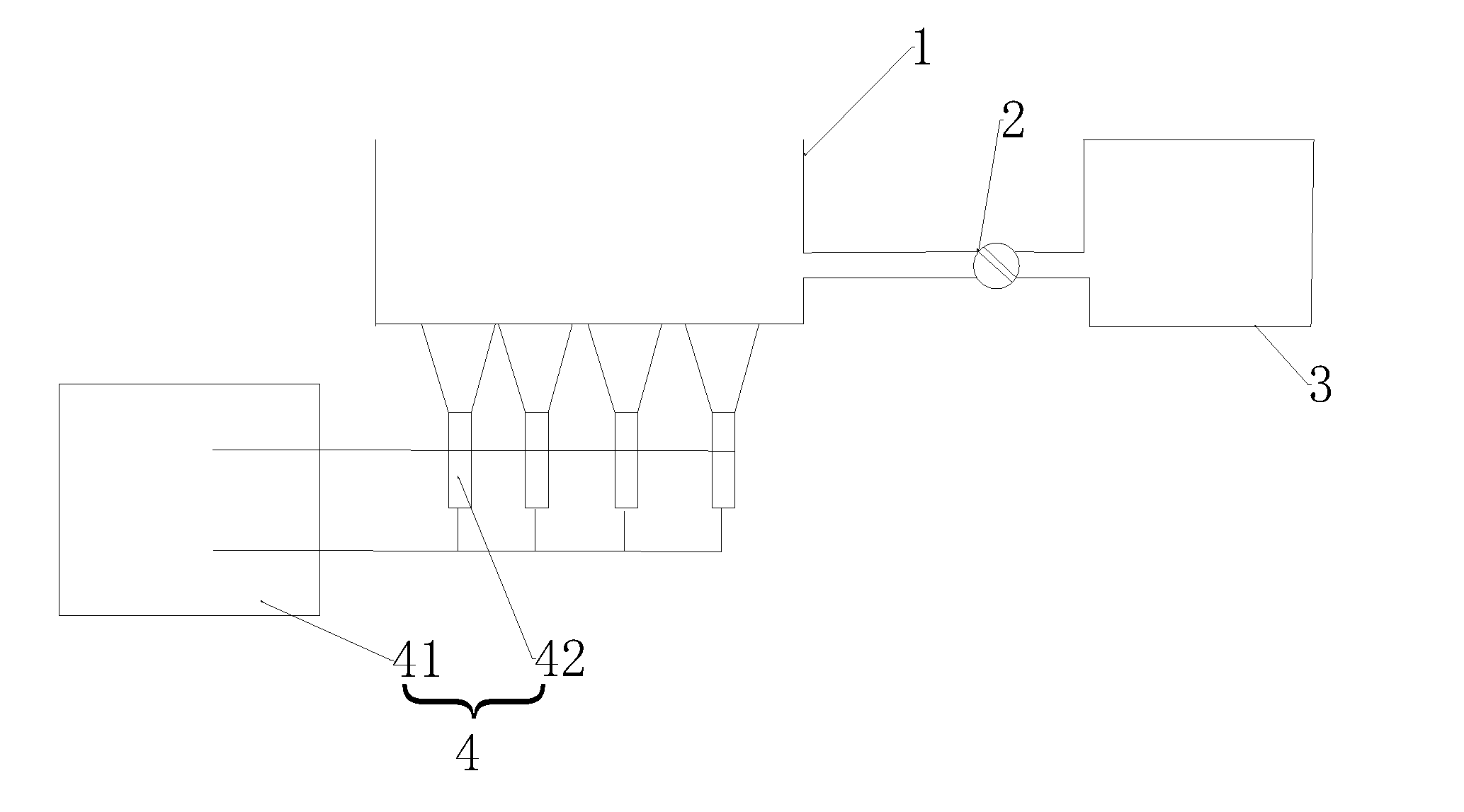

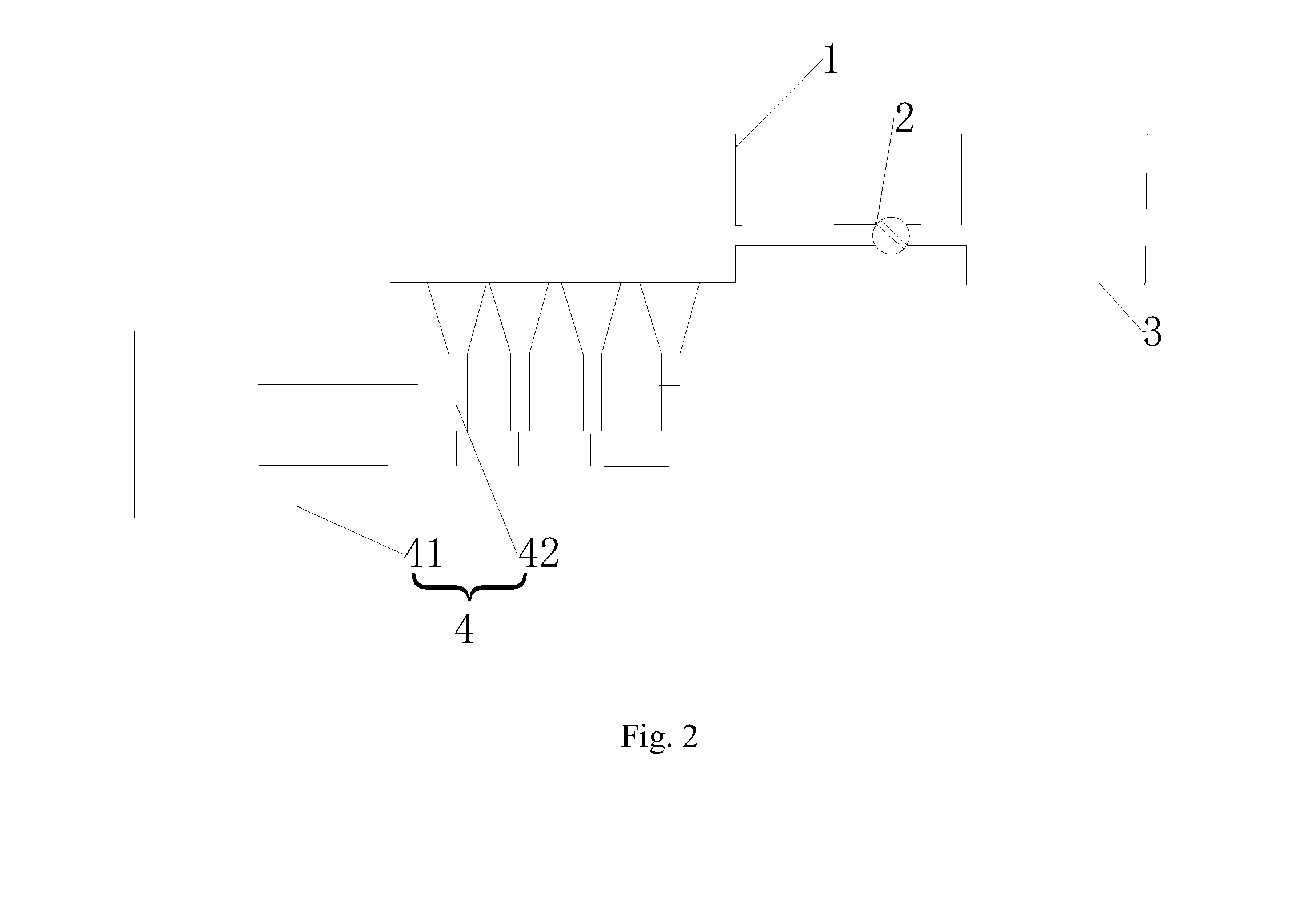

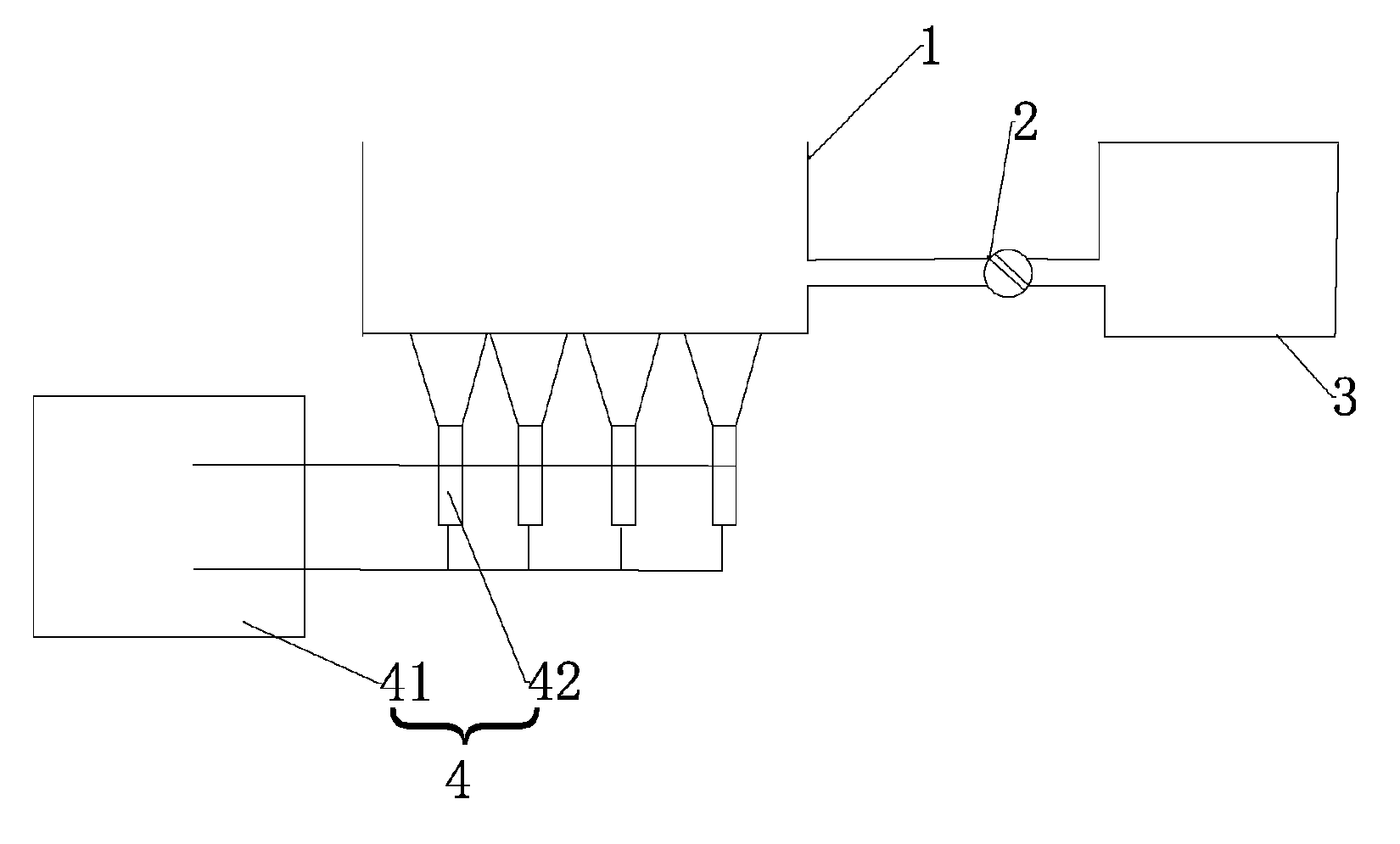

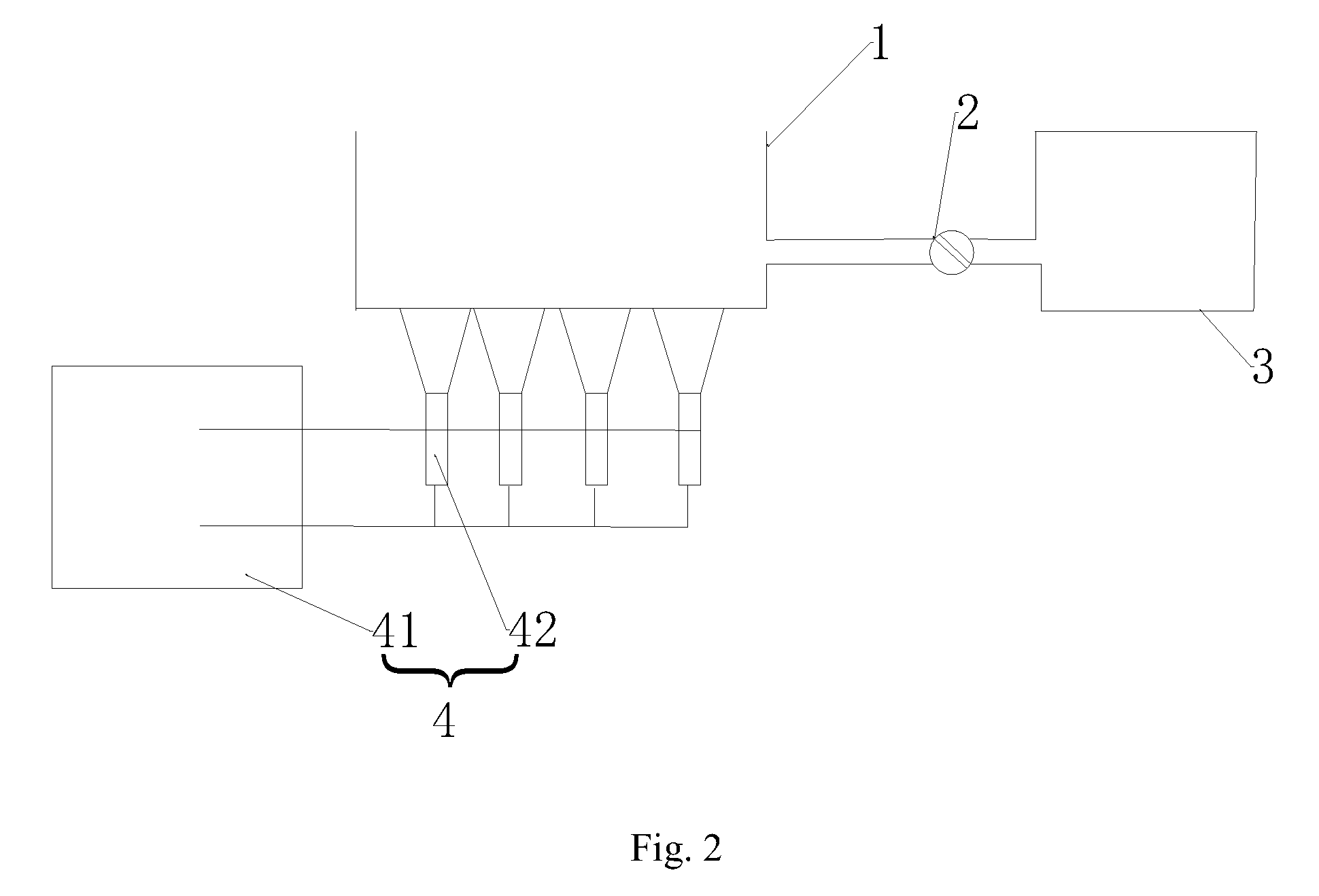

Ultrasonic cleaner and coater equipped with the ultrasonic cleaner

ActiveUS20150174621A1Many timesAffect efficiencyLiquid surface applicatorsElectrostatic cleaningMegasonic cleaningEngineering

An ultrasonic cleaner and a coater equipped with the ultrasonic cleaner are provided. The ultrasonic cleaner is configured to clean an inkjet head for ejecting an alignment solution. The cleaner comprises a cleaning receiver for receiving a clean agent, an ultrasonic generator for generating an ultrasonic, and a storing device for retrieving and storing the clean agent, and each of the ultrasonic generator and the storing device is connected to the cleaning receiver. The ultrasonic cleaner can clean the blocked nozzle hole of the inkjet head quickly and thoroughly in a short time. Besides, the cleanliness in the equipment will not be destroyed and the cleaning agent can be retrieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

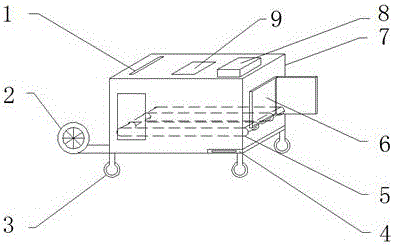

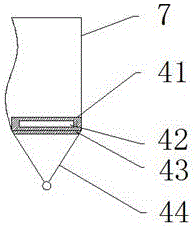

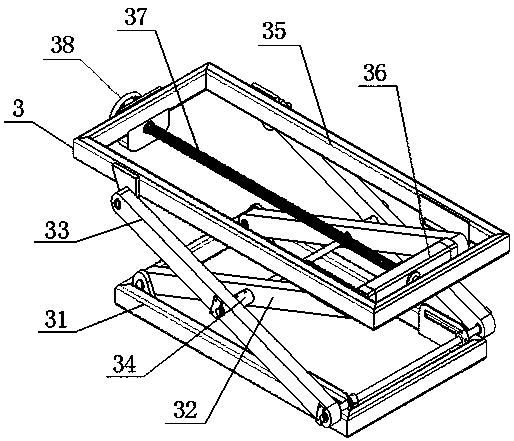

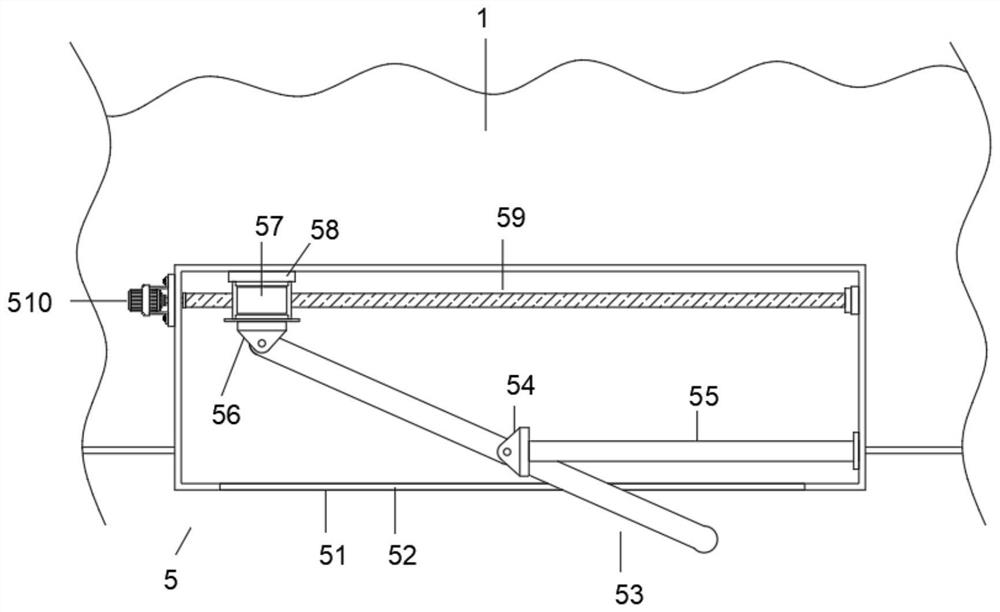

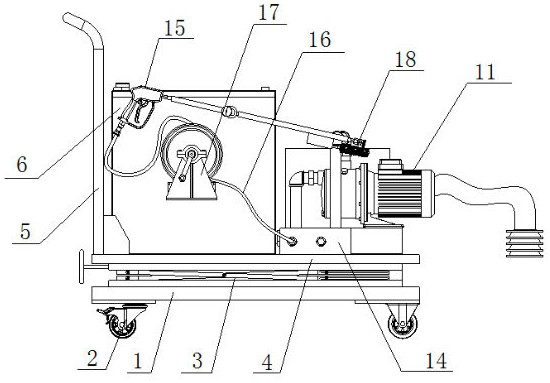

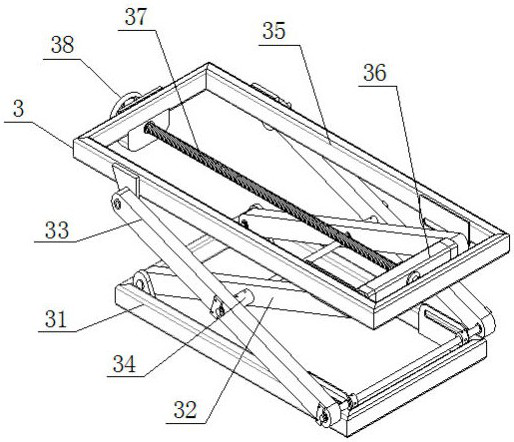

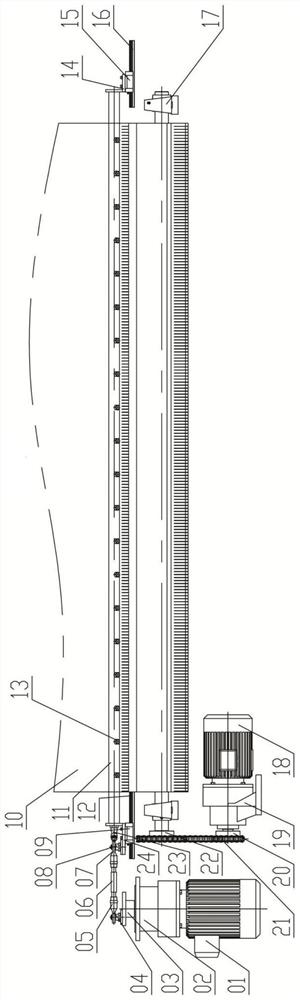

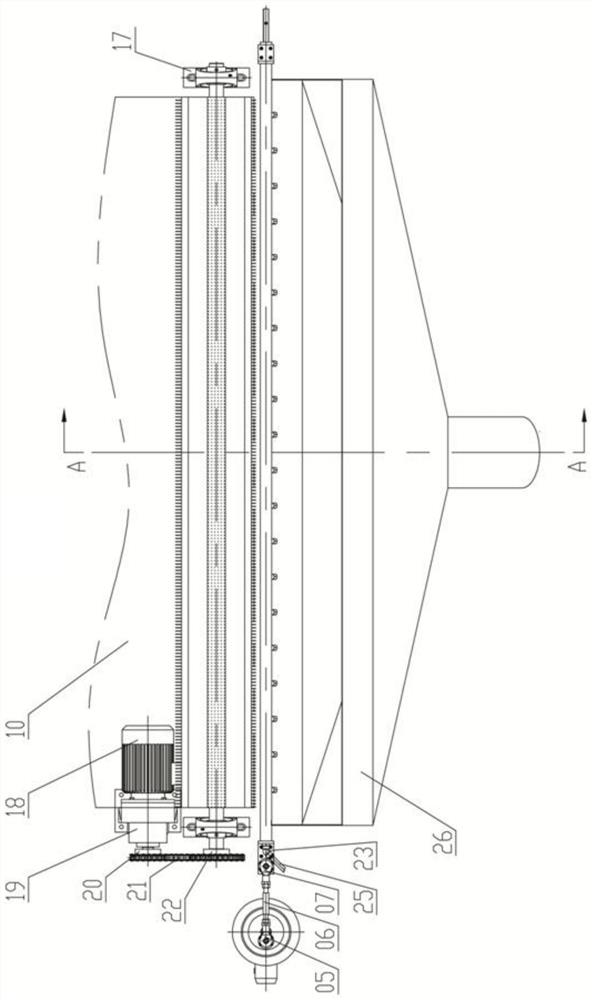

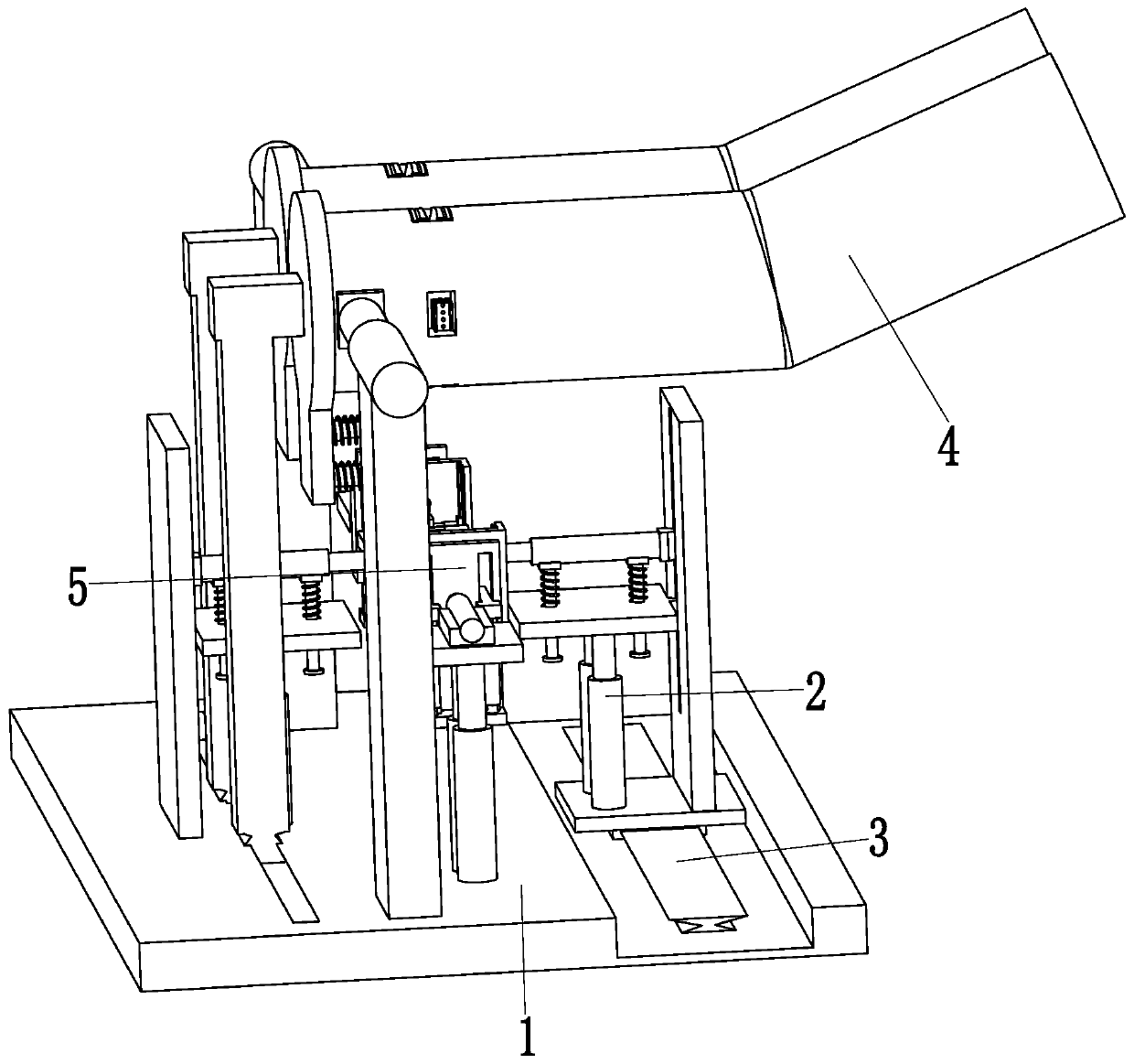

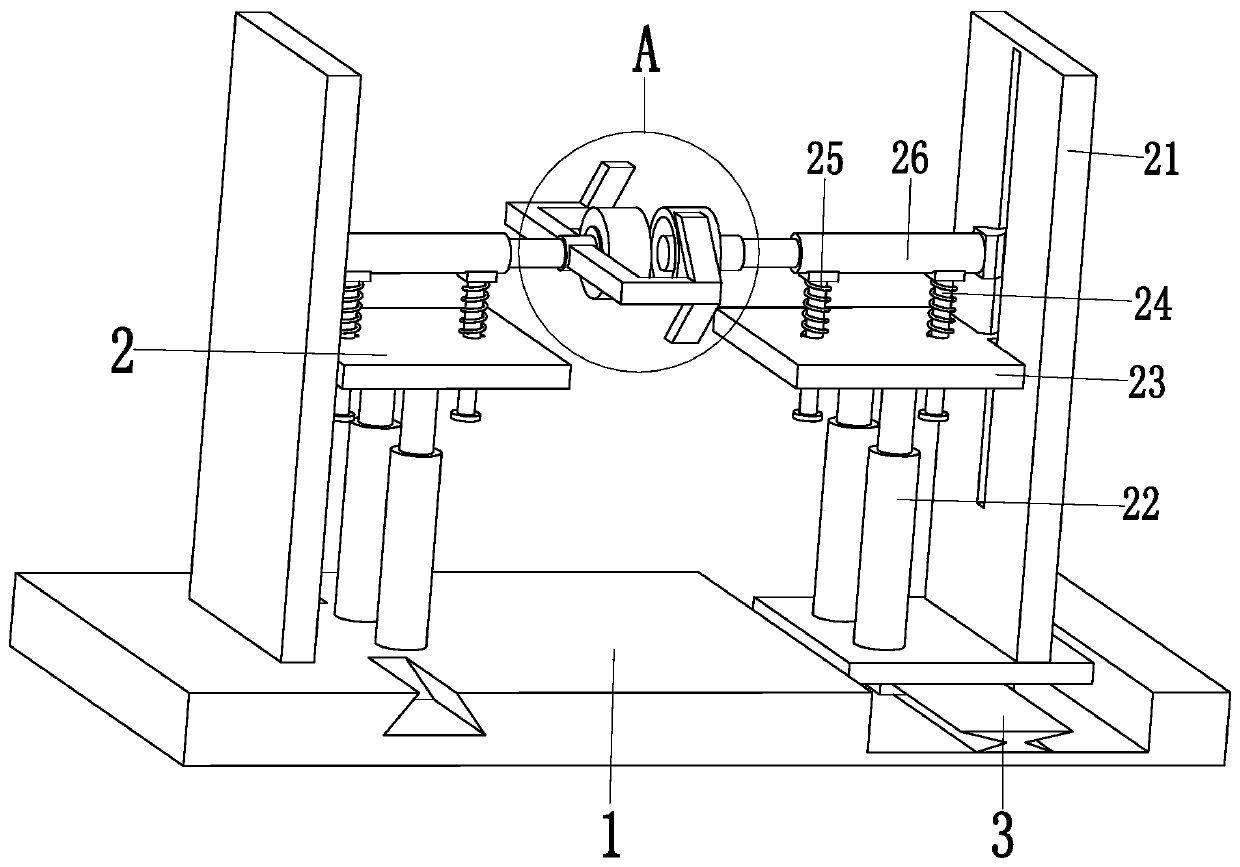

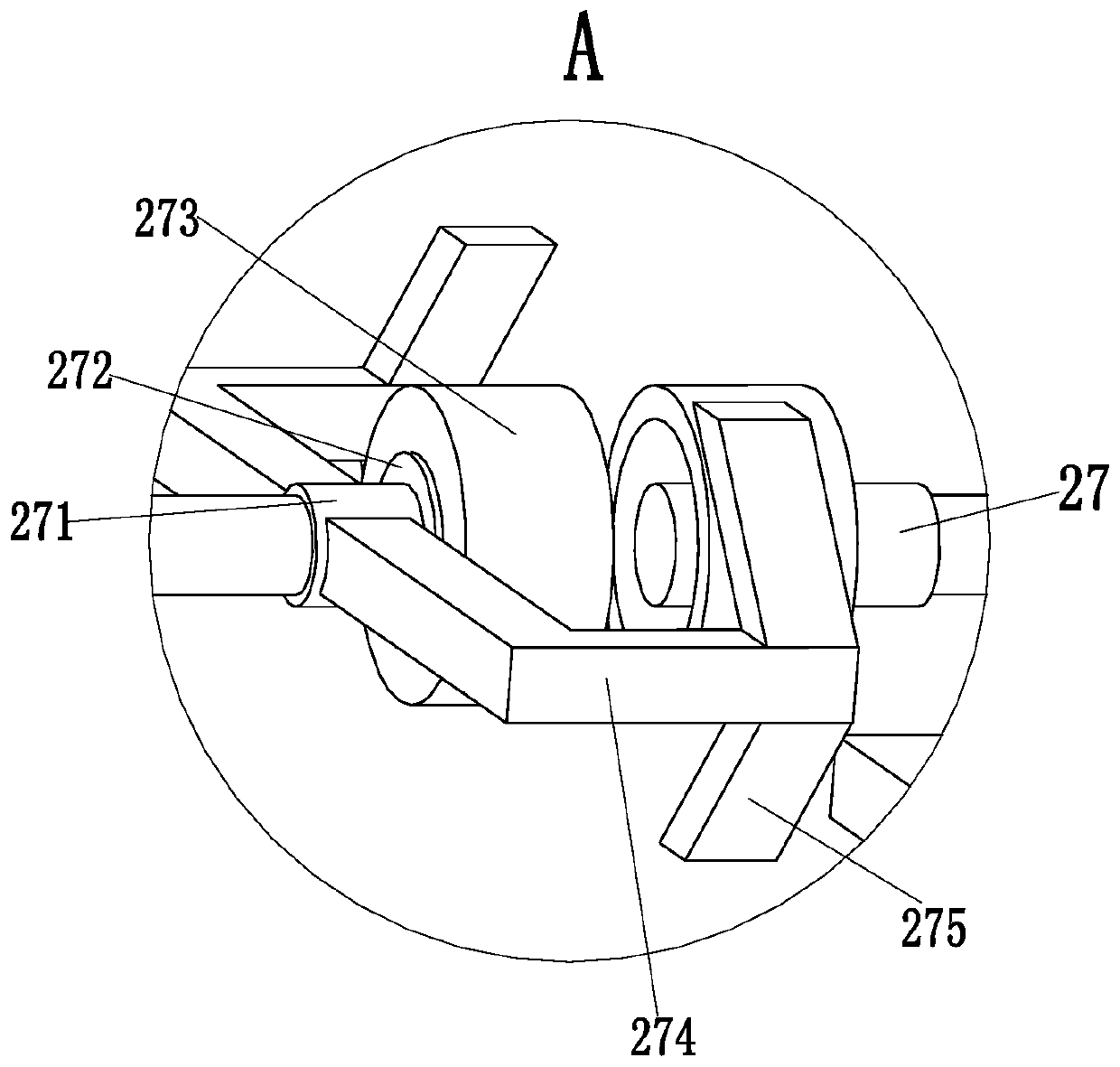

Inner wall scale flushing equipment for industrial pump and working method of inner wall scale flushing equipment

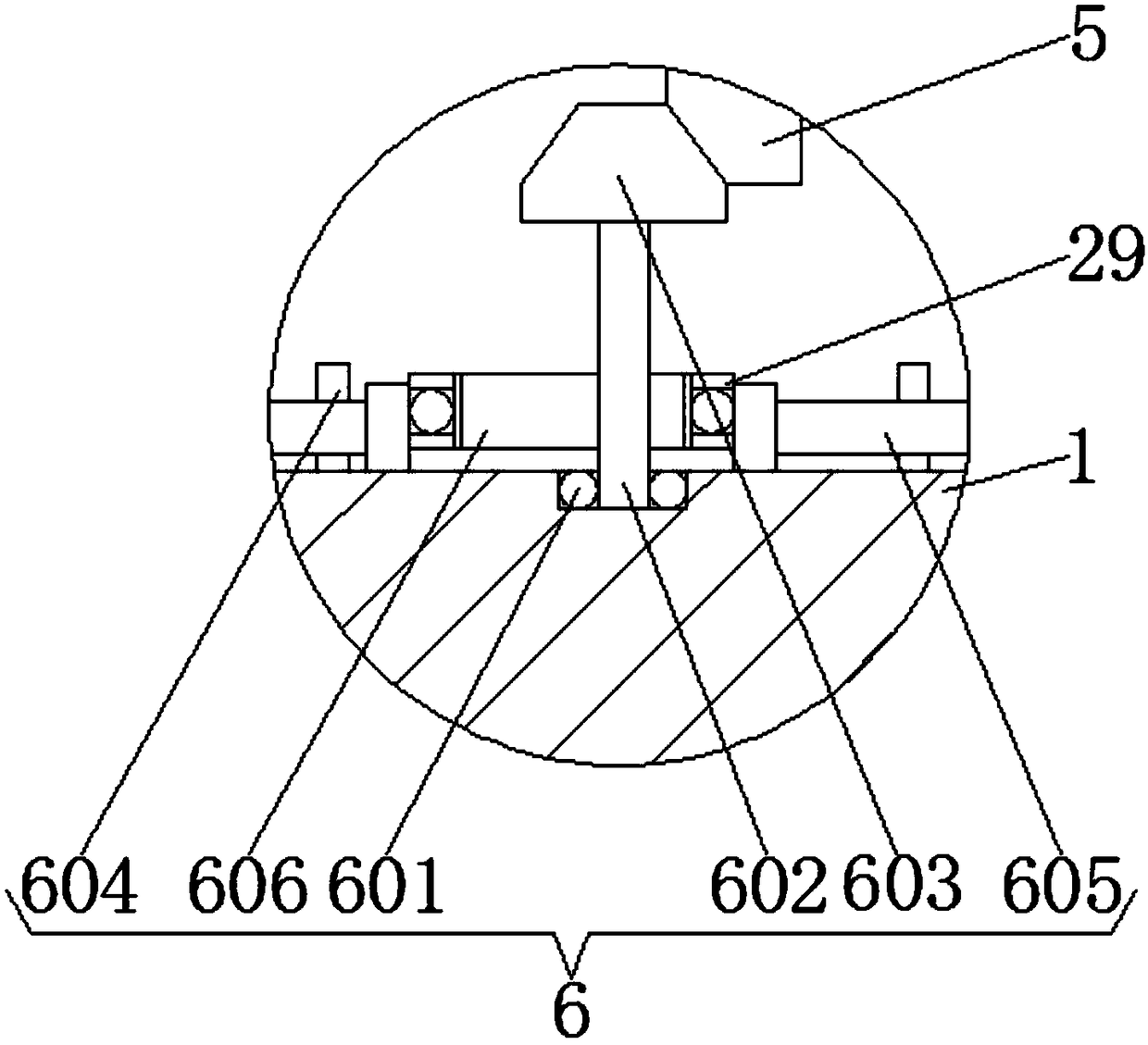

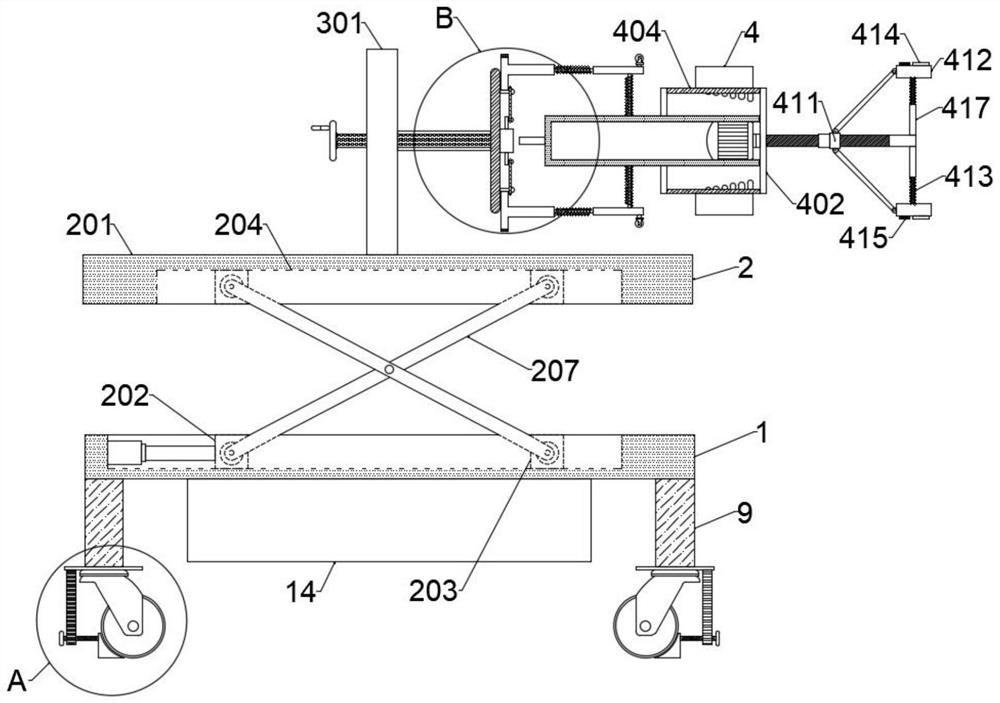

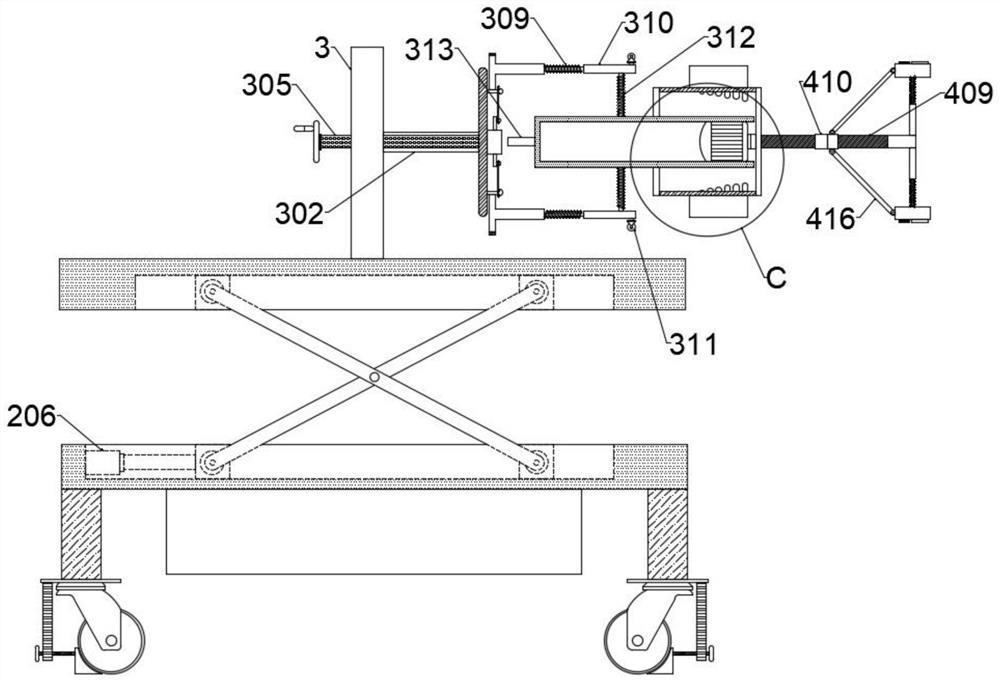

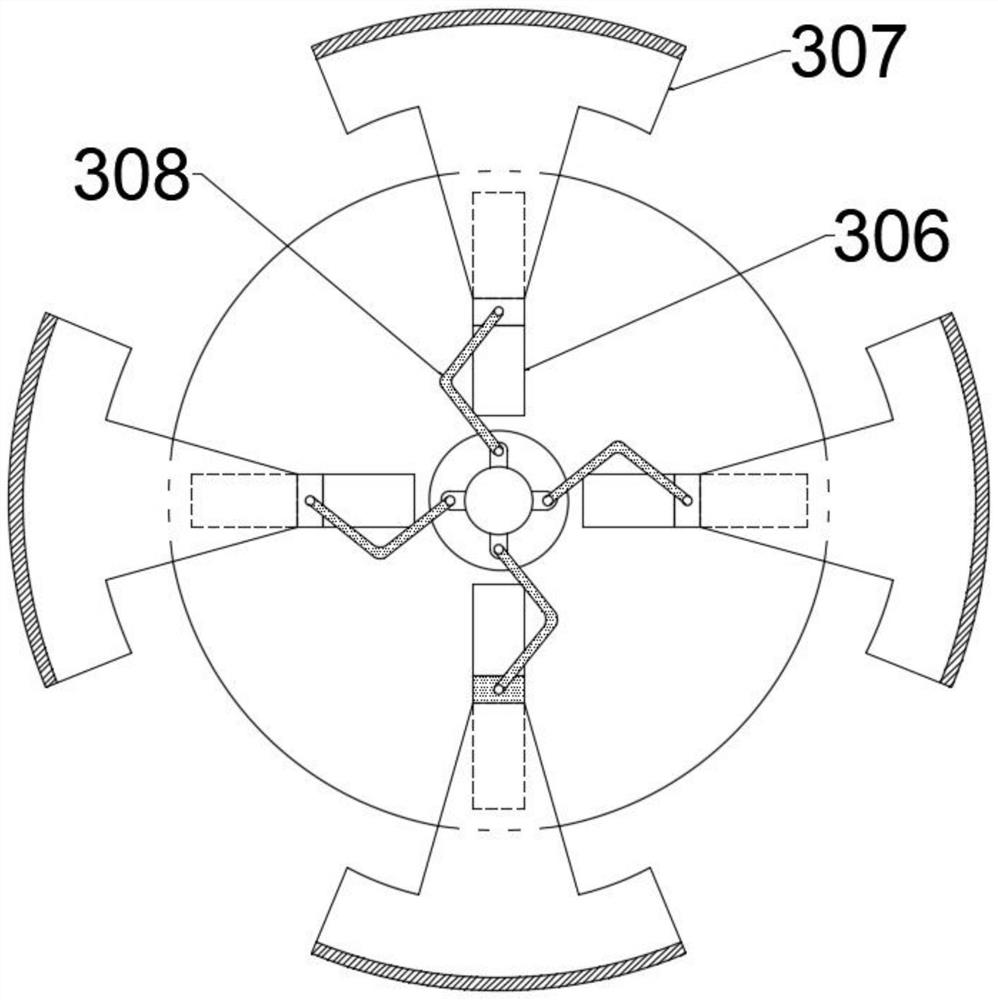

ActiveCN113996610AScrape evenlyIncomplete cleaningHollow article cleaningCastorsWater source heat pumpSpot welding

The invention discloses inner wall scale flushing equipment for an industrial pump and a working method of the inner wall scale flushing equipment, relates to the technical field of industrial pump scale cleaning, and aims at solving the problems that: existing devices are prone to deviation in the pipe wall scale cleaning process, the scale cleaning effect is poor, and the pipe wall and a scraper are damaged due to excessive scraping on one side of the pipe wall. The equipment comprises a chassis frame, supporting columns and rolling wheels, the supporting columns are fixed to the four corners of the bottom of the chassis frame through spot welding, the rolling wheels are movably connected to the bottoms of the supporting columns through bearings, a lifting assembly is installed at the top of the chassis frame, the lifting assembly comprises a moving plate, an expanding fixing assembly and a cleaning assembly are mounted at the top of the movable plate, and the fixed plate is fixedly connected to the top of the movable plate. Compared with the prior art, water source heat pumps with different lengths can be thoroughly cleaned, and the problem that one side of the pipe wall is excessively scraped, so that the pipe wall and a scraper are damaged can be avoided.

Owner:ANHUI JINWAN PUMP TECH CO LTD

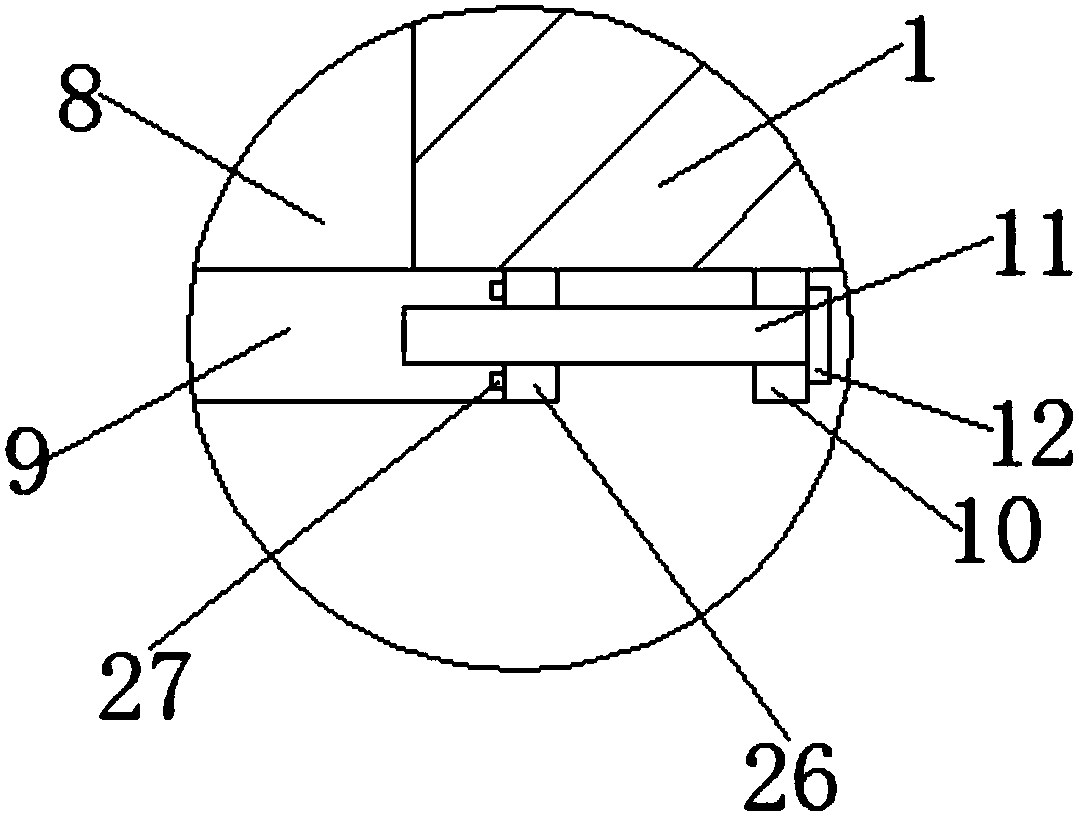

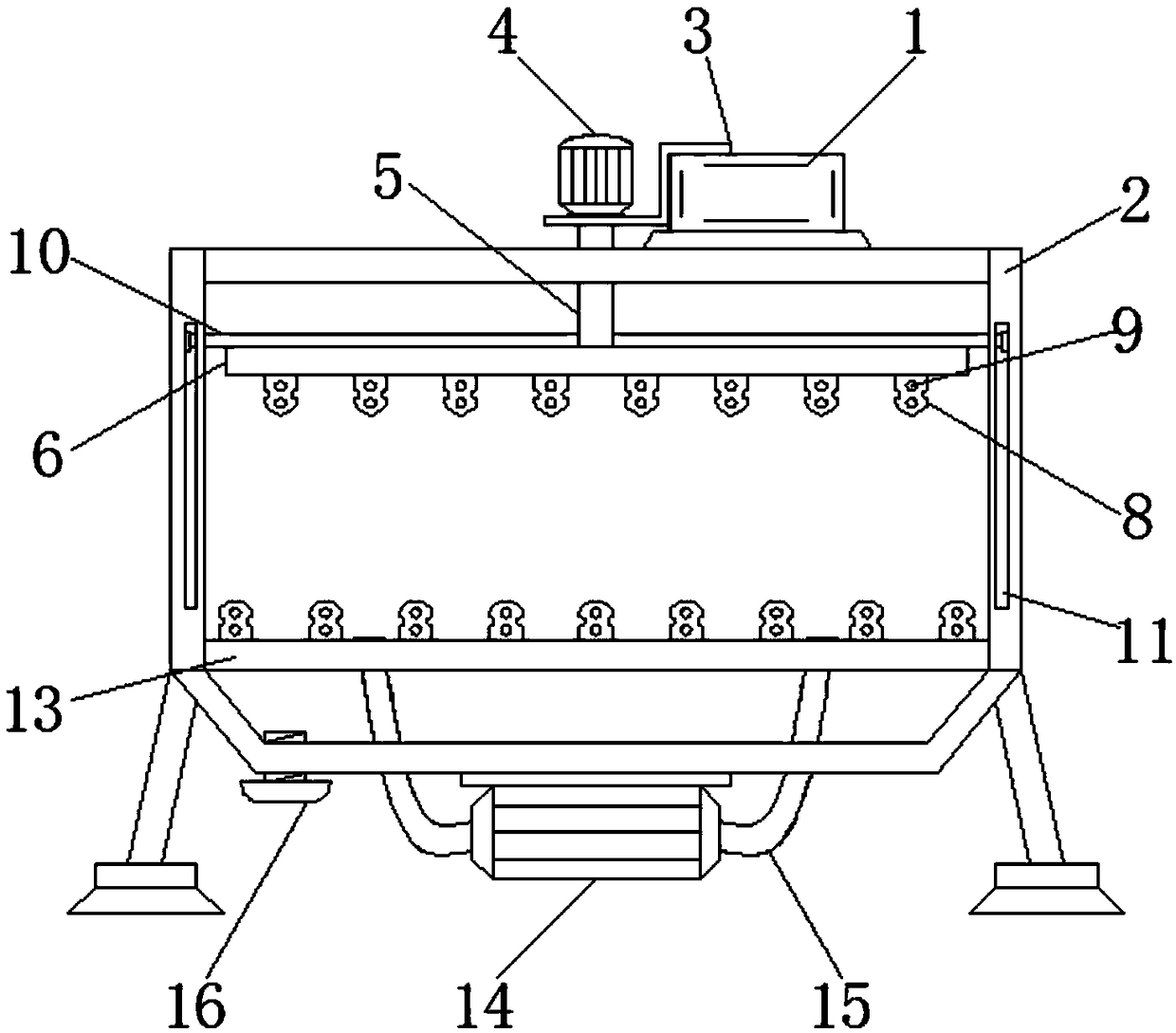

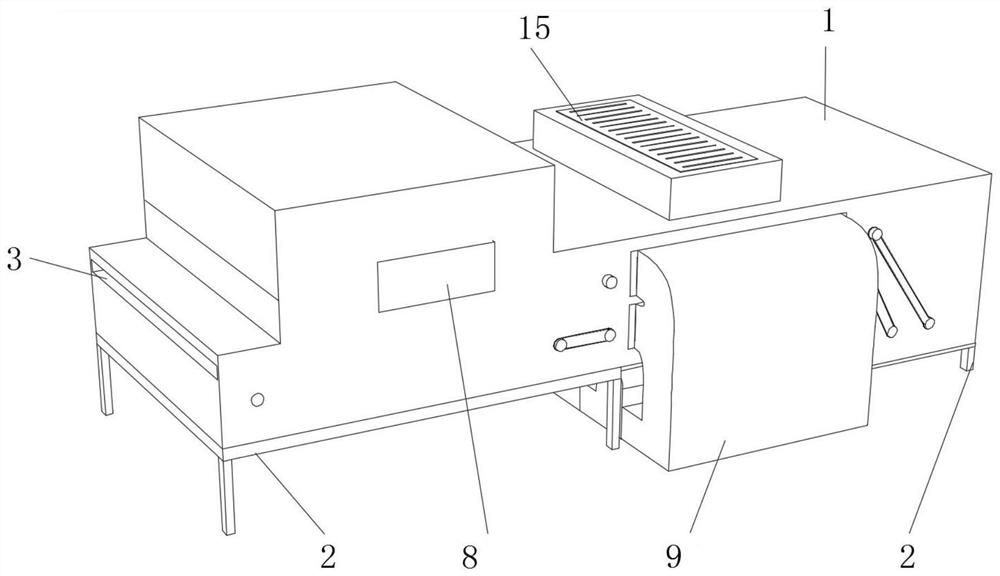

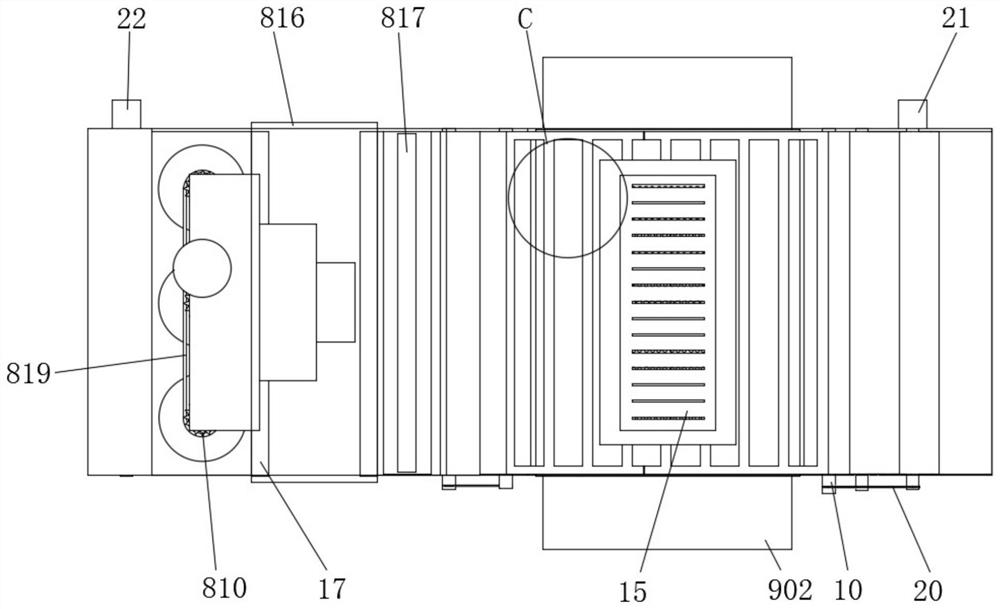

Leather cleaning device in production

ActiveCN111719302AAvoid savingImprove adsorption capacityMechanical cleaningPressure cleaningAir filtrationAir filter

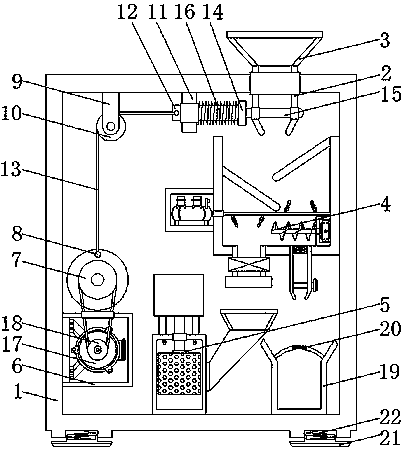

The invention relates to the technical field of leather cleaning, in particular to a leather cleaning device in production. The leather cleaning device comprises a machine shell, a bracket, a feedingopening, a discharging opening, a first transferring device, a second transferring device, a third transferring device, a leather cleaning mechanism, a drying mechanism, a rotary shaft, a cylinder, anarc-shaped baffle, an air filtering box, an air inlet, a filtering net plate, a filter screen, an electrostatic absorption device, a fixed plate, a baffle, a triangular belt, a second driving motor and a third driving motor. The machine shell is arranged at the top end of the bracket, the second driving motor is connected to the position, close to the tail end, of the left side of the machine shell, the third driving motor is arranged on the left side of the machine shell, the air filtering box is arranged on the right side of the top end of the machine shell, the feeding opening is formed inthe front surface of the machine shell, the discharging opening is formed in the back surface of the machine shell, the first transferring device is arranged in the machine shell, and the leather cleaning mechanism is arranged on the first transferring device. According to the leather cleaning device in the production, the problems that the leather cleaning is insufficiently thorough and the leather compaction degree is not ideal in the production are solved.

Owner:RUIAN DAHU SHOES IND CO LTD

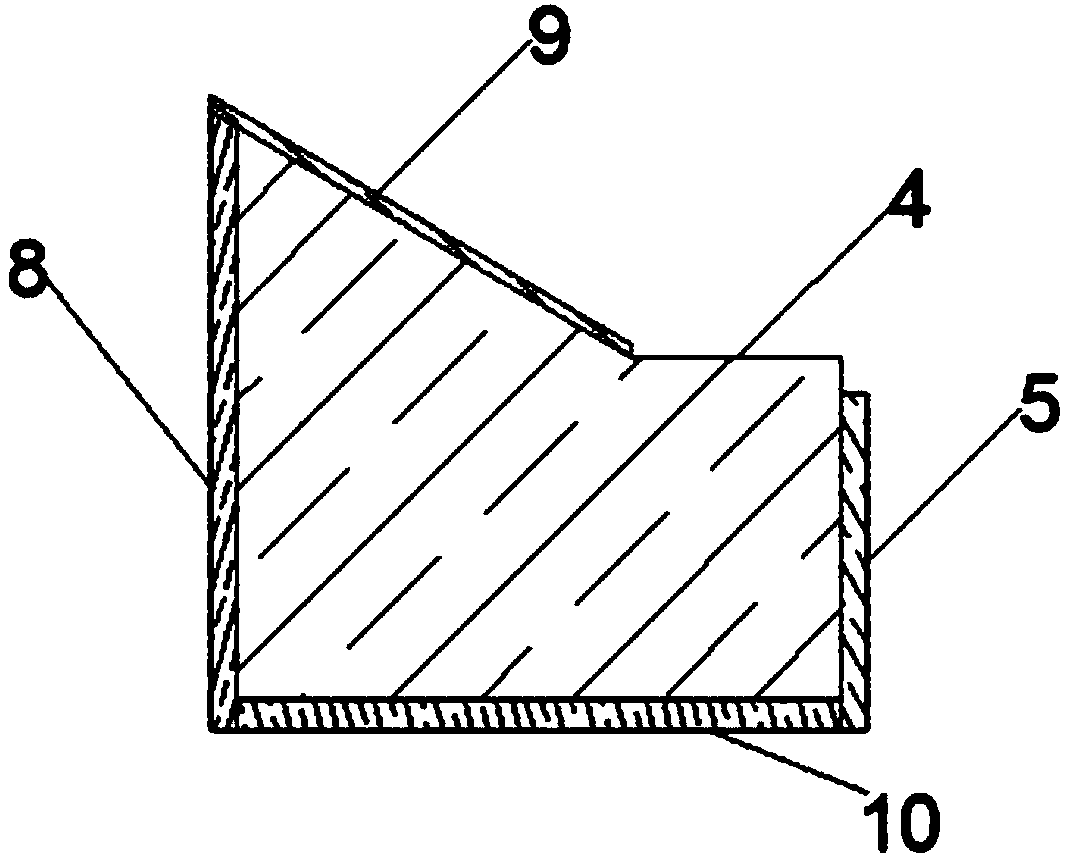

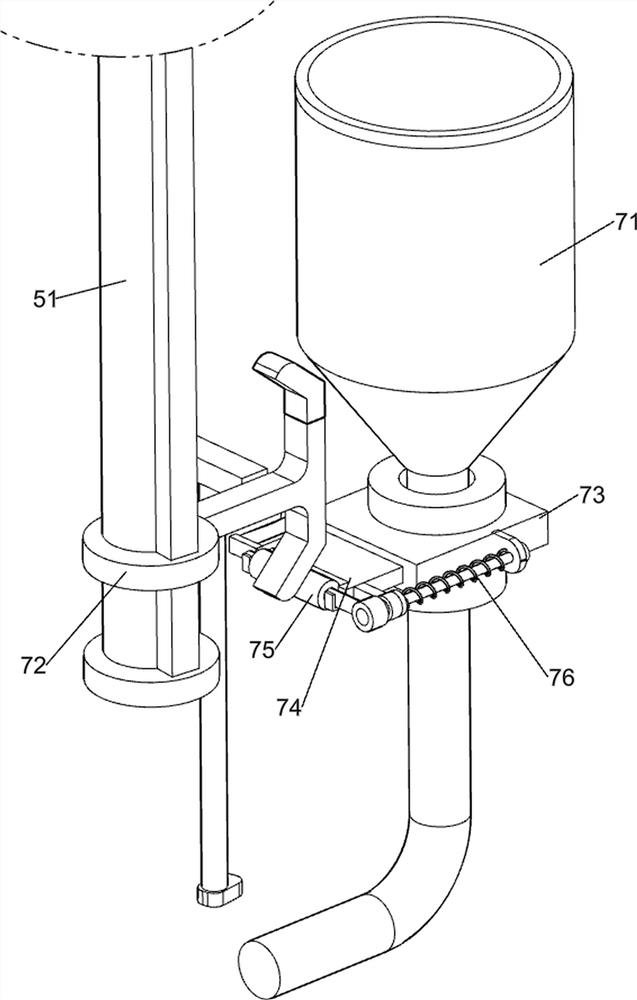

Egg chicken feeding crib convenient to clean

The invention belongs to the technical field of poultry breeding, and discloses an egg chicken feeding crib convenient to clean. The egg chicken feeding crib convenient to clean comprises a crib box,the crib box comprises a baseboard, a left side board, a right side board, a front baffle and a rear baffle, the left side plate is detachably connected with the baseboard, a slant anti-splash feed board is connected to the top of the rear baffle, a scraping plate matched with the internal profile of the crib box is embedded inside the crib box, and a push rod is connected to one side of the scraping plate, penetrates through the right side plate of the crib box and stretches out of the crib box. When the scraping plate is driven to move in the crib box, the scraping plate can scrape off feedattached to the inner wall of the crib box, and cleaning is thorough.

Owner:遵义宏伟农业科技有限责任公司

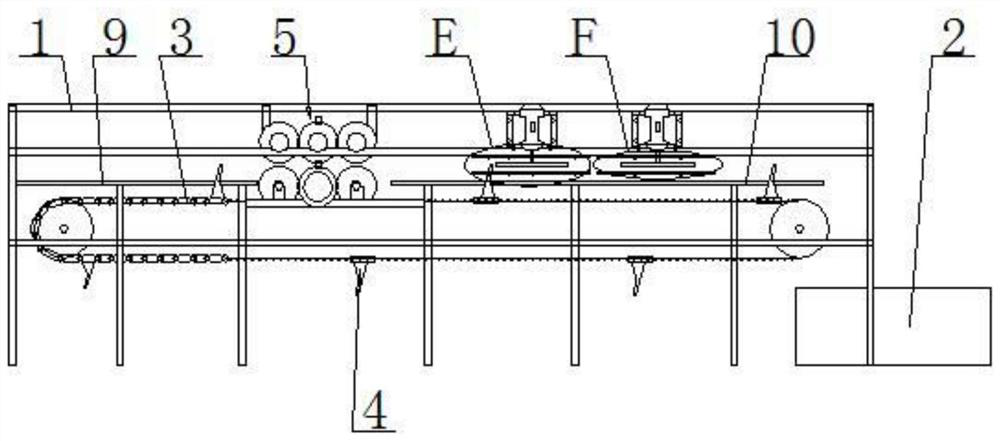

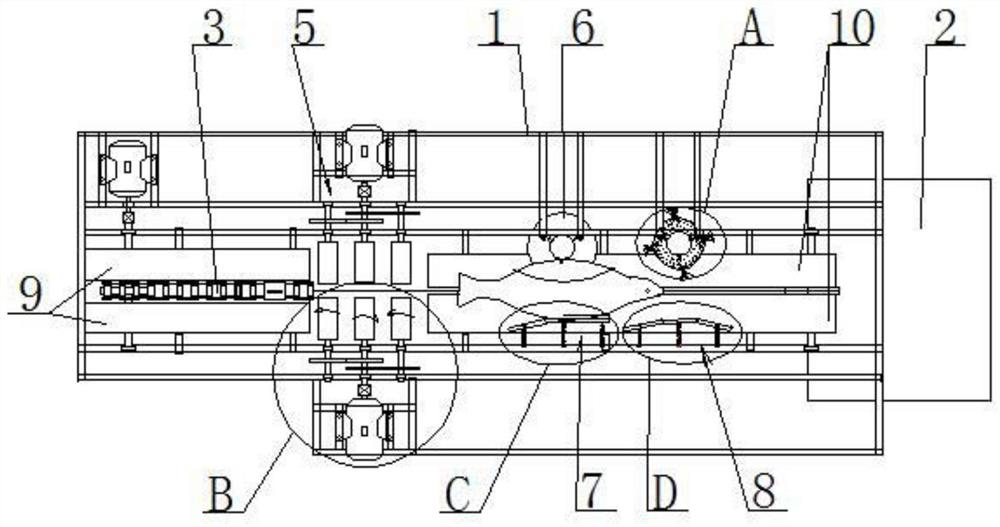

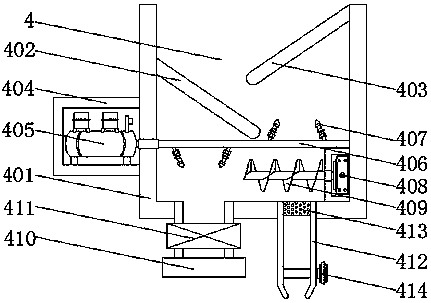

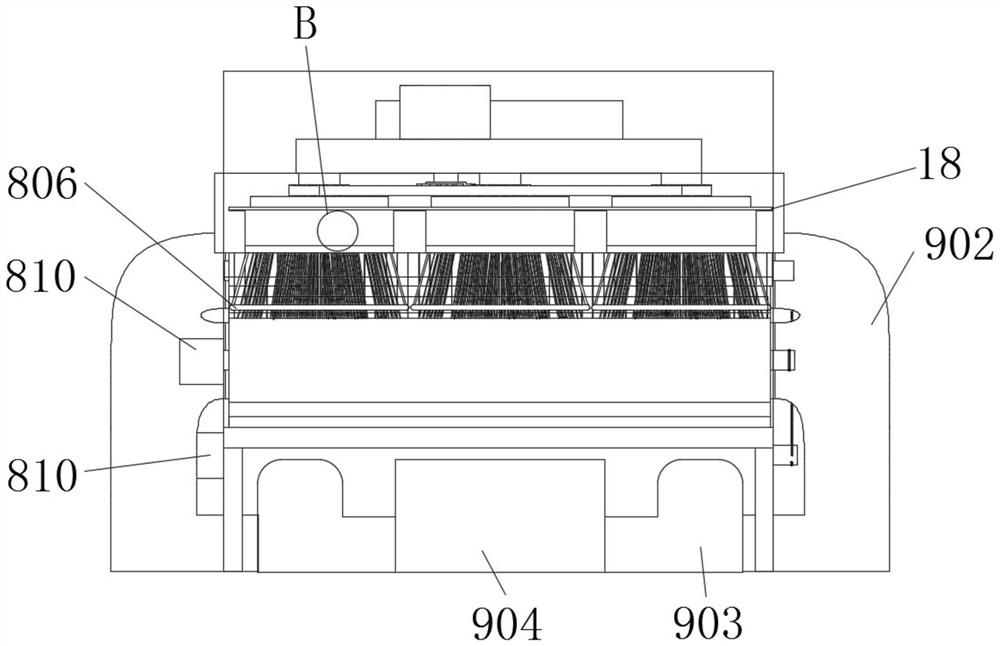

Scaled fish treatment device

ActiveCN112970824ACompact structureIngenious designFish washing/descalingFish processingElectric machinery

The invention relates to a scaled fish processing device, and belongs to the technical field of fish processing equipment. The scaled fish processing device comprises a rack, a fish collecting basket, a conveying chain, fishhooks, a scaling device, a sectioning knife, a viscera removing device, a guiding device A and a guiding device B, wherein the conveying chain is arranged on the rack through a chain wheel and a motor, a plurality of fishhooks are mounted on the outer side of the conveying chain at intervals, bearing plates A are symmetrically arranged on the rack on the two sides above the conveying chain, a bearing plate B is mounted on the rack at one end of the bearing plate A, the scaling device is arranged on the rack between the bearing plate A and the bearing plate B, the sectioning knife is arranged on the rack above the bearing plate B on one side of the conveying chain through the motor, and the viscera removing device is arranged on the rack on one side of the sectioning knife through the motor. The scaled fish processing device solves the problems that an existing scaled fish processing device cannot thoroughly remove dirt and is likely to damage fish bodies, and is particularly suitable for being used by fish processing enterprises.

Owner:YANGTZE UNIVERSITY

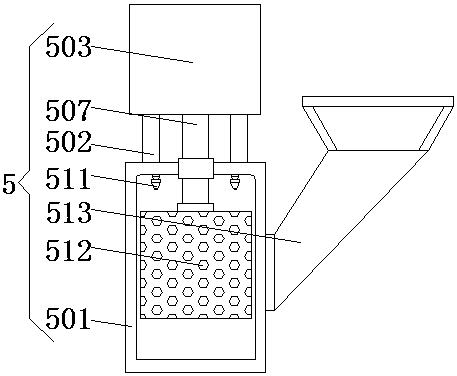

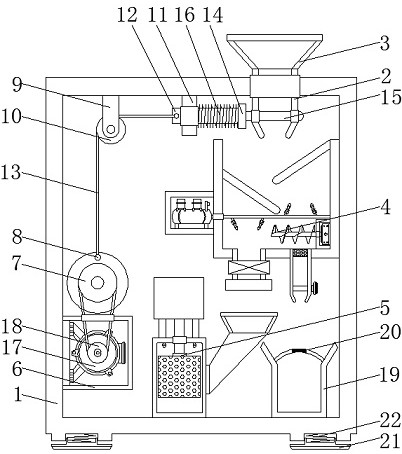

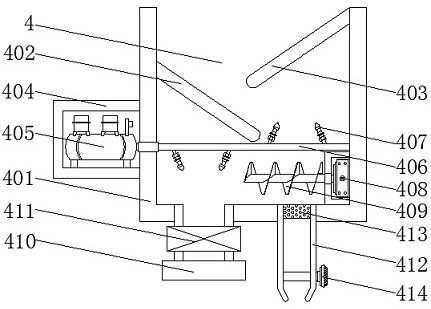

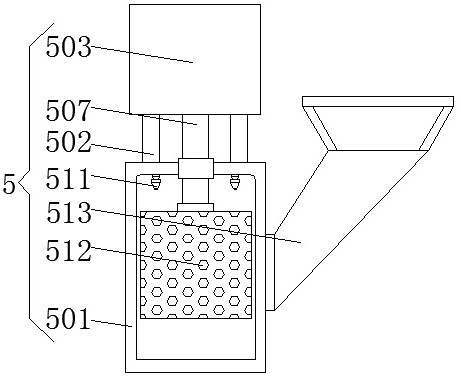

Quantitative cleaning vibrating disinfecting device for bioexperiment

InactiveCN109909210AAvoid cloggingImprove cleaning efficiencyLavatory sanitoryCleaning using liquidsEngineeringHand washing

The invention discloses a quantitative cleaning vibrating disinfecting device for a bioexperiment, and relates to the field of bioexperiment auxiliary equipment The device comprises a box body, an input channel is fixedly connected to the right side of the top of the box body, the input channel penetrates through the top of the box body and extends into the box body, the end, located on the top ofthe box body, of the input channel communicates with an input hopper, a cleaning device is fixedly connected to the upper portion of the right side of the inner wall of the box body, a vibrating disinfecting device is fixedly connected to the central position of the bottom of the box body, a first motor is fixedly connected to the lower portion of the left side of the inner wall of the box body,the front end of the first motor is rotatably connected with a first belt wheel through an output shaft, and a first outer frame is arranged on the outer portion of the first motor. The quantitative cleaning vibrating disinfecting device for the bioexperiment solves the problems that an existing bioexperiment article adopts manual hand washing, work is tedious, time and labor are wasted, and cleaning is not in place, the aim of more effectively improving the cleaning efficiency and the disinfecting efficiency is achieved, and excessive articles are prevented from blocking the channel.

Owner:HUAIYIN TEACHERS COLLEGE

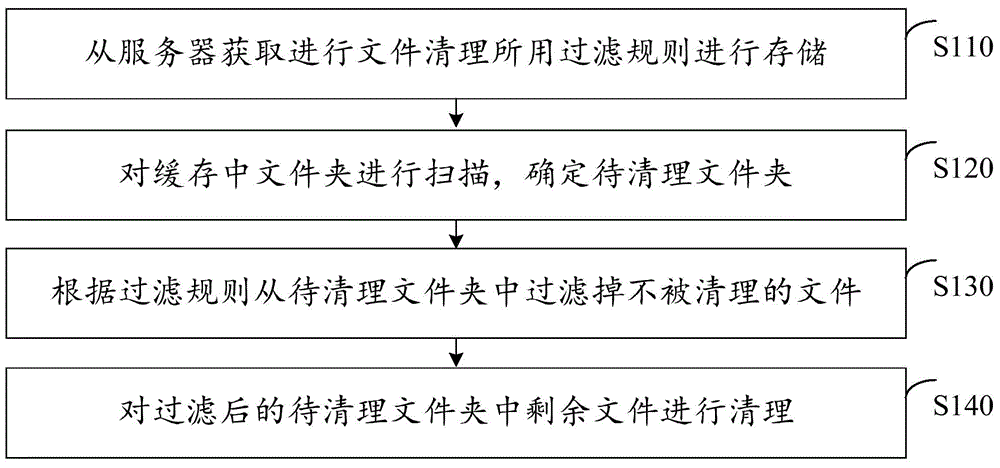

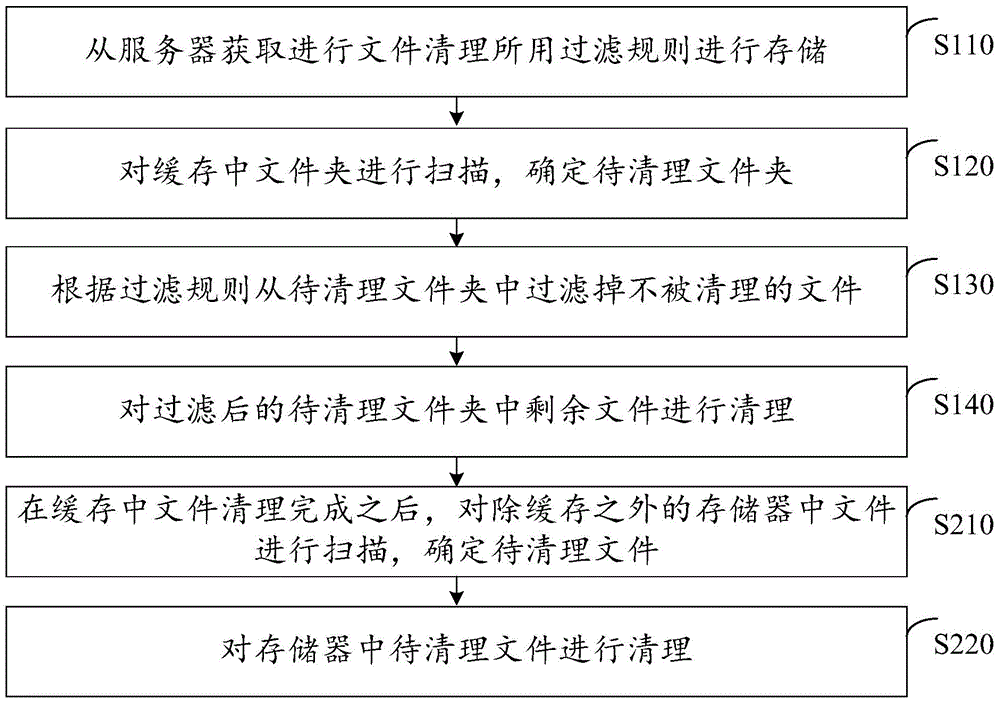

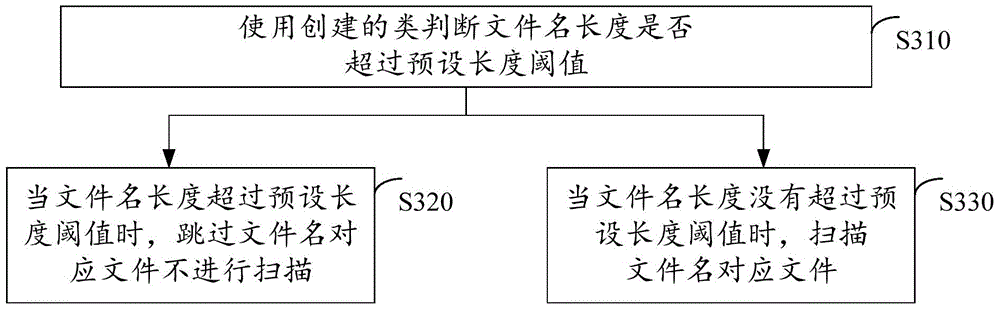

Method and apparatus for cleaning up files in cache

InactiveCN104978152AAvoid being deleted by mistakeIncomplete cleaningInput/output to record carriersMemory adressing/allocation/relocationOperating systemComputer science

The present invention discloses a method and apparatus for cleaning up files in a cache. The method comprises: acquiring filtering rules for carrying out file cleanup from a server so as to carry out storage; scanning folders in the cache and determining folders to be cleaned up; according to the filtering rules, filtering files in the folders to be cleaned up, which do not need to be cleaned up; and cleaning up the rest of files in the filtered folders to be cleaned up. The method solves the problem that when the folders comprise the files which do not need to be cleaned up, the folders are retained and are not cleaned up, so that the cache is incompletely cleaned up; and the method obtains the beneficial effects of saving cache resources, improving device performance and avoiding the files being deleted by mistake.

Owner:BEIJING QIHOO TECH CO LTD +1

Automatic wrinkle remover

InactiveCN106637881AAchieve dry wrinkle removalSolve the problem of incomplete wrinkle removalIroning machinesTextiles and paperWrinkle skinEngineering

The invention provides an automatic wrinkle remover, comprising a body, a blower, a dust collection channel, a vacuum unit, transmission wheel I, transmission wheel II, a motor, a support frame, a liquid storage chamber and a water pump; the blower is disposed at the left of the body, and the problem that a traditional wrinkle remover provides incomplete removal for clothes wrinkles is solved by using the design; the dust collection channel is mounted at the right of the inner lower end of the body, the vacuum unit is mounted at the lower end of the dust collection channel, and the problem that a traditional wrinkle remover provides non-thorough cleaning for clothes is solved by using the design; the transmission wheel I is disposed at the left of the transmission wheel II, the support frame is fitted to the right of the inner upper surface of the body, and the motor is fitted to the front end of the support frame, and the problem of waste of a user's time and energy is solved by using the design; the liquid storage chamber is mounted at the inner upper end of the body, and the water pump is disposed at the right of the liquid storage chamber, and the problem that a traditional wrinkle remover requires manual spraying a wrinkle removing agent, resulting in non-uniform spraying and waste of time and labor, is solved by using the design. The automatic wrinkle remover saves resources, provides comprehensive caring, and is simple to operate and highly practical.

Owner:ZHONGSHAN JIEXIN TECH SERVICES CO LTD

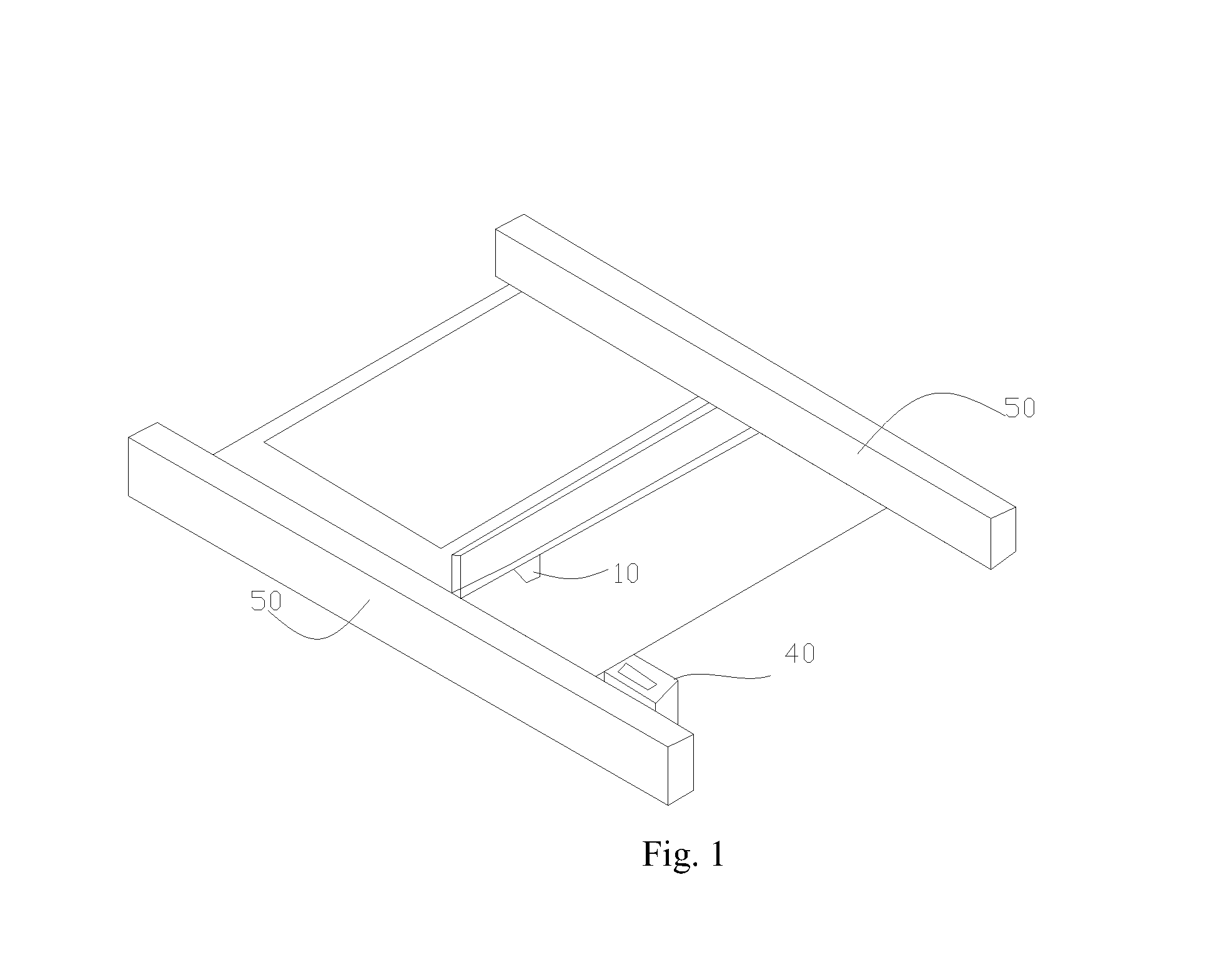

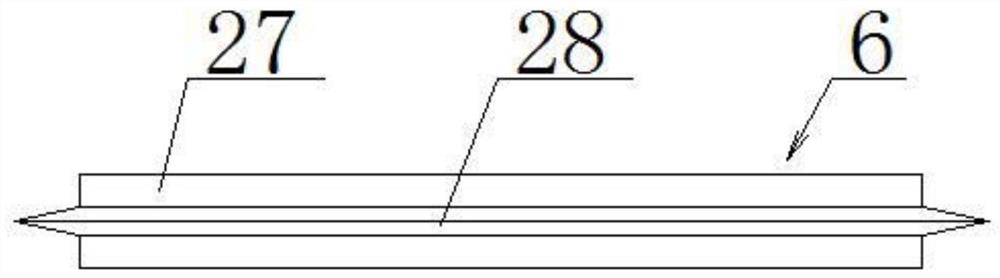

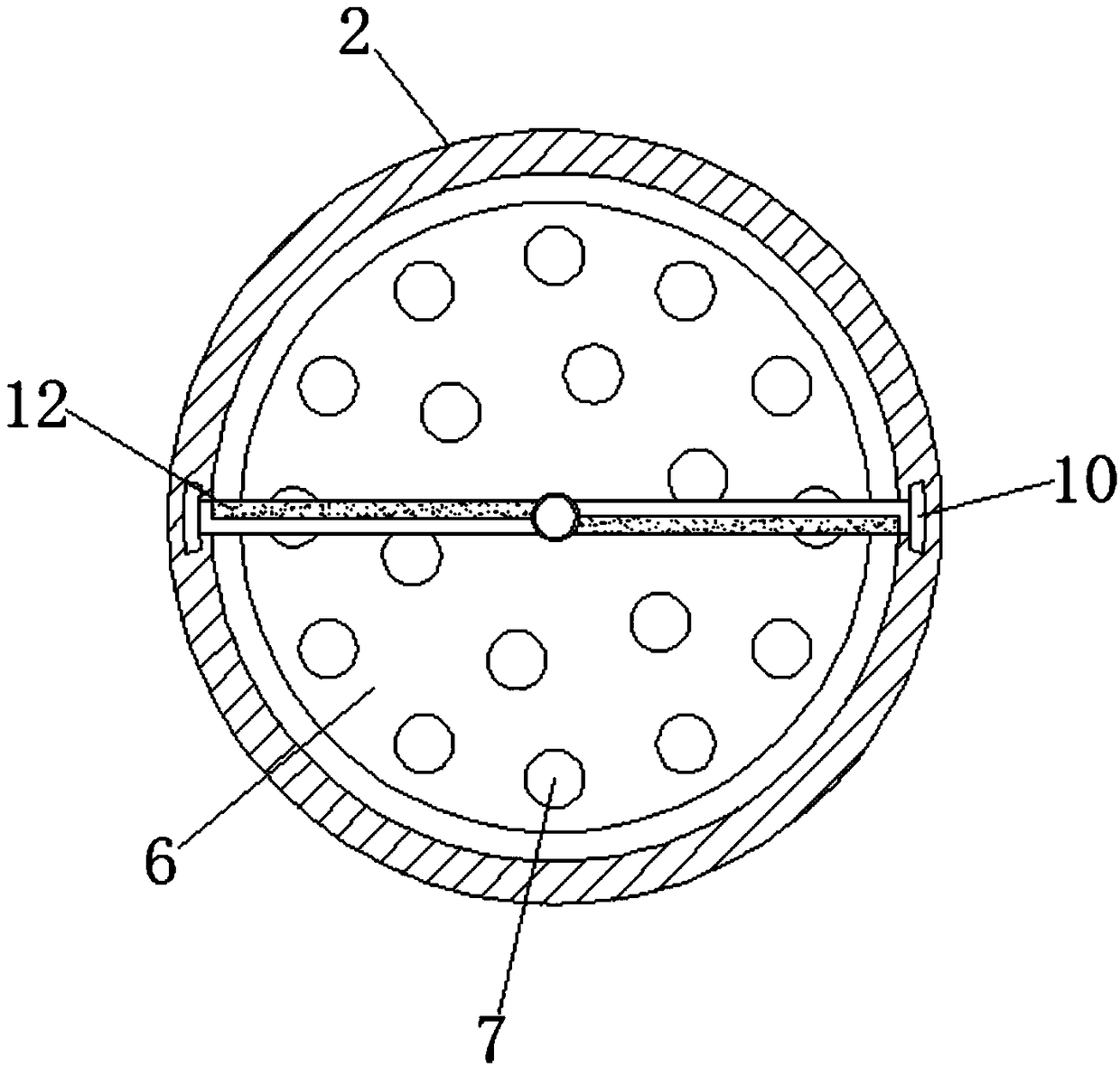

Textile fabric cleaning equipment

InactiveCN108505248AAchieve cleaningMinus the problems with agitation cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsArchitectural engineeringTextile

The invention discloses textile fabric cleaning equipment. The textile fabric cleaning equipment comprises a cleaning air cylinder, a cross bar and closing members. A cleaning tank is fixedly mountedon a top plate of the cleaning air cylinder and connected to the bottom of a servo motor through a transmission force arm, and a connecting rod is connected to the bottom of the servo motor; the rod end of the connecting rod is disposed at a central point of a cleaning disc, and the cleaning disc is located in the cleaning tank; water overflow holes are formed in the junctions of the cleaning discand pressing blocks, and water suction holes are reserved in the pressing block; one end of the cross bar is fixed to the connecting rod, and the other end of the cross bar is connected to the innerwall of the cleaning tank through sliding grooves; the closing members are fixed to the sides of the cross bar on the connecting rod, A clapboard is disposed in the cleaning tank and located below thecleaning disc, and a closing bolt and a circulating water pump are mounted at the bottom of the cleaning tank from left to right in sequence. The textile fabric cleaning equipment solves the problemthat existing cleaning devices easily cause partial damage of the blended surface of a textile fabric.

Owner:JIANGSU BEILIN TEXTILE CO LTD

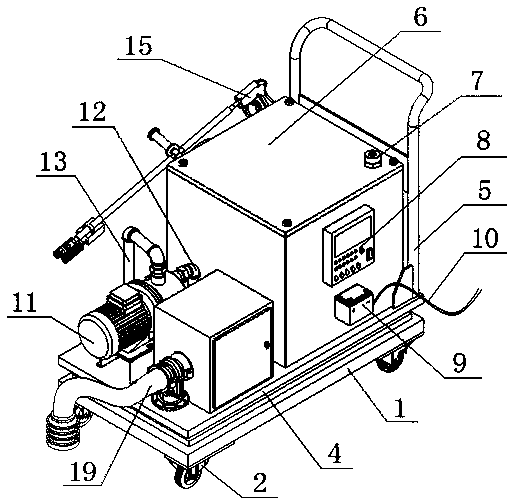

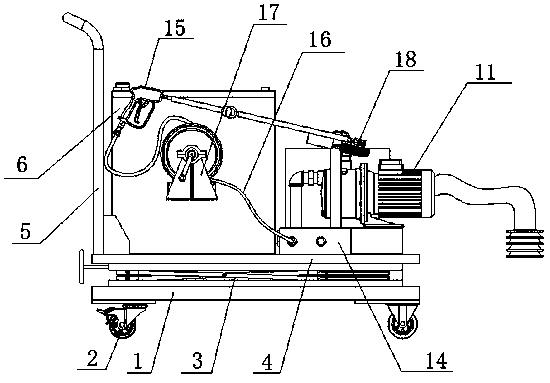

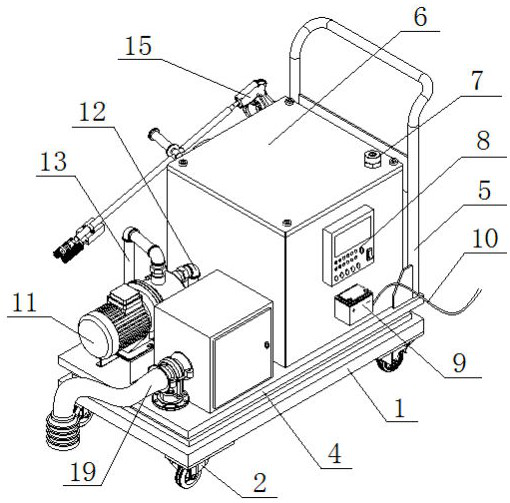

Furnace wall cleaning device for smelting furnace

ActiveCN109341368AThe solution is not easy to cleanAvoid excessive lengthIncrustation removal devicesGear wheelDrive shaft

The invention discloses a furnace wall cleaning device for a smelting furnace. The furnace wall cleaning device comprises a base, walking wheels, a supporting plate, a pushing rod, a water storage tank, a water adding opening, a control panel, a storage battery, a power line, a water pump, a first connecting pipe, a second connecting pipe, an adapter, a spraying gun, a water conveying pipe, a lifting mechanism, a winding device, a descaling device and a dust suction device. Through the arrangement of the descaling device, a first transmission shaft is driven to rotate after a motor works, andthe first transmission shaft rotates to drive a first rotating roller to rotate; meanwhile, a main gear outside the first transmission shaft is driven to rotate, and through the meshing with the maingear, an auxiliary gear is enabled to rotate; the auxiliary gear rotates to drive a second transmission shaft to rotate so that the second rotating roller can be driven to rotate, and the first rotating roller and the second rotating roller rotate and are in contact with the furnace wall to perform descaling work; and the problem that the interior of the furnace wall is not thoroughly cleaned dueto the fact that residues are attached to the interior of the furnace wall is solved.

Owner:广东华劲金属型材有限公司

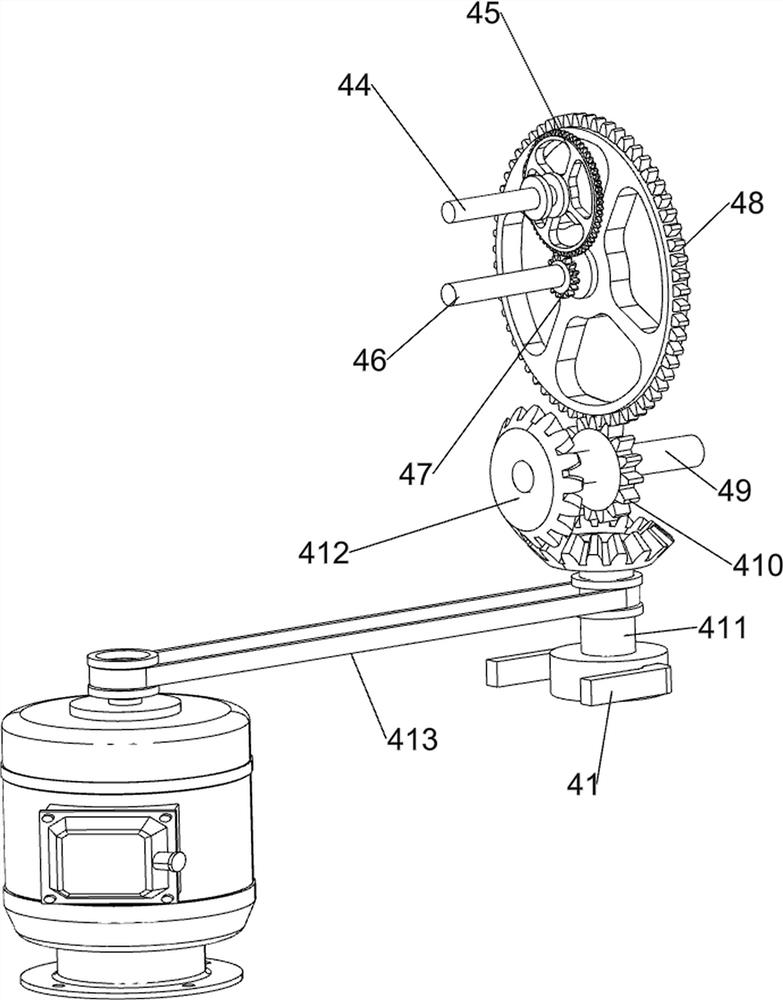

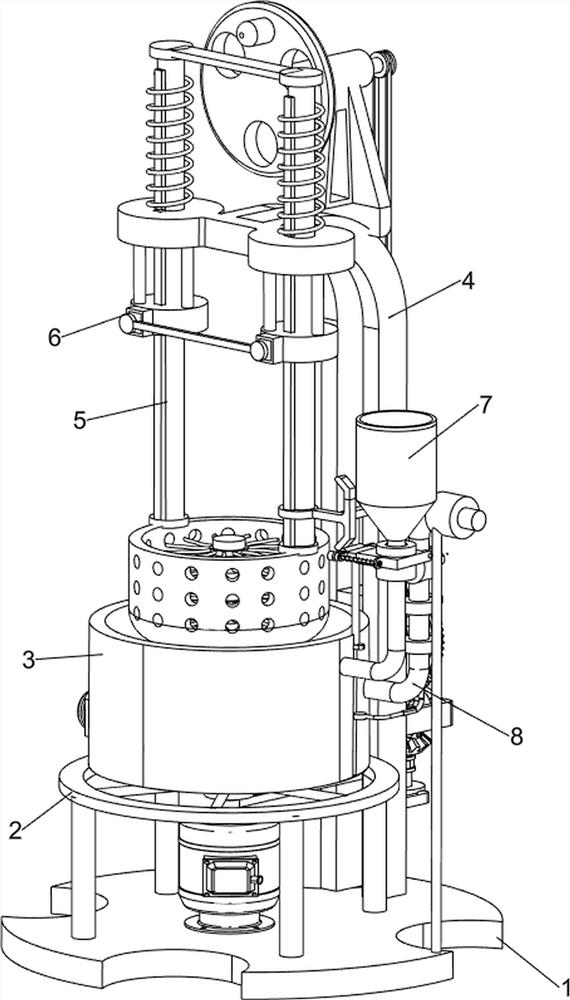

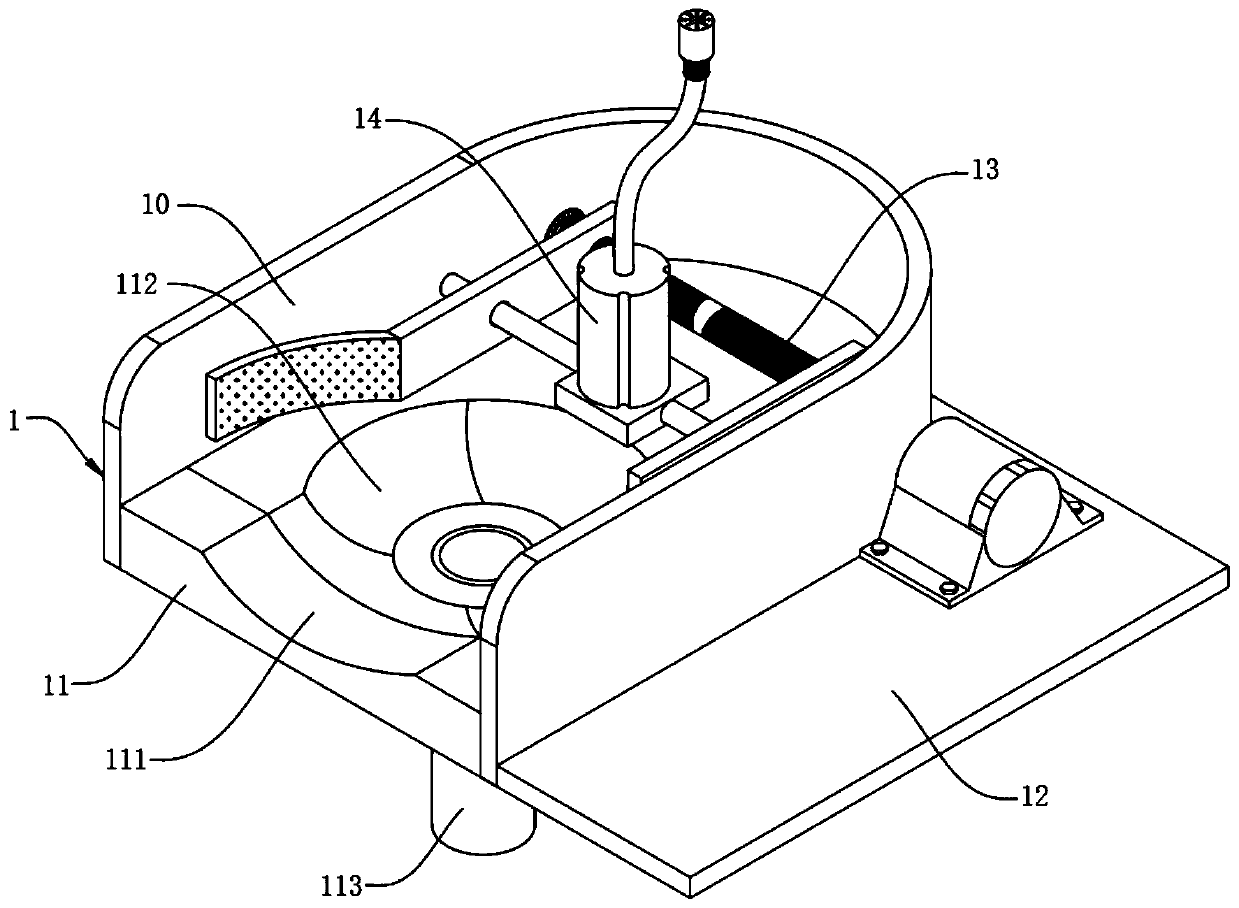

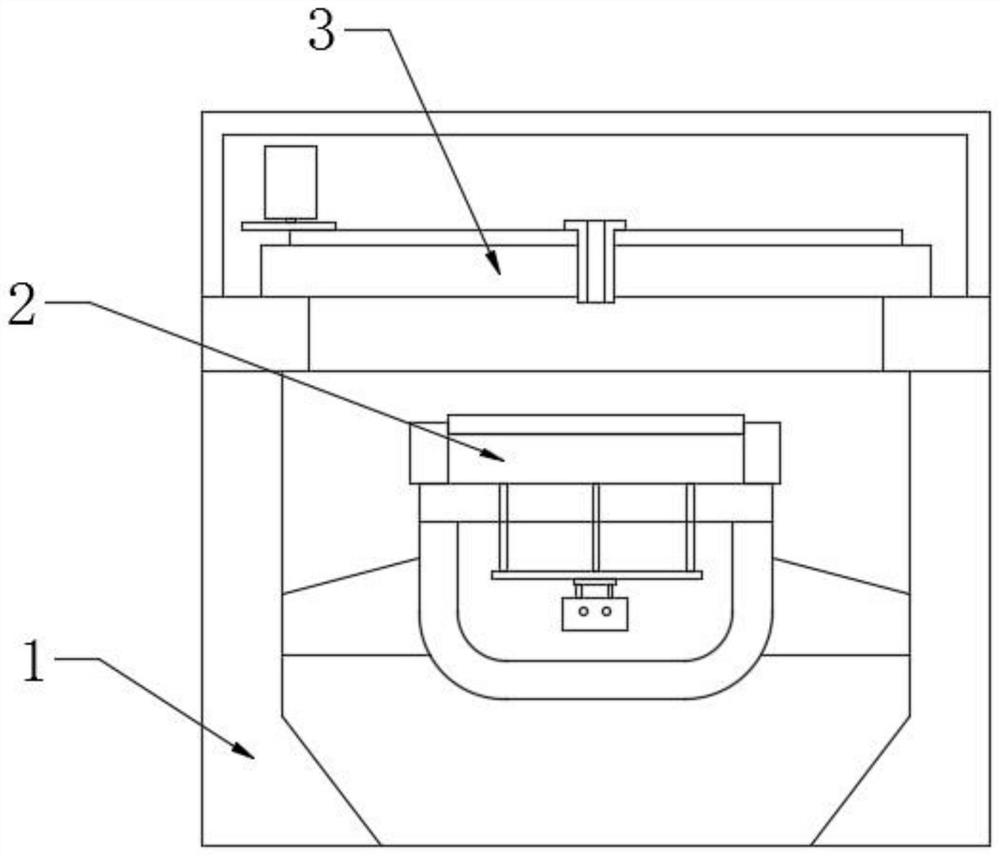

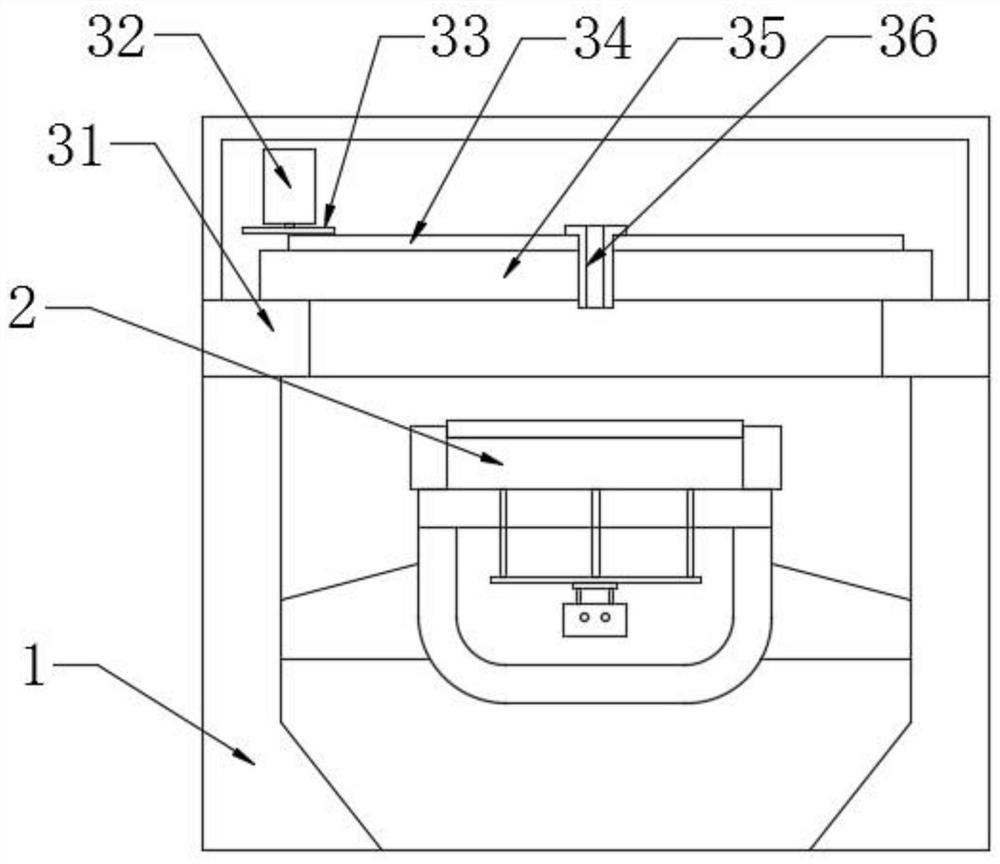

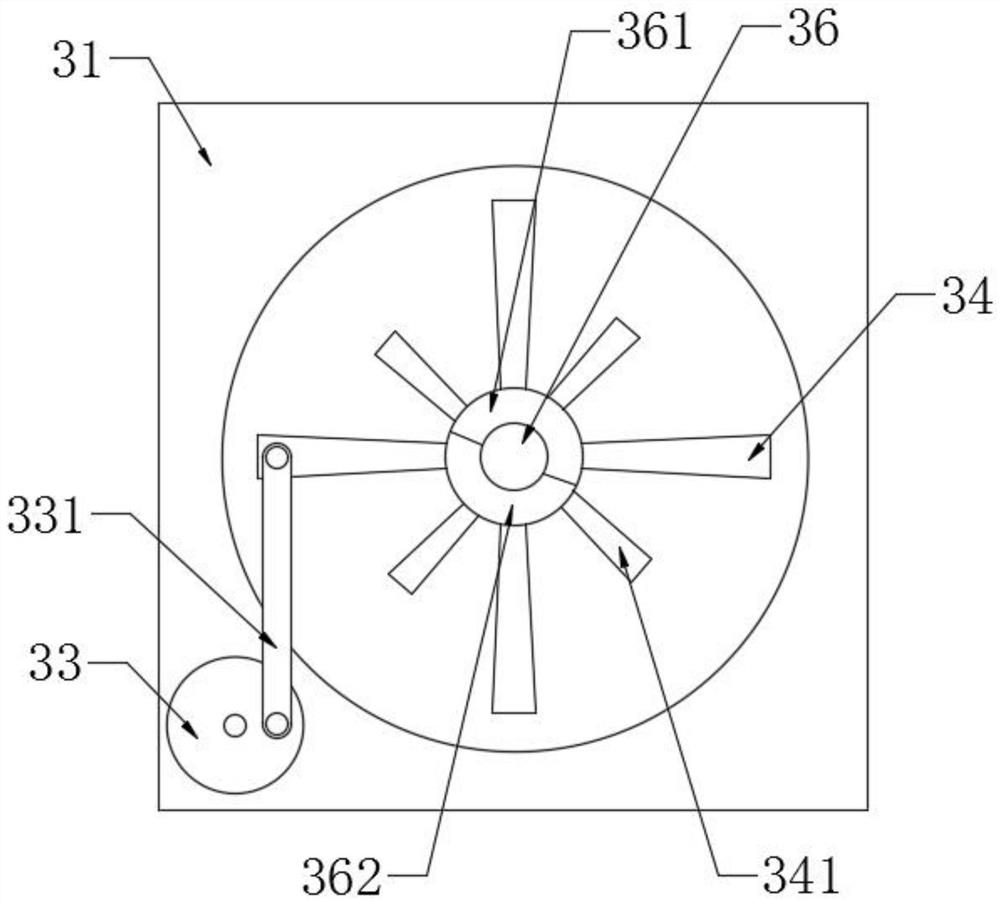

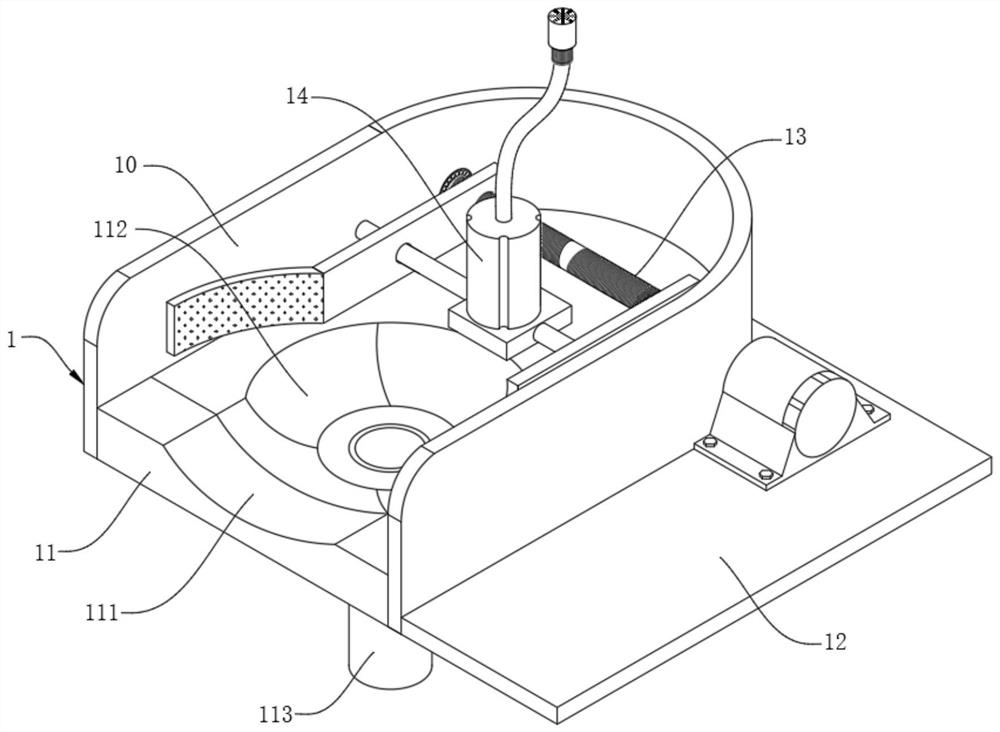

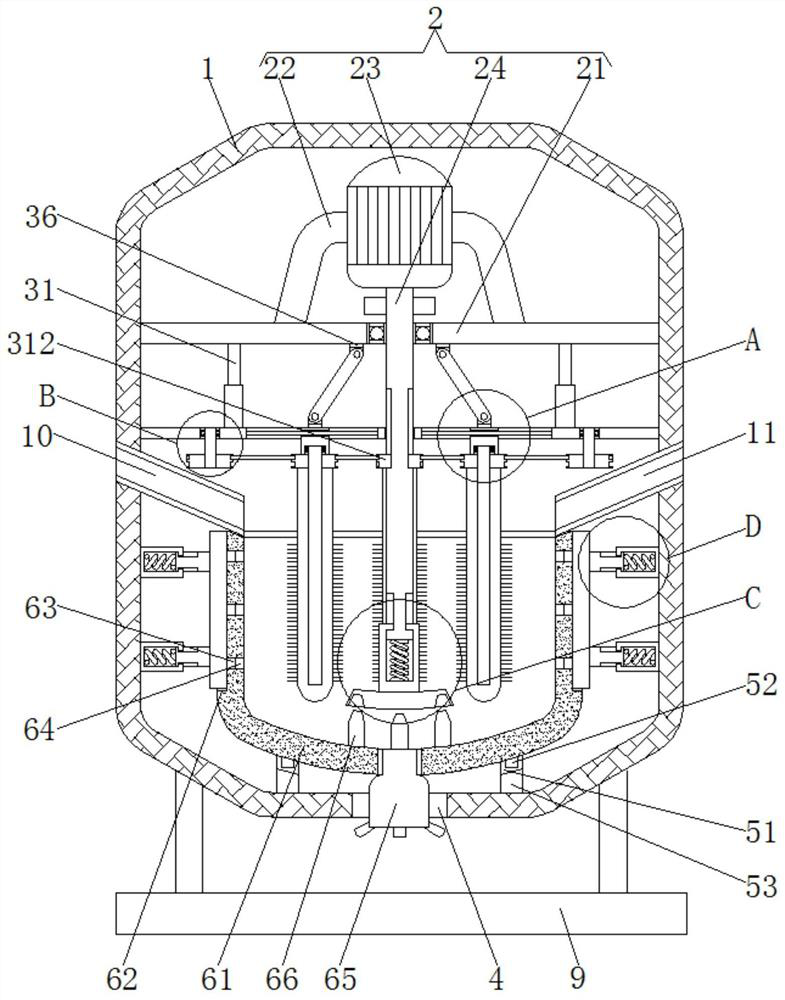

Surgical instrument cleaning and disinfecting equipment for neurology department

The invention relates to cleaning and disinfecting equipment, in particular to surgical instrument cleaning and disinfecting equipment for the neurology department. The surgical instrument cleaning and disinfecting equipment for the neurology department aims to achieve the technical effects of being capable of automatically cleaning surgical instruments, easy to operate and capable of controlling the use amount of a cleaning agent. The surgical instrument cleaning and disinfecting equipment for the neurology department comprises a base, a rotating mechanism, a transmission mechanism and a stirring mechanism, wherein a supporting table is arranged on the base, the rotating mechanism is arranged on the base, the transmission mechanism is arranged on the base, the stirring mechanism is arranged on the transmission mechanism, and the rotating mechanism cooperates with the stirring mechanism. Through cooperation of the rotating mechanism and the stirring mechanism, surgical instruments can be automatically cleaned, manual cleaning is not needed, and the cleaning efficiency is improved.

Owner:南京市蓝业科技有限公司

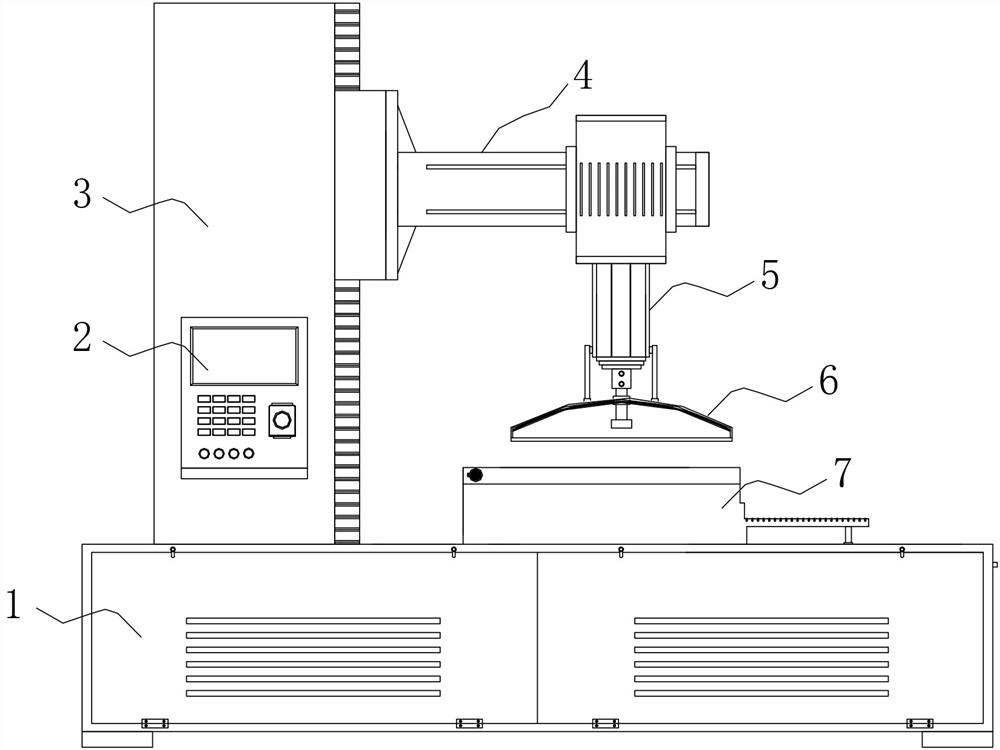

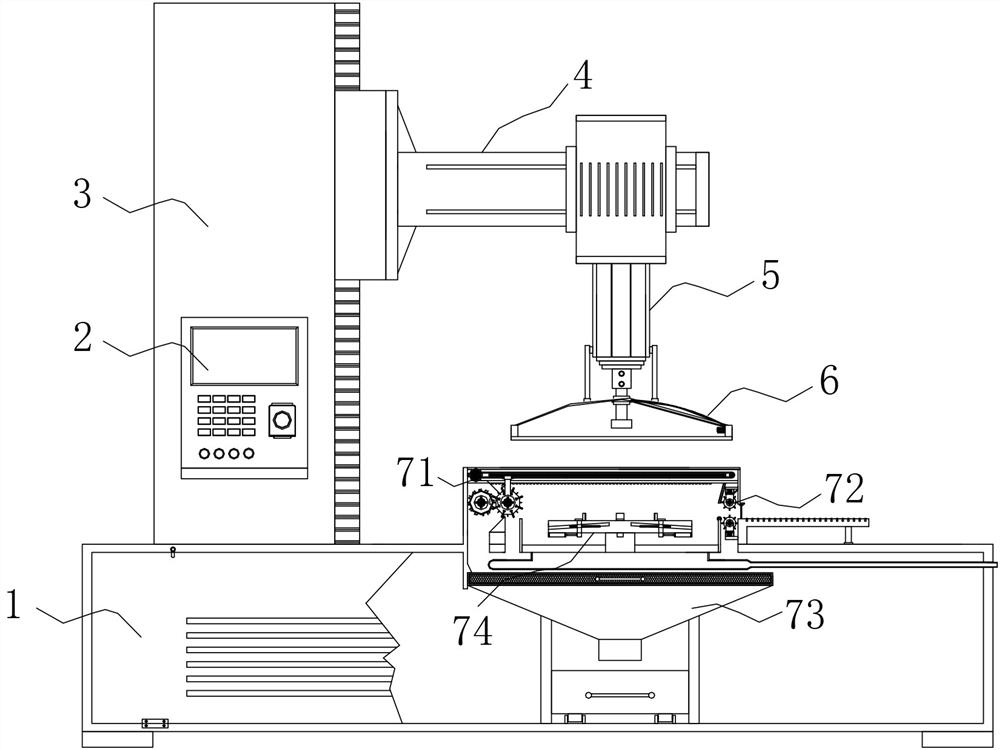

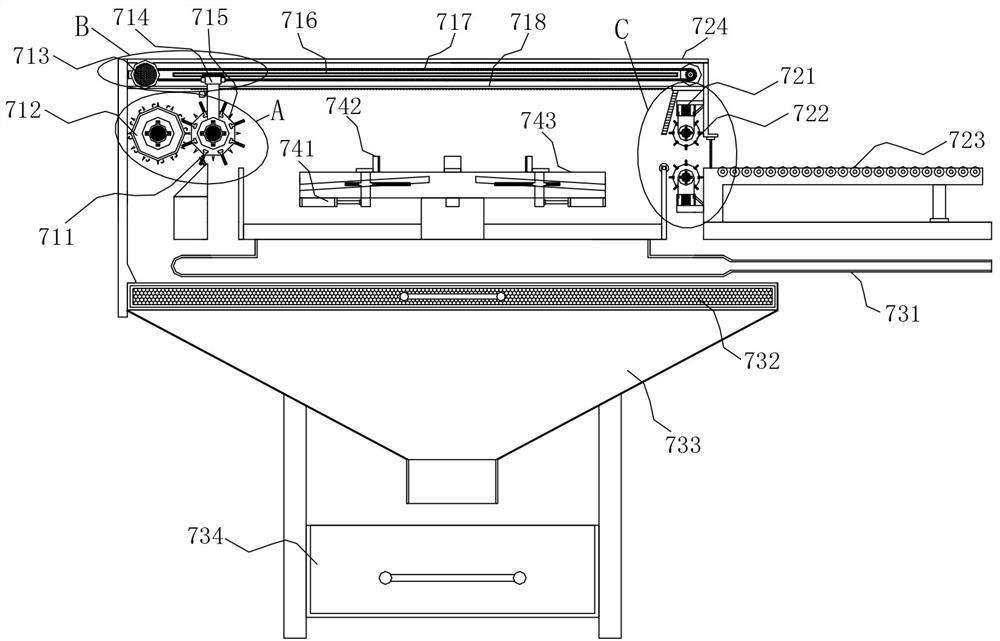

Automatic grinding machine tool with cleaning and recycling mechanism and using method of automatic grinding machine tool

InactiveCN113601360AReduce power supplyReduce cost consumptionGrinding carriagesGrinding drivesProcess engineeringEnergy cost

The invention relates to an automatic grinding machine tool with a cleaning and recycling mechanism and a using method of the automatic grinding machine tool. According to the automatic grinding machine tool with the cleaning and recycling mechanism and the using method of the automatic grinding machine tool, through a grinding base station assembly and a cleaning mechanism, a processing mechanism, a recycling mechanism, an adaptive tool and a protective cover assembly of the grinding base station assembly, impurities on the surface of a workpiece can be pretreated when the workpiece is subjected to grinding machining; and the probability of unnecessary abrasion caused by impurities in the subsequent grinding process is reduced, the grinding quality of the workpiece is effectively guaranteed, generated flying dust and irritant smoke can be sucked away in time in the machining period, the environment-friendly production and machining concept is better met, generated grinding chips, grinding wires difficult to clean and the like can be conveniently cleaned after machining, the time, manpower and energy cost invested for cleaning grinding wires in a traditional mode is effectively reduced, grinding fluid and grinding chips can be conveniently separated, and follow-up recycling is more convenient.

Owner:湖南致用科技有限公司

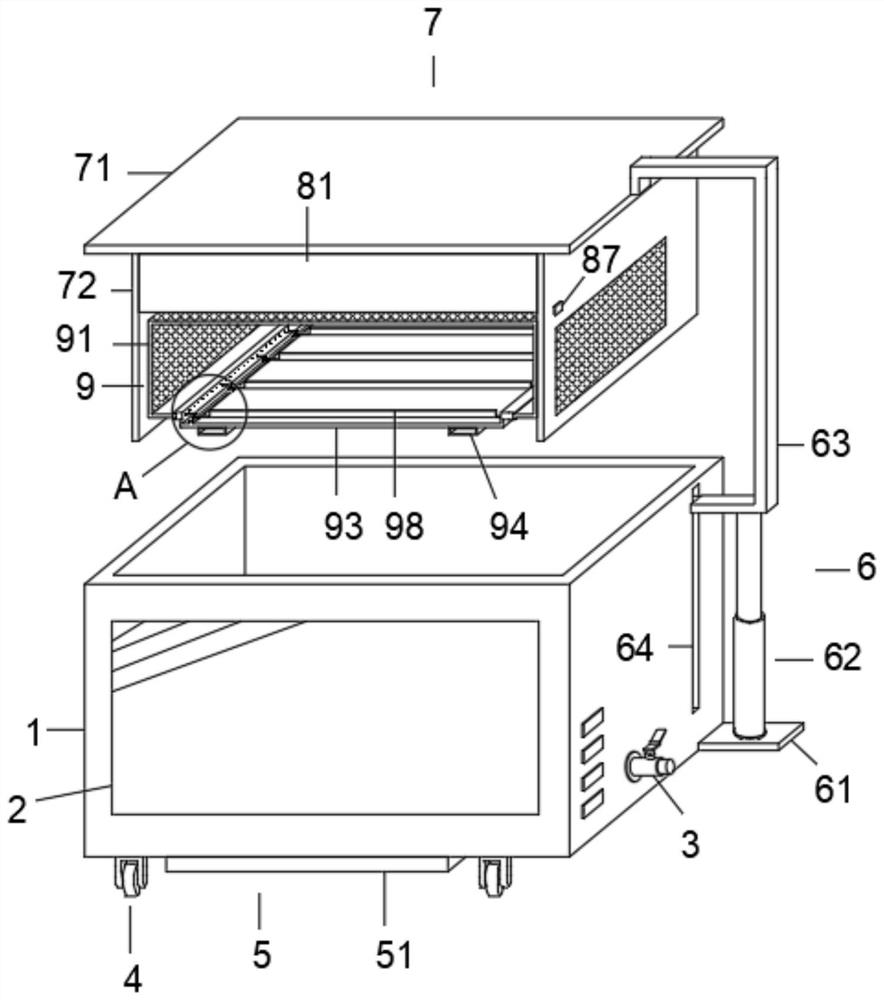

Ultrasonic cleaning equipment for power battery production

ActiveCN111495862BEasy to fixIncomplete cleaningDrying gas arrangementsCleaning using liquidsPower batteryProcess engineering

The invention discloses an ultrasonic cleaning device for power battery production, comprising an ultrasonic cleaner body whose model is CJ-010B, an observation window is arranged on the front of the ultrasonic cleaner body, and the ultrasonic cleaner body The lower part of one side of the main body is fixedly connected with a sewage pipe. The beneficial effect is: this device is used in combination with the loading and unloading mechanism and the storage mechanism, so that the power battery is very conveniently fixed on the storage mechanism. The inside of the sonic cleaner body is cleaned. This design can effectively ensure that the power battery will not be cleaned thoroughly due to the contact between the bottom of the power battery and the bottom of the ultrasonic cleaner body during the cleaning process. The mechanism and the moving wheels make the device very convenient to move and fix, which greatly improves the flexibility of the device. The air-drying mechanism can effectively dry the surface of the power battery after cleaning.

Owner:SUZHOU WANXIANG TECH CO LTD

A smelting furnace wall cleaning device

ActiveCN109341368BThe solution is not easy to cleanIncomplete cleaningIncrustation removal devicesGear driveWater storage tank

The invention discloses a furnace wall cleaning device for a smelting furnace, which comprises a base, a walking wheel, a support plate, a push rod, a water storage tank, a water filling port, a control panel, a storage battery, a power cord, a water pump, a first connecting pipe, and a second connecting pipe. Pipes, adapters, spray guns, water pipes, lifting mechanisms, winding devices, descaling devices and dust suction devices. After the descaling device is installed, the motor drives the first transmission shaft to rotate after the first transmission shaft rotates. Drive the first rotating roller to rotate, and at the same time drive the external main gear of the first transmission shaft to rotate. By meshing with the main gear, the auxiliary gear rotates, and the rotation of the auxiliary gear drives the second transmission shaft to rotate, so that it drives the second The rotating roller rotates, and the first rotating roller and the second rotating roller contact the furnace wall to descale it, which solves the problem that there is residue attached to the furnace wall, and the ordinary flushing does not clean the furnace wall thoroughly.

Owner:广东华劲金属型材有限公司

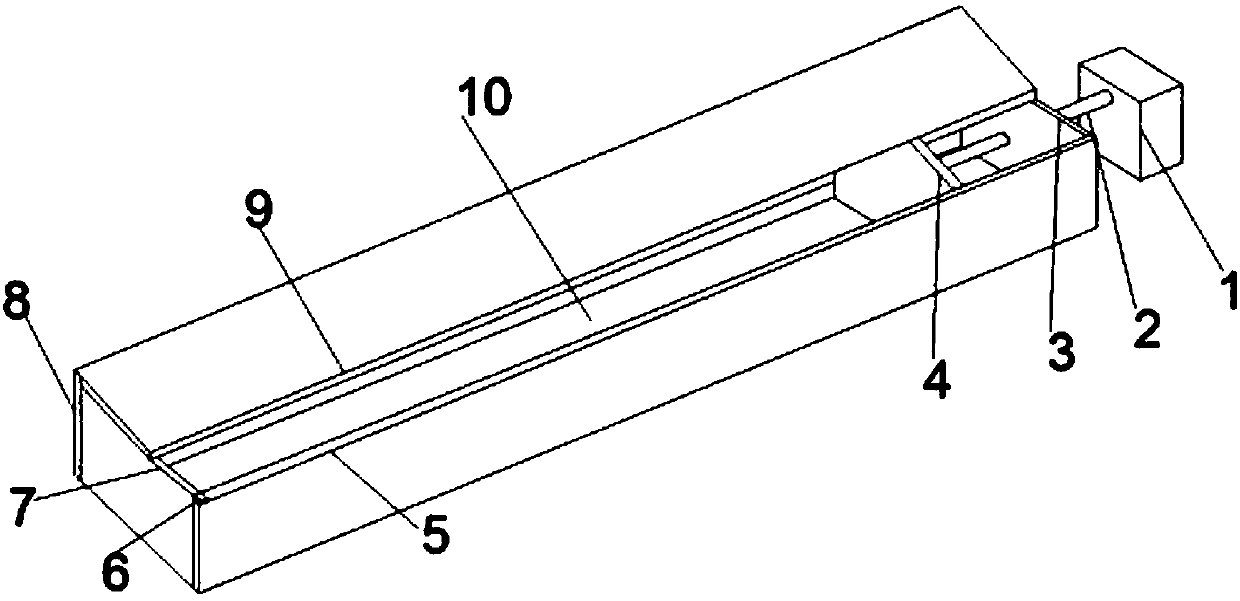

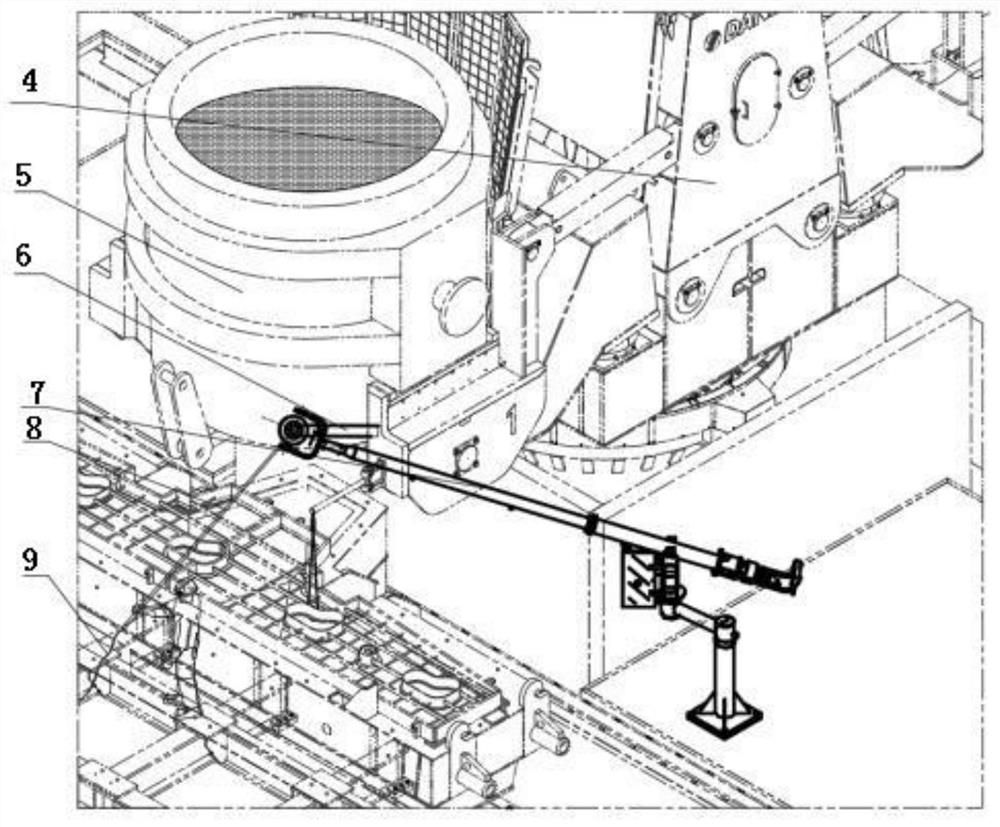

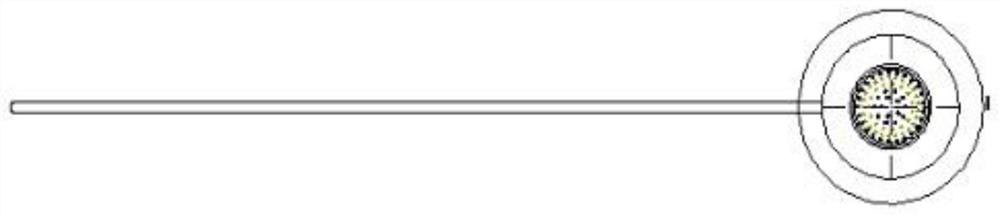

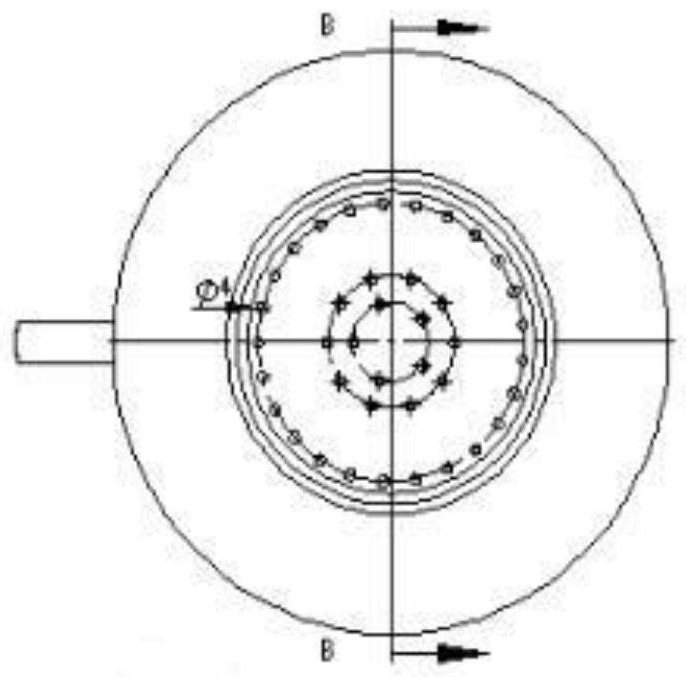

Continuous casting ladle long nozzle residual steel cleaning equipment and using method thereof

The invention discloses continuous casting ladle long nozzle residual steel cleaning equipment and a using method thereof, and relates to the technical field of metallurgical continuous casting machines. The continuous casting ladle long nozzle residual steel cleaning equipment comprises a connecting pipe, a pressing plate is arranged at the right end of the connecting pipe, a purging spray head is arranged on the pressing plate, the connecting pipe is a stainless steel seamless steel pipe, and the inlet end of the connecting pipe is connected with an argon gas source on site. The continuous casting bale long nozzle residual steel cleaning equipment is installed on a casting platform of a continuous casting machine, one end of the continuous casting bale long nozzle residual steel cleaning equipment is connected with argon, the other end of the continuous casting bale long nozzle residual steel cleaning equipment is aligned with the inlet end of a long nozzle, residual steel in the long nozzle can be conveniently and rapidly blown and swept, timely cleaning of the long nozzle residual steel is achieved, the service life of the nozzle is prolonged, and excessive molten steel residual steel attached to the nozzle is prevented, influence to the flow speed of molten steel is avoided, and potential influence factors (blowing is not uniform and residual steel cleaning is not thorough due to the fact that argon is introduced into a common steel pipe for cleaning before) which influence the fluctuation of the liquid level of the intermediate tank are eliminated.

Owner:MAANSHAN IRON & STEEL CO LTD

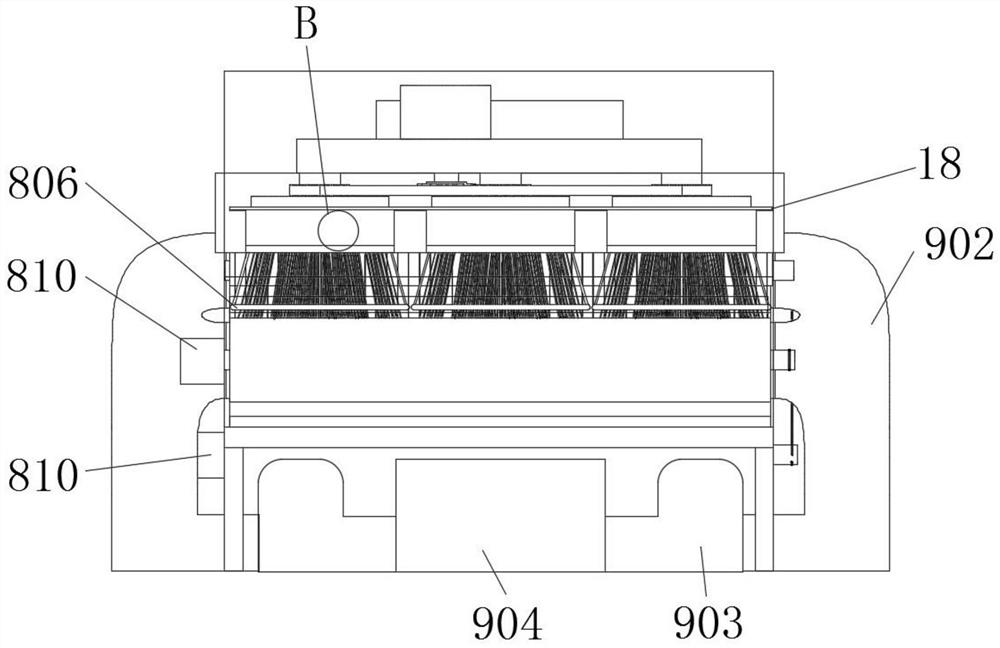

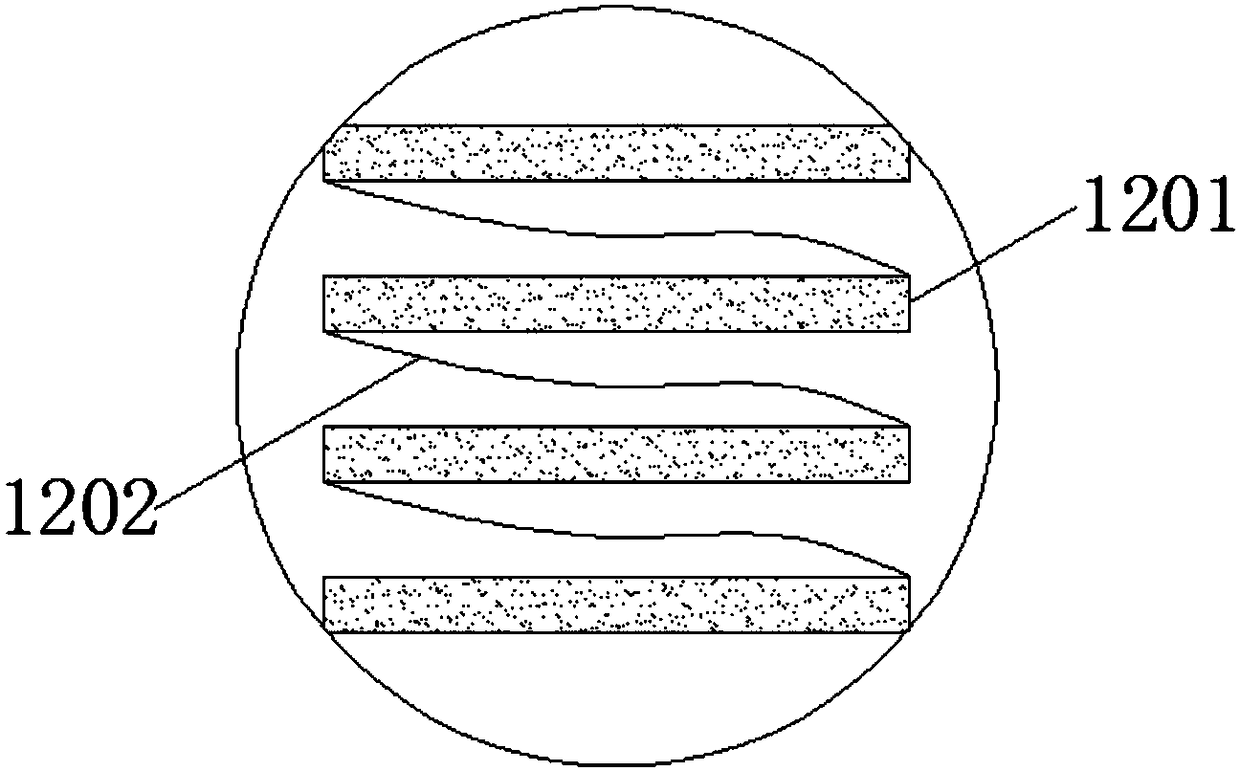

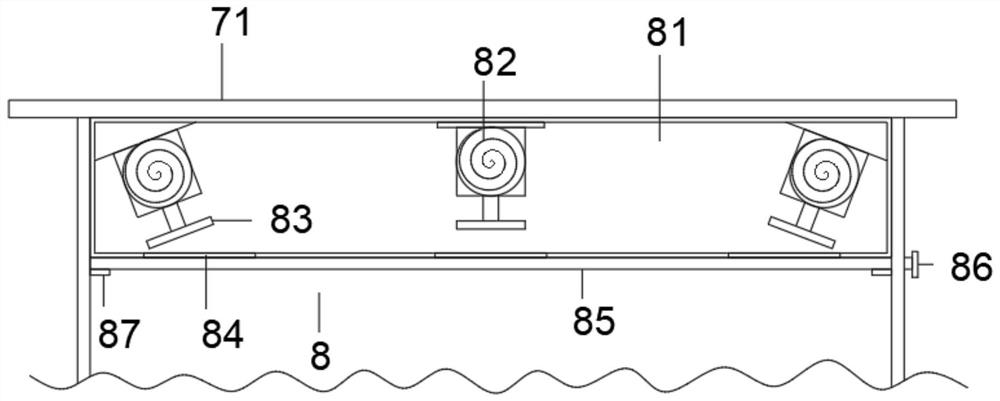

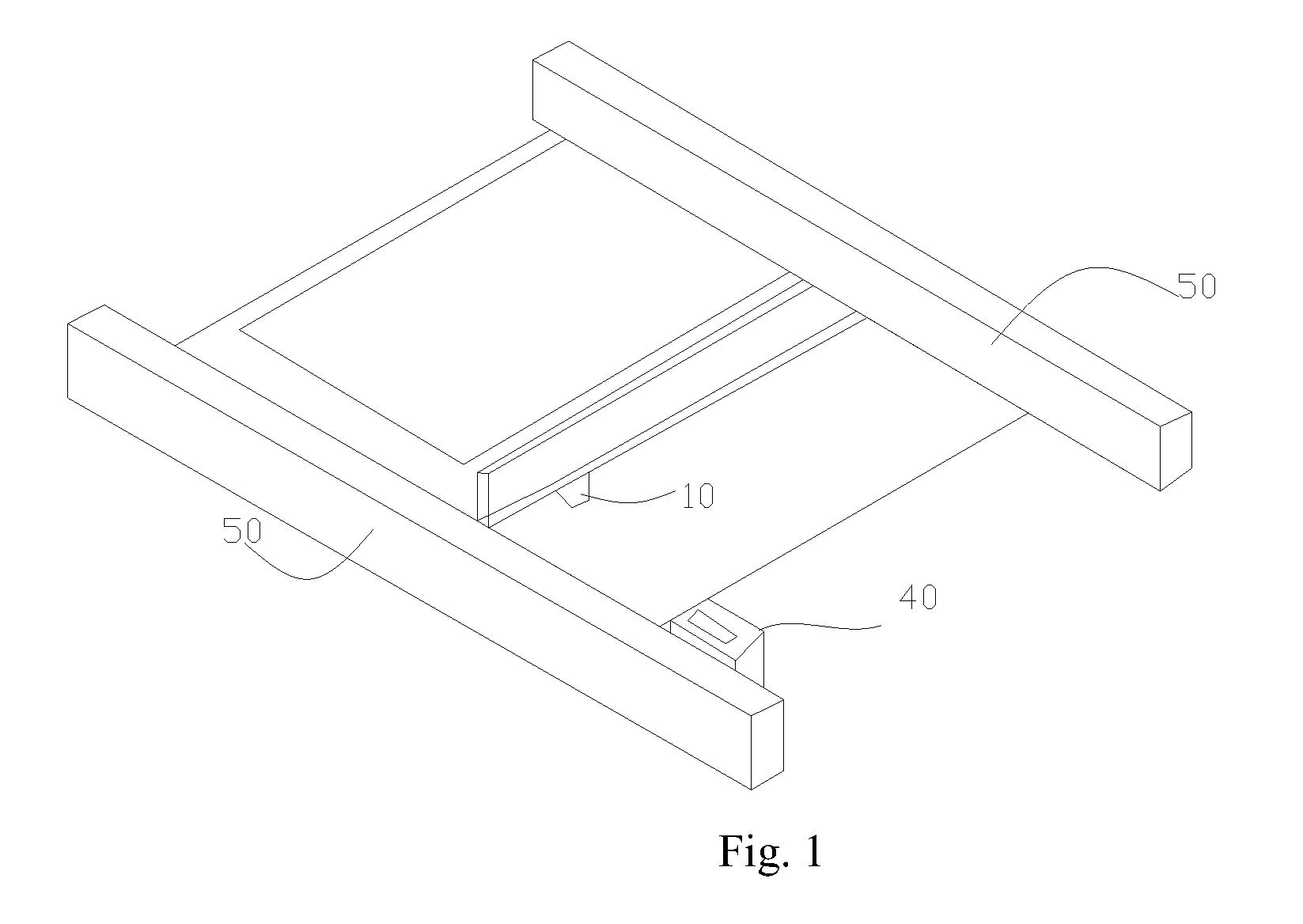

A mesh belt cleaning device for a ceramic fiber collector

ActiveCN108393288BAchieve sheddingEasy to cleanDirt cleaningCleaning using toolsFiberMechanical engineering

The invention discloses a mesh belt cleaning device for ceramic fiber collectors, which includes: a rotating roller. The rotating roller is provided with at least two wire brushes for cleaning the mesh belt of the cotton collector. The rotating roller is connected to a driving device, and the driving device drives the rotating roller. The roller rotates so that the wire brush can clean the cotton collector mesh belt during rotation; a broken cotton blowing system is used to blow the cotton collector mesh belt. The nozzle of the broken cotton blowing system can be relative to the cotton collector. The mesh belt moves; the dust collecting hood is used to collect the broken cotton falling from the mesh belt of the cotton collector. The dust collecting hood is arranged under the rotating roller. When the cleaning device provided by this application works, the rotating roller rotates so that the wire brush provided on the rotating roller first cleans and loosens the broken cotton. The loosened broken cotton is blown off by the nozzle and then enters the dust collector located below the rotating roller or nozzle. Inside the cover, the cotton collector mesh belt cleaning device is equipped with a movable nozzle, which can solve the problem of incomplete cleaning of broken cotton.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

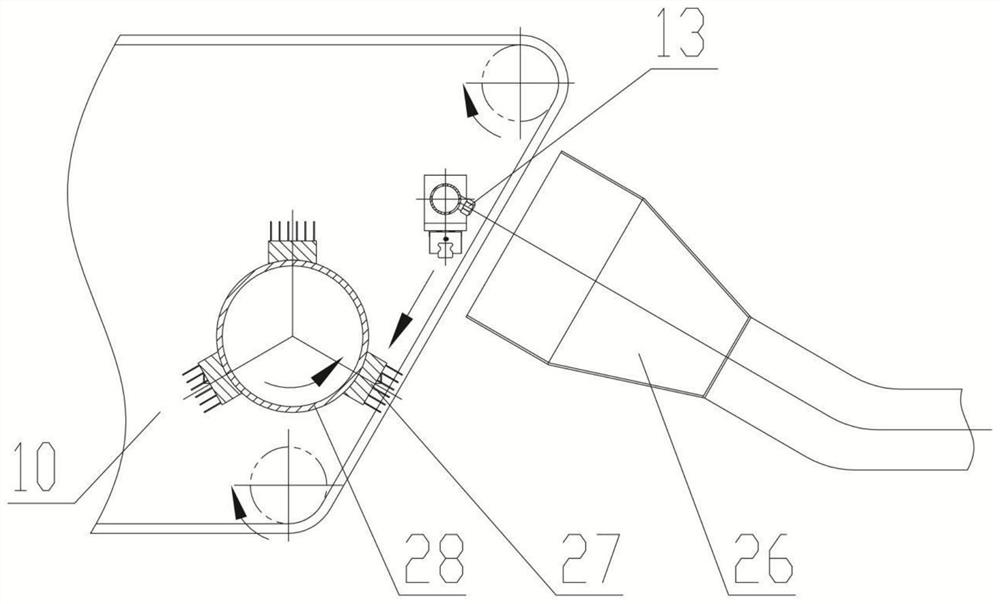

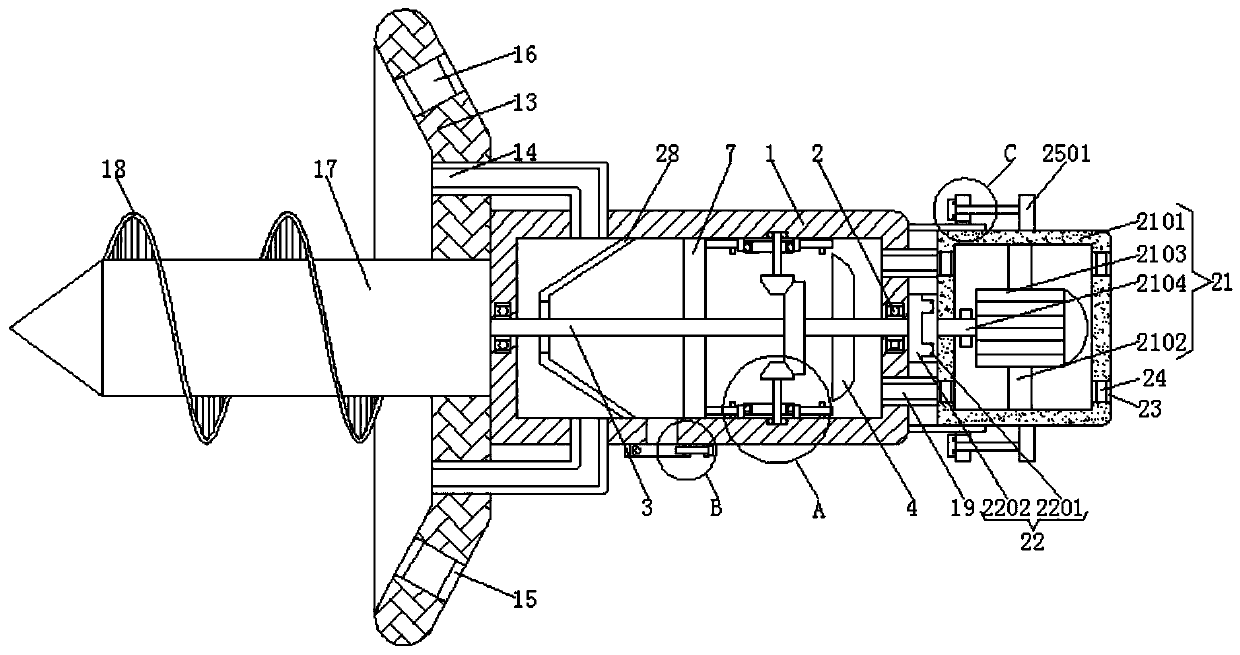

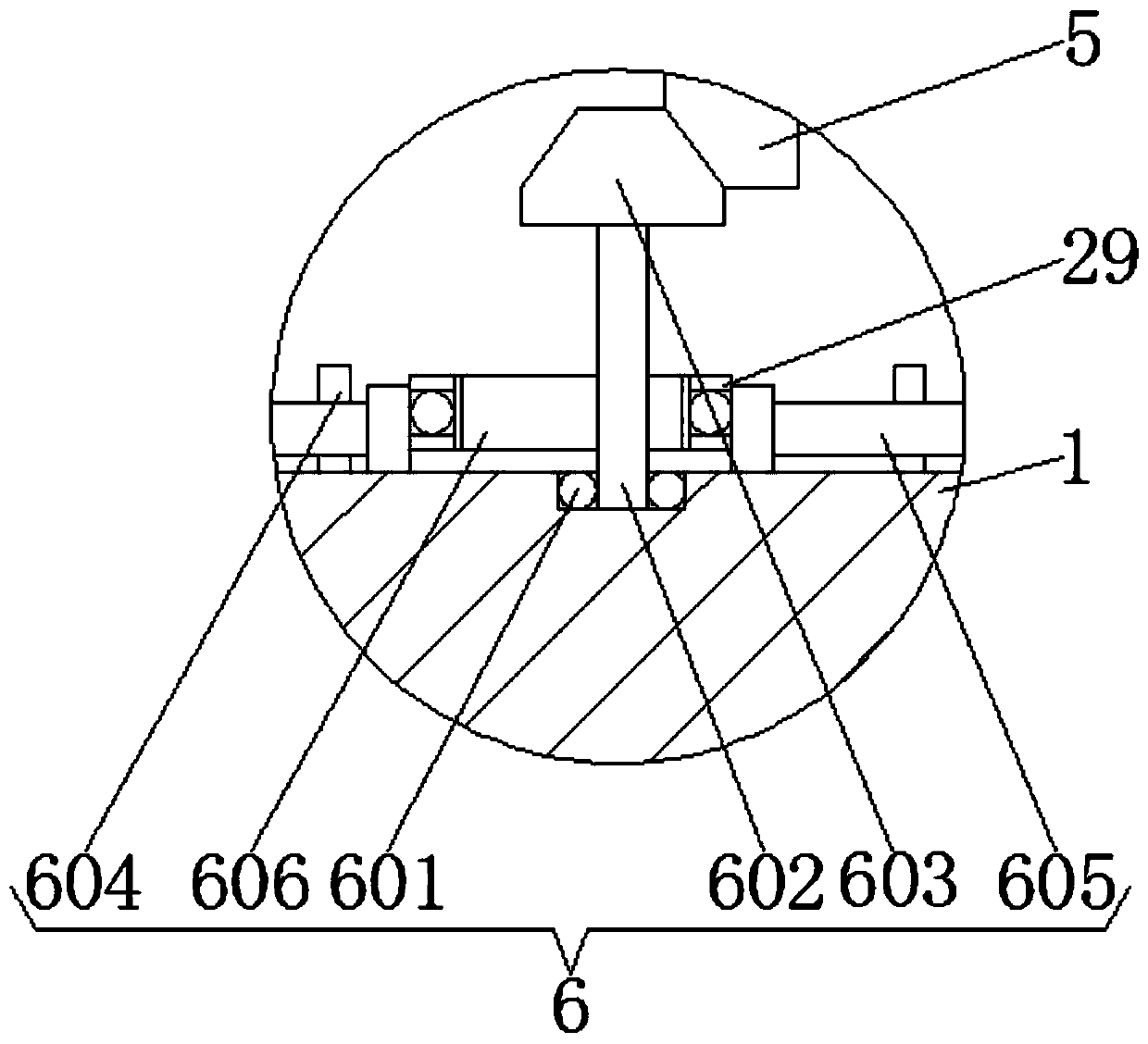

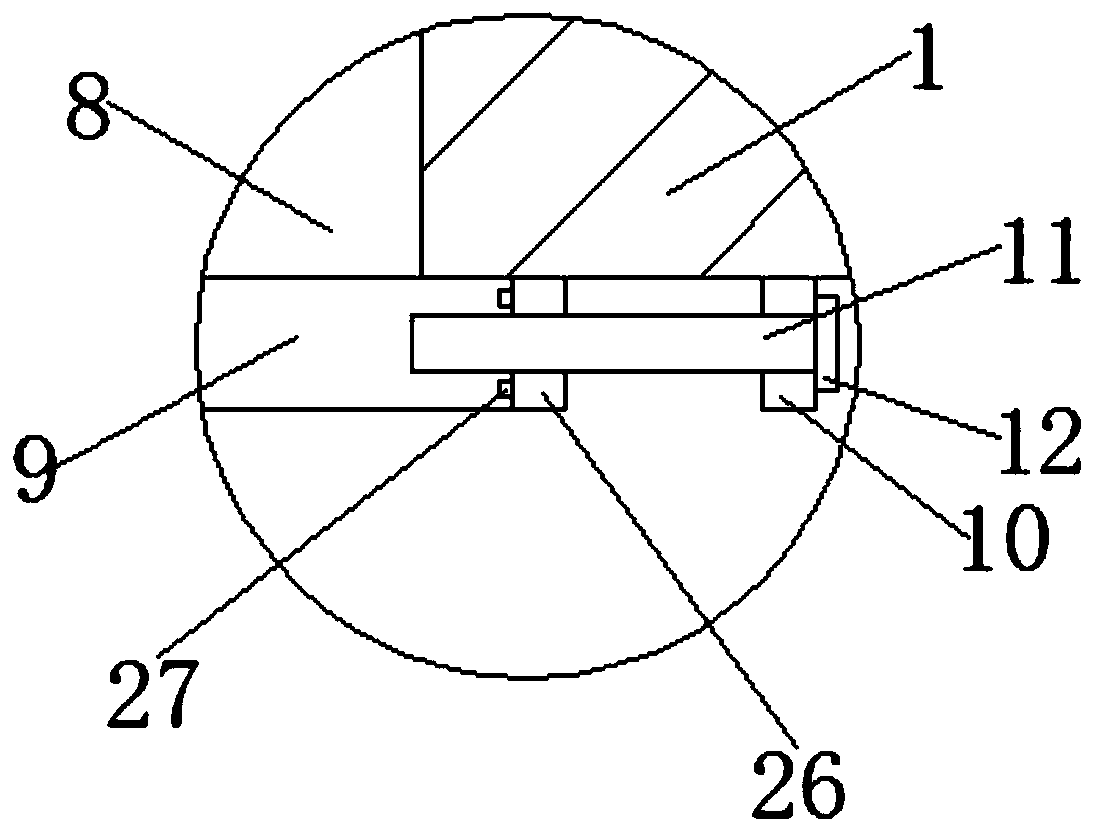

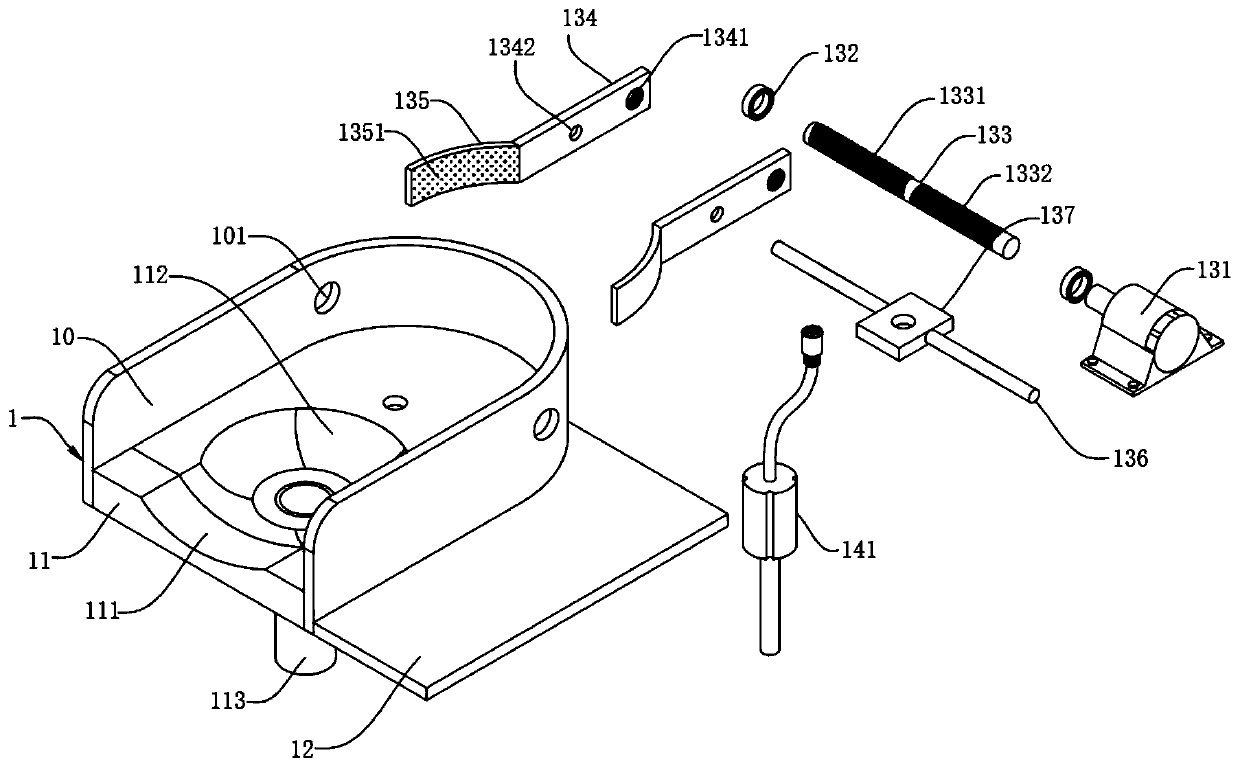

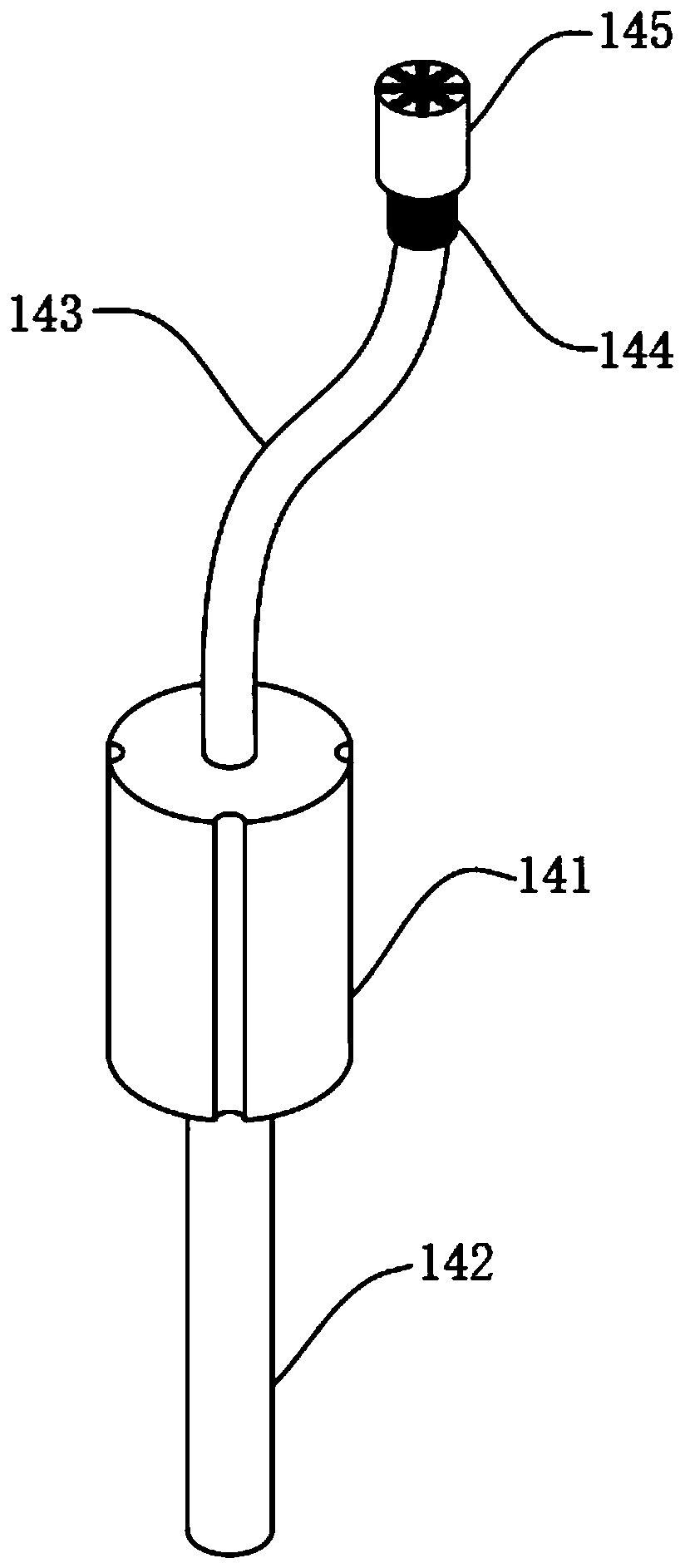

A kind of anti-diffusion tunnel surrounding rock blasting blasthole slag cleaning device

The invention discloses an anti-diffusion tunnel surrounding rock blasting hole slag removal device, and relates to the technical field of tunnel construction. The anti-diffusion tunnel surrounding rock blasting hole slag removal device comprises a box body; first ball bearings are fixedly connected into the left side and the right side of the box body; a first rotary shaft is fixedly connected tothe inner walls of the first ball bearings, and the right side of the surface of the first rotary shaft is fixedly connected with fan blades; and a first conical fluted disc is fixedly connected to the position, located on the left sides of the fan blades, of the surface of the first rotary shaft. According to the anti-diffusion tunnel surrounding rock blasting hole slag removal device, negativepressure forms in the box body through rotation of the fan blades, waste slag removed from blasting holes is collected into the box body through a first pipeline and prevented from being diffused intothe other blasting holes, and accordingly, the problems that a slag removal device on the market at present cannot collect waste slag removed from blasting holes, the waste slag removed from the blasting holes are prone to being diffused into the cleaned blasting holes, and then, the blasting holes are not thoroughly cleaned are effectively solved.

Owner:广德昊宇新型材料有限公司

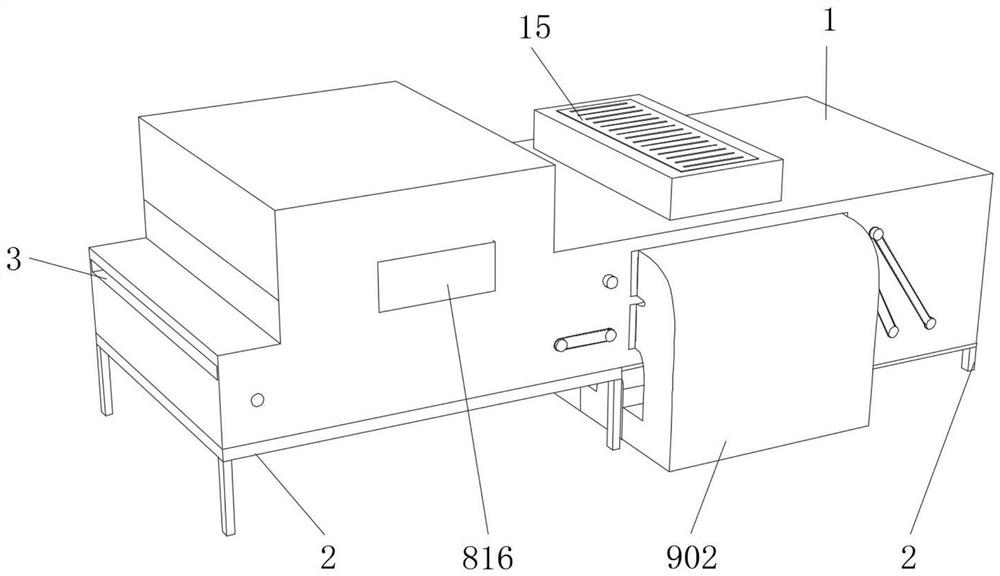

A leather cleaning device in production

ActiveCN111719302BAvoid savingImprove adsorption capacityMechanical cleaningPressure cleaningAir filtrationAir filter

The invention discloses that the invention relates to the technical field of leather cleaning, in particular to a leather cleaning device in production, including a casing, a bracket, a material inlet, a material outlet, a first transmission device, a second transmission device, and a third transmission device , leather cleaning mechanism, drying mechanism, shaft, cylinder, arc baffle, air filter box, air inlet, filter plate, filter, electrostatic adsorption device, fixed plate, baffle, V-belt, the second drive motor, the first Three driving motors, the top of the bracket is placed with an organic casing, the left side of the casing is connected to the second driving motor near the end, the third driving motor is installed on the left side of the casing, the air filter box is installed on the right side of the top of the casing, and the front of the casing There is a material inlet, a material outlet on the back of the casing, a first transmission device inside the casing, and a leather cleaning mechanism above the first transmission device. The invention solves the problem of insufficient cleaning of leather during production. Problems with unsatisfactory leather compression.

Owner:RUIAN DAHU SHOES IND CO LTD

Face fixing device with face washing function

ActiveCN110338551AEasy to operateAchieve a fixed effectPackaging toiletriesPackaging cosmeticsPlastic surgeryBiomedical engineering

The invention relates to the technical field of plastic surgery devices, and in particular relates to a face fixing device with a face washing function. The device comprises a device shell, a face fixing device body is arranged on the device shell, a face washing mechanism is arranged in the face fixing device body, the face washing mechanism comprises a pump, a water inlet pipe is arranged at thewater inlet end of the pump, a water outlet pipe is arranged at the water outlet end of the pump, a threaded joint is arranged at the tail end of the water outlet pipe, a face cleaning device is further arranged on a side face plate, the face cleaning device comprises an impurity collecting barrel arranged on the side face plate, and an impurity filtering device is further arranged in a second groove. The face fixing device is easy and rapid to operate, while the face of a user is fixed, the face of the user also can be conveniently washed, and thus more convenient is brought to an operator.

Owner:高扬

High-efficiency sand stone separator

The invention discloses a high-efficiency sand stone separator. The sand stone separator comprises a feeding frame, a discharging frame and a screening device, wherein an inner circular track and an outer circular track are arranged in the lower side of the feeding frame; the screening device comprises a screening cylinder, wherein the screening cylinder is obliquely placed, an annular plate matched with the inner circular track is arranged at the upper end of the screening cylinder, a lifting ring is arranged on the upper side of the lower end of the screening cylinder, a sliding rod body isarranged on the lifting ring, and the sliding rod body and the outer circular track are in sliding fit; and the discharging frame is composed of an outer ring frame for discharging outwards and an inner ring frame for discharging inwards, wherein the tail end of the screening cylinder extends out of the outer ring frame, the screening cylinder is located above the inner ring frame. The high-efficiency sand stone separator has high commercial value and use value.

Owner:徐州瑞杰机械科技有限公司

Ultrasonic cleaner and coater equipped with the ultrasonic cleaner

ActiveUS9321086B2Many timesAffect efficiencyLiquid spraying apparatusCleaning using liquidsMegasonic cleaningEngineering

An ultrasonic cleaner and a coater equipped with the ultrasonic cleaner are provided. The ultrasonic cleaner is configured to clean an inkjet head for ejecting an alignment solution. The cleaner comprises a cleaning receiver for receiving a clean agent, an ultrasonic generator for generating an ultrasonic, and a storing device for retrieving and storing the clean agent, and each of the ultrasonic generator and the storing device is connected to the cleaning receiver. The ultrasonic cleaner can clean the blocked nozzle hole of the inkjet head quickly and thoroughly in a short time. Besides, the cleanliness in the equipment will not be destroyed and the cleaning agent can be retrieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

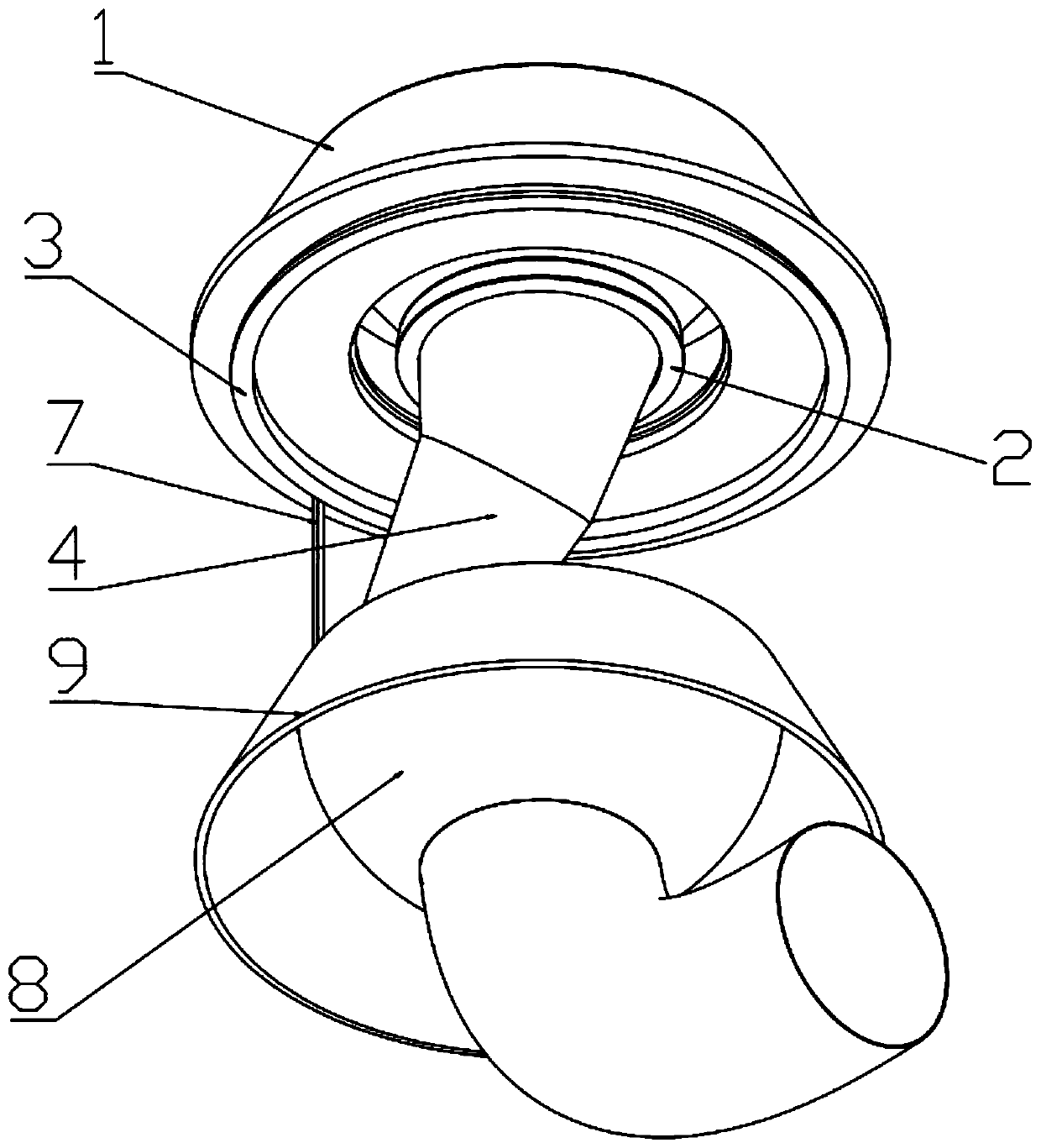

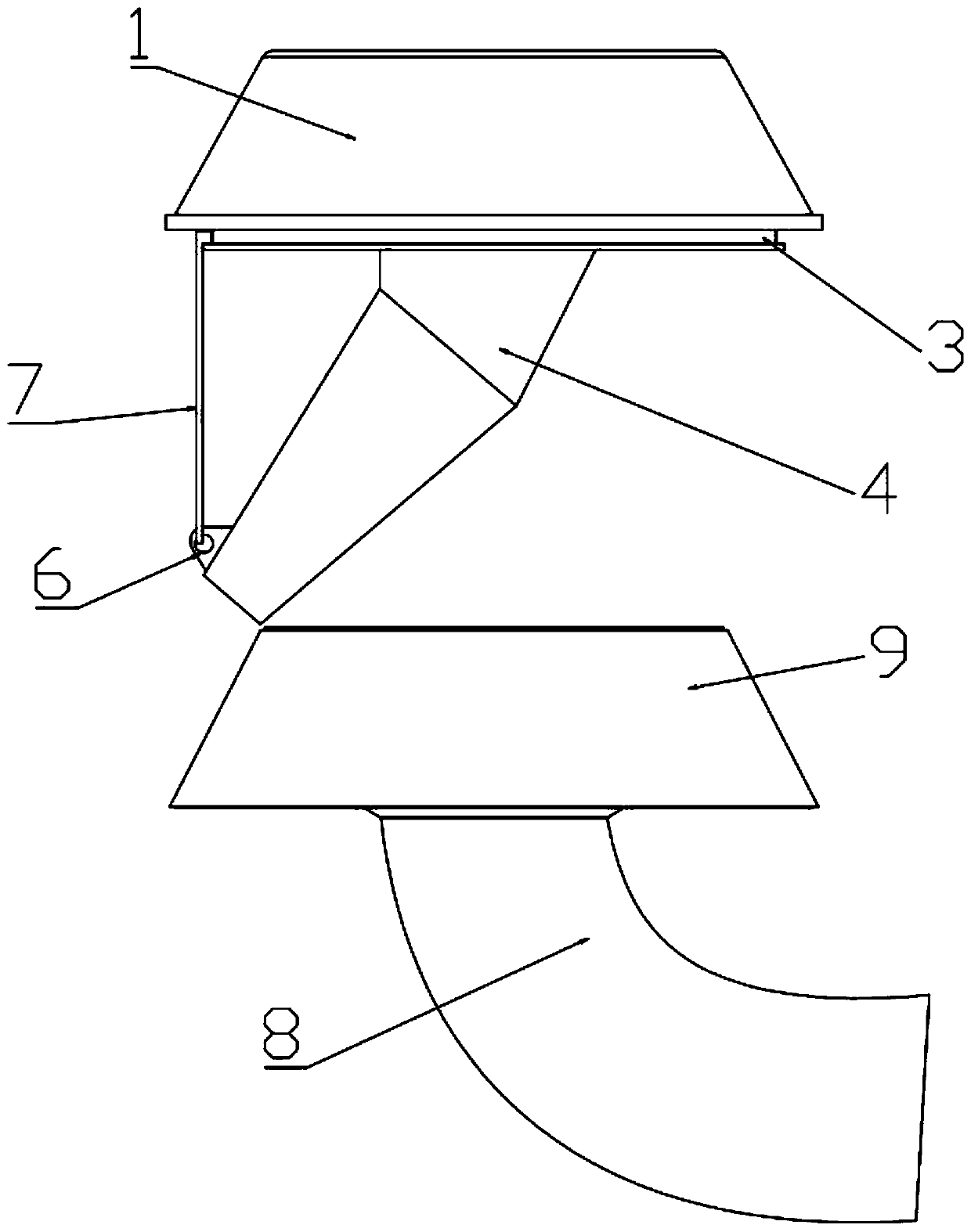

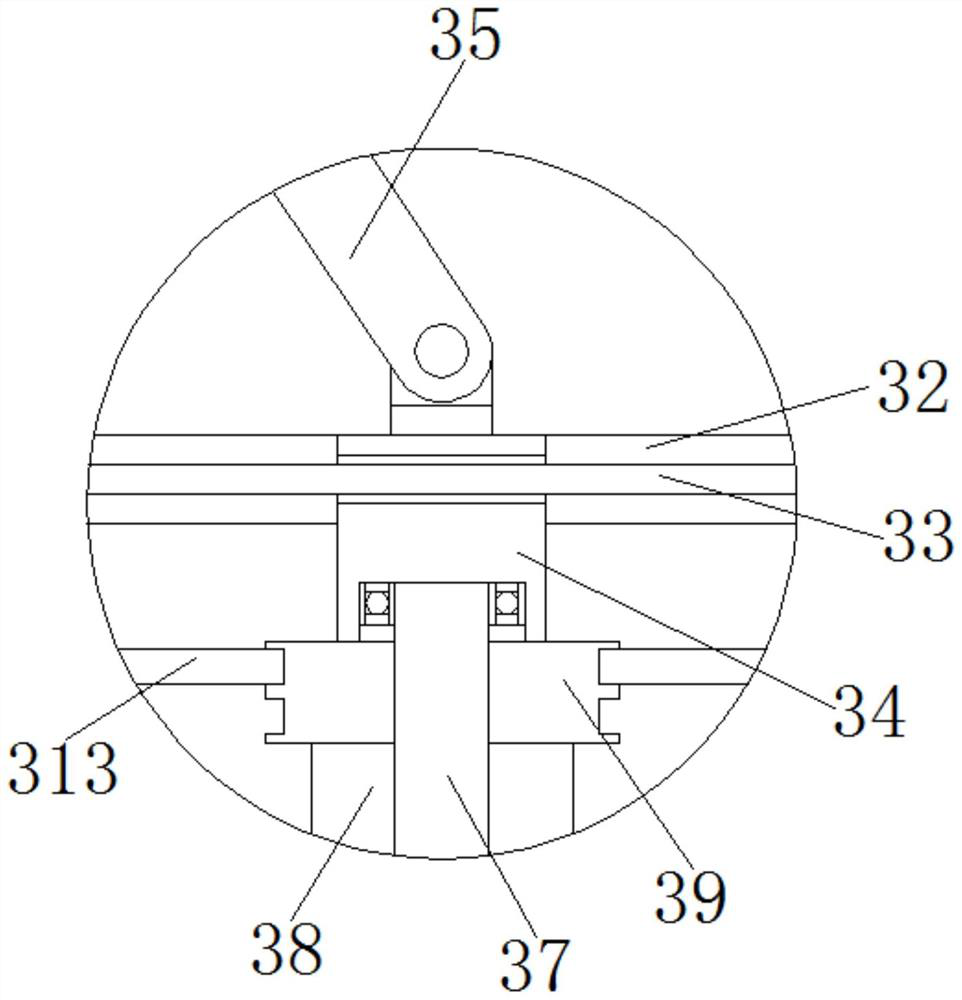

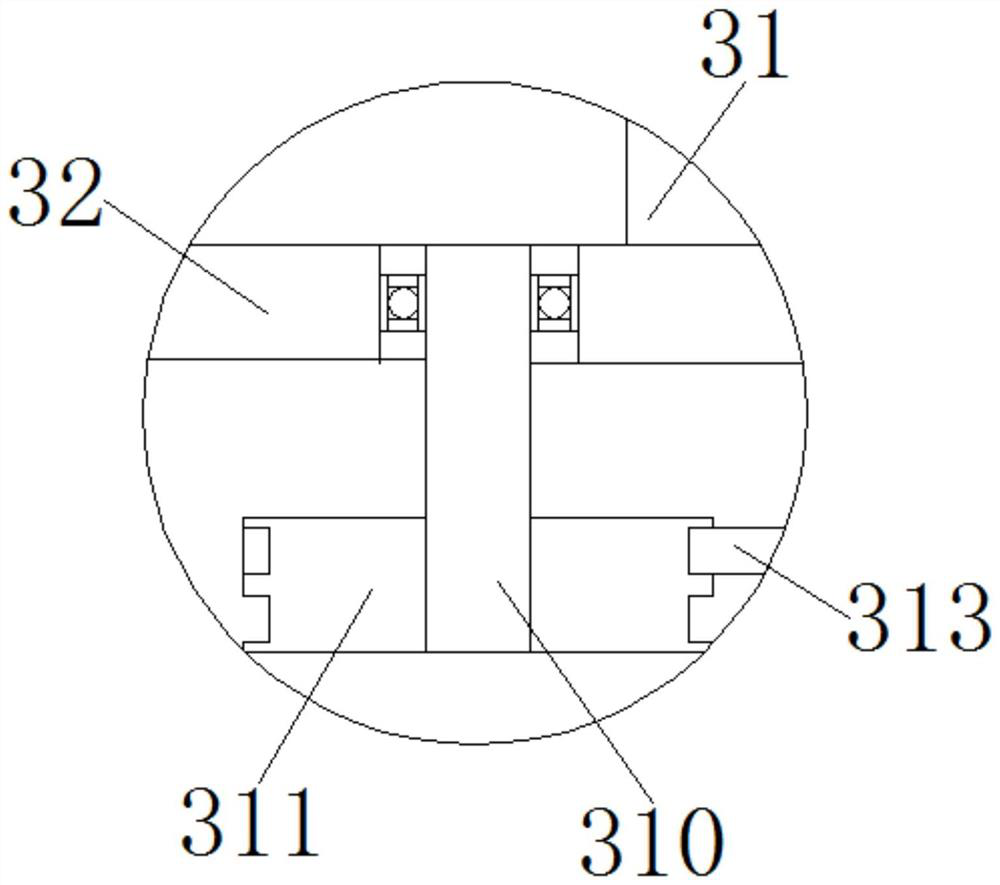

A rotatable Faraday cleaning device and plasma processing system

ActiveCN111081524BEasy to cleanEffective rotation for cleaningElectric discharge tubesHollow article cleaningElectric machineryEngineering

The invention provides a rotatable Faraday cleaning device and a plasma processing system, including a cavity cover, a motor, an eccentric wheel, a long petal assembly, a coupling window, an air inlet nozzle, a connecting rod, a short petal assembly, a fan-shaped conductive part 1 and a fan-shaped Conductor 2, the upper side of the main body of the reaction chamber is equipped with a chamber cover, the inner side of the chamber cover is equipped with a coupling window, the middle of the coupling window is provided with an air inlet nozzle, the outer side of the air inlet nozzle is equipped with a fan-shaped conductive member 1, and the outer side of the air inlet nozzle is equipped with a fan-shaped conductive Part 2, the outer side of the intake nozzle is equipped with a long petal assembly, the outer side of the air intake nozzle is equipped with a short petal assembly, the left side of the long petal assembly is equipped with a connecting rod, the front side of the connecting rod is equipped with an eccentric wheel, and the upper side of the eccentric wheel is equipped with a motor. This design solves the problem that the original ICP reaction chamber is inconvenient to clean, and the invention has a reasonable structure, is convenient for effective and comprehensive cleaning of the ICP reaction chamber.

Owner:JIANGSU LEUVEN INSTR CO LTD

A face fixing device with a face washing function

ActiveCN110338551BAchieve a fixed effectAchieve cleaningPackaging toiletriesPackaging cosmeticsPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of plastic surgery equipment, in particular to a face fixing device with a face cleaning function, comprising a device shell, a face fixing device is arranged on the device shell, a face cleaning mechanism is arranged in the face fixing device, and the face cleaning mechanism It includes a water pump, the water inlet end of the water pump is provided with a water inlet pipe, the water outlet end of the water pump is provided with a water outlet pipe, the end of the water outlet pipe is provided with a threaded joint, and a face cleaning device is also arranged on the side panel. The impurity collection cylinder on the panel, and an impurity filtering device is also arranged in the second groove. The invention is simple and fast in operation, realizes fixing the user's face and also facilitates cleaning of the user's face, bringing more convenience to the operator.

Owner:高扬

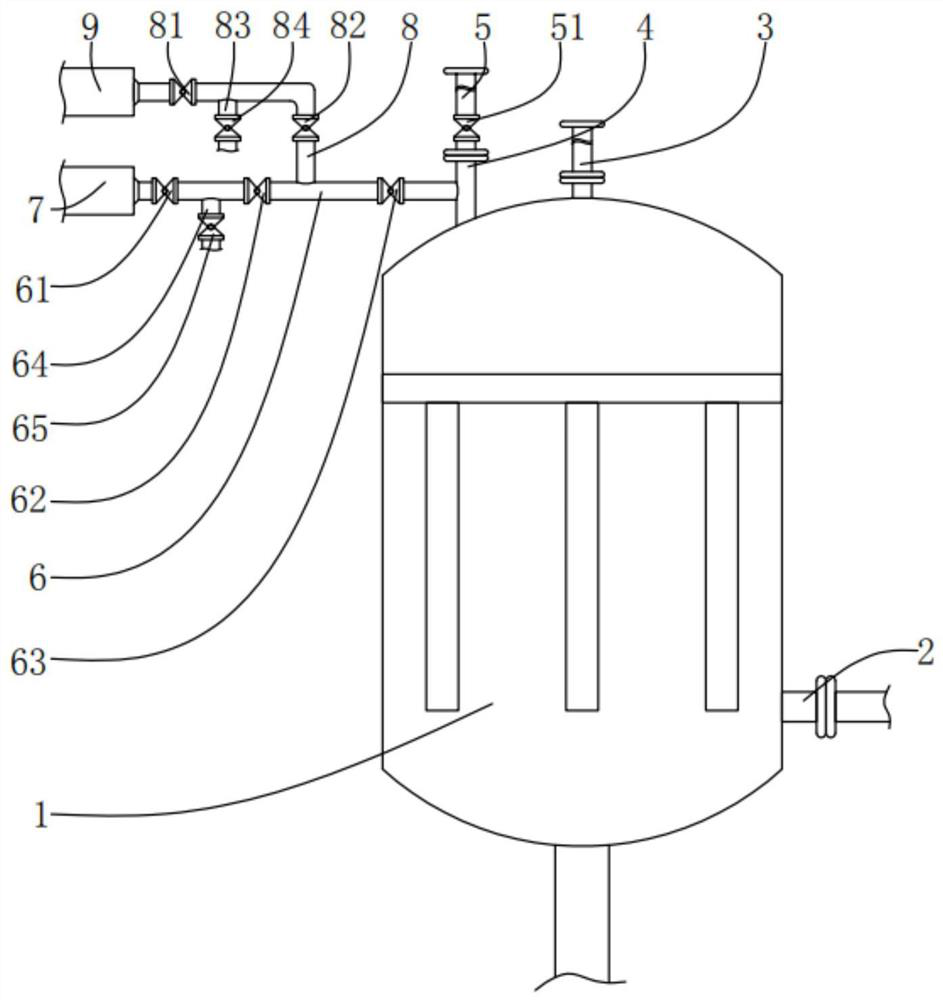

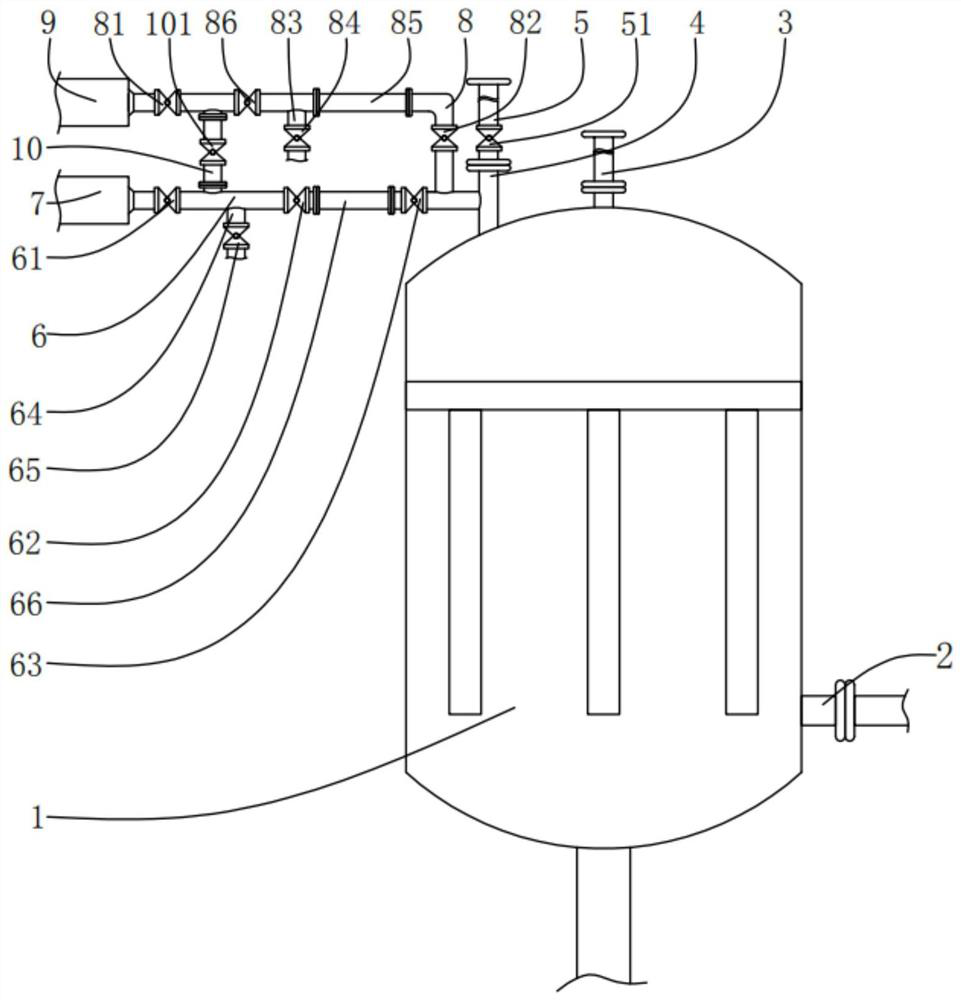

Online cleaning device for methanol washing methanol filter

PendingCN111921262AEasy to cleanTo achieve the purpose of multi-media clarityFiltration separationProcess engineeringEnvironmental engineering

The invention provides an online cleaning device for a methanol washing methanol filter. The online cleaning device for the methanol washing methanol filter comprises a methanol filter; a high methanol washing input end which is arranged at the input end of the methanol filter; a medium methanol washing output end which is arranged at the output end of the top of the methanol filter; and a cleaning pipeline inlet which is formed in a cleaning input port in the top of the methanol filter. According to the online cleaning device for the methanol washing methanol filter, the online cleaning device is provided with a hot desalted water input end pipe and a steam pipeline, the hot desalted water input port and the steam input port are respectively adopted to enter the inlet of the cleaning pipeline and the interior of the methanol filter for filtering so that the interior of the methanol filter is conveniently cleaned again through steam, the purpose of multi-medium cleaning is achieved, and the problem of incomplete cleaning is solved by adopting multiple media and multiple cleaning methods.

Owner:ANHUI HAOYUAN CHEM IND GRP

Swinging type raisin surface cleaning device with power rotation function

PendingCN112545013AWash thoroughlyCause re-pollutionDrying solid materials without heatCleaning using toolsDried fruitsDried fruit

The invention discloses a swinging type raisin surface cleaning device with a power rotation function, and relates to the technical field of dried fruit processing equipment. The swinging type raisinsurface cleaning device with the power rotation function comprises a device shell, wherein a driving mechanism is slidably connected to the top of the inner wall of the device shell, a cleaning mechanism is fixedly connected to the bottom of the driving mechanism, the surface of the cleaning mechanism is fixedly connected with the inner wall of the device shell, the inner wall of the cleaning mechanism is slidably connected with the inner wall of the driving mechanism, and a discharging port is formed in the bottom of the inner wall of the device shell. According to the swinging type raisin surface cleaning device with the power rotation function, a first rotating shaft is connected with a material collecting device to drive a material collecting box to rotate, and waste water obtained after cleaning is thrown out through water outlet holes, so that the problem that after raisins are cleaned, the waste water cannot be quickly separated from the raisins, the waste water obtained after cleaning is still adsorbed on the surfaces of raisins and the raisins are not thoroughly cleaned are effectively solved.

Owner:梁海珍

Quantitative cleaning and vibration disinfection equipment for biological experiments

InactiveCN109909210BAvoid cloggingImprove cleaning efficiencyLavatory sanitoryCleaning using liquidsElectric machineryEngineering

The invention discloses a quantitative cleaning and vibration disinfection equipment for biological experiments, which comprises a box body, the right side of the top of the box body is fixedly connected with an input channel, and the input channel runs through the top of the box body and extends to the inside of the box body, and the input channel is located in the box body. One end of the top of the box is connected with a hopper, the upper part on the right side of the inner wall of the box is fixedly connected with a cleaning device, the center of the bottom of the box is fixedly connected with a vibration disinfection device, and the lower part of the left side of the inner wall of the box is fixedly connected with the first motor. The front end of a motor is rotatably connected with a first pulley through an output shaft, and a first outer frame is arranged outside the first motor. The invention relates to the field of biological experiment auxiliary equipment. The quantitative cleaning and vibration disinfection equipment for biological experiments solves the problems of manual hand washing of existing biological experimental supplies, tedious work, time-consuming and laborious work, and inadequate cleaning. It achieves the purpose of more effectively improving cleaning and disinfection efficiency, and prevents Excess supply clogging the channel.

Owner:HUAIYIN TEACHERS COLLEGE

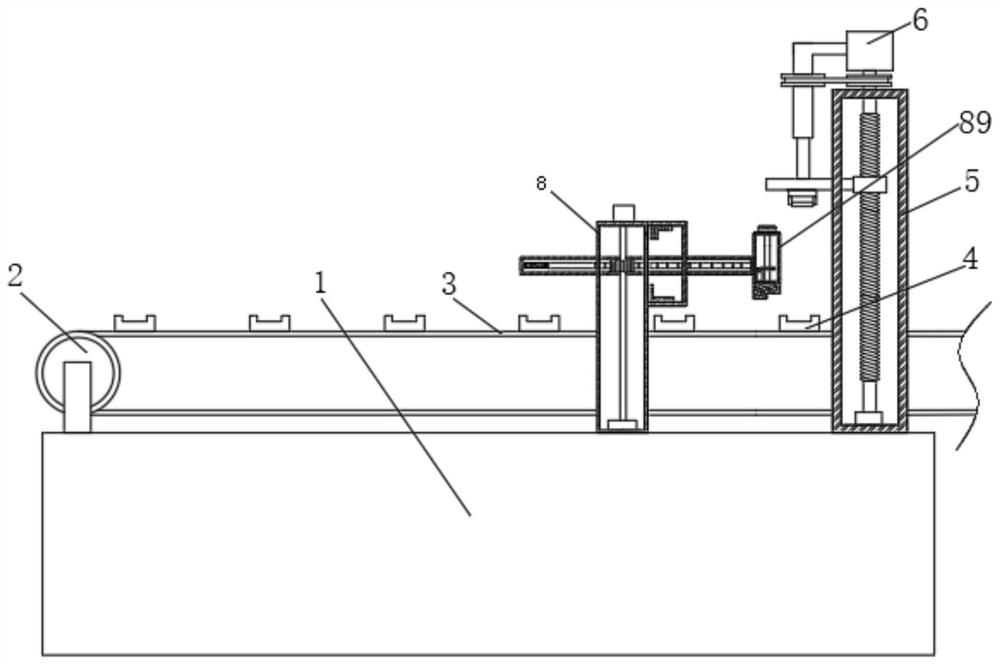

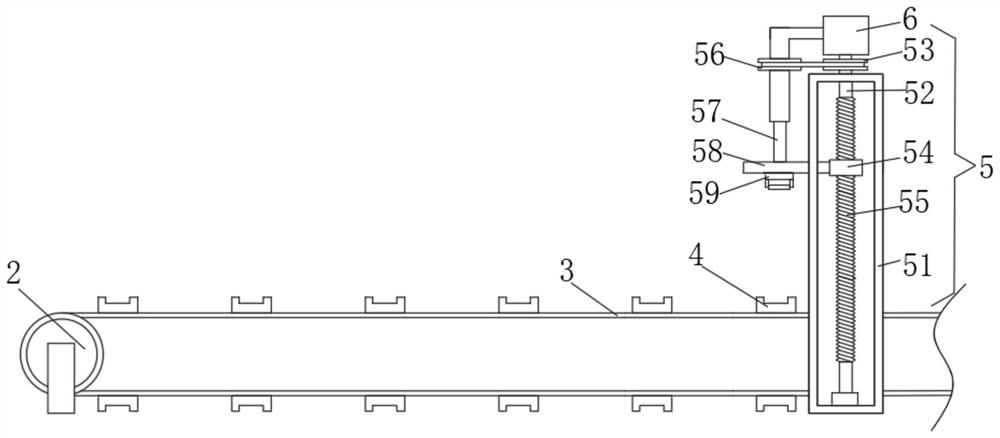

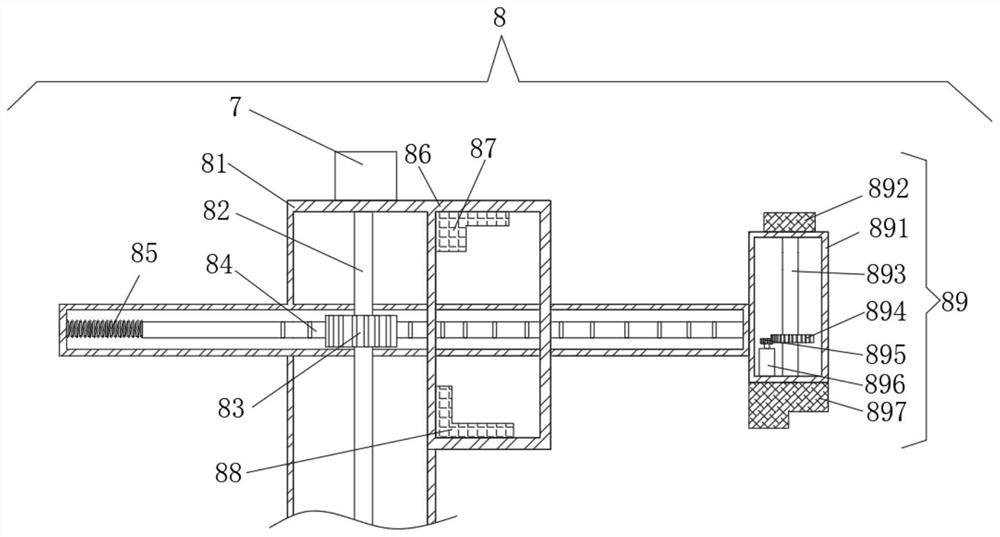

Cosmetic bottle cap assembling device

ActiveCN113173547AAvoid cleaningIncrease productivityCapsThreaded caps applicationEngineeringStructural engineering

The invention discloses a cosmetic bottle cap assembling device, and relates to the technical field of cosmetic processing. The cosmetic bottle cap assembling device comprises a device base, a driving belt wheel, a belt, a first clamping module, an assembling module and a cleaning module, wherein the driving belt wheel is arranged above the device base; the driving belt wheel is rotationally connected with the device base through a supporting column; the belt is wound on the outer wall of the driving belt wheel; a bottle body clamping module is fixed above the belt; the cleaning module is fixed on one side, far away from the driving belt wheel, above the device base; and the assembling module is fixed on one side, far away from the cleaning module, above the device base. A cleaning mechanism can clean a bottle cap and a bottle opening through a mechanism inside the cleaning module, so that manual cleaning of the bottle opening in the later period is avoided; and a brush cleaning seat can clean residual cosmetics on the surface of a cleaning brush, so that the cleaning brush cannot be used for cleaning the bottle opening and the surface of the bottle cap thoroughly due to the fact that the cosmetics are left on the surface of the cleaning brush.

Owner:SHEN ZHEN SHI JIN ZHENG JIANG DA METAL & PLASTIC WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com