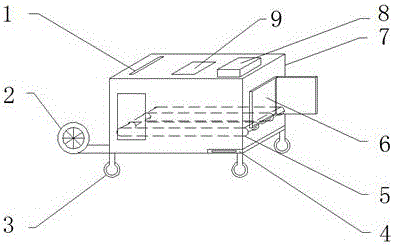

Automatic wrinkle remover

A wrinkle remover and machine body technology, applied in ironing machines, household clothes dryers, washing devices, etc., can solve the problems of clothing quality decline, low degree of automation, carbonization, etc., and achieve simple operation, strong practicability, and resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

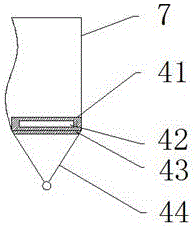

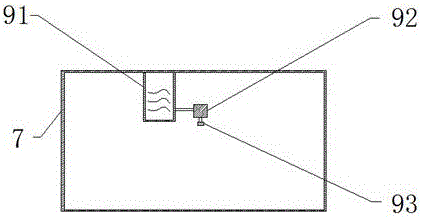

[0033] The specific embodiment: the user moves the present invention to a suitable position through the universal wheel 3, puts the clothes into the body 7 from the inlet 6, and spreads them on the transmission belt, and at the same time, the user connects the power output member 8 with the external The power supply is connected, and the external power supply transmits the electric energy to the power output component 8 through the wire, and the power output component 8 transmits the electric energy to the vacuum machine 44 through the wire, and the vacuum machine 44 converts the electric energy into mechanical energy. Under the action, it moves downward and enters the dust collection tank 41. Due to the blocking of the filter screen 43, solid dirt is prevented from entering the inside of the vacuum machine 44, causing damage to the vacuum machine 44. Cleaning solves the problem of incomplete cleaning of clothes by traditional wrinkle removers.

[0034] When the user connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com