Inner wall scale flushing equipment for industrial pump and working method of inner wall scale flushing equipment

A technology for industrial pumps and scales, applied in cleaning methods and utensils, chemical instruments and methods, vehicle parts, etc., can solve problems such as difficulty in cleaning, inability to completely remove scale, and deviation of cleaning devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

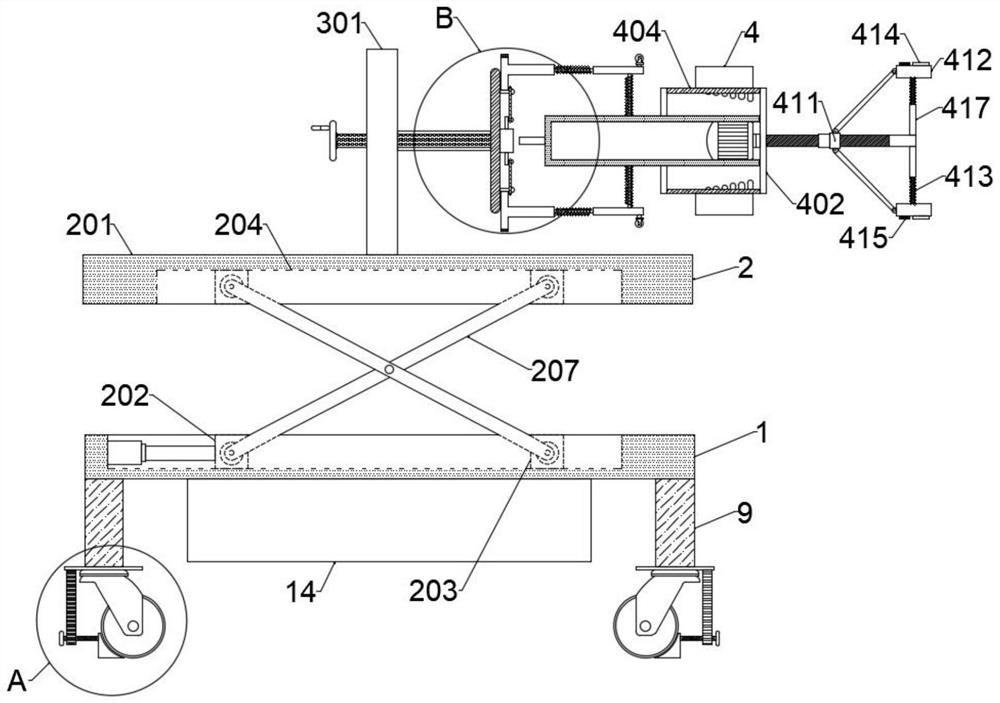

[0039] Such as Figure 1-2 and Figure 5-6 As shown, first spray cleaning liquid on the scale on the pipe wall of the water source heat pump, and after the cleaning liquid reacts with the scale for a period of time, push the present invention to the vicinity of the water source heat pump, and place the four corners of the bottom of the chassis frame 1 through the rollers 10 connected by the supporting columns 9 Carry out fixing, be installed in the rotating rod two 12 of long board 11 middle parts by handle rotation, the arc baffle plate 13 that one end of rotating rod two 12 is connected through the bearing movably carries out spacing to roller 10, prevents that the present invention when carrying out work, due to vibration The position deviation of the present invention affects the removal of scale on the inner wall of the water source heat pump. Open the electric push rod 206 included in the lifting assembly 2, and the electric push rod 206 pushes the second connecting rod ...

Embodiment 2

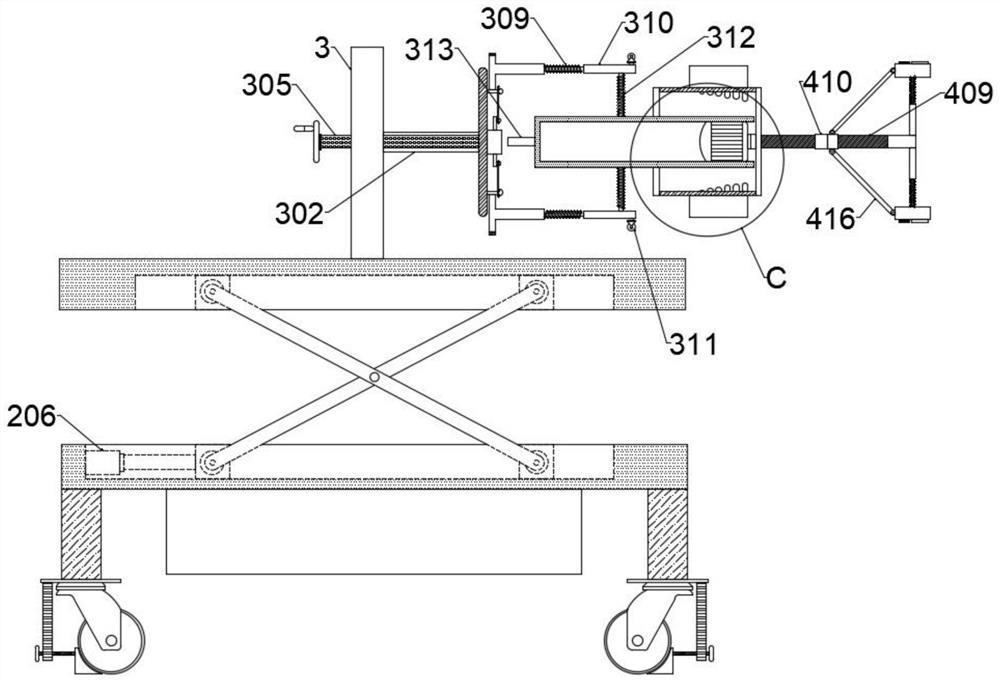

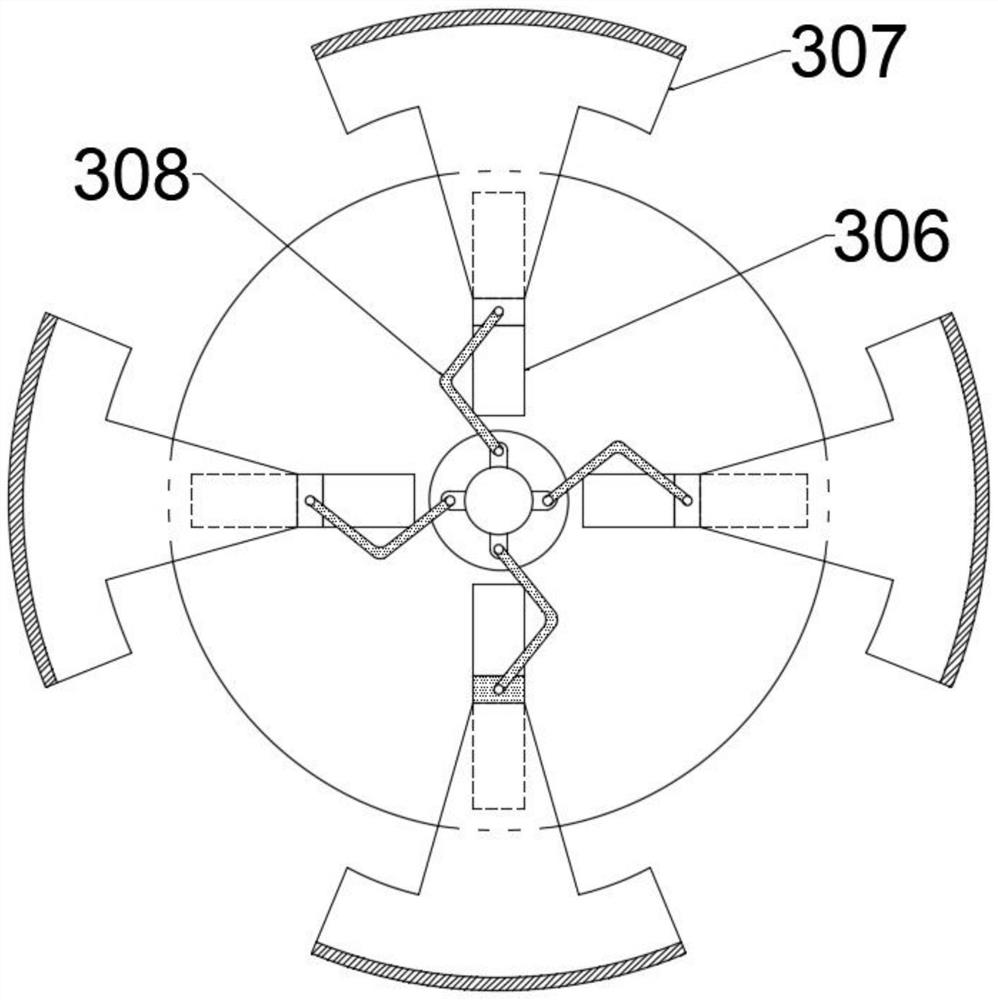

[0041] Such as Figure 1-3 and Figure 7 As shown, first use a shovel to scrape off the scale near the edge of the water source heat pump pipe wall, so that the expansion and fixing assembly 3 of the present invention can fit better with the water source heat pump pipe wall, and ensure that the scraper 414 scrapes the scale on the pipe wall. In addition to being uniform, turn the first sleeve 410 sleeved on the outside of the rotating rod 409. The rotation of the first sleeve 410 and the fine thread will drive the second sleeve 411 to move horizontally. The horizontal movement of the second sleeve 411 makes , the adjustment rod 416 deflects the angle, and then drives the third sleeve 412 connected with the adjustment rod 416 to move in the vertical direction until the scraper 414 is attached to the wall of the water source heat pump, and the third sleeve 412 and the long rod 417 pass through the third sleeve 412 The four telescopic rods 413 are connected so that the scraper 4...

Embodiment 3

[0043] Such as Figure 1-4 and Figure 8 As shown, the driving motor 401 is turned on, the operator holds the water pipe to spray the scraper 414, the brush 415 and scale, and at the same time the operator pushes the push rod 313 by hand, and the pulley 311 rolls on the pipe wall of the water source heat pump to ensure that the scraper 414 is always in the water source At the center of the tube wall of the heat pump, when specifically setting, when the length of the water source heat pump to be cleaned is long, the push rod 313 is disassembled, and the push rod 313 corresponding to the length of the water source heat pump is replaced, so that the scraper 414 of the present invention can clean the water source heat pump. The scale deeper in the pipe wall is scraped to solve the problem that the existing device cannot clean the water source heat pump with a longer size. With the cooperation of the first telescopic rod 309, the scraper 414 can clean the scale deeper in the pipe w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com