Hawthorn pulp scraping machine

A scraper and slurry technology, applied in the field of hawthorn slurry scraper, can solve the problems of high labor intensity, uneven thickness, low scraper efficiency, etc., and achieve uniform scraper, high efficiency and good sanitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

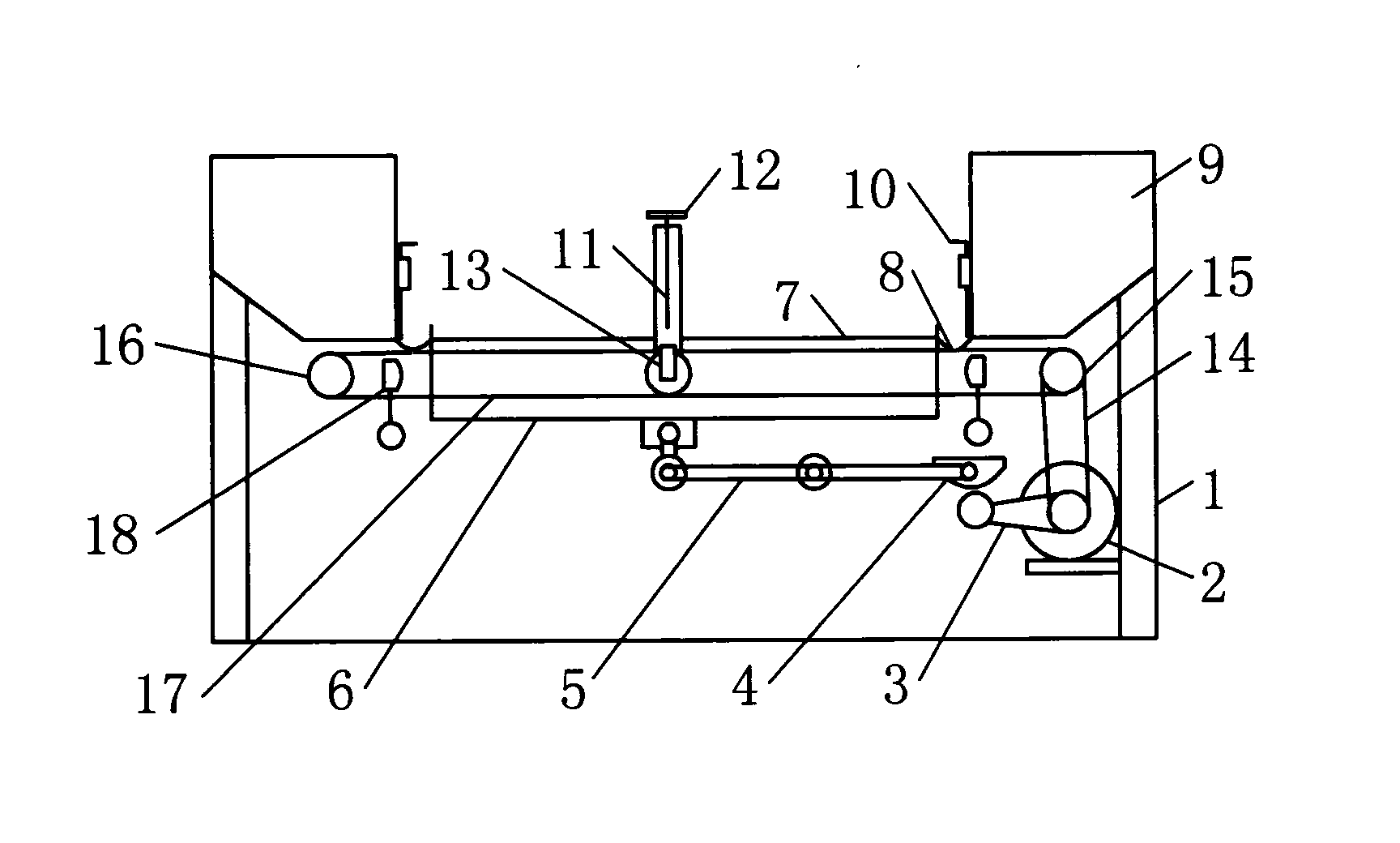

[0011] According to the picture:

[0012] A hopper 9 is installed on both sides of the upper part of the machine body 1, and a hopper insert plate 10 is installed inside the hopper;

[0013] The lower part of the machine body is equipped with a motor 2. The output wheel of the motor is connected to the right transmission sprocket 15 through the motor transmission chain 14, and the right transmission wheel is connected to the left transmission sprocket 16 through the reciprocating chain 17. There is a thickness adjustment rod 11 through the thickness adjustment rod walking wheel 13, and a thickness adjustment knob 12 is connected to the upper part of the thickness adjustment rod;

[0014] Inside the two hoppers on the upper part of the machine body are respectively provided with troughs 8;

[0015] A lifting frame 6 capable of lifting up and down is installed on the body between the two troughs, and a lifting platform 7 is provided on the lifting frame;

[0016] The lower part of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com