Patents

Literature

204results about How to "Movement restrictions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for regulating internet page layout

InactiveCN101261642AMovement restrictionsMobile clutterSpecial data processing applicationsThe InternetWeb page

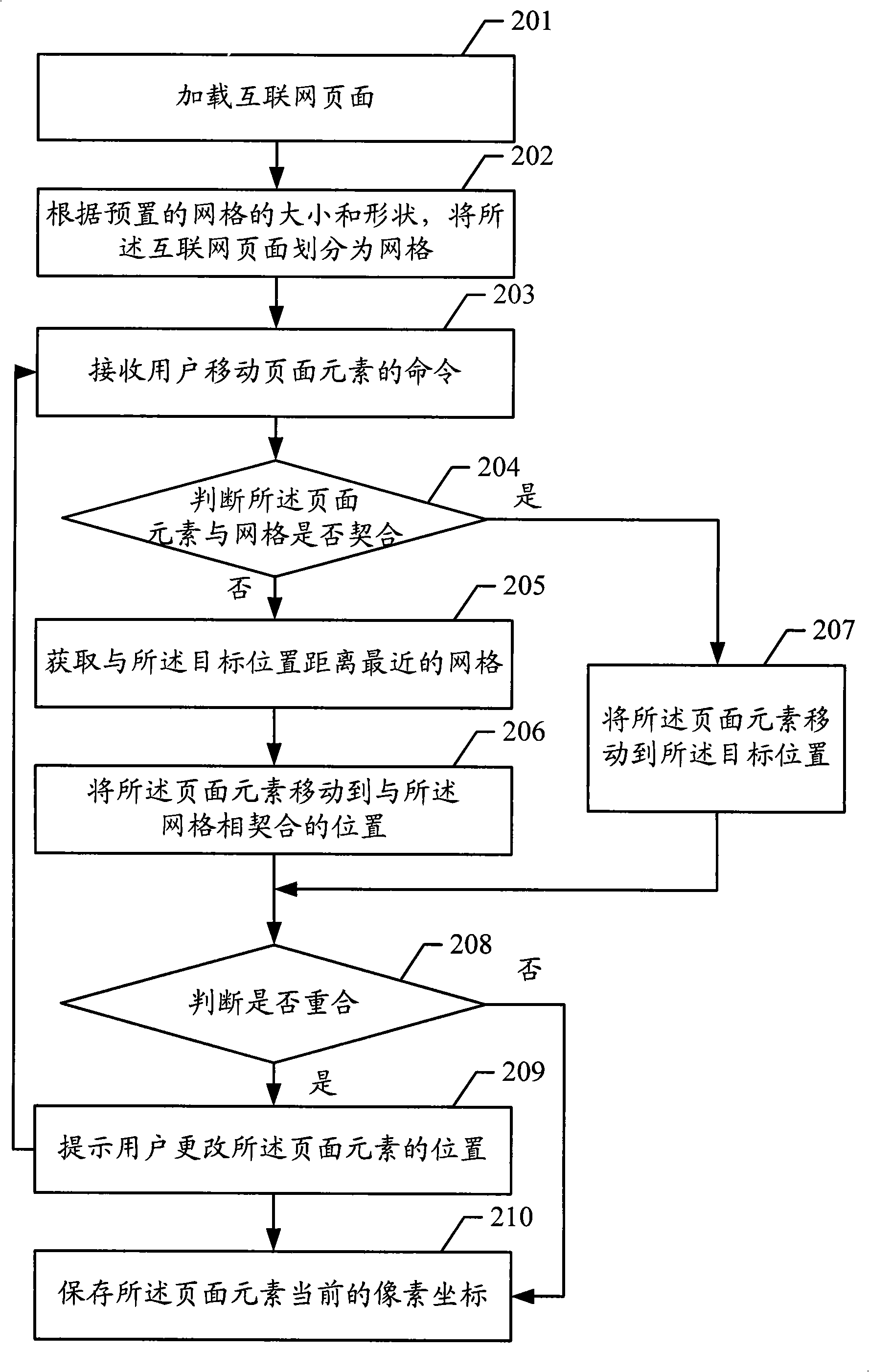

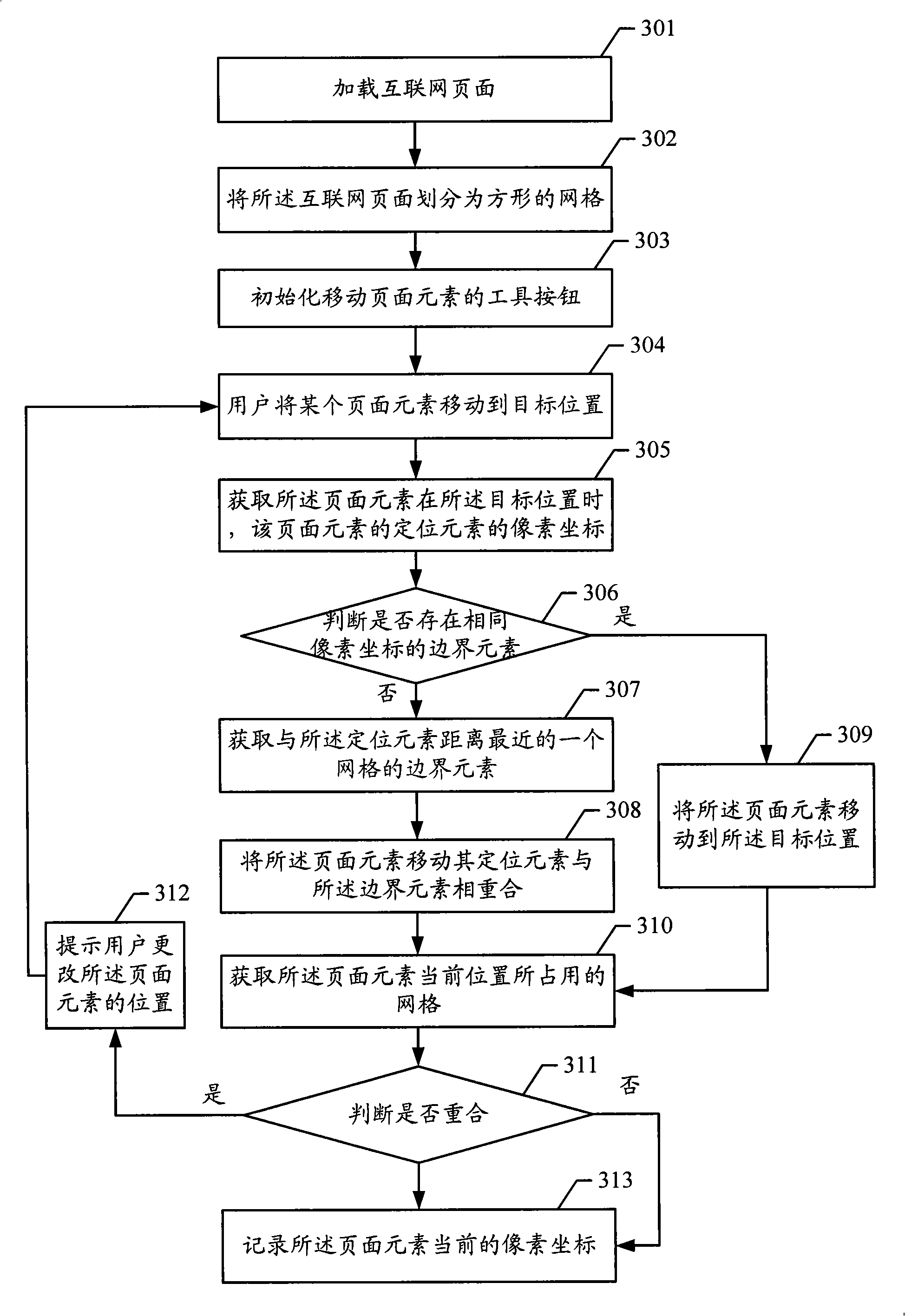

The invention discloses a method and a device used for regulating internet page arrangement, aiming at solving the problems of the prior art that module factors can just be moved up and down in a fixed column; users have small customizing scopes; and more requirements of web page customization of users cannot be met. In the method, the internet web pages are divided into grids according to the size and form of pre-set grids when loading internet web pages; the instructions of removing page factors of users are received; the page factors are removed to positions corresponding to the grids which are nearest to the target positions once the page factors cannot correspond to the grids of the internet pages when judging whether the page factors are on the positions appointed by users. According to the proposal provided by the invention, the customization requirement of users can be satisfied to the utmost extent and the disorder removing of the page factors by users can be restricted.

Owner:SHENZHEN THUNDER NETWORK TECH

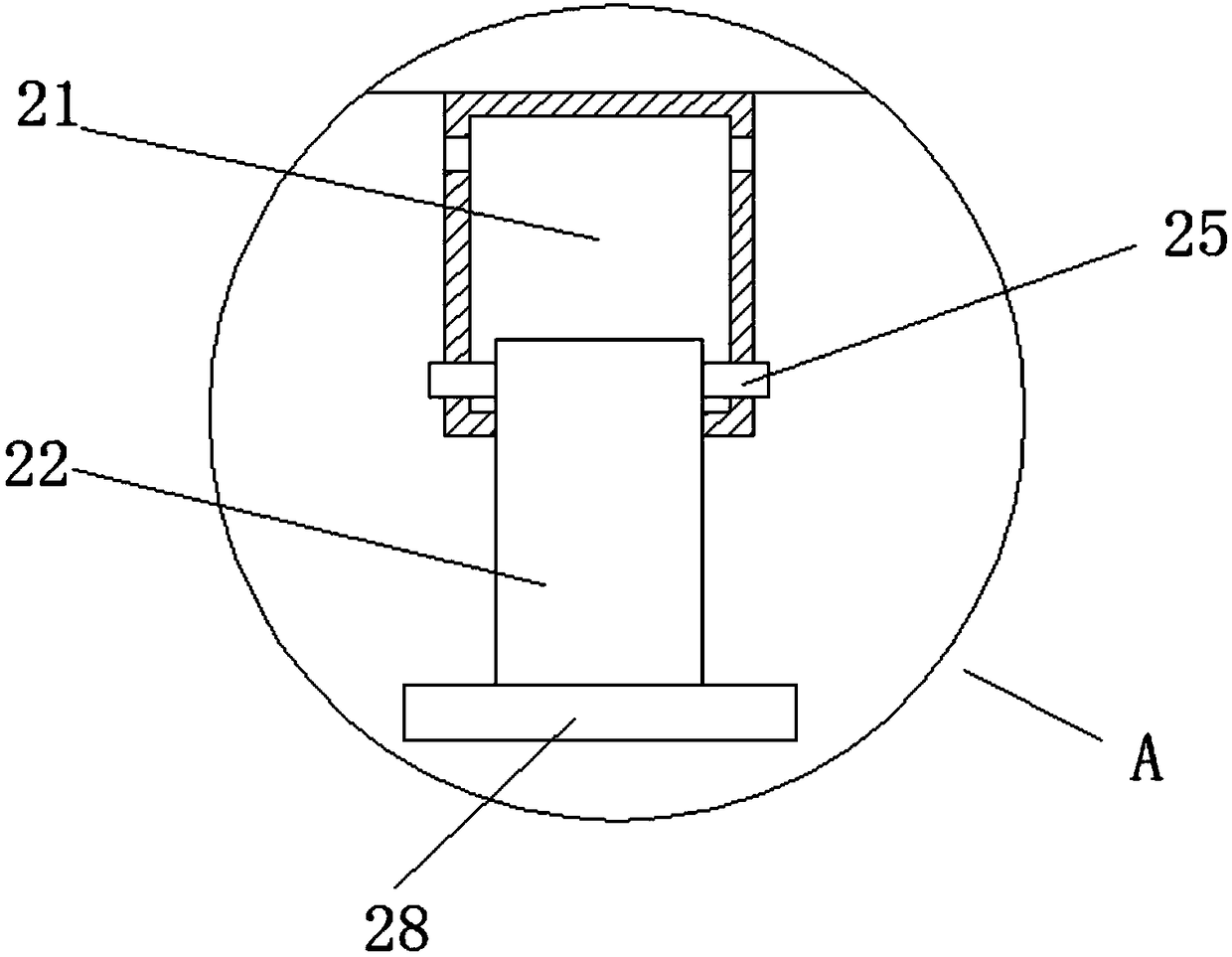

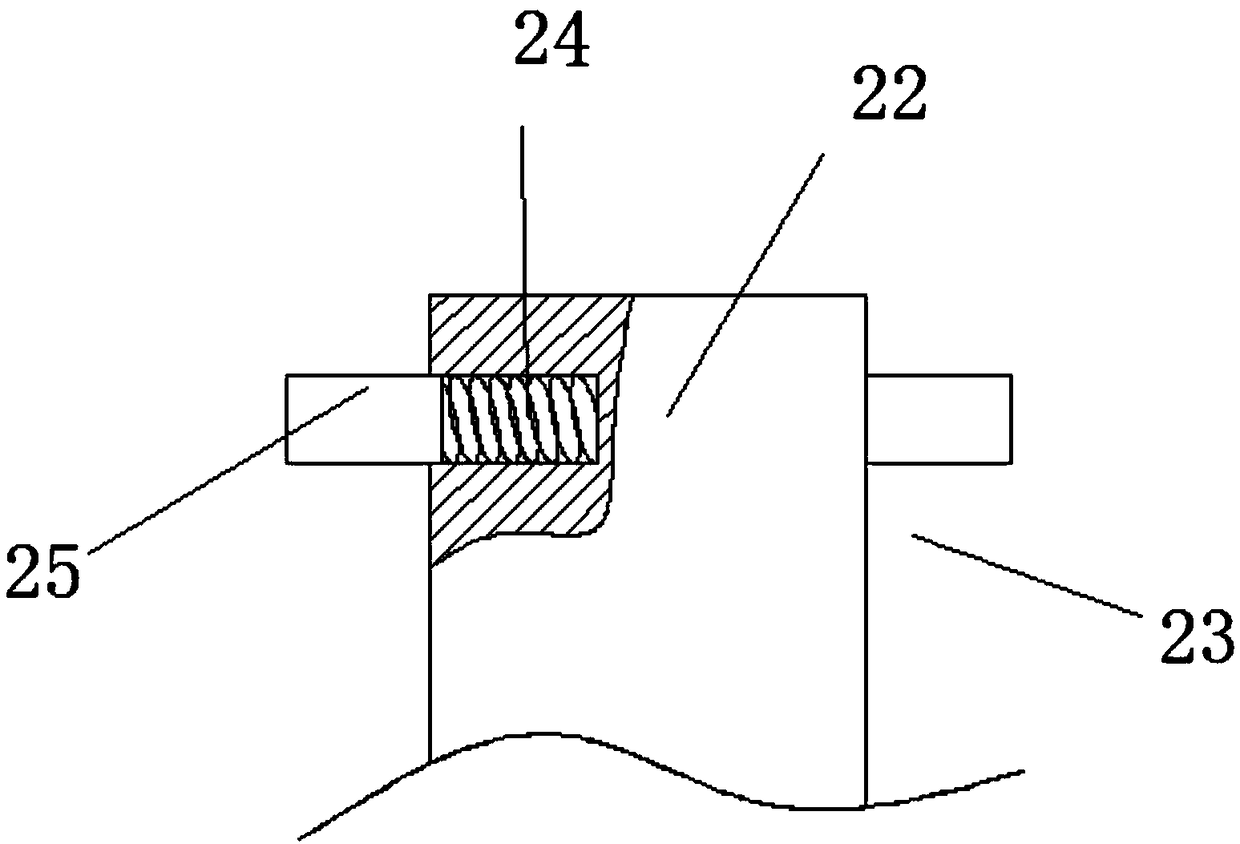

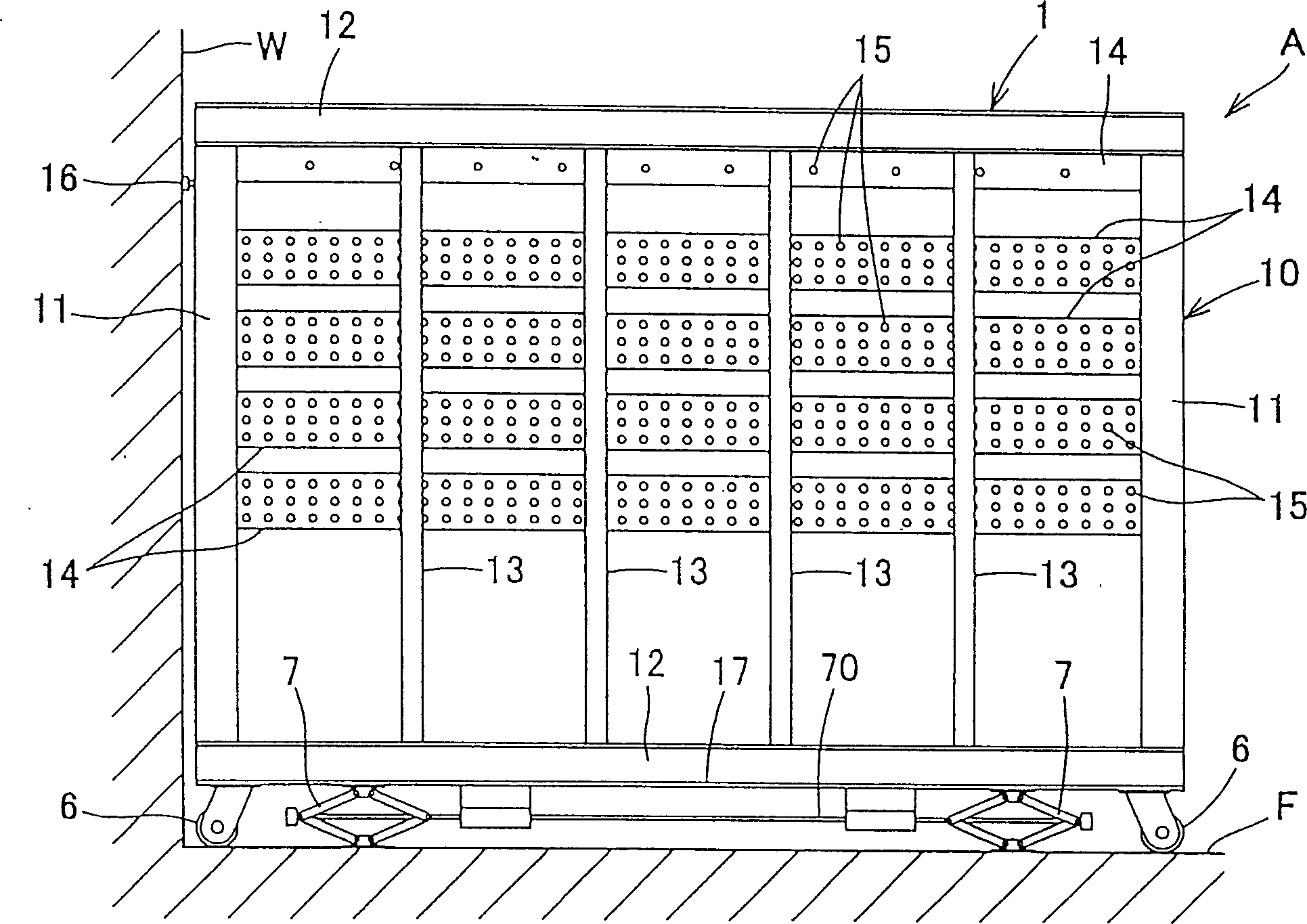

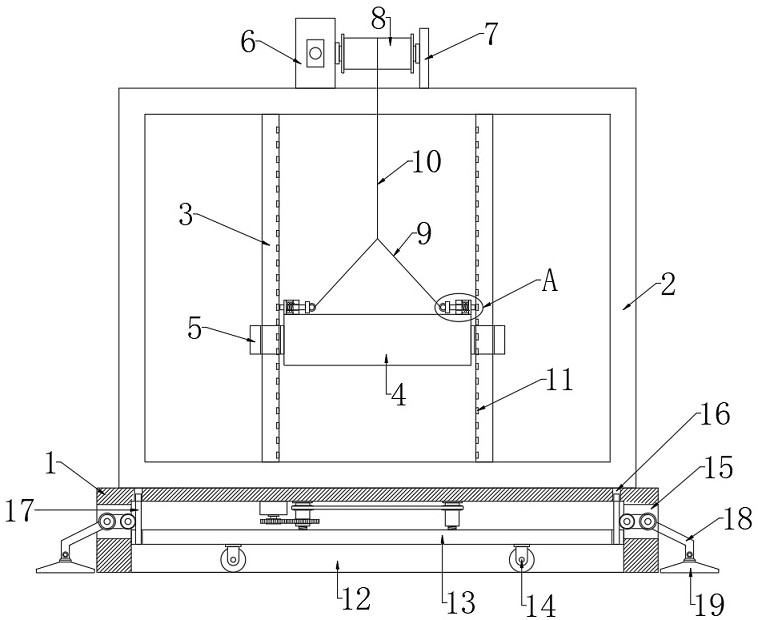

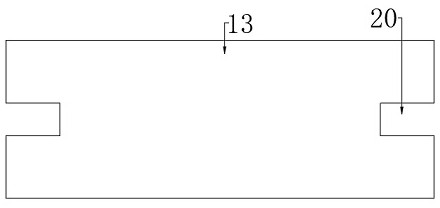

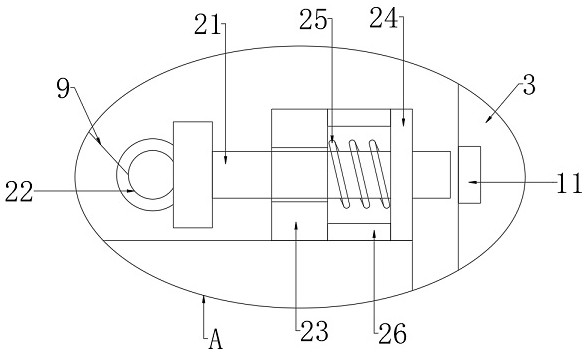

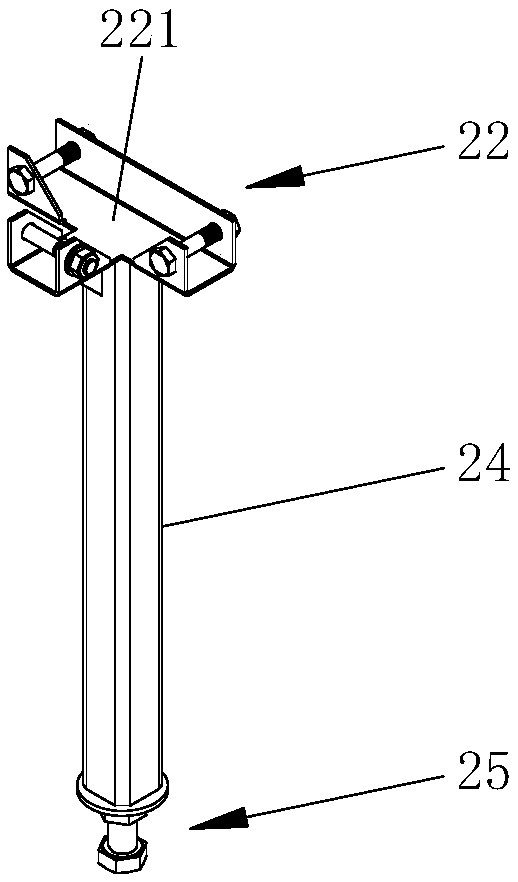

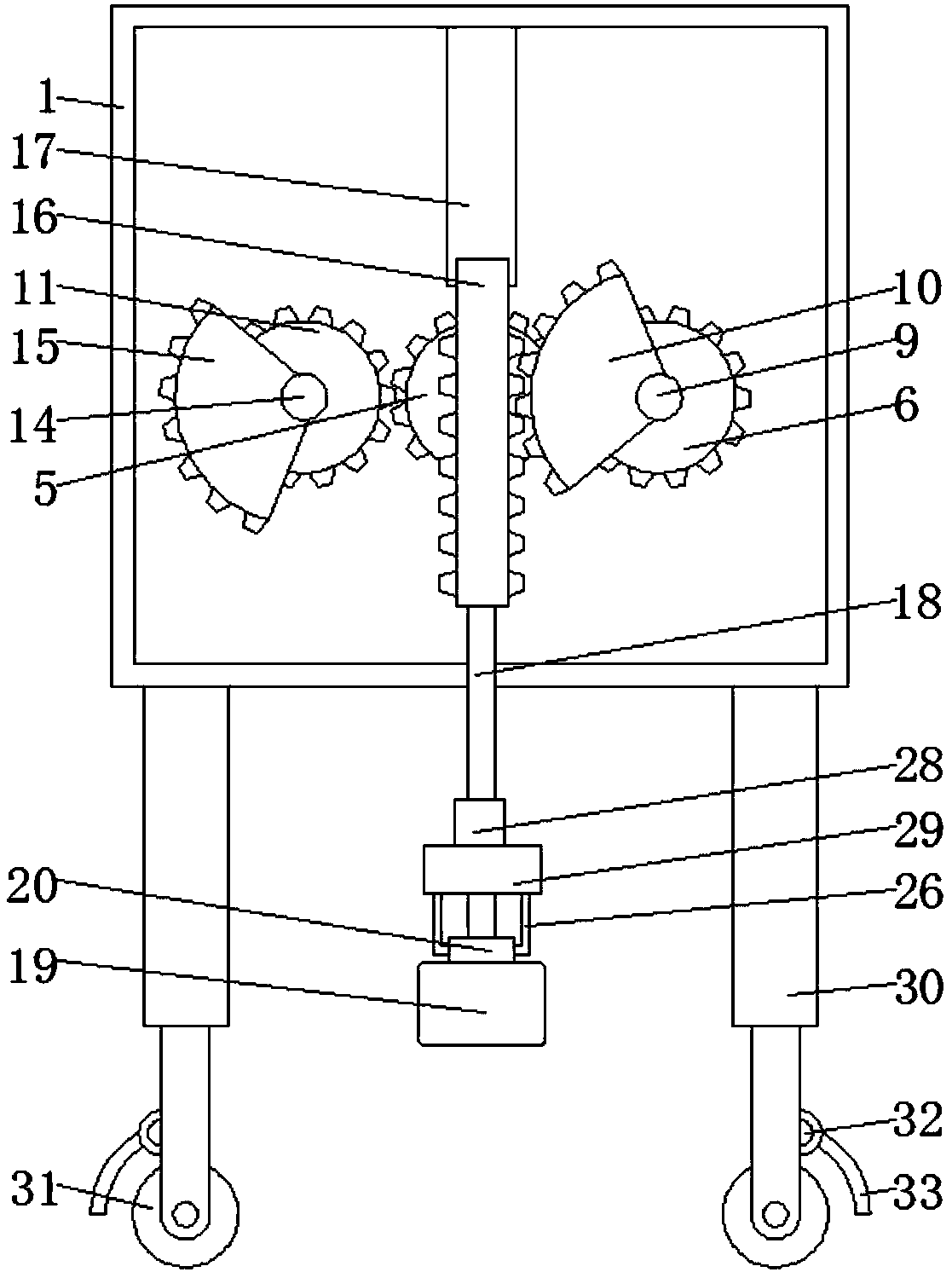

Outer wall insulation board installation mechanism

InactiveCN108590200AAccurate installationEasy to installBuilding material handlingEngineeringExternal wall insulation

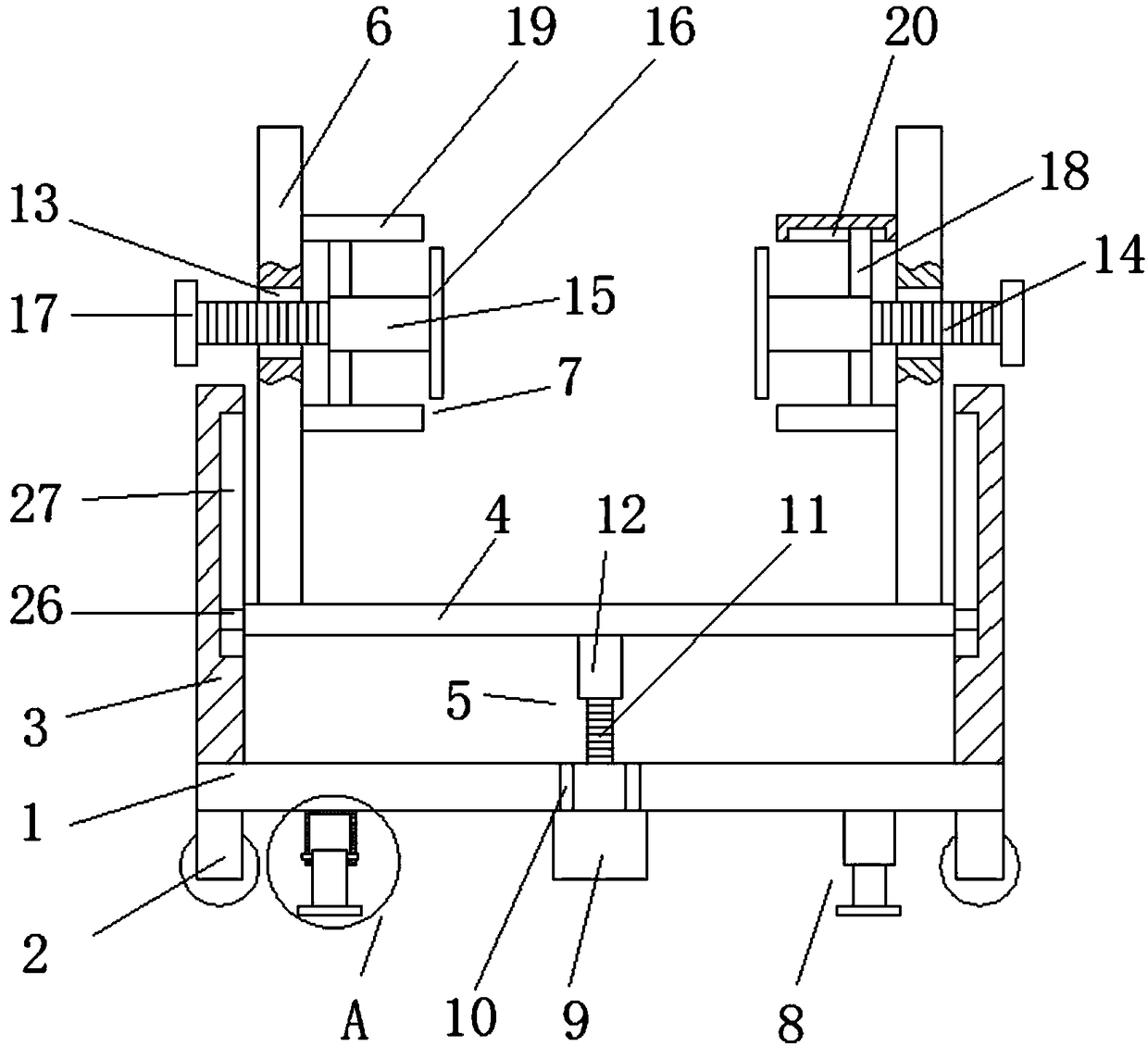

The invention discloses an outer wall insulation board installation mechanism which comprises a car body and wheels. The upper surface of the car body is fixedly connected with two symmetrically arranged first supporting rods; a placement plate is arranged between the two first supporting rods; an adjustment mechanism is arranged at the bottom of the placement plate; the upper surface of the placement plate is fixedly connected with two symmetrically arranged second supporting rods; a clamping mechanism is arranged between the two second supporting rods; and a limiting mechanism is arranged onone side of the wheels. The operation is convenient, the outer wall insulation board is convenient to install, and the problems of high danger and safety impact to workers due to the fact that when the outer wall insulation board is installed, workers need to stand on a lift and hold the insulation board for the installation are avoided; and meanwhile, movement of the installation mechanism is effectively limited; and the problems of unstable placement and influenced installation efficiency and installation quality during moving the installation mechanism to a designated position are avoided.

Owner:马鞍山市金韩防水保温工程股份有限公司

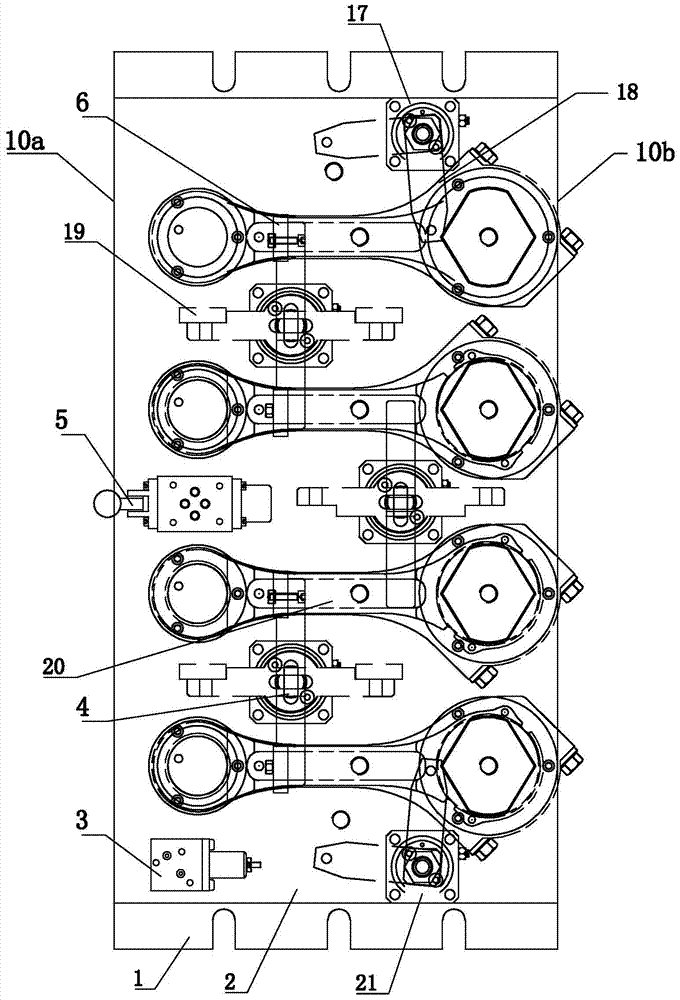

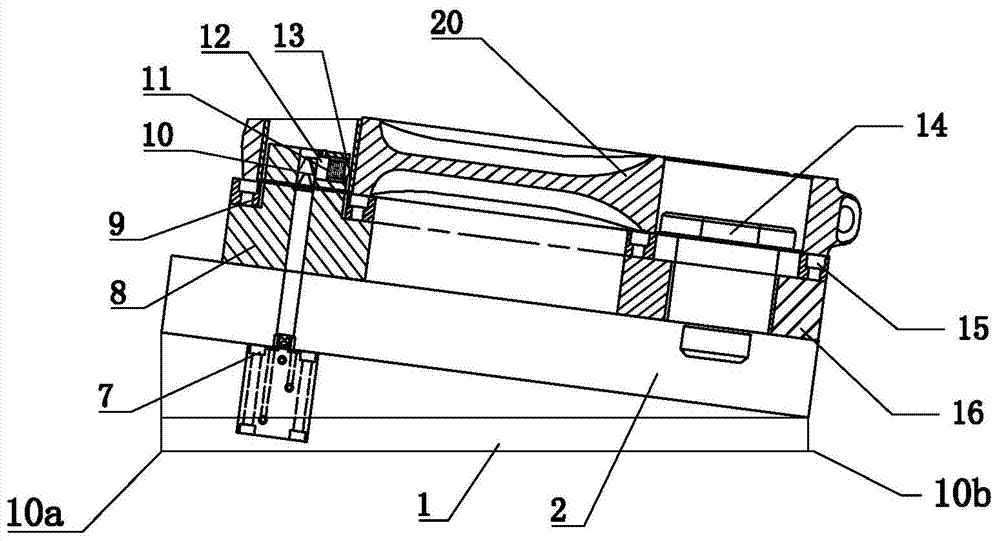

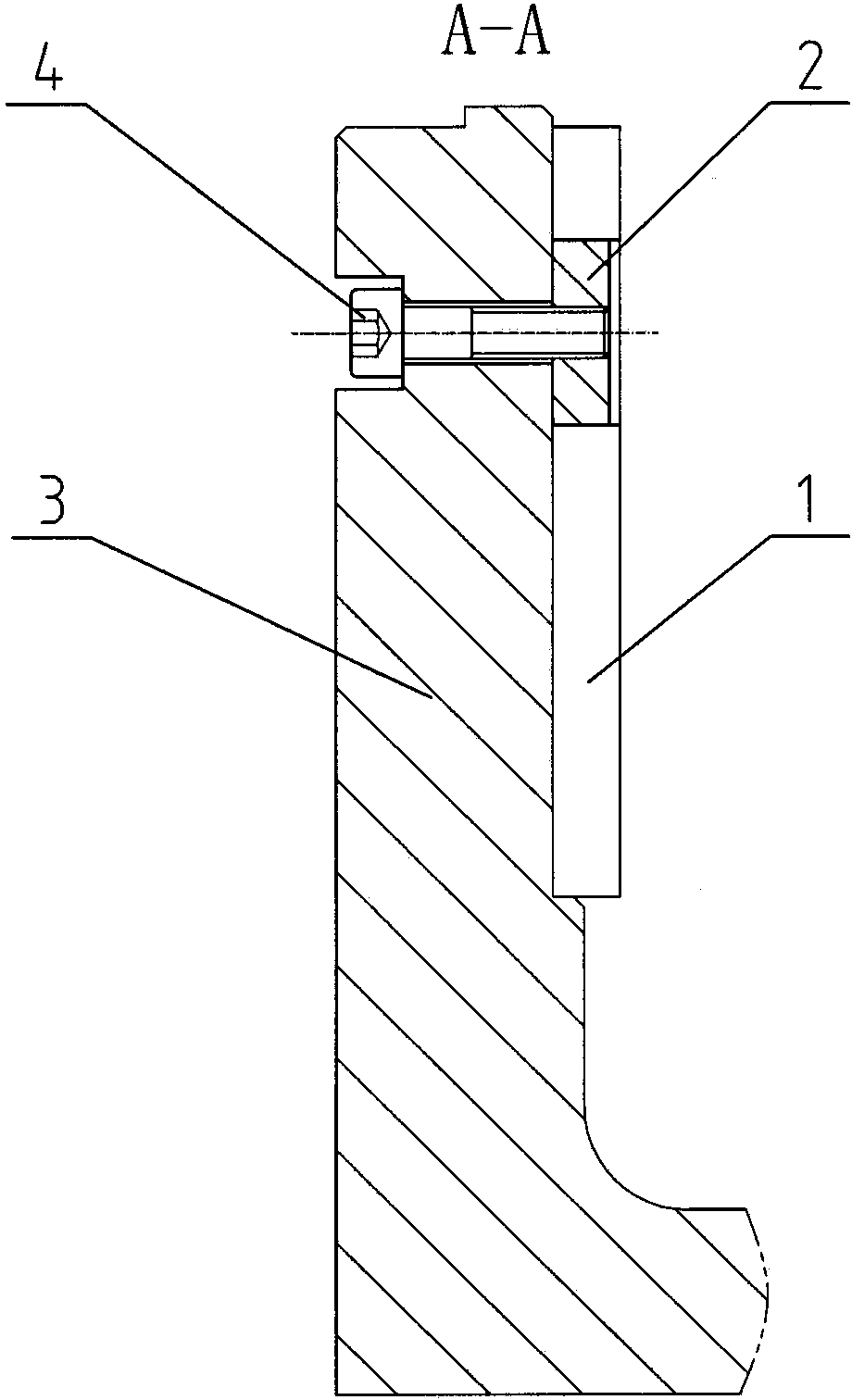

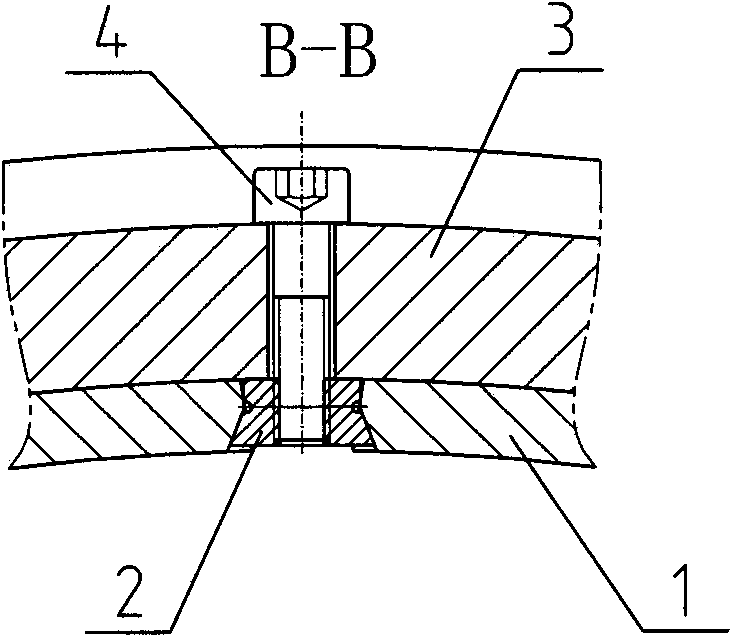

Hydraulic clamping and positioning device for slope processing of connecting rod

ActiveCN104325327AStable jobRapid positioningPositioning apparatusMetal-working holdersBaseboardEngineering

The invention discloses a hydraulic clamping and positioning device for slope processing of connecting rod. The hydraulic clamping and positioning device for slope processing of connecting rod comprises a baseboard provided with a clamp board, wherein a small end hole positioning device is arranged on the clamp board, the small end hole positioning device comprises a first cushion block provided with a first through hole, a horizontal through hole is formed in a boss of the first through hole, an ejecting column is arranged inside the horizontal through hole, a piston rod of a thin-wall oil cylinder extends from the first through hole and abuts against a cone head rod, the cone head slope of the cone head rod can push the slope of the ejecting column to position a small end hole, a large end hole positioning device comprises a second cushion block provided with a second through hole in the middle, a positioning pin of the second through hole positions a large end hole, and two single head pressing boards and a plurality of double head pressing boards are used for clamping a connecting rod. A hydraulic oil cylinder can fast position and clamp the small end hole, the large end hole is positioned by the positioning pin, the hydraulic oil cylinder also can fast control the pressing of the single head pressing boards and the double head pressing boards on the connecting rod of each working position, so that the connecting rod slope processing can be smoothly conducted, and the processing efficiency is improved.

Owner:山东盛祥智能制造有限公司

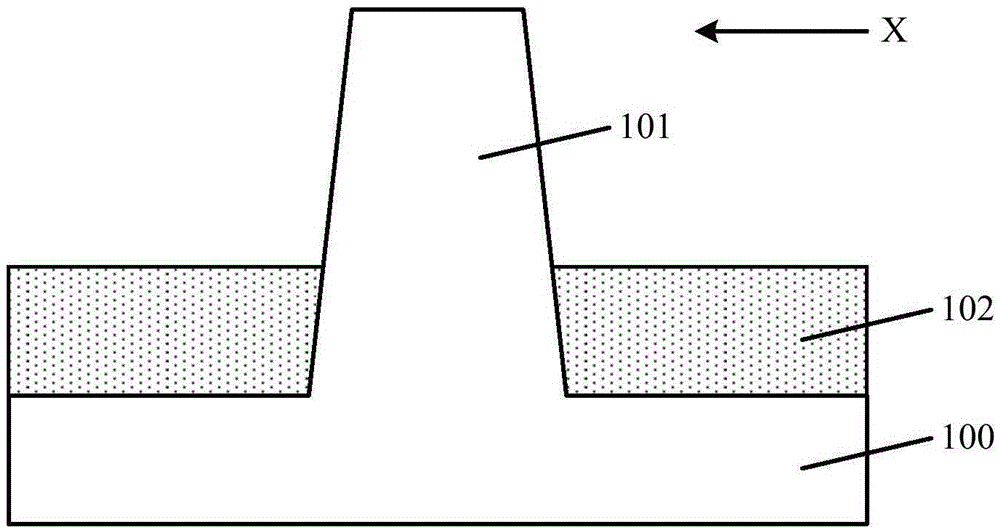

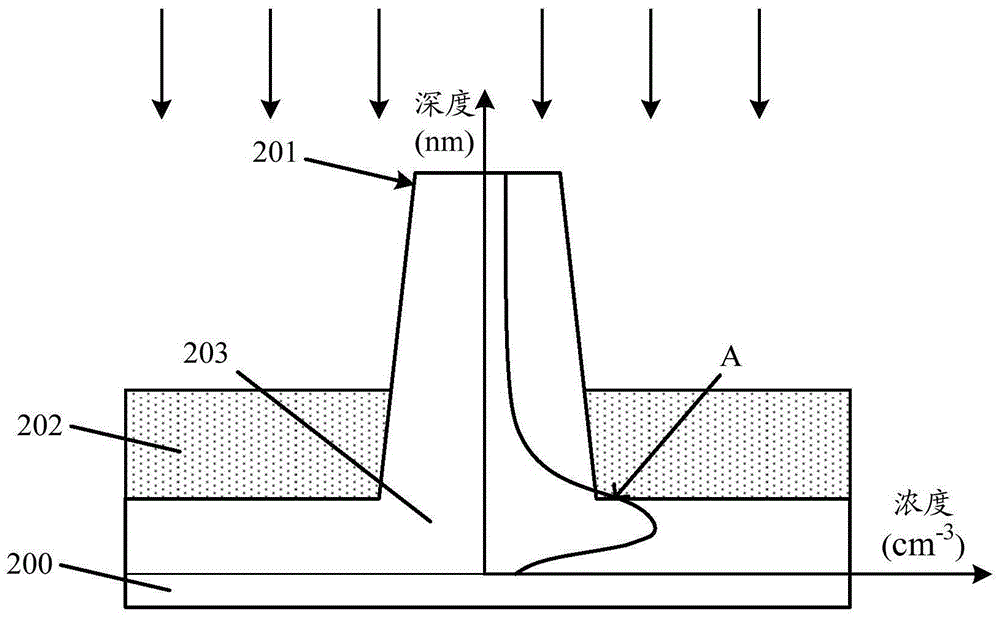

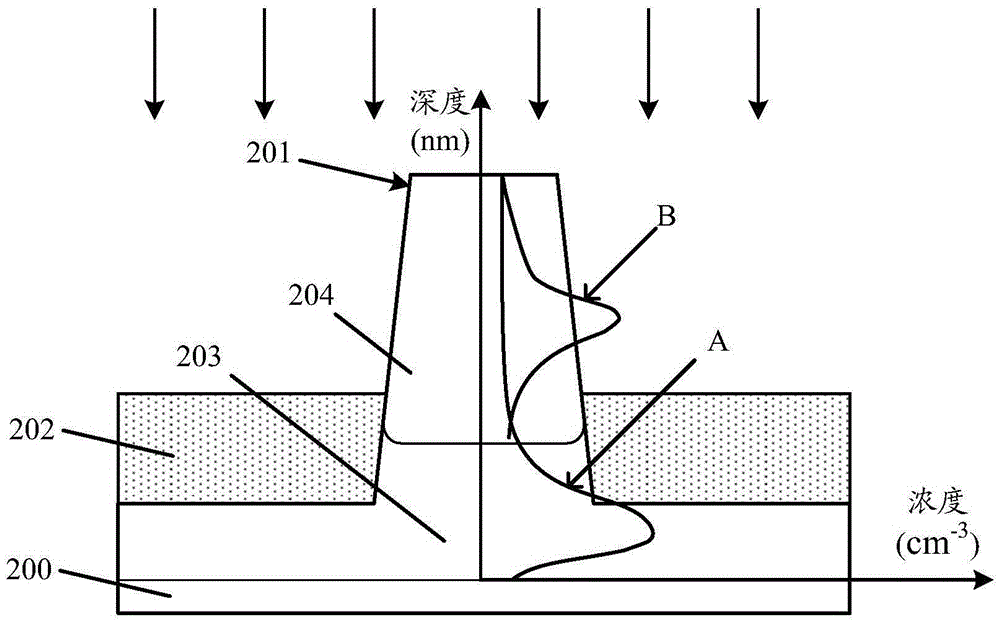

Semiconductor structure forming method

ActiveCN106449405AInhibited DiffusionSuppression of short channel effectsSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon ionSemiconductor structure

The invention provides a semiconductor structure forming method which comprises the following steps: providing a substrate with a well region, wherein a first type of ions are disposed in the well region; using a first anti-punch-through-injection process to inject the first type of ion into the well region wherein the depth of the first anti- punch-through injection process is less than the distance from the bottom of the well region to the top surface of the substrate, forming an anti-punch-through region in the well region; using a second anti- punch-through-injection process to inject carbon ions into the well region to form a carbon doped region in the well region wherein the doped concentration of the carbon ions is greater than that of the first type of ion in the anti-punch-through region and the carbon doped region surrounds the anti-punch-through region; and using a third anti-punch-through-injection process to inject nitrogen ions into the well region wherein the third anti-punch-through-injection depth is less than those of the first anti- punch-through -injection and the second anti-punch-through-injection, forming a nitrogen doped region between the anti- punch-through regions and the top part of the substrate. According to the semiconductor structure forming method, it is possible to improve the performances of a semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

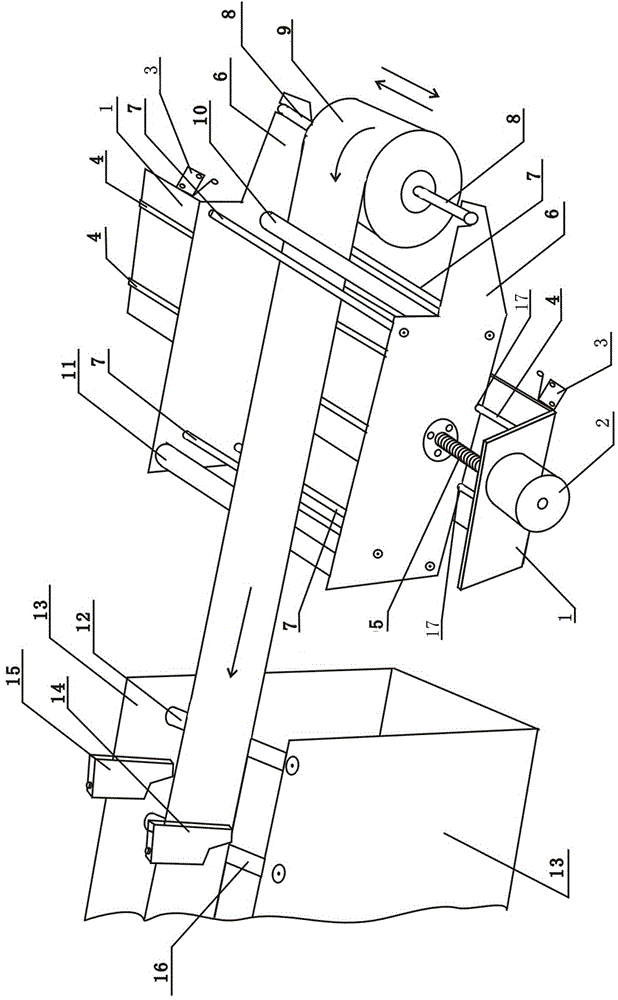

Coiled material deviation rectifying device of bag making machine

InactiveCN103601024AMovement restrictionsSubsequent work is fineWebs handlingEngineeringLimit switch

The invention discloses a coiled material deviation rectifying device of a bag making machine. The coiled material deviation rectifying device comprises a framework, photoelectric sensors and an accommodating rack. The accommodating rack is arranged on one side of the framework. Compared with the prior art, the coiled material deviation rectifying device is characterized in that a front guide roller and a rear guide roller are arranged on the framework, and the left photoelectric sensor and the right photoelectric sensor are arranged between the two guide rollers and are fixed to the edge of a coiled material; the accommodating rack is arranged on sliding guide rails of a base frame, and limit switches are arranged on two sides of the bottom of the base frame and can limit the accommodating frame when the accommodating frame excessively moves left and right. The coiled material deviation rectifying device has the advantages that the left photoelectric sensor and the right photoelectric sensor are fixed to the edge of the coiled material, and signals can be emitted when the edge of the coiled material is deviated from detection ranges of the photoelectric sensors and are transmitted through a control circuit, so that a brushless motor can rotate clockwise and anticlockwise, the coiled material can return to a correct position, and normal follow-up operation can be guaranteed.

Owner:陈志高

Substrate-levitating device

InactiveCN1697768AMovement restrictionsSemiconductor/solid-state device manufacturingCharge manipulationMechanical engineeringEngineering

Owner:OLYMPUS CORP

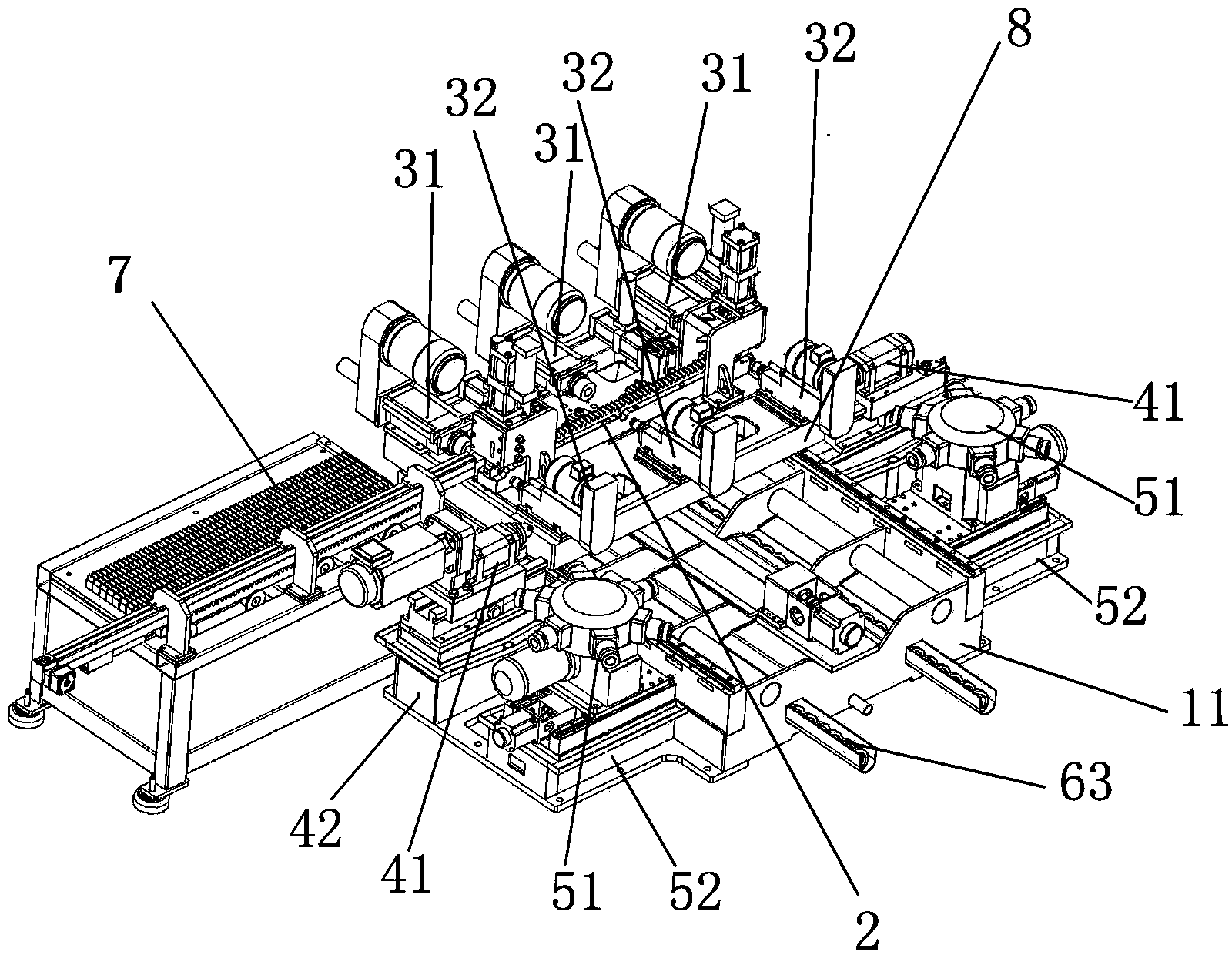

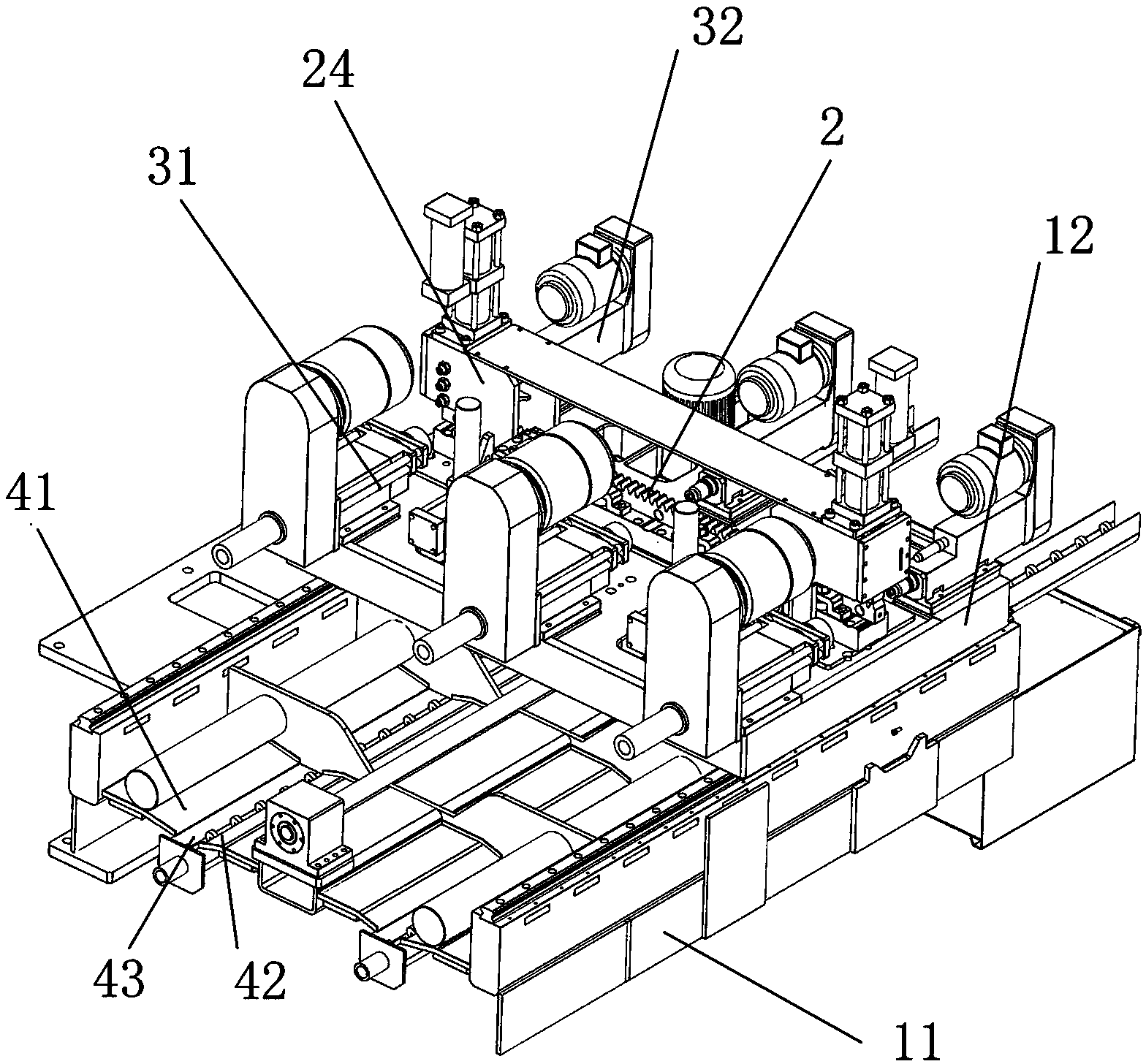

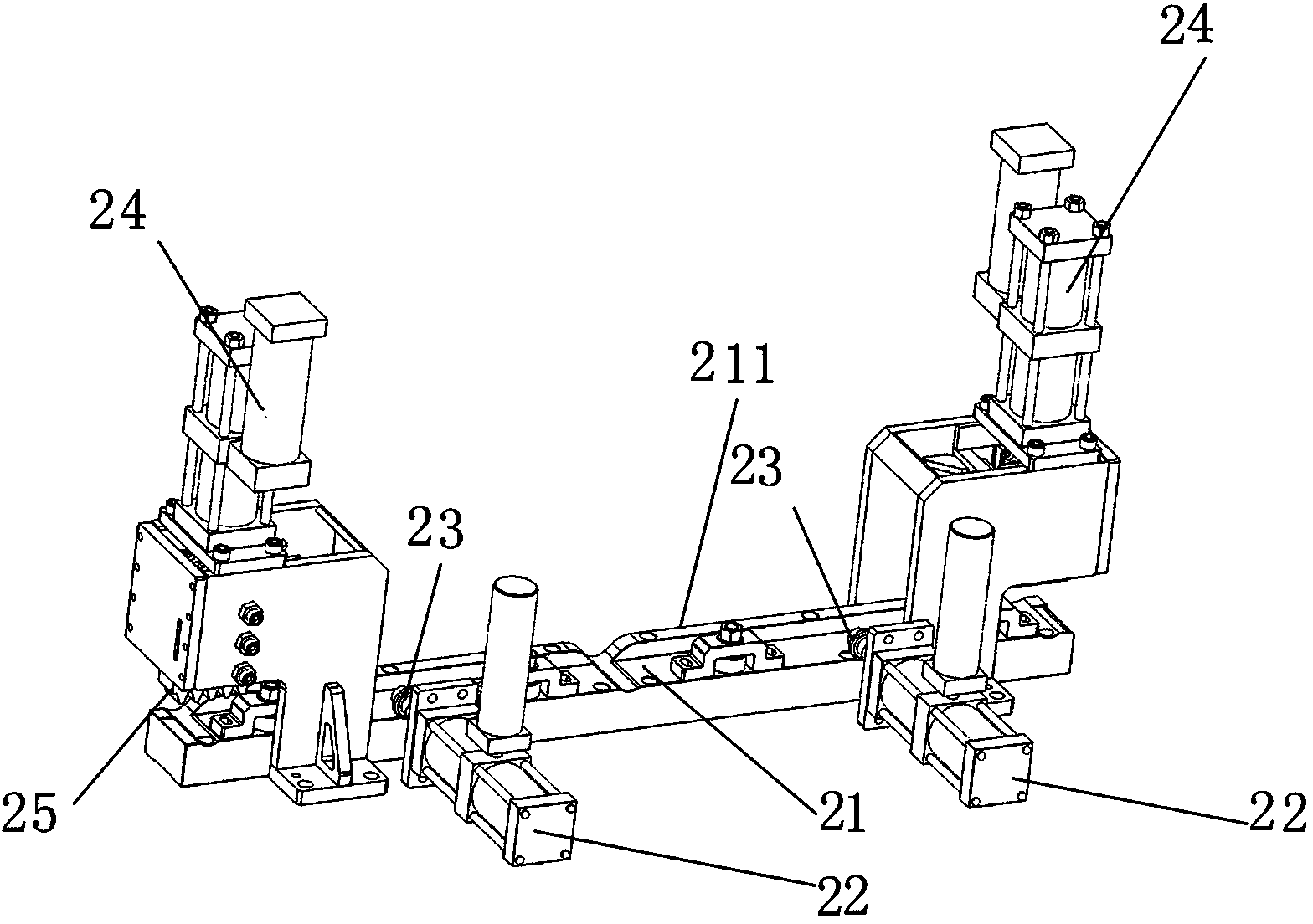

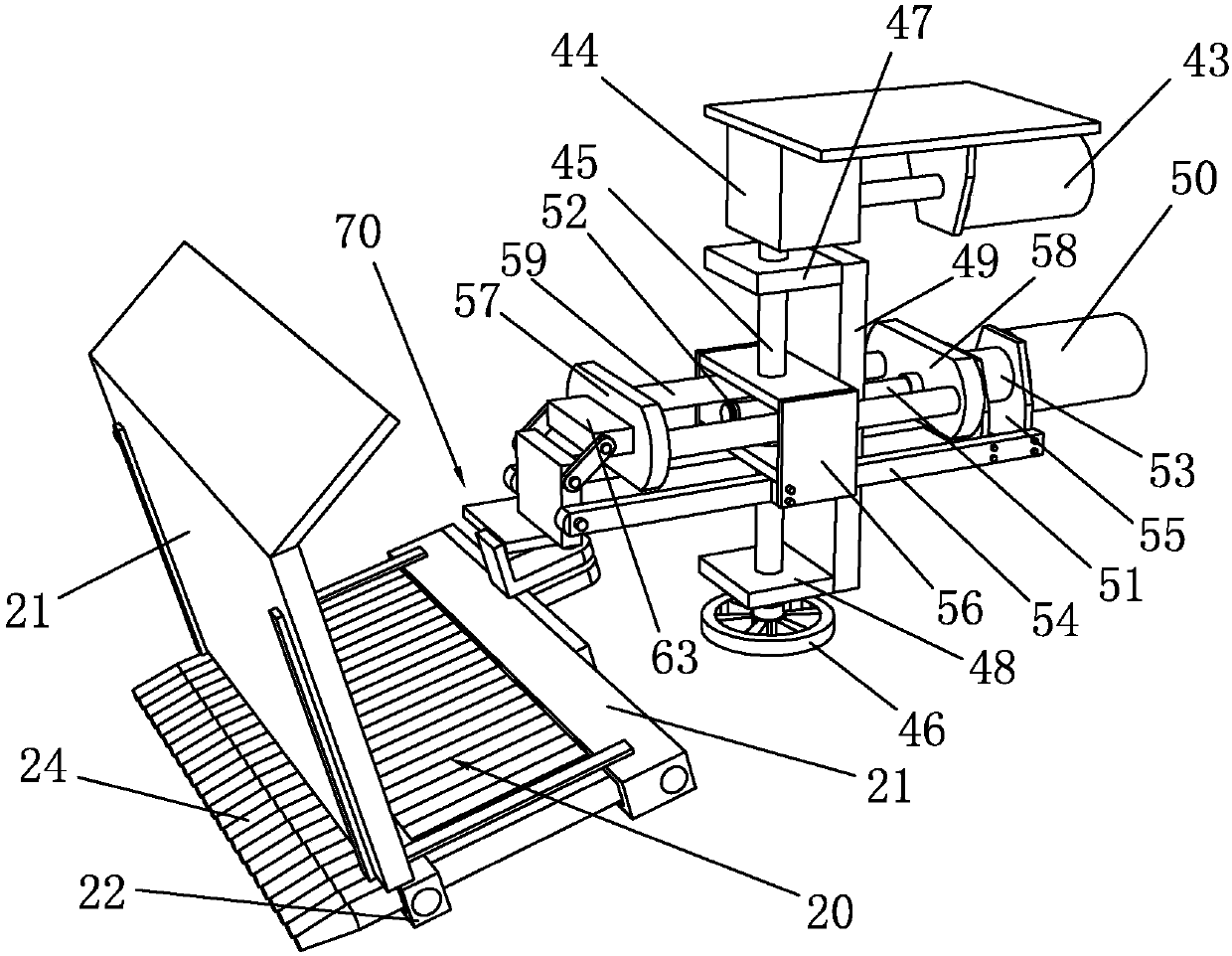

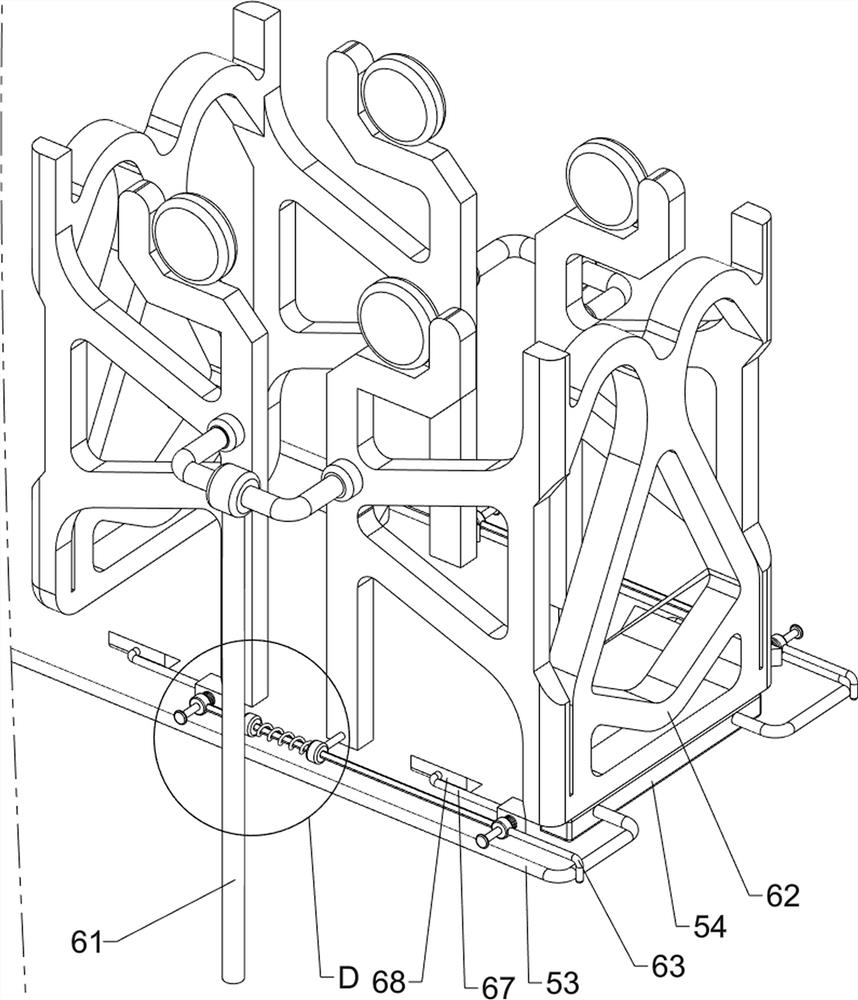

Rack milling and drilling center with feeding platform

InactiveCN103921128AEasy to moveMovement restrictionsWork clamping meansOther manufacturing equipments/toolsMulti axisMachining

The invention discloses a rack milling and drilling center with a feeding platform. The rack milling and drilling center comprises a workbench base, a workbench, a rack positioning structure and a first lead screw power head. The rack positioning structure is arranged on the workbench and comprises a rack base, a rack fixing pressure cylinder, a rack fixing pressurizing block, a rack positioning pressure cylinder and a rack positioning pressurizing block. The two sides of the rack base are provided with a plurality of counterbore machining power heads and a plurality of counterbore chamfering power heads respectively, the positions of the counterbore machining power heads correspond to the positions of the counterbore chamfering power heads one to one, the two ends of the rack base are respectively provided with a rack end face machining power head and a rack end face drilling power head, the rack end face drilling power heads are multi-axis power heads, and the feeding side of the rack base is provided with the rack feeding platform. According to the rack milling and drilling center, the full-automatic processes of rack machining feeding, positioning and clamping are achieved, and sequential machining of multiple working procedures can be achieved only through one-time clamping.

Owner:珠海市俊凯机械科技有限公司

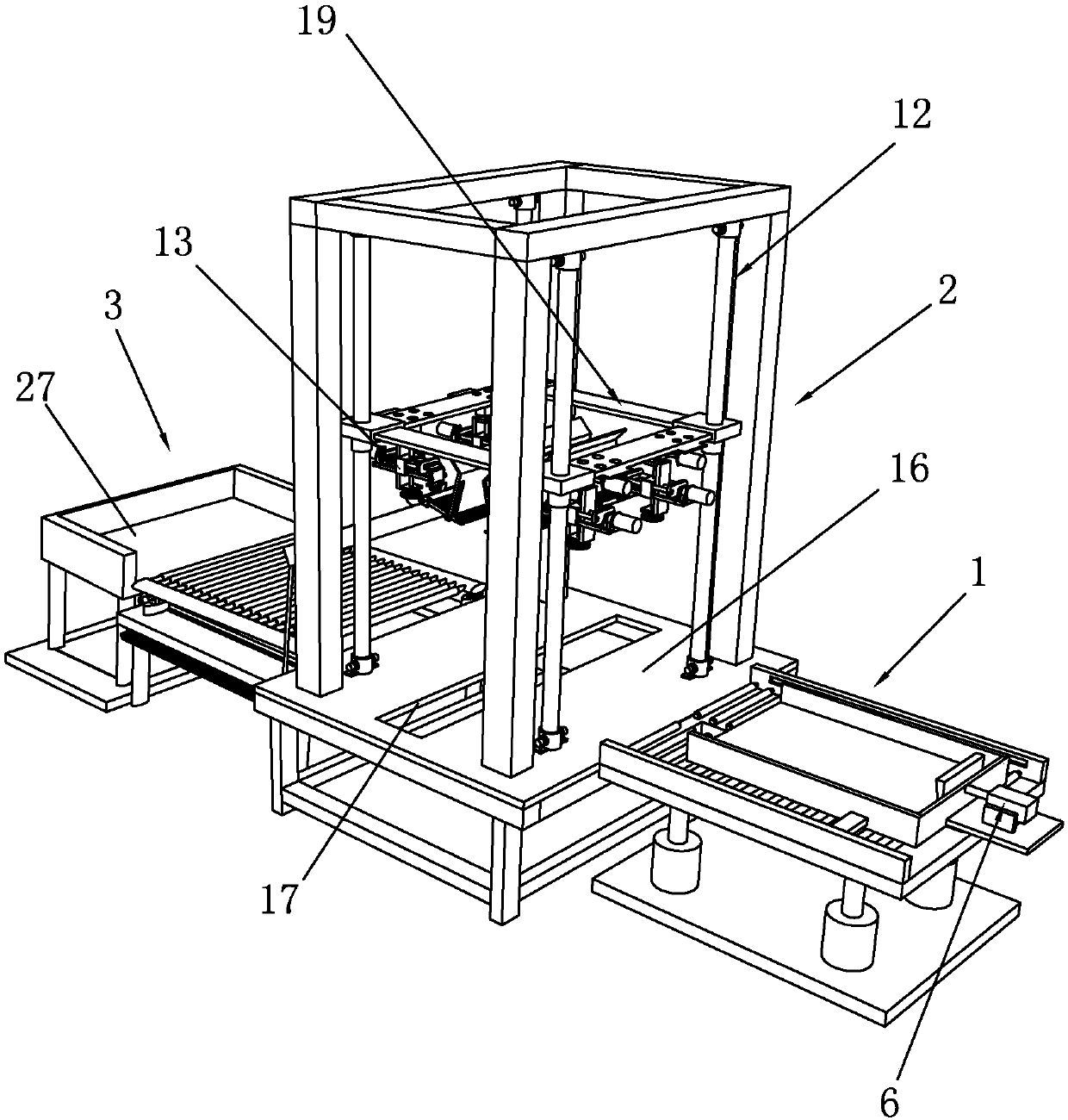

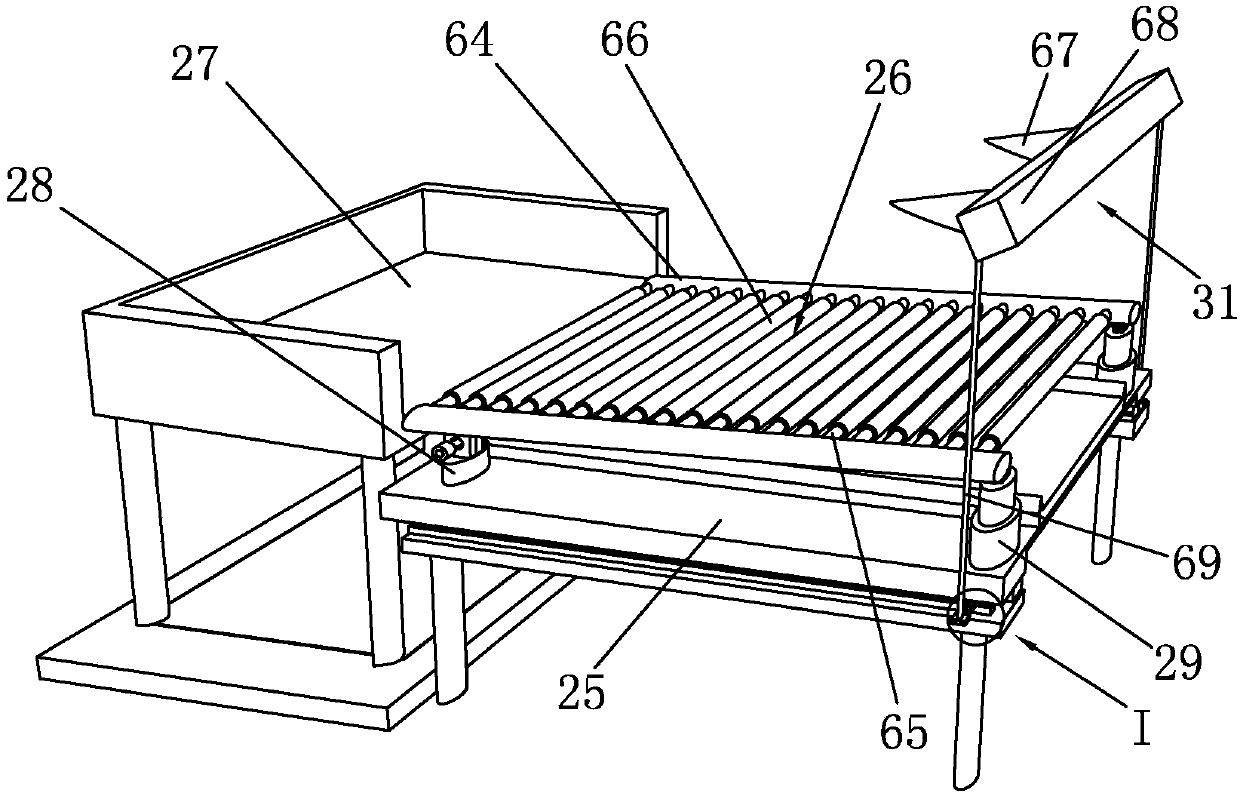

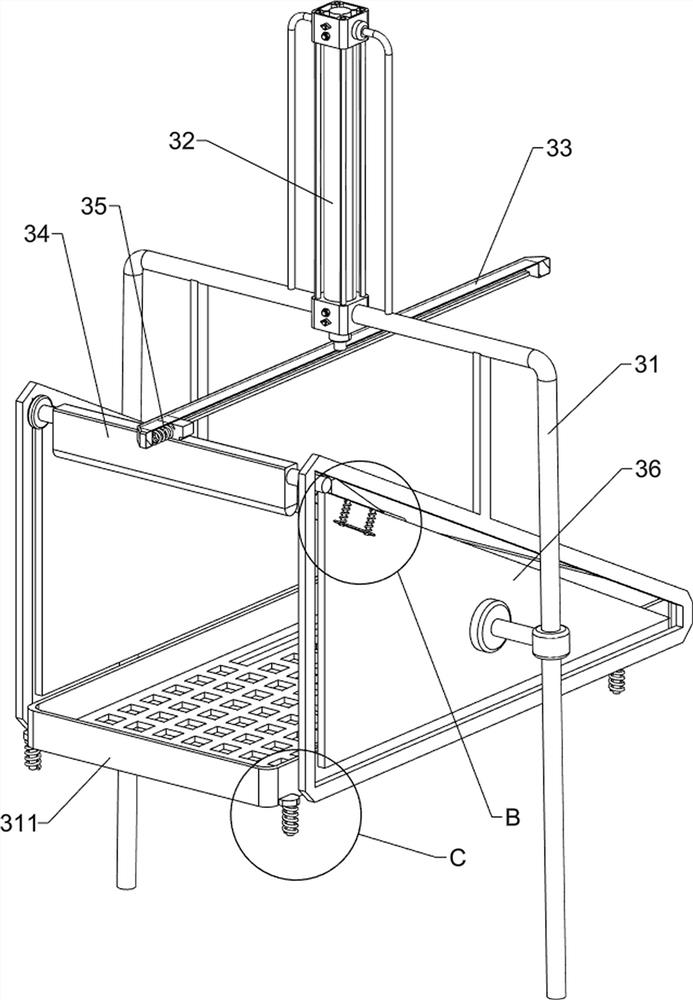

Linear flame welding machine and welding method thereof

ActiveCN107717171AEasy to handleIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

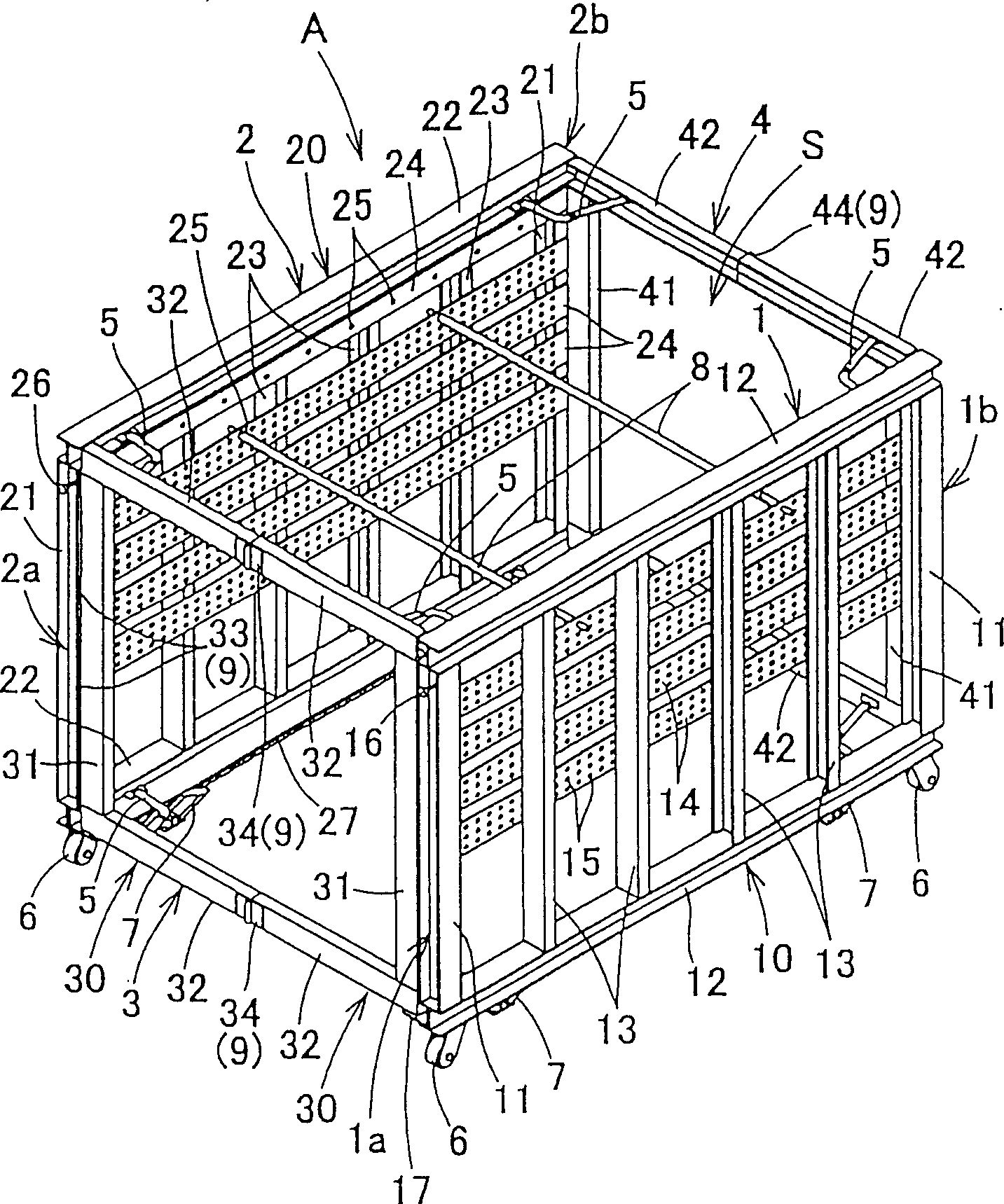

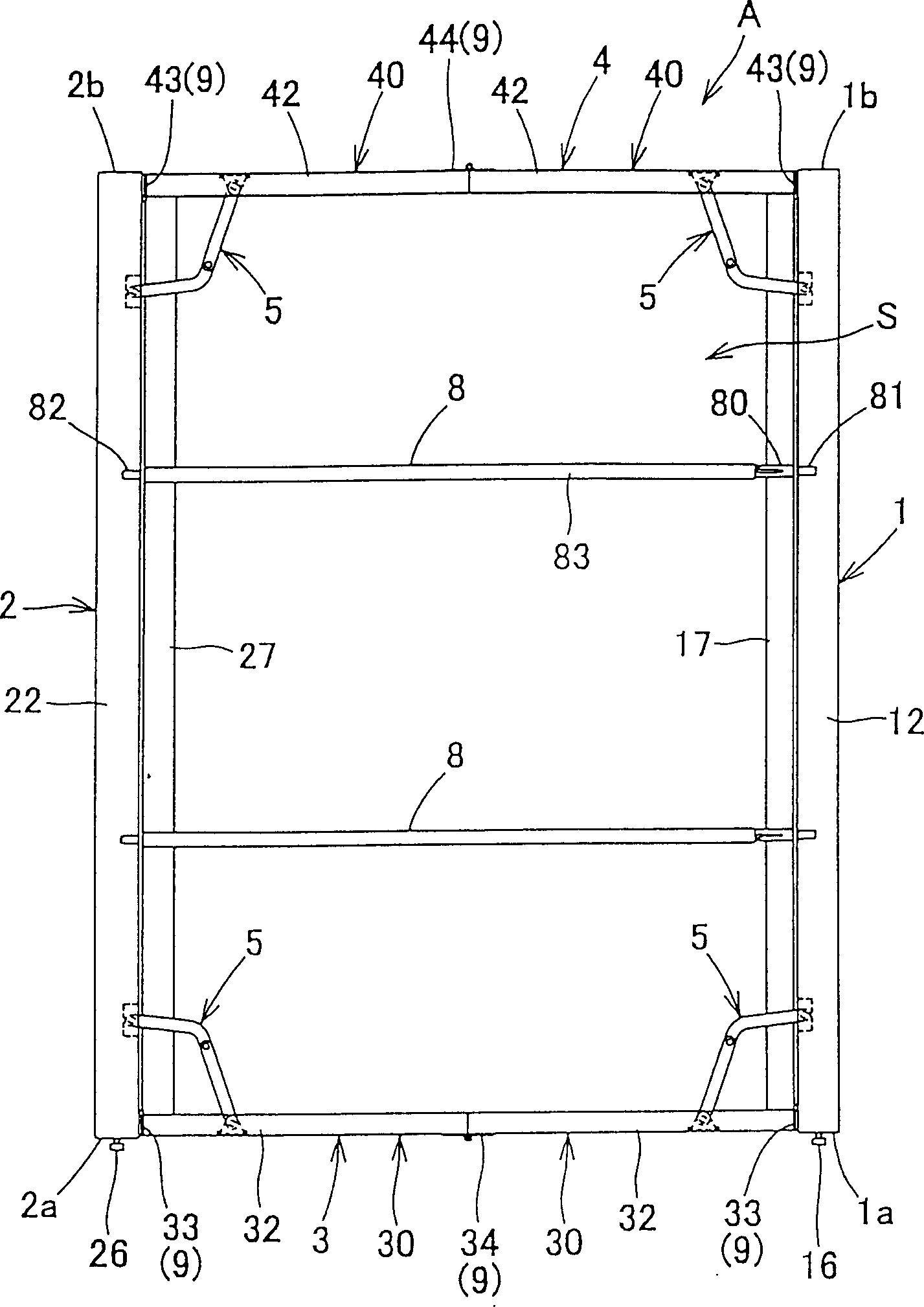

Holding box

InactiveCN1433937ANarrow down the place of storageReduce logistics costsGarmentsLarge containersGeneral purposeEngineering

The present invention provides a means capable of utilizing a general-purpose container such as a dry container and the like and capable of efficiently transporting hanger set clothes at a low cost. The storing box comprises connecting members 3, 4 for connecting each of the front ends 1a, 2a of a pair of side structures to each other and each of the rear ends 1b, 2b to each other. There is provided a bending means 9 for bending these connecting members inwardly. Its attitude can be changed between a developed attitude in which each of the connecting members 3, 4 is kept in its extended state and a storing space S for arranging a hanger pipe 8 is formed between a pair of side structures 1, 2 and a folded attitude in which each of the connecting members is folded inwardly, thereby the side structures are approached to each other.

Owner:DAIICHI FASHION SERVICE

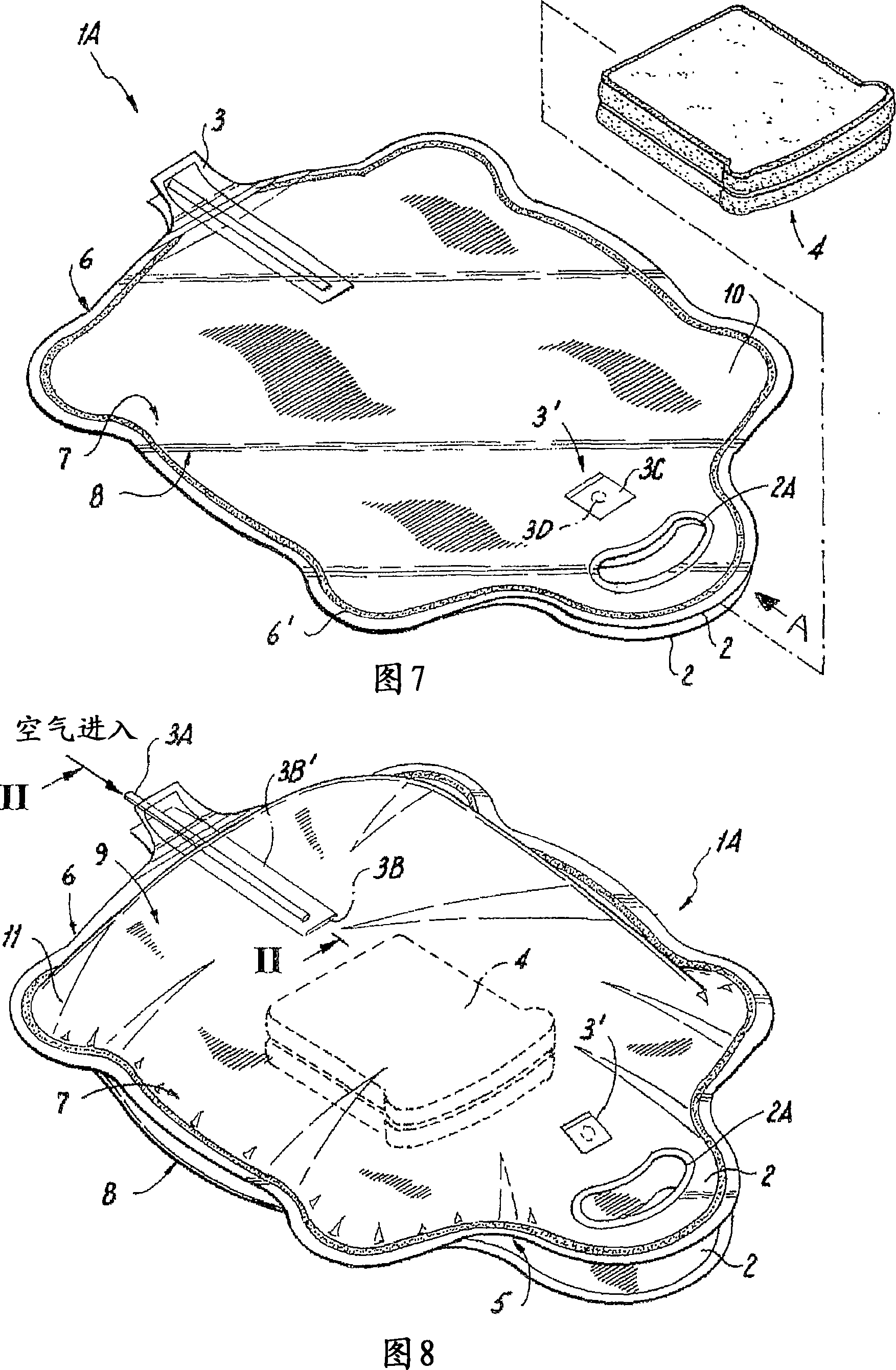

Carry device

In one embodiment a carry device includes a first inner carry pouch made from a first material and an outer bounding pouch or layer made from a second material defining at least one cavity therebetween. An access port may include a release and inflation actuator and provides volumetric access to the at least one cavity allowing passage of a pressurizing atmosphere or temperature effecting medium, or combination thereof. A sealable access is provided, and a common pressure is applied to an outer uniform-pressure region of a non-rigid or rigid item being carried thereby preventing damage and crushing thereof through high contact pressure gradients. In another embodiment handles are inflatable to aid sealing the inner carry pouch and provide a comfortable grip.

Owner:纽约布伊尔特股份有限公司

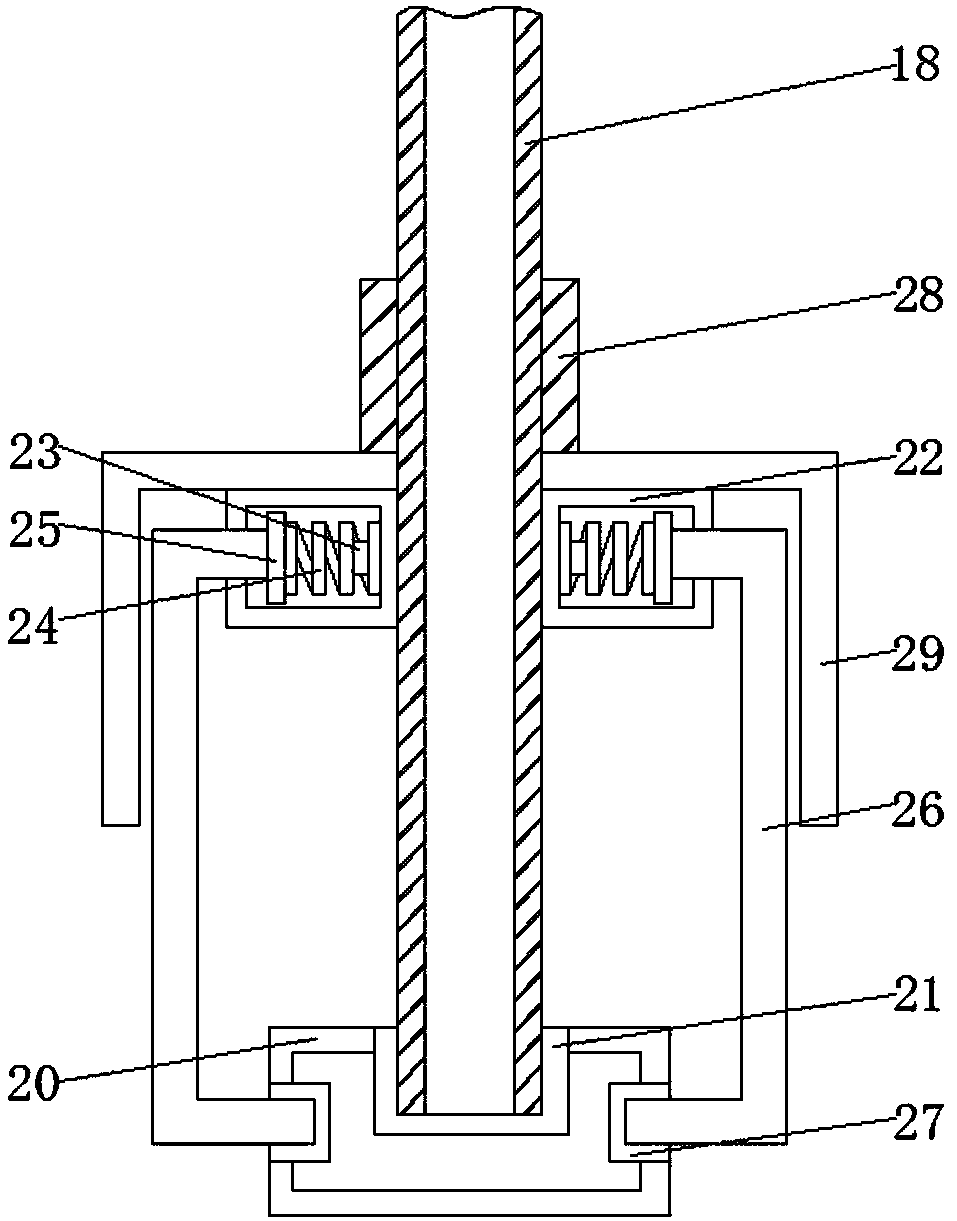

Eye drop packaging bottle

InactiveCN105662855AMovement restrictionsPharmaceutical containersMedical packagingPipetteEngineering

The invention discloses an eye drop packaging bottle which comprises a bottle body, a dropping pipette and a bottle cap. A piston assembly is connected in the bottle body in a sliding mode and comprises a piston body and a piston rod. Outer threads are formed on the piston rod. A one-way pushing groove is formed in the piston rod. The bottle body is connected with a nut part. Inner threads are formed on the inner wall of the nut part. A first clamping head is formed on the nut part, and a clamping opening is formed in the bottle body. A pushing block groove is formed in the outer wall of the upper portion of the nut part. A pushing block assembly is connected in the pushing block groove in a sliding mode and comprises a pushing block, an elastic plate and a pushing plate. A second clamping head is formed on the pushing block, and a strip-shaped clamping opening is formed in the pushing groove. An elastic plate inlet-outlet is formed in the pushing groove. Two spring grooves are formed on the pushing block. Springs are installed in the spring grooves. The pushing block groove is connected with a spring positioning column. Both the bottle body and the cap body can be respectively and integrally formed by plastic, and the eye drop packaging bottle is convenient to manufacture and low in cost.

Owner:由新英

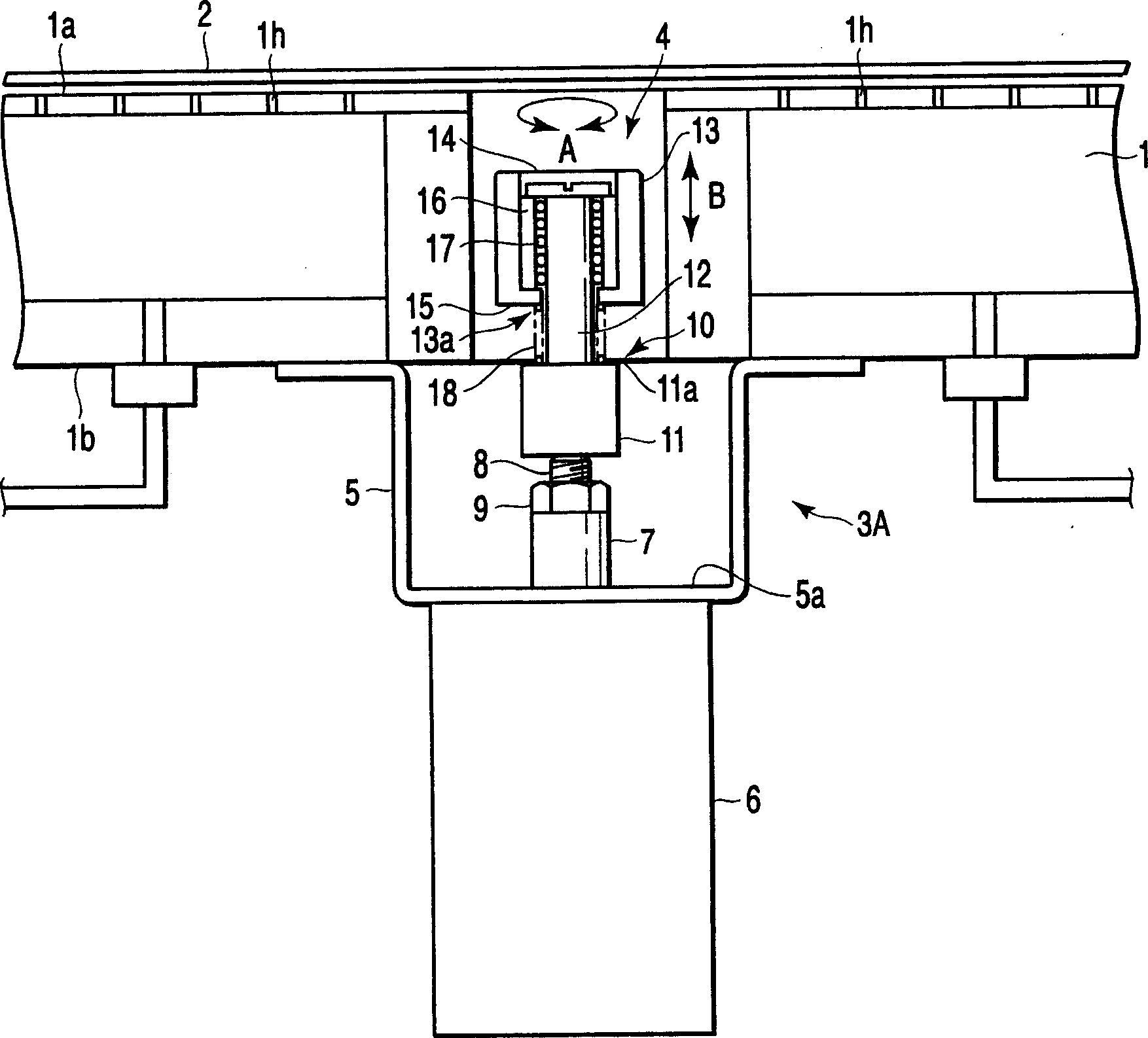

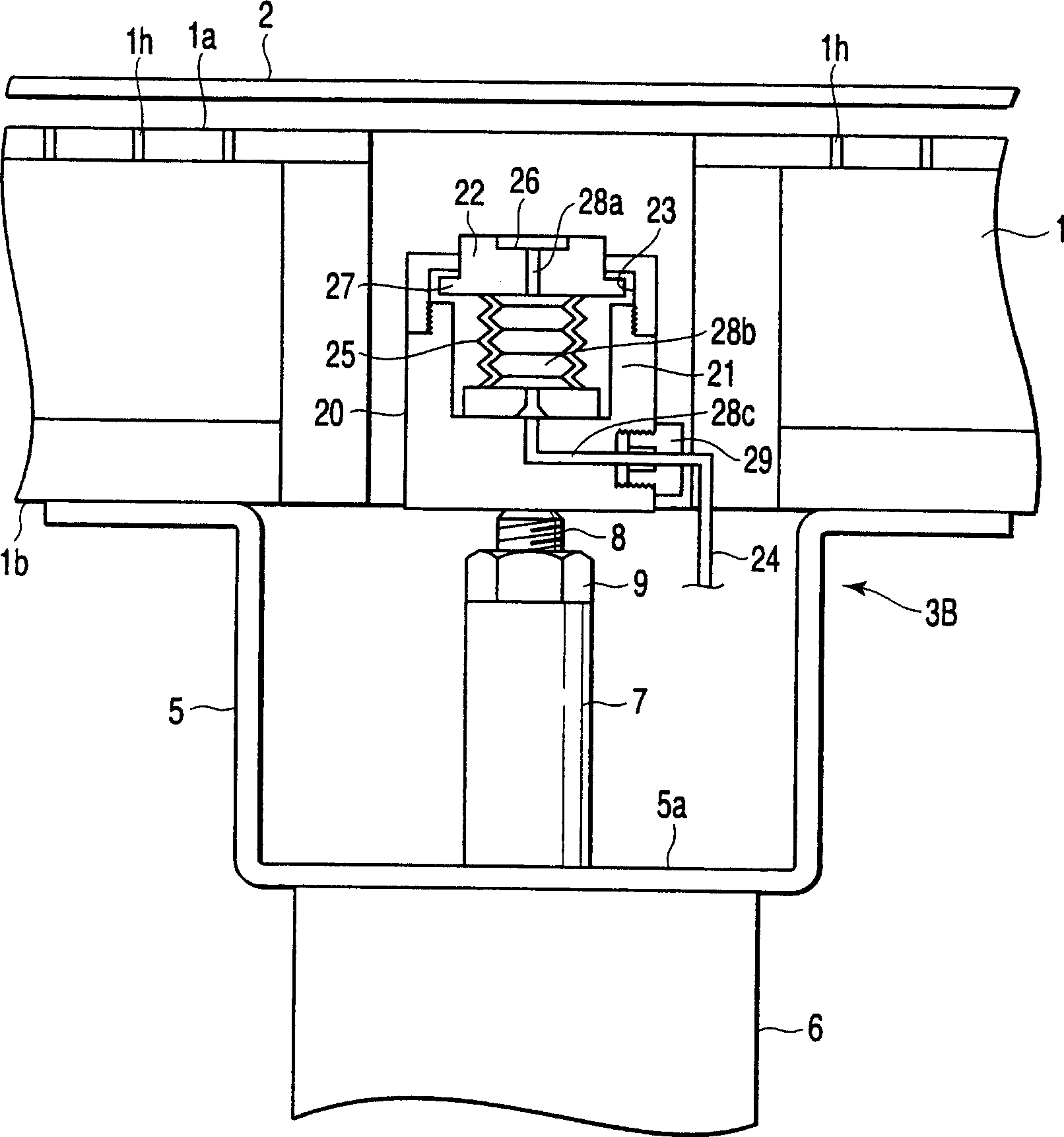

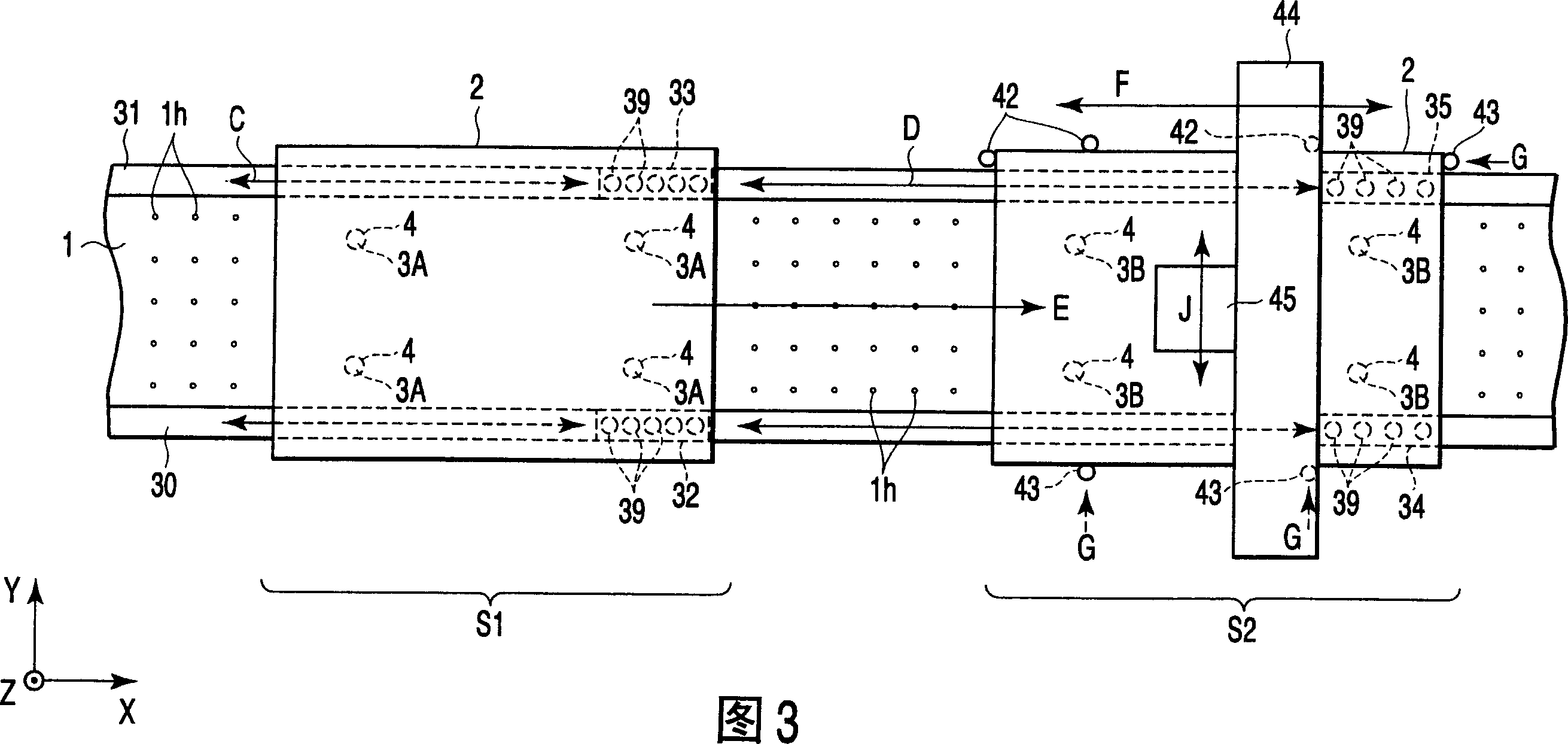

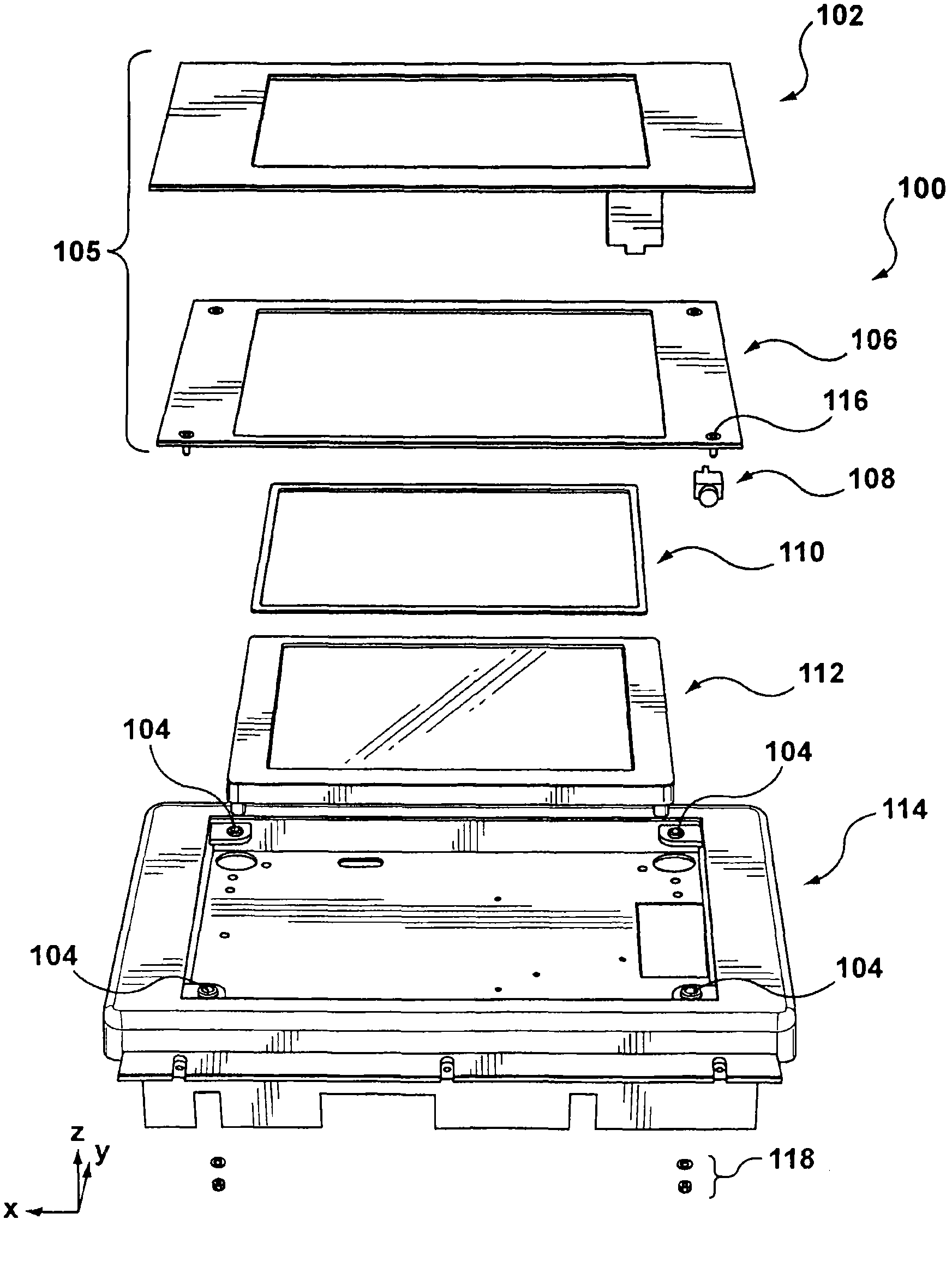

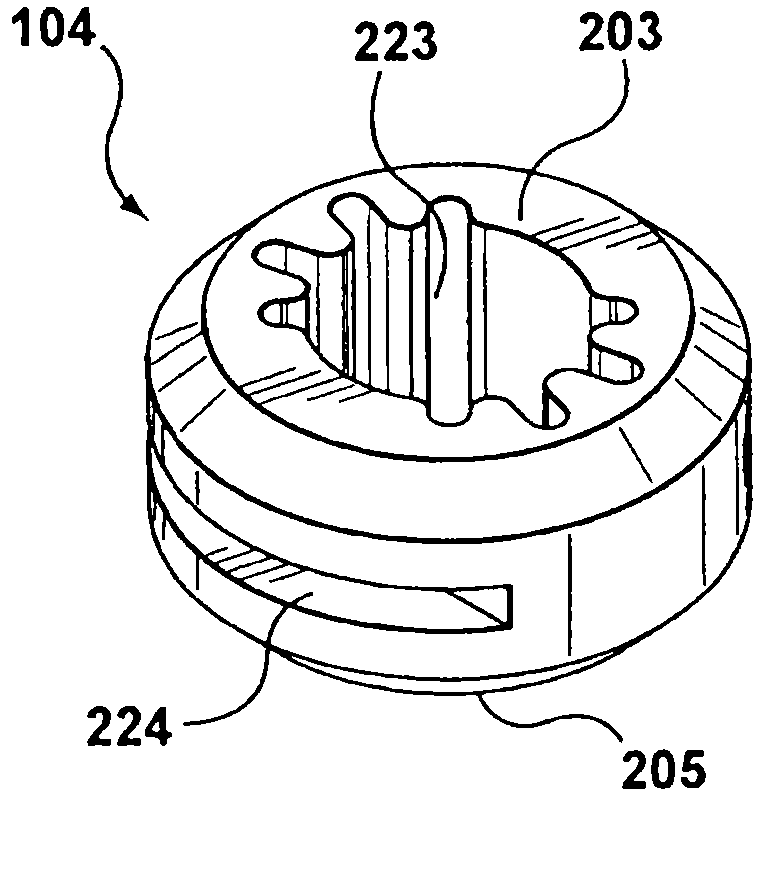

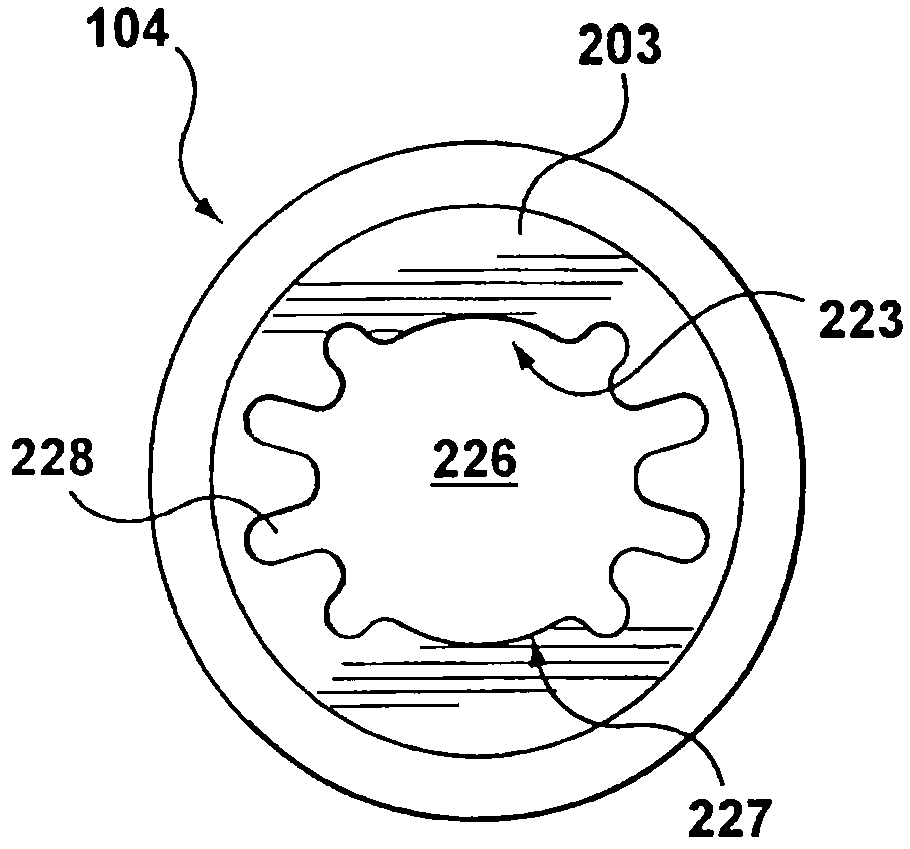

Grommet suspension component and system

InactiveCN102221930AMovement restrictionsInput/output processes for data processingEngineeringGrommet

A compliant grommet-based suspension system is disclosed for use in mounting an electronic touch screen or touch surface. The grommets may be designed to provide more or less movement in any direction, i.e., along the x-axis, the y-axis, and / or the z-axis, depending on the suspension application in which they are implemented.

Owner:IMMERSION CORPORATION

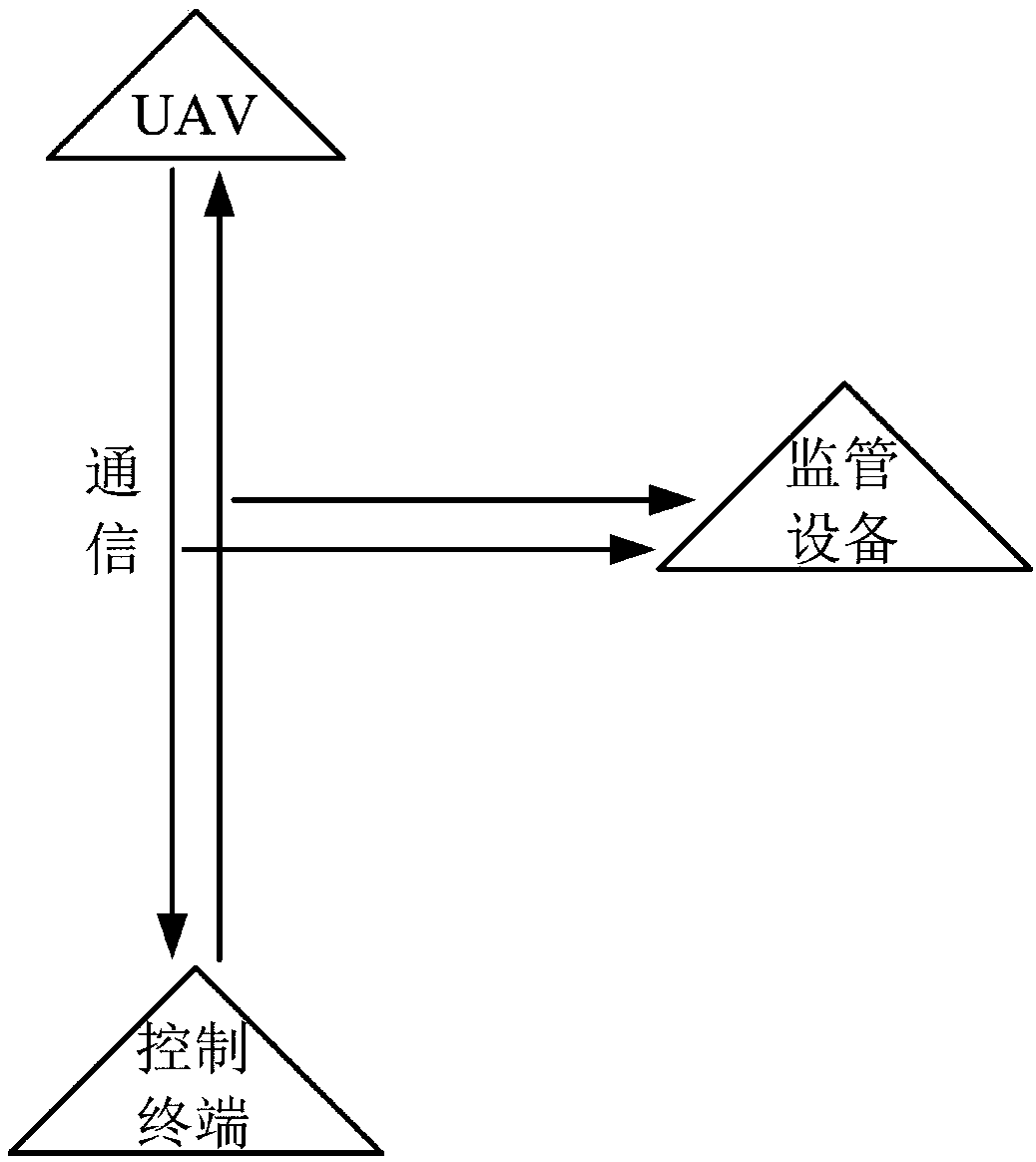

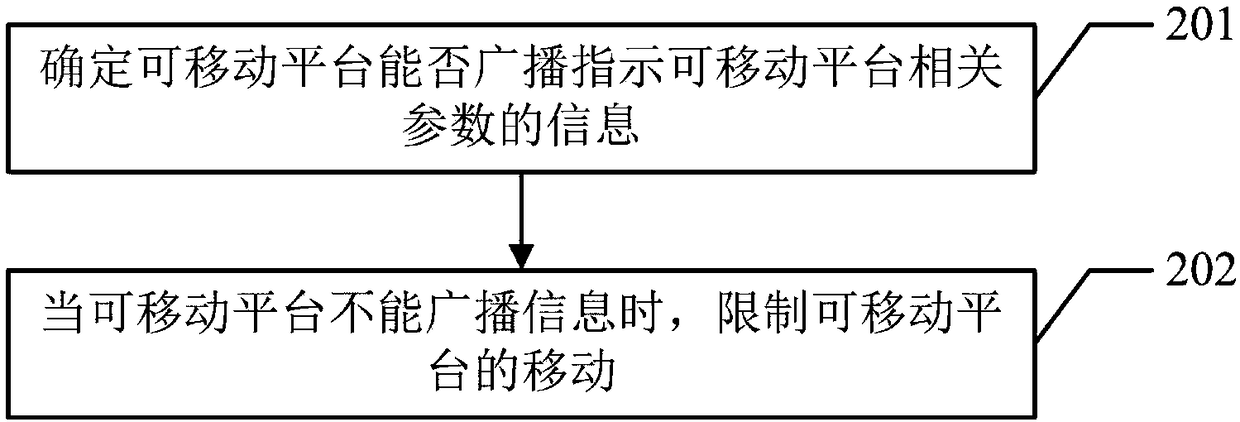

CONTROL METHOD FOR MOVABLE PLATFORM AND MOVABLE PLATFORMz

ActiveCN108513640AMovement restrictionsEffective monitoringAircraft componentsReceivers monitoringEngineeringPotential risk

Owner:SZ DJI TECH CO LTD

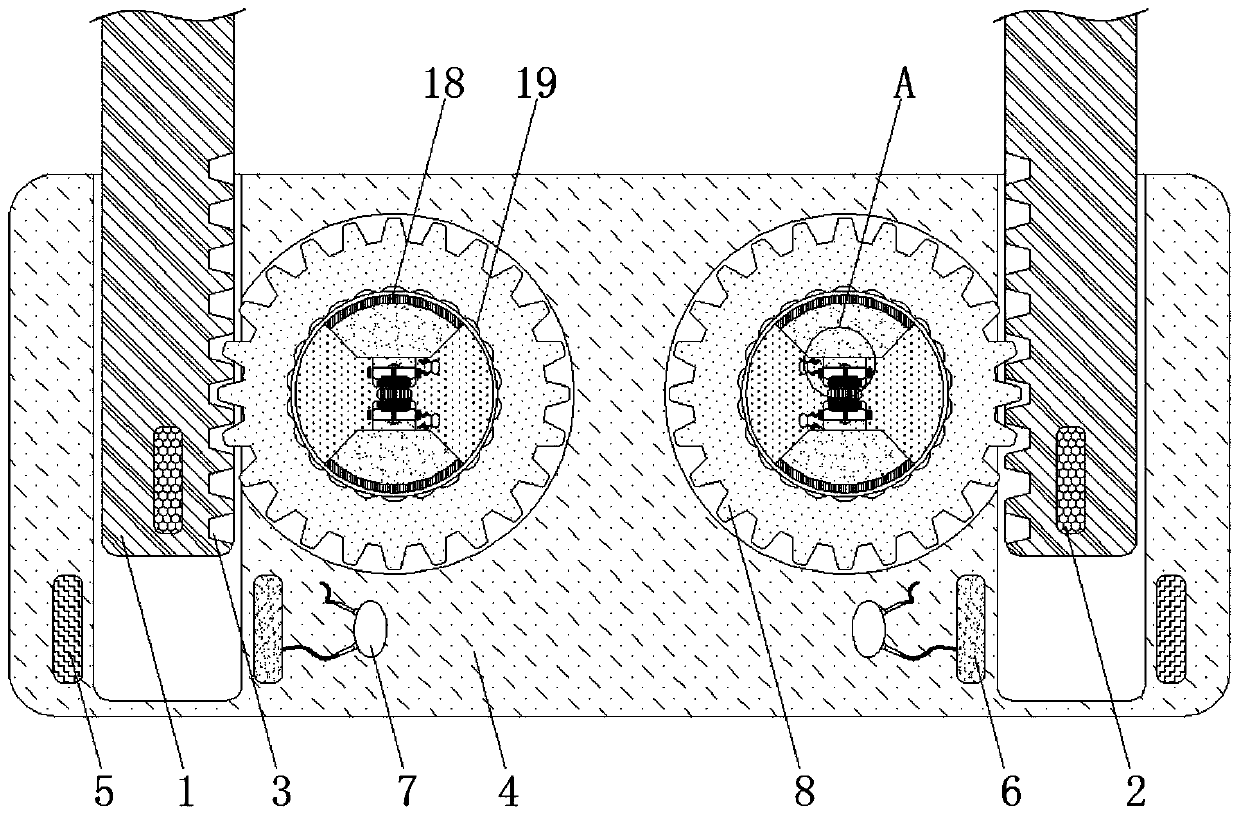

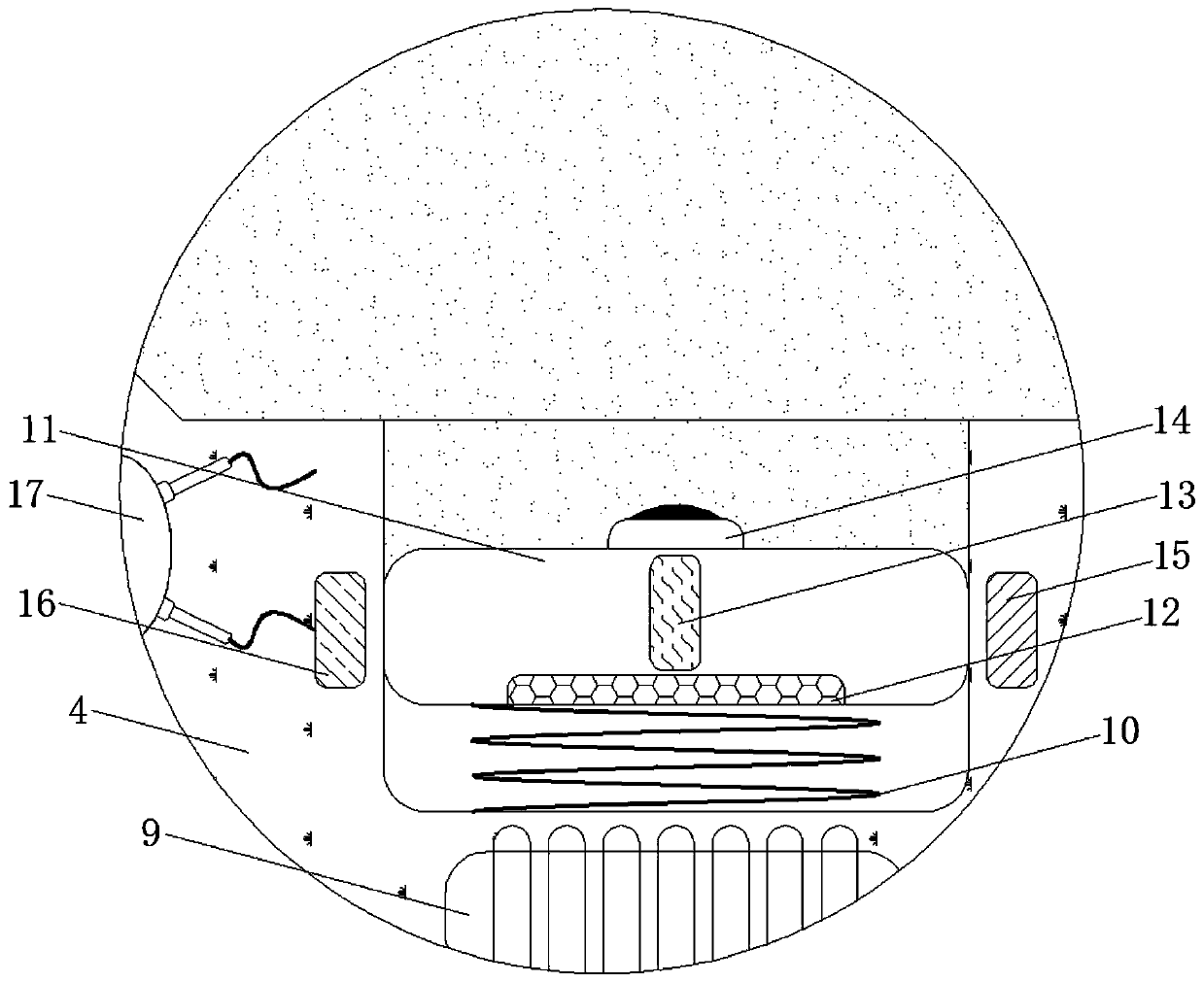

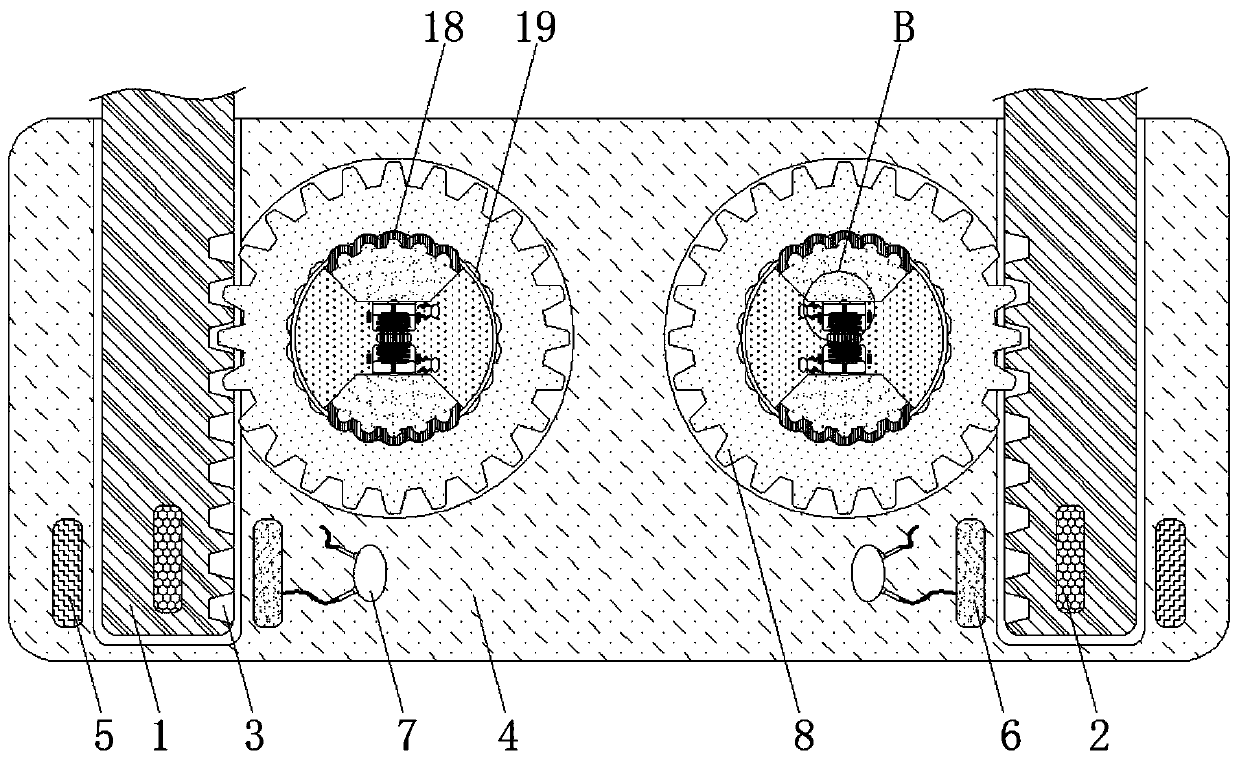

Electrorheological fluid-based socket unit for non-medical entertainment equipment

InactiveCN111585110AEasy to useMovement restrictionsCoupling device detailsDielectric plateEngineering

The invention discloses a socket unit for non-medical entertainment equipment based on electrorheological fluid. A plug relates to the technical field of non-medical health information consultation and comprises a plug body, a first dielectric plate is fixedly connected to the middle of the plug body, uniformly distributed tooth grooves are formed in the inner side of the plug body, a shell is inserted into the bottom of the plug body, and a first positive plate is fixedly connected to the inner wall of the shell and close to the outer side of the plug body. The invention discloses an electrorheological fluid-based socket unit for non-medical entertainment equipment. The gear is matched with the rubber plate for use; when the plug is completely inserted into the shell; at the moment, the piston block extrudes the electrorheological fluid to the outer side; when the piston block moves to the outermost side, the electrorheological fluid is changed into a solid state, the clamping connection between the rubber plate and the clamping groove is enhanced, the rotation of the gear is limited, and the movement of the plug is further limited, so that the effect of preventing the plug from being pulled out by mistake is achieved, and the stable use of entertainment equipment is ensured.

Owner:杭州承隆健康咨询有限公司

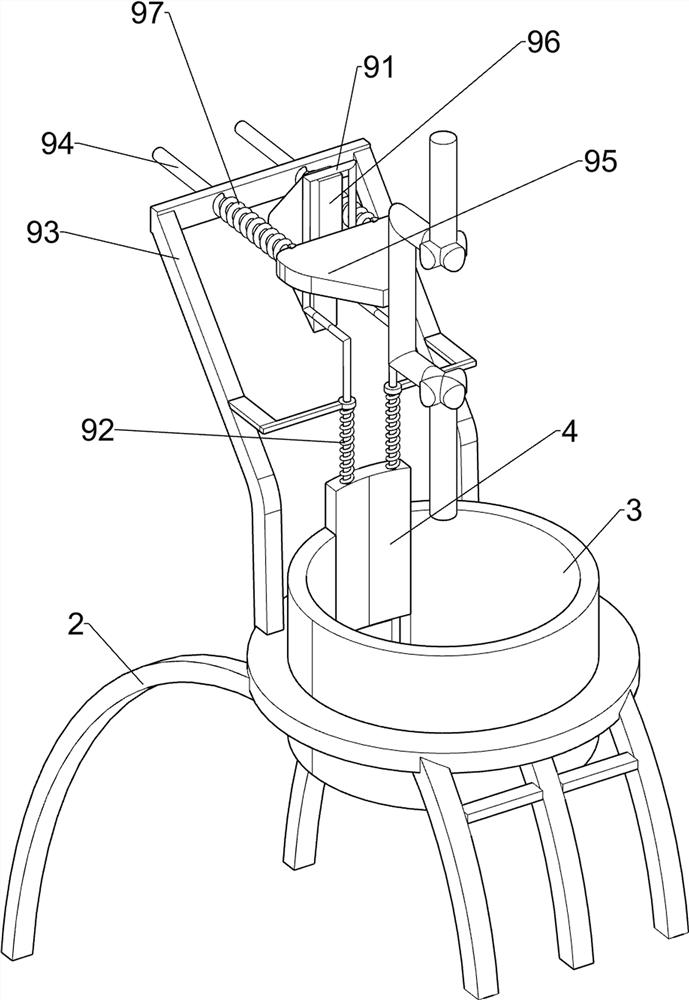

External variable-resistance anti-stall furniture coating stirring auxiliary device

InactiveCN111530364AAvoid wastingRheostat increaseTransportation and packagingMixer accessoriesStructural engineeringCentrifugal force

The invention discloses an external variable-resistance anti-stall furniture coating stirring auxiliary device, and relates to the technical field of furniture. The device comprises a rotating shaft,uniformly distributed clamping grooves are formed in the outer side of the rotating shaft, a mounting base is clamped to the outer side of the rotating shaft, uniformly distributed first springs are fixedly connected to the inner side of the mounting base, clamping blocks clamped to the clamping grooves are fixedly connected to the inner sides of the first springs, and uniformly distributed sliding grooves are formed in the inner wall of the mounting base. According to the external variable-resistance anti-stall furniture coating stirring auxiliary device, the variable resistance block and theconductive block are matched for use, when the rotating shaft rotates, the mounting base is driven to rotate simultaneously, and the centrifugal force of the mounting base drives the sliding block tomove outwards and drives the conductive block to move outwards at the same time so that the resistance value of each resistor is increased, the resistance of the whole circuit is increased, the voltage of the circuit is reduced, the effect of preventing the rotating shaft from stalling is achieved, waste of paint is effectively prevented, and it can be guaranteed that the coating is not accumulated on the outer side.

Owner:山东鑫联胜运输有限公司

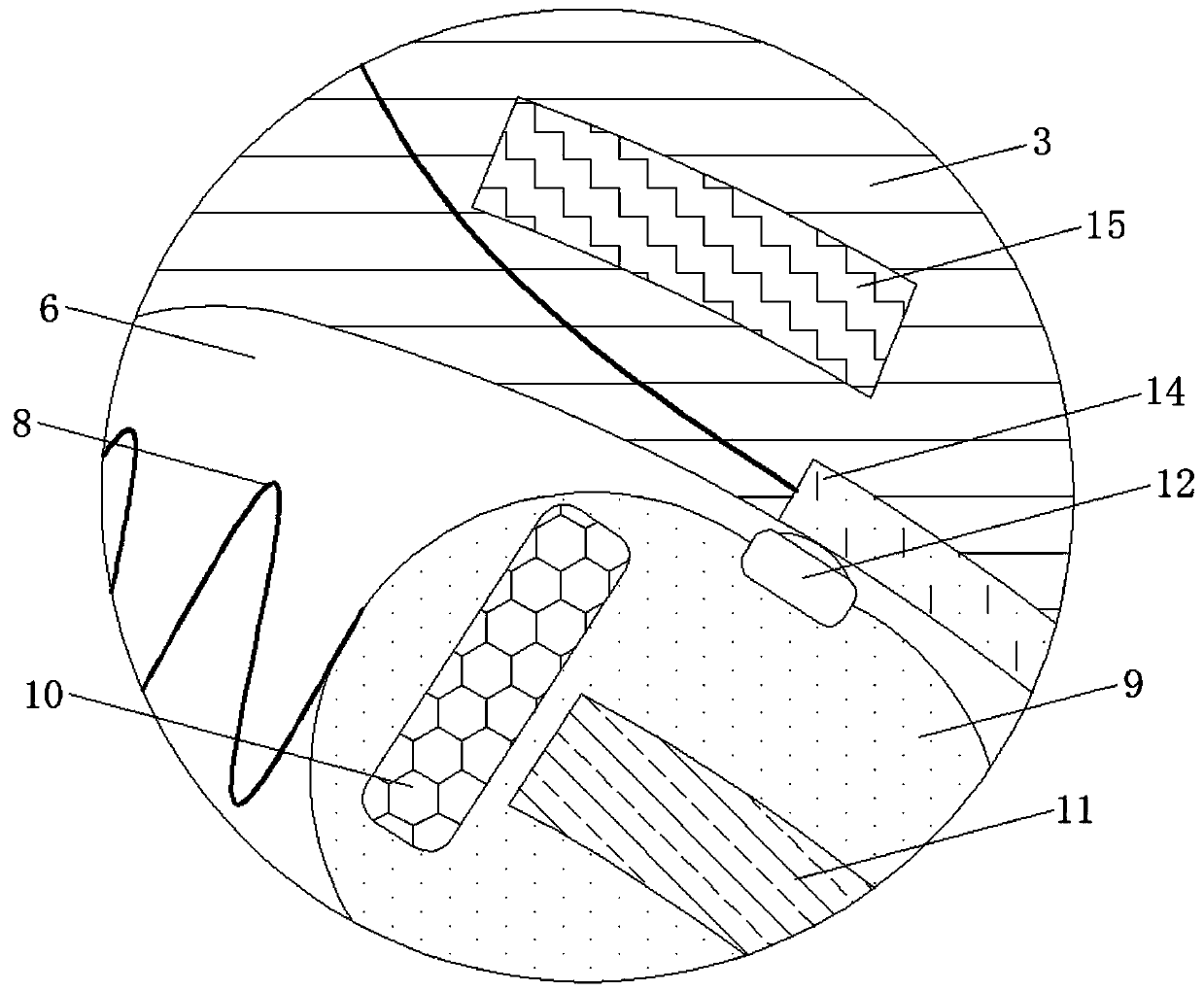

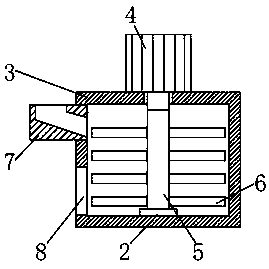

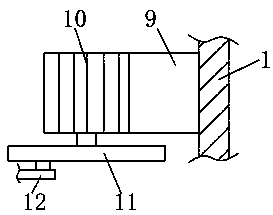

Motor permanent magnet fixing device

InactiveCN103441593AIncrease profitLimit horizontal movementMagnetic circuit rotating partsElectric machineEngineering

A motor permanent magnet fixing device solves the problem that in the prior art, a permanent magnet in a permanent magnet motor can easily fall off and comprises permanent magnets, a rotor support and a fixing piece. The rotor support and the fixing piece fix the permanent magnets. The motor permanent magnet fixing device is characterized in that the fixing piece comprises a non-permeability fixing block and a non-permeability inner hexagon bolt, each permanent magnet is provided with a locating slope, the non-permeability fixing block is provided with a slope face and a limiting face respectively, the length of the slope face is the same as the length of the locating slope of each permanent magnet, the threads of the bolt penetrate through a through hole of the rotor support and are connected with a thread hole of the non-permeability fixing block, the slope face of the non-permeability fixing block is matched with the locating slope of the permanent slope in inclined angle, tight contacting is achieved, and the non-permeability fixing block is used for fixing each permanent magnet on the rotor support. The motor permanent magnet fixing device is simple in structure, reasonable in design, easy to manufacture and capable of achieving fixing of the permanent magnets in a motor under any air gap size, the permanent magnets are evenly distributed and can be effectively prevented from falling off, mounting efficiency and permanent magnet using rate are improved, and permanent magnet materials are saved.

Owner:SHENYANG YUANDA INTELLECTUAL IND GRP CO LTD

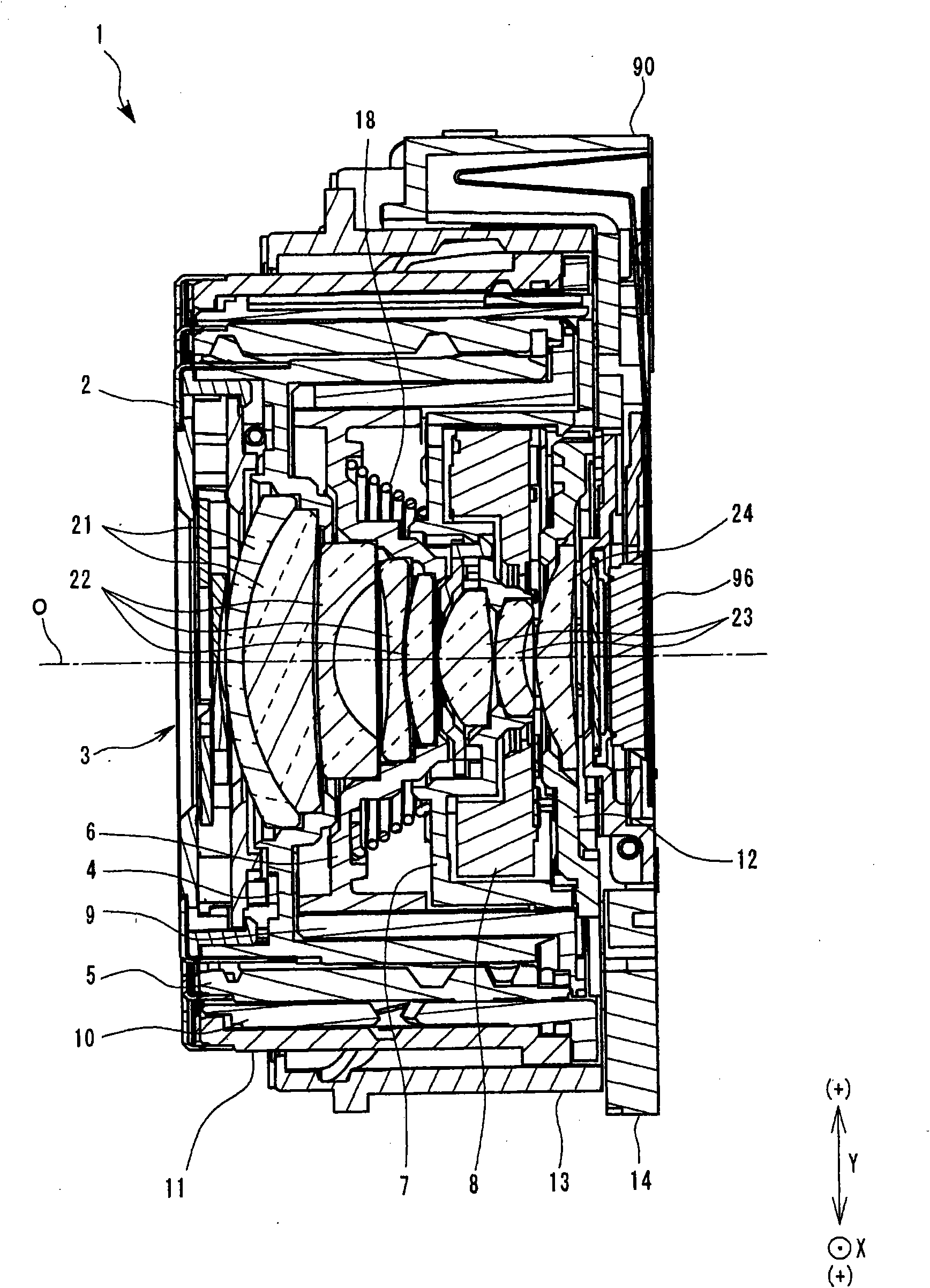

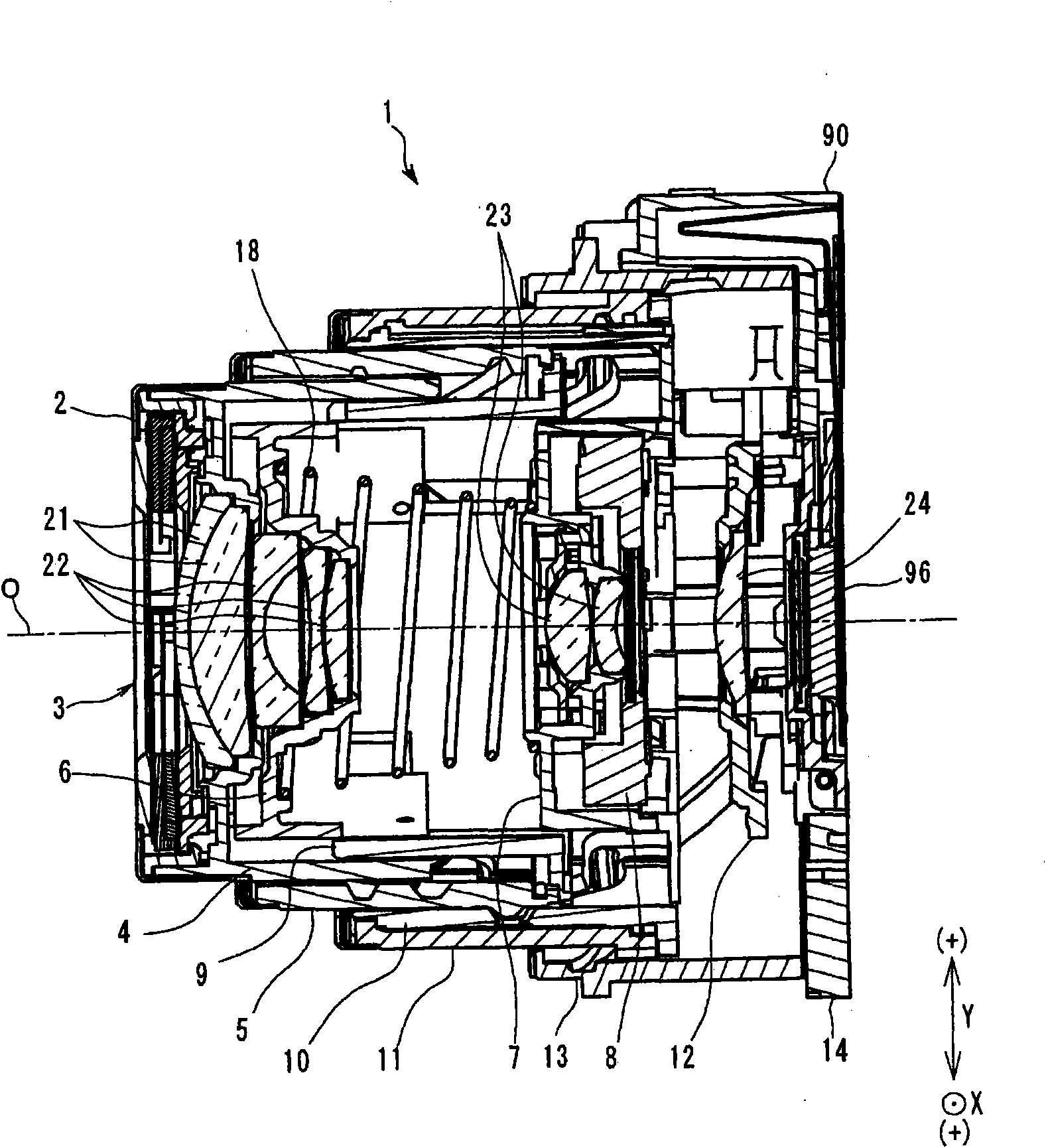

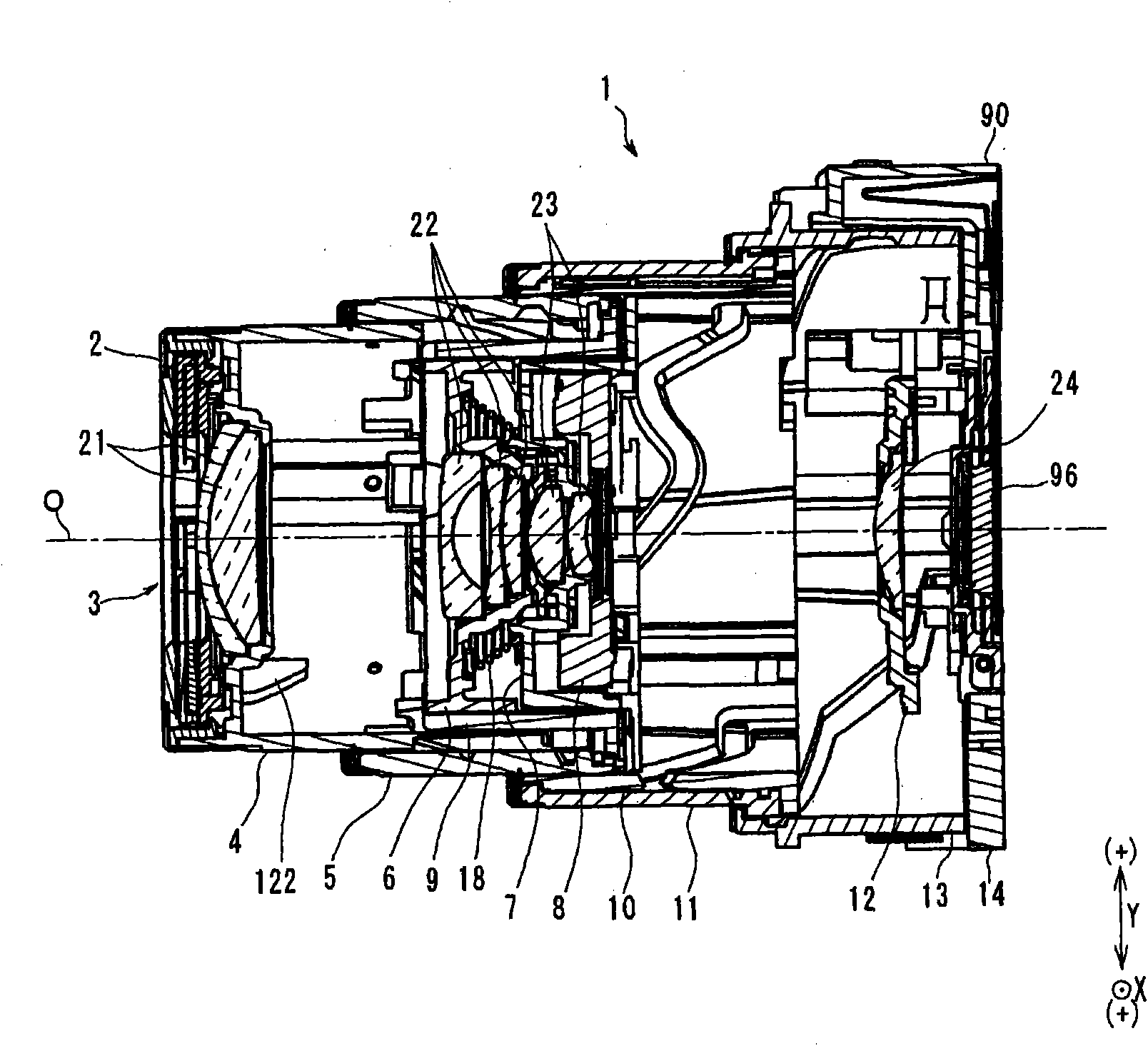

Lens barrel

The present invention provides a lens barrel, including a fixed frame having a cam groove, one end part of which arranged on a first direction side is an open end; a rotary frame having a plurality of cam followers on its peripheral surface; a first gear wheel arranged on the peripheral surface of the rotary frame; a second gear wheel joggled with the first gear wheel; and an electric motor for driving the second gear wheel to rotate, and making the rotary frame to move toward the first direction by rotating the rotary frame toward a second rotating direction. The lens barrel is characterized in that the lens barrel is provided with a convex part on the open end, and the convex part prevents the cam followers from moving toward the radial outer side when the rotation of the rotary frame toward the second rotating direction is limited by a butting part.

Owner:OLYMPUS CORP

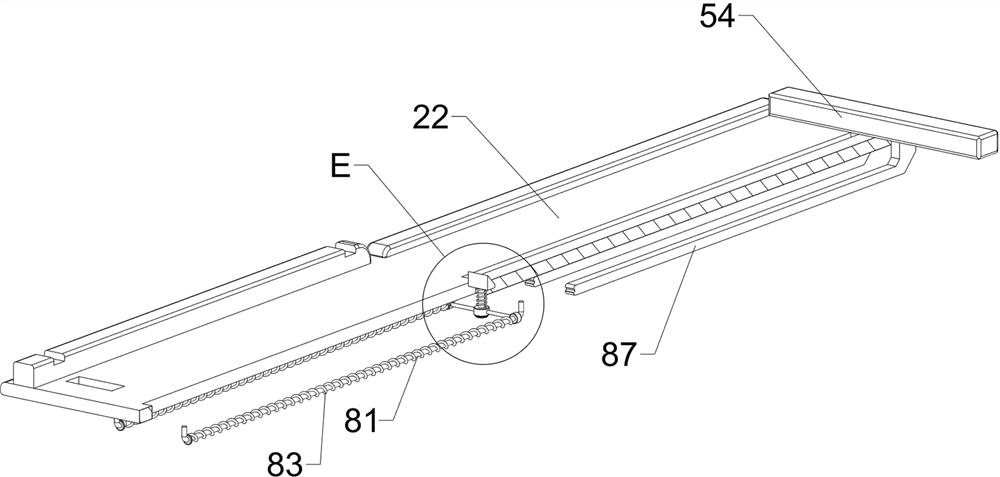

Office keyboard key printing equipment

ActiveCN112895698AAchieve automatic pushTo achieve the effect of auxiliary dischargeElectric switchesRotary pressesKey pressingSoftware engineering

The invention relates to printing equipment, in particular to office keyboard key printing equipment. The office keyboard key printing equipment which can complete keyboard key printing through simple operation, automatically, sequentially and quantitatively feed, automatically push out a keyboard and conveniently slide down the keyboard and collect the keyboard is provided. According to the technical solution, the office keyboard key printing equipment comprises a base and a printing assembly, wherein a placing assembly is arranged on the upper portion of the base, the printing assembly is arranged between one side of the upper portion of the base and the placing assembly. According to the office keyboard key printing equipment, a first connecting rod moves leftwards to be away from a second connecting rod, under the action of a sixth spring and a seventh spring, a third wedge-shaped block is pushed to move towards the left inner side, a fourth wedge-shaped block is driven to move towards the left inner side, remaining keyboards are ejected up, the effects of facilitating feeding and automatically and quantitatively feeding in sequence are achieved, and the printing efficiency is improved.

Owner:成都戴德网络科技有限公司

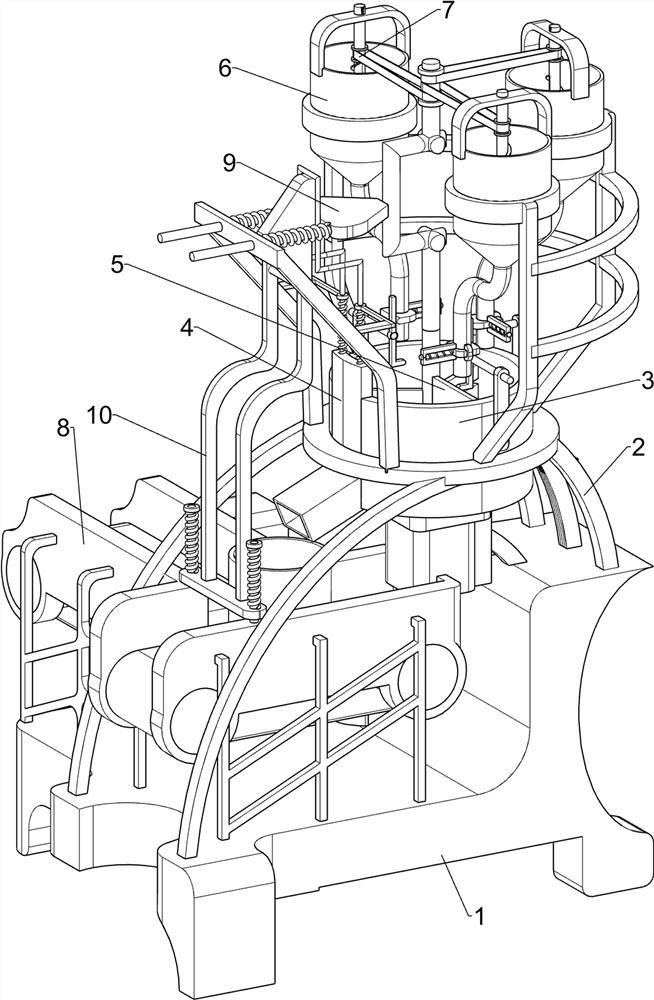

Wiring construction device for power equipment installation

ActiveCN112744739AStable supportGuaranteed stabilityLifting framesApparatus for overhead lines/cablesArchitectural engineeringElectric power equipment

The invention discloses a wiring construction device for power equipment installation. The wiring construction device comprises a base, wherein a frame is installed on the base, four guide rods are externally sleeved with guide blocks, the four guide blocks are jointly and fixedly connected with a placement box, anti-falling self-locking pieces are arranged between the placement box and the four guide rods, a lifting mechanism is arranged between the four anti-falling self-locking pieces and the upper end of the frame, a sliding groove is formed in the bottom of the base, a sliding plate is slidably connected into the sliding groove, four universal wheels are installed at the bottom of the sliding plate, and a driving mechanism is arranged between the sliding plate and the inner top of the sliding groove. The wiring construction device is reasonable in structure, the base and the frame can be stably supported, the stability during working is guaranteed, meanwhile, the placement box can be prevented from shaking, stable installation of power equipment is guaranteed, the placement box has an anti-falling function, accidents can be effectively avoided, and economic losses are reduced.

Owner:陕西恒德信义电力设备有限公司

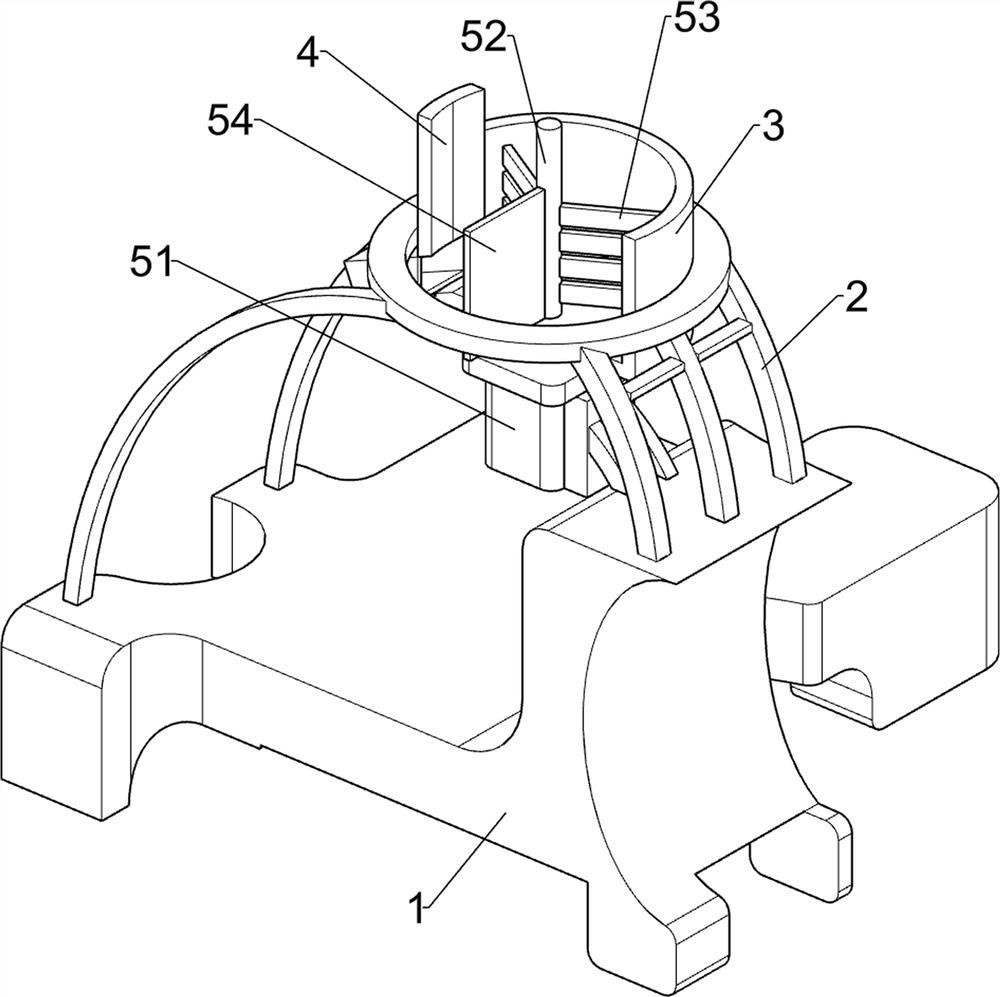

Multi-feed stirring equipment for animal husbandry

PendingCN113069955AAchieve stirring effectAchieve the effect of automatic feedingFeeding-stuffRotary stirring mixersAnimal scienceAgricultural science

The invention relates to stirring equipment, in particular to multi-feed stirring equipment for animal husbandry. The invention provides the multi-feed stirring equipment for animal husbandry, which has the advantages of automatic feeding and automatic stirring and is simple and convenient. The multi-feed stirring equipment for animal husbandry comprises a bottom plate, a support, a stirring barrel, a baffle, a stirring mechanism and an interval discharging mechanism; and the support is arranged on the bottom plate; the stirring barrel is arranged on the support; the baffle is arranged on the stirring barrel in a sliding manner; the stirring mechanism is arranged between the bottom plate and the stirring barrel; and the interval discharging mechanism is arranged between the support and the stirring barrel. A first servo motor is started, an output shaft of the first servo motor rotates to drive a first rotating shaft to rotate, so that a stirring plate and a scraping plate are driven to rotate, and when feed falls into a stirring barrel, the stirring effect is achieved.

Owner:张引

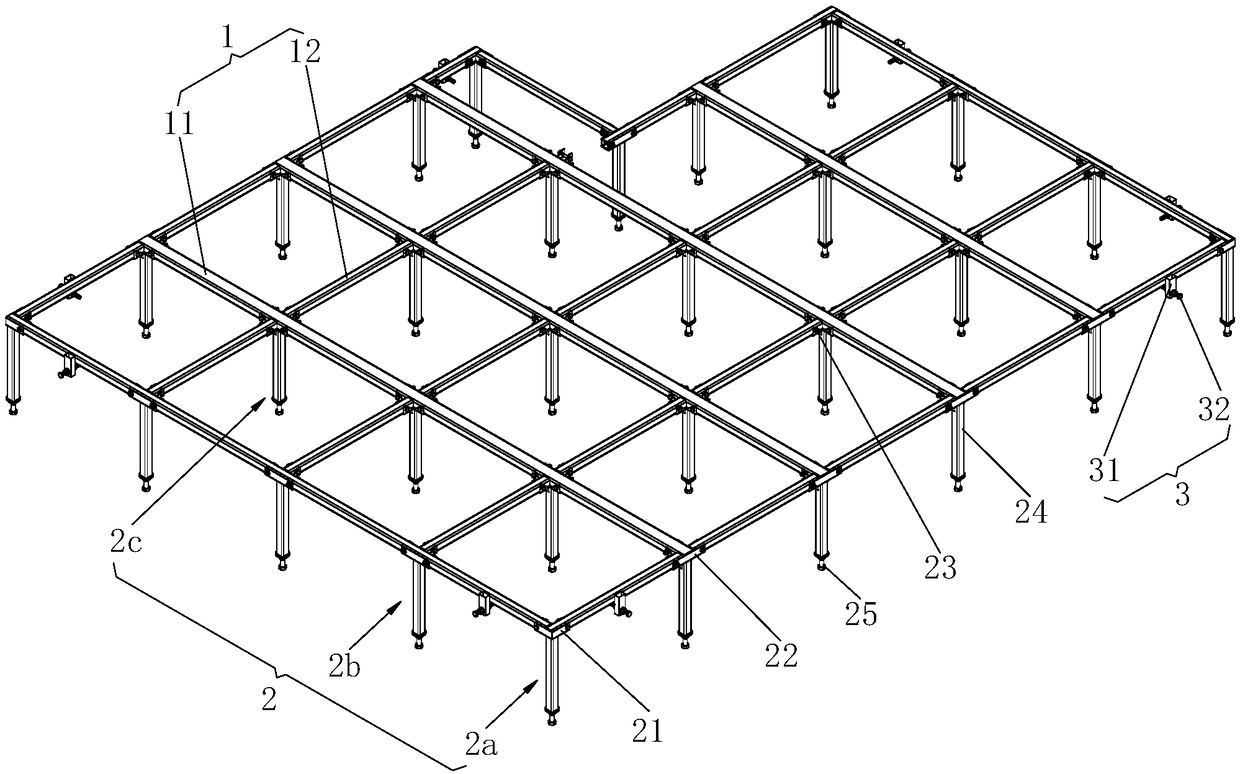

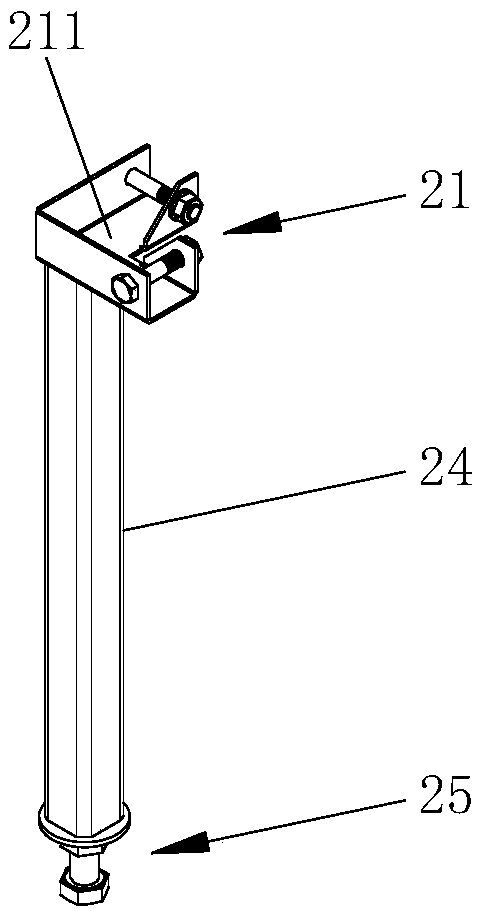

Overhead steel frame and mounting method thereof

The invention discloses an overhead steel frame and a mounting method thereof. The overhead steel frame comprises keels, a vertical supporting frame and a transverse supporting frame. The keels constitute a rectangular platform, and the keels in the rectangular platform are in a net shape. The vertical supporting frame is used for supporting the keels and adjusting the heights of the keels, and the transverse supporting frame is fixed to the keels at the four edges of the rectangular platform to prevent the keels from moving relative to the wall surface. The overhead steel frame is stable in structure and low in keel leveling difficulty.

Owner:重庆互邦莱装配式建筑工程有限公司

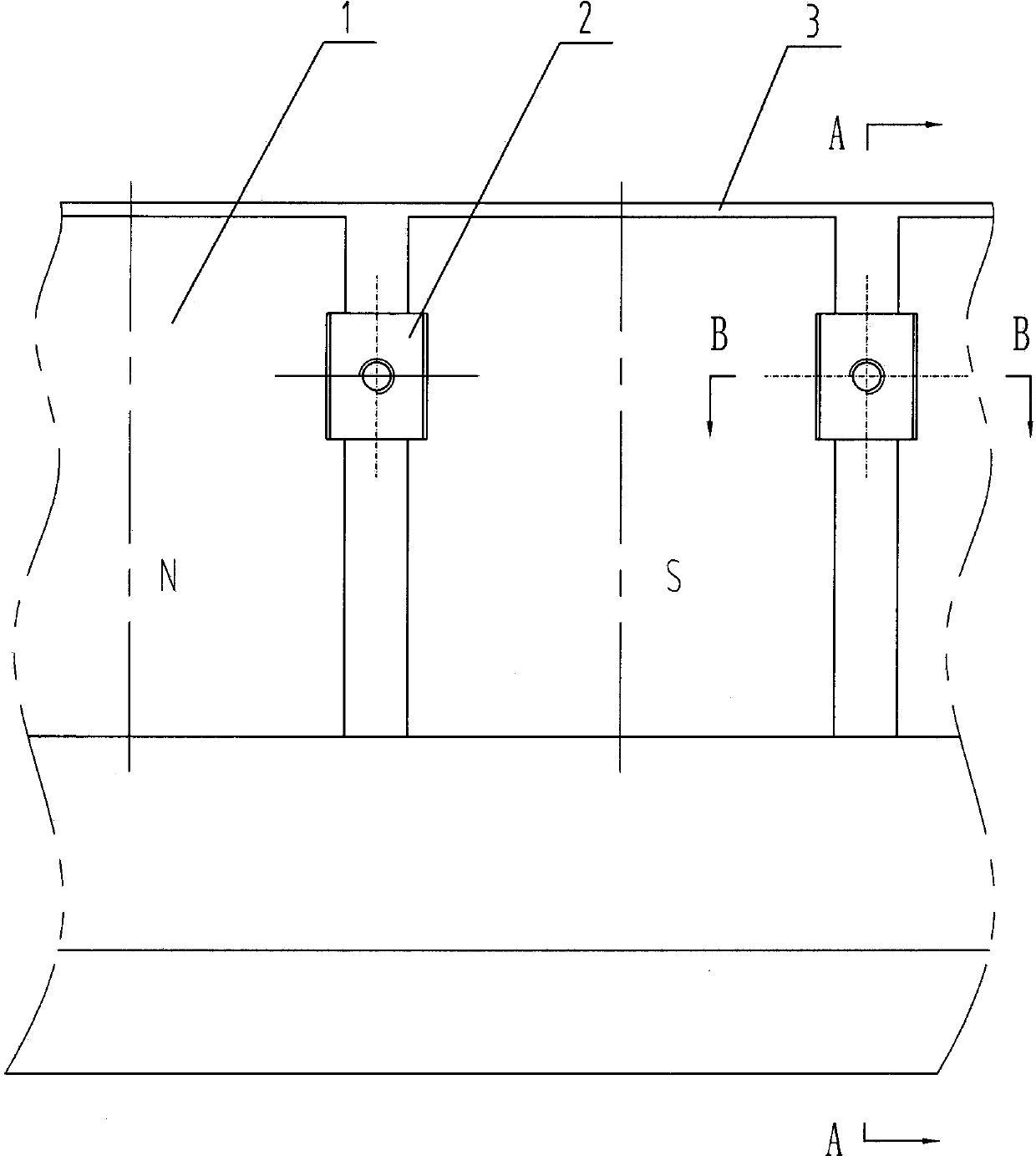

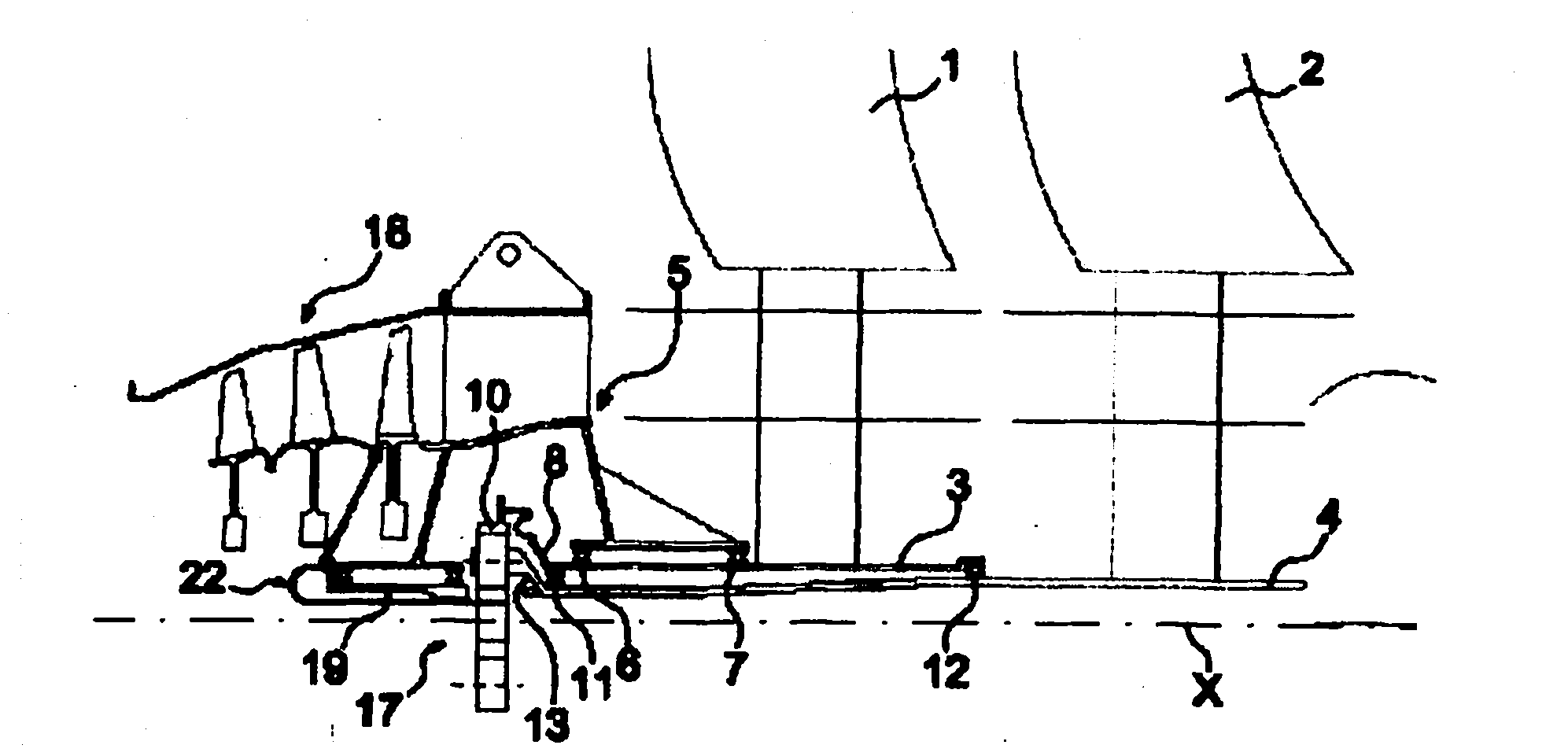

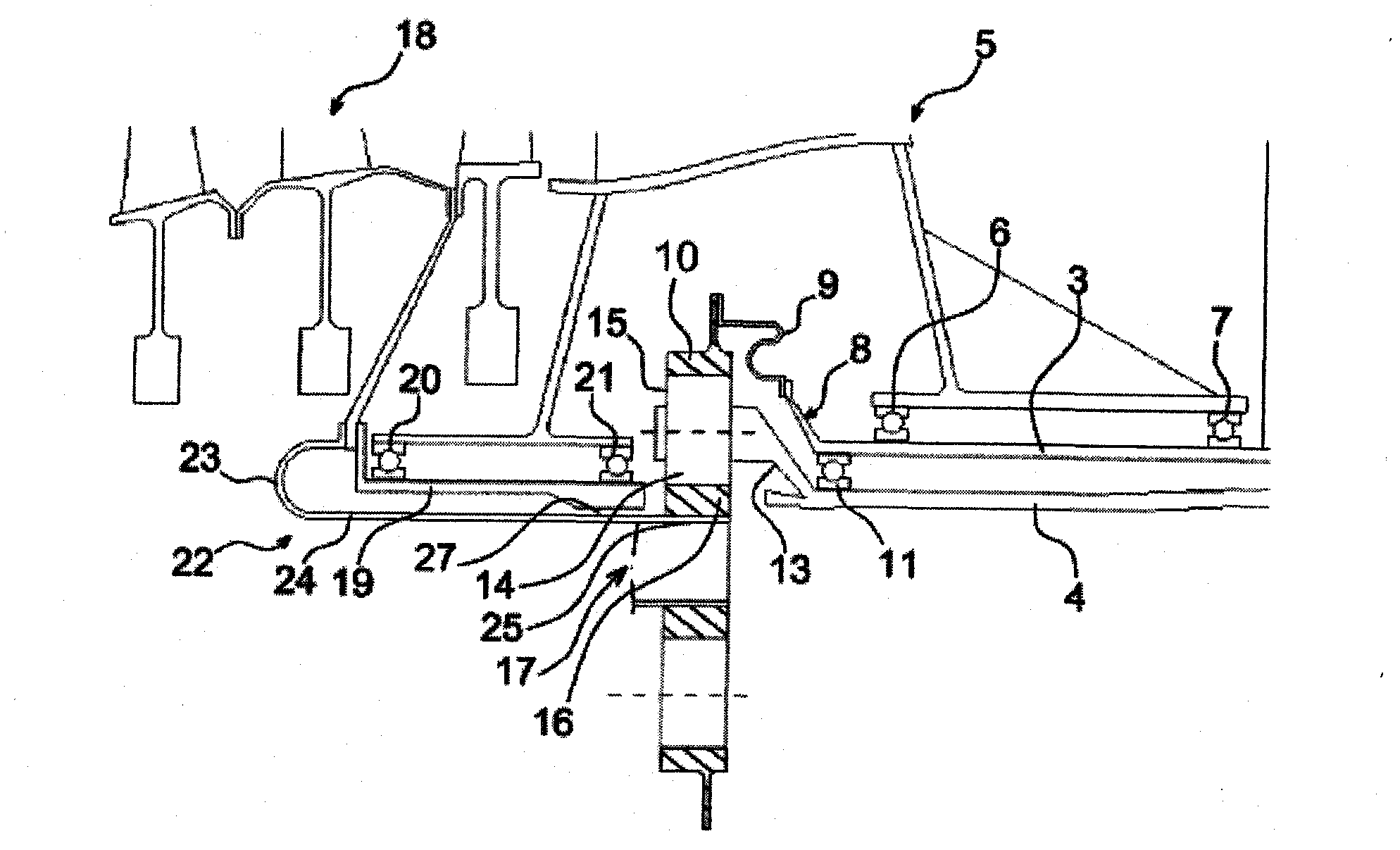

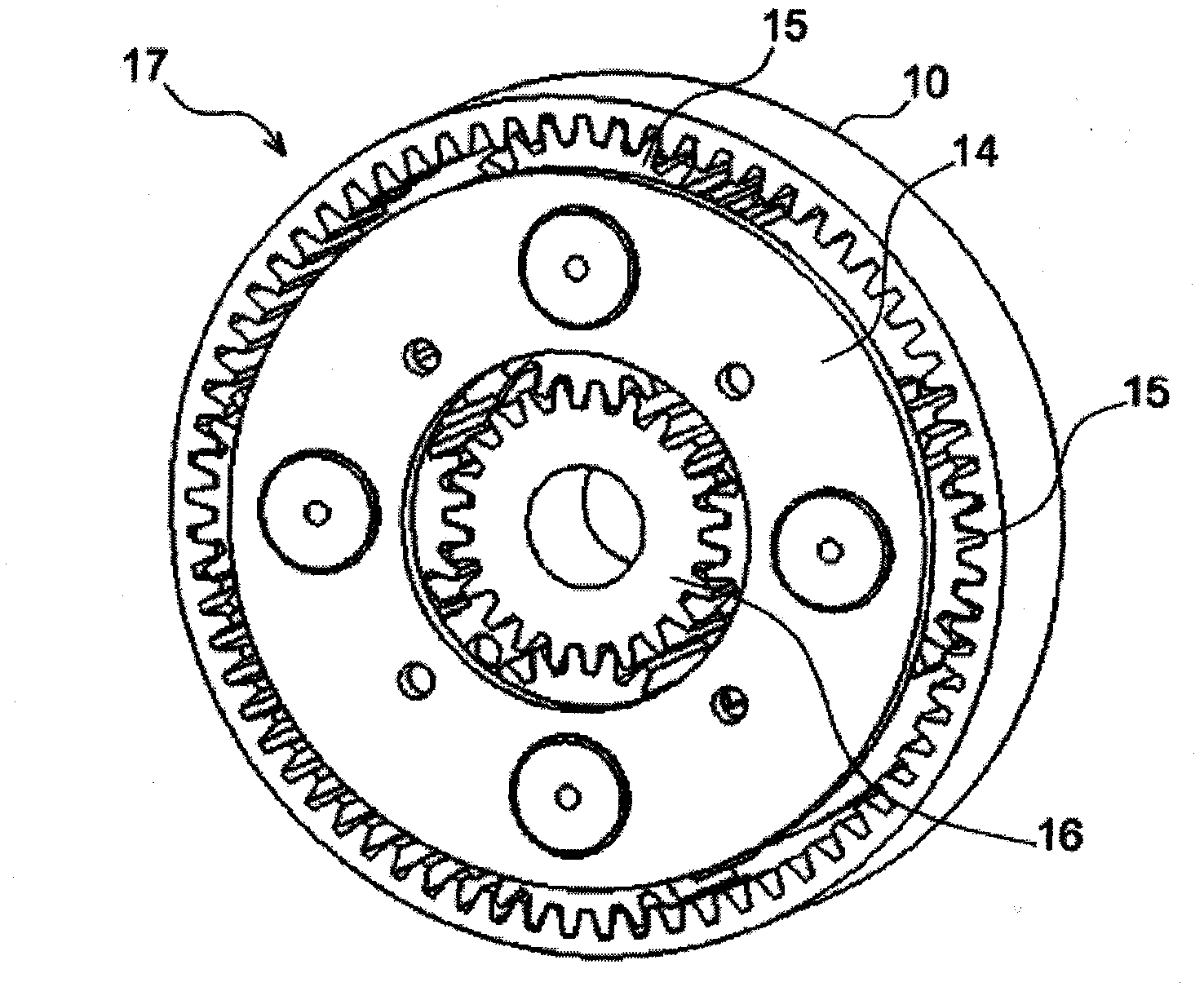

Device for driving a pair of counter-rotating propellers by means of an epicyclic gear train

ActiveCN102341588ARun accuratelyFlexible preventionEngine fuctionsBlade accessoriesGear driveGear wheel

The invention relates to a turbine (18) for driving a planetary gear (16) and an epicyclic gear train (17), further including a satellite holder (14) and a wheel (10) for rotating two propellers, wherein said turbine is connected to the planetary gear by means of a flexible sleeve (22) surrounding a turbine-supporting shaft (19) rather than by means of the supporting shaft itself, so as to provide a mounting that is flexible with an abutment position against the shaft (19) in order to relieve the epicyclic gear train (17) from parasitic inner stresses without allowing for a loose mounting or a breakage of the sleeve due to the abutment condition once the clearance (27) has disappeared.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

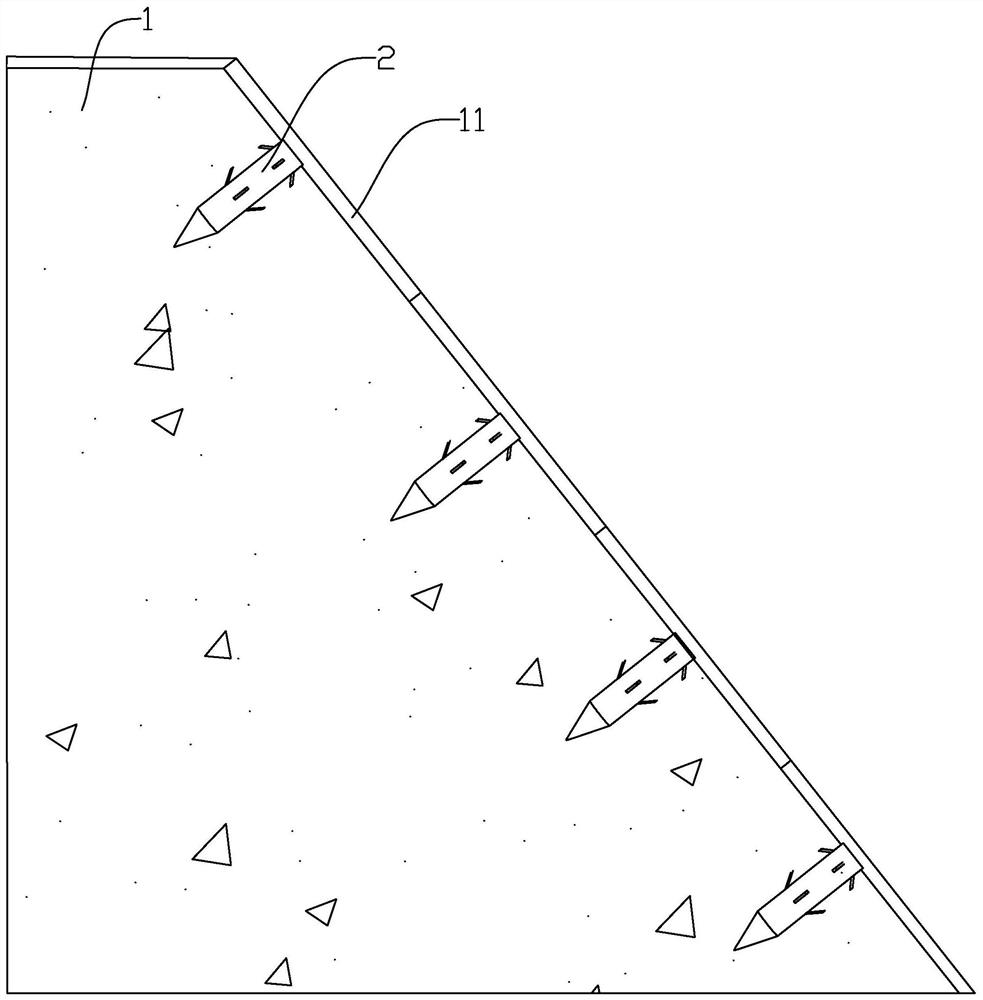

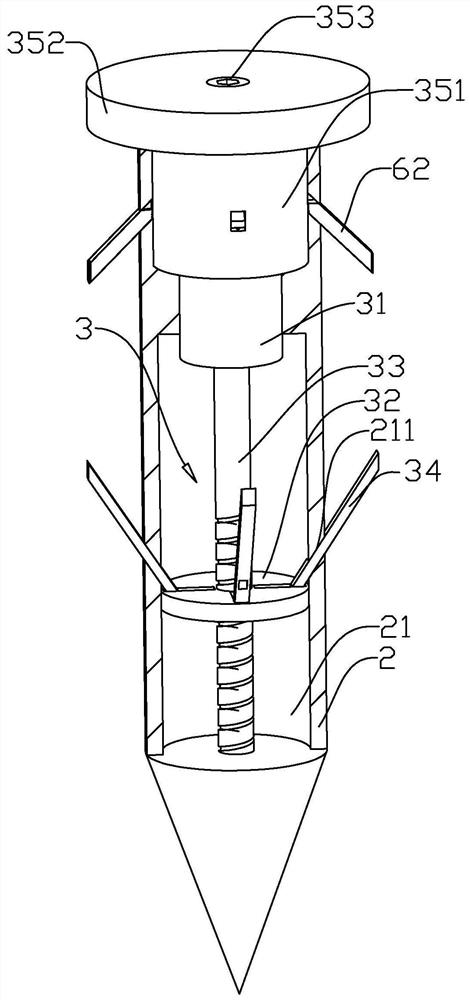

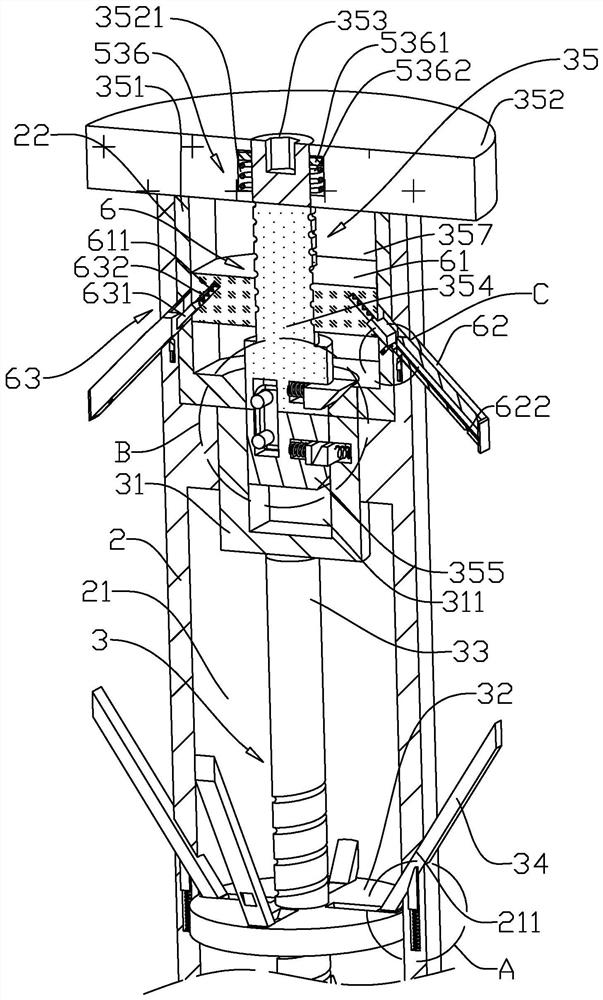

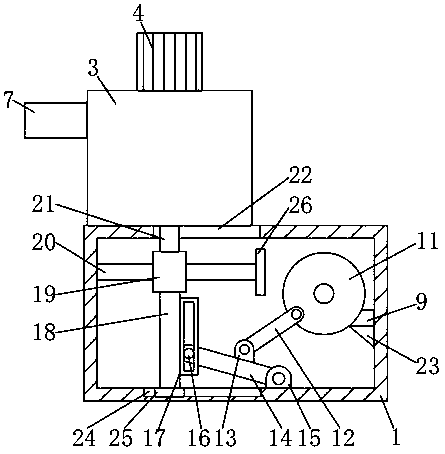

Hydraulic engineering revetment

ActiveCN112392003AImprove connection strengthMovement restrictionsCoastlines protectionExcavationsHydraulic engineeringScrew thread

The invention relates to a hydraulic engineering revetment. The hydraulic engineering revetment comprises a slope body, a plurality of revetment plates are laid on the slope body, anchor rods are arranged on the revetment plates, the anchor rods are inserted into the slope body, and the ends, away from the slope body, of the anchor rods are pre-buried in the revetment plates; a first inner cavityis formed in each anchor rod, a first fixing device used for enhancing the connecting strength between the anchor rod and the slope body is arranged in the first inner cavity, the first fixing devicecomprises a first rotating block, a first push plate, a lead screw and a plurality of reinforcing rods, the first rotating block is rotationally connected with the side wall of the first inner cavity,one end of the lead screw is fixedly connected with the first rotating block, the first push plate is slidably connected with the inner side wall of the first inner cavity, and the first push plate is in threaded connection with the lead screw; the end of each reinforcing rod is slidably connected with the first push plate, and the end, away from the first push plate, of each reinforcing rod penetrates through the inner side wall of the first inner cavity and is located on the outer side of the anchor rod; and the first fixing device further comprises a driving mechanism used for driving thefirst rotating block to rotate. The hydraulic engineering revetment has the effect of enhancing the connecting strength between the anchor rods and the slope body.

Owner:安徽百年基业建设工程有限公司

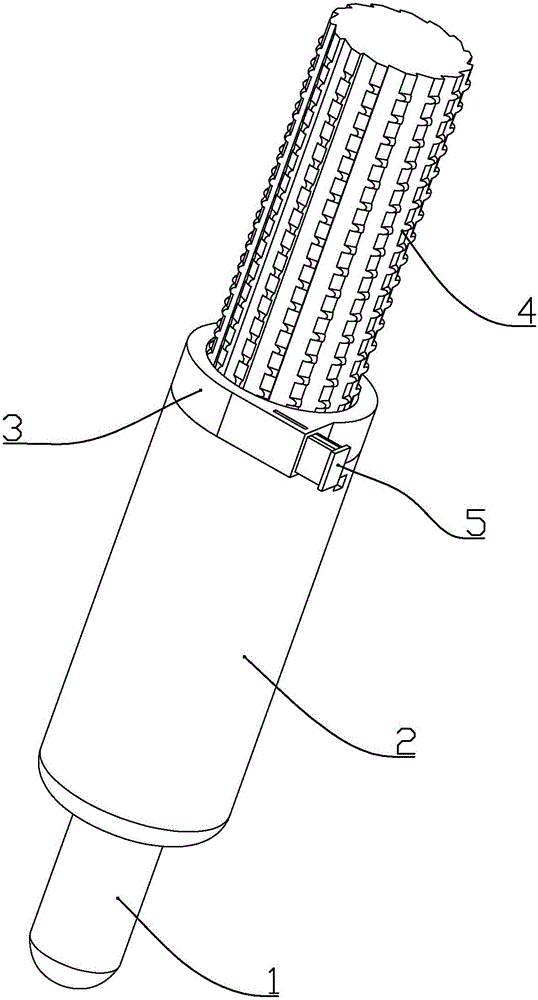

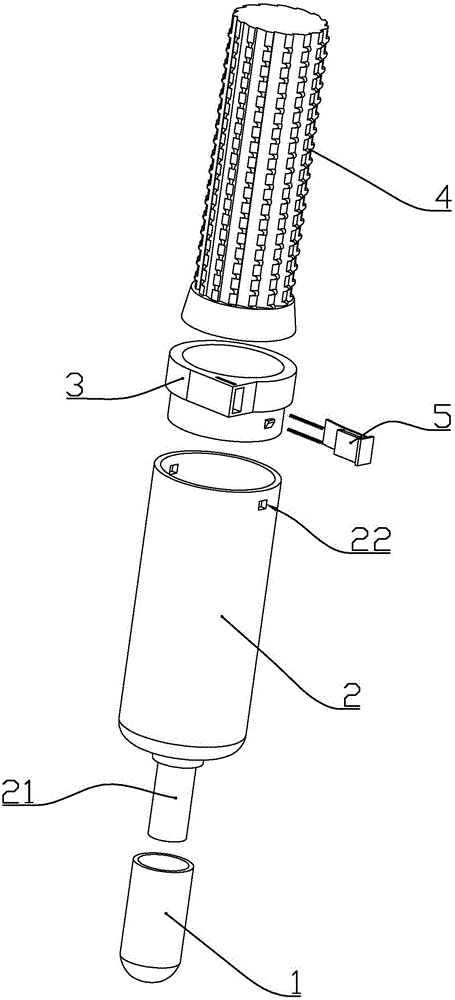

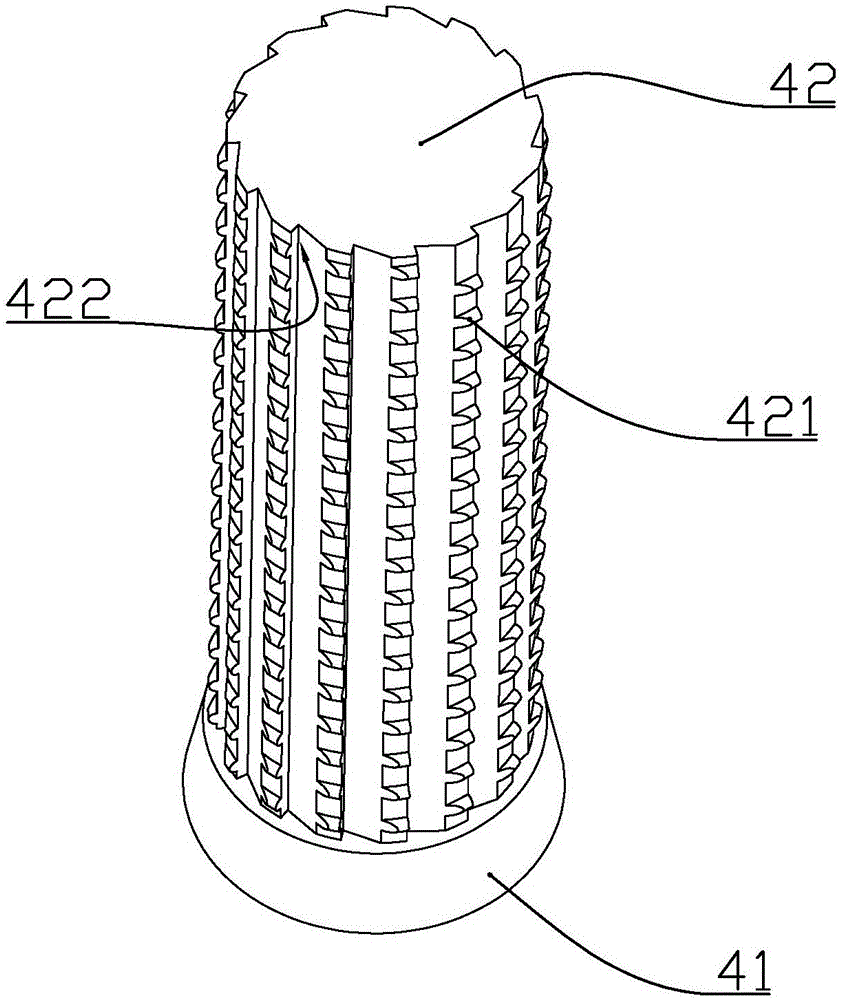

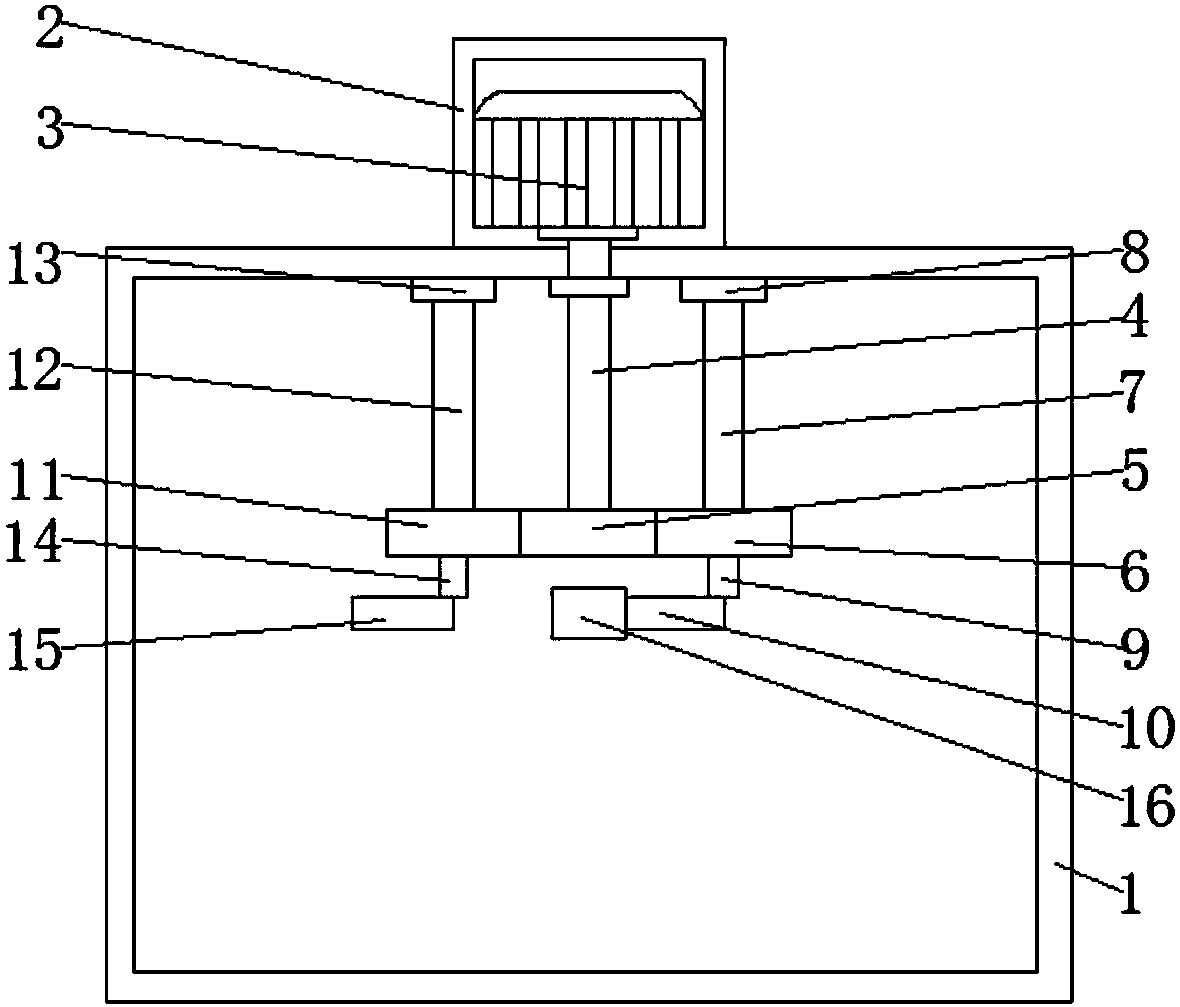

Crushing equipment for bamboo charcoal processing

InactiveCN107597335ASolve low work efficiencyImprove practicalityGrain treatmentsArchitectural engineeringBamboo charcoal

The invention discloses crushing equipment for bamboo charcoal processing. The crushing equipment comprises a bottom box, the top of the bottom box is slidably connected with a crushing box, and the top of the crushing box is fixedly connected with a first motor. The output end of the first motor penetrates through the crushing box and extends into the crushing box to be fixedly connected with a crushing rod, and the bottom of the crushing rod is fixedly connected with a bearing. The bottom of the bearing is fixedly connected with the bottom of the inner wall of the crushing box, and the two sides of the crushing rod are fixedly connected with crushing blades correspondingly. By arranging a supporting plate, a second motor, a rotary disc, a movable rod, a first connecting block, a transmission plate, a second connecting block, a transmission column, a transmission frame, a movable plate, a sliding sleeve, a polished rod and a transmission rod for matching use, the problem that the working efficiency of an existing crushing device is low is solved, the crushing equipment for bamboo charcoal processing has the advantages of being efficient, when the equipment is used by a user, a large amount of time is saved, and the practicability of the crushing equipment is improved.

Owner:耒阳腾升环保科技开发有限责任公司

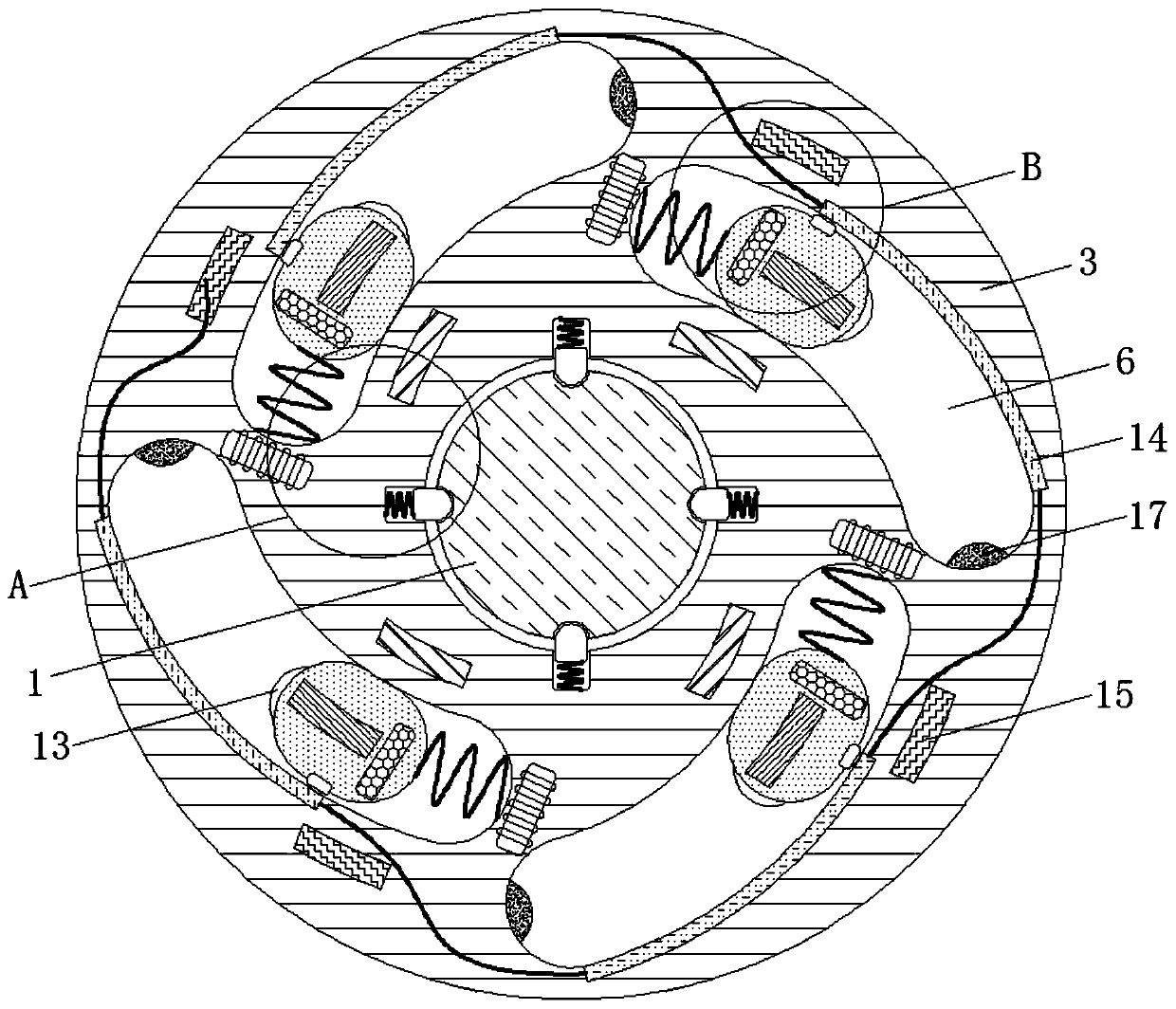

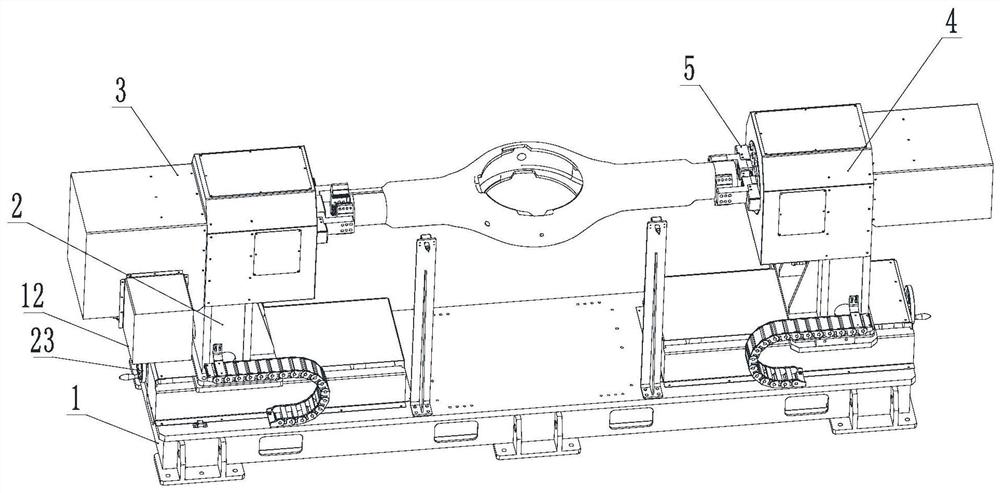

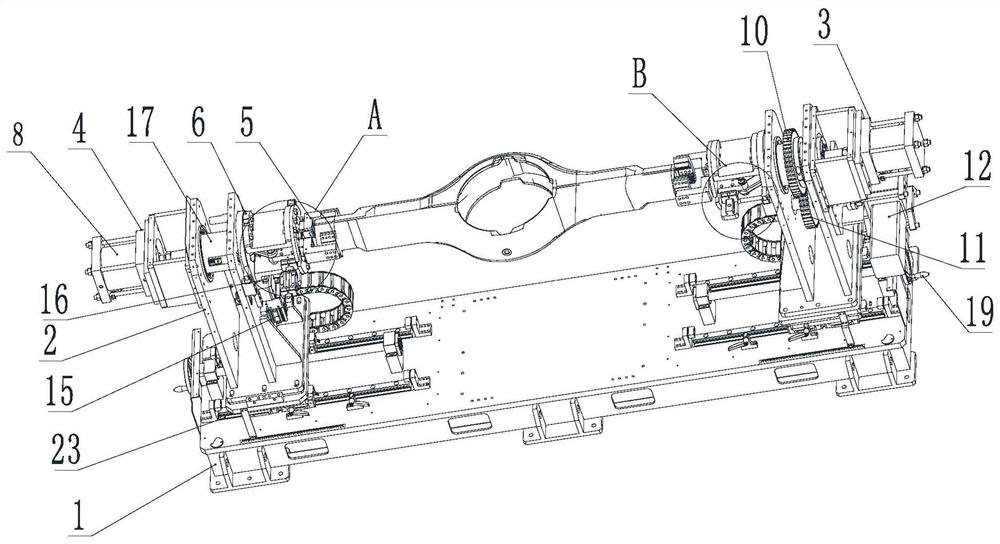

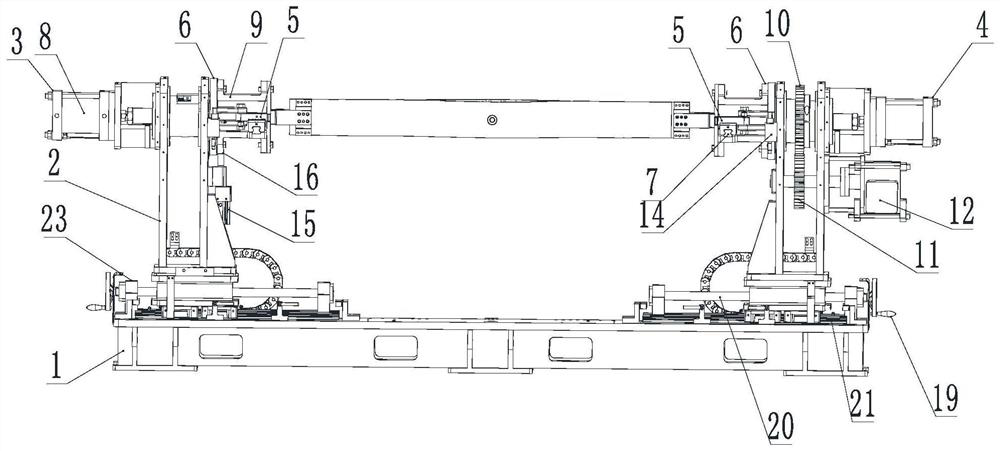

Pneumatic centering clamping and overturning mechanism for axle housing welding

PendingCN112743282ABig expansionEasy to storeWelding/cutting auxillary devicesAuxillary welding devicesSupport planeWelding

The invention discloses a pneumatic centering clamping and overturning mechanism for axle housing welding, and belongs to axle housing positioning and clamping equipment. The problems that due to the size difference of the two ends of different axle housings, a clamping assembly cannot be adjusted to expand outwards, and consequently the axle housings are inconvenient to assemble, disassemble or clamp are solved. The pneumatic centering clamping and overturning mechanism for axle housing welding comprises a base, wherein supporting frames are arranged at the two ends of the base; a driving end clamping mechanism is arranged on one supporting frame, and a driven end clamping mechanism matched with the driving end clamping mechanism is arranged on the other supporting frame; the driving end clamping mechanism and the driven end clamping mechanism each comprise an overturning device; and a directional moving mechanism is arranged at the bottom of each supporting frame. The pneumatic centering clamping and overturning mechanism is suitable for positioning, clamping and welding of the axle housings of various lengths and sizes. The overturning devices achieve 360-degree dead-corner-free welding of the axle housings, the clamping assembly moves directionally, and synchronous centering clamping of the two ends of the axle housings is achieved through the cooperative movement of connecting rods and sliding rails.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

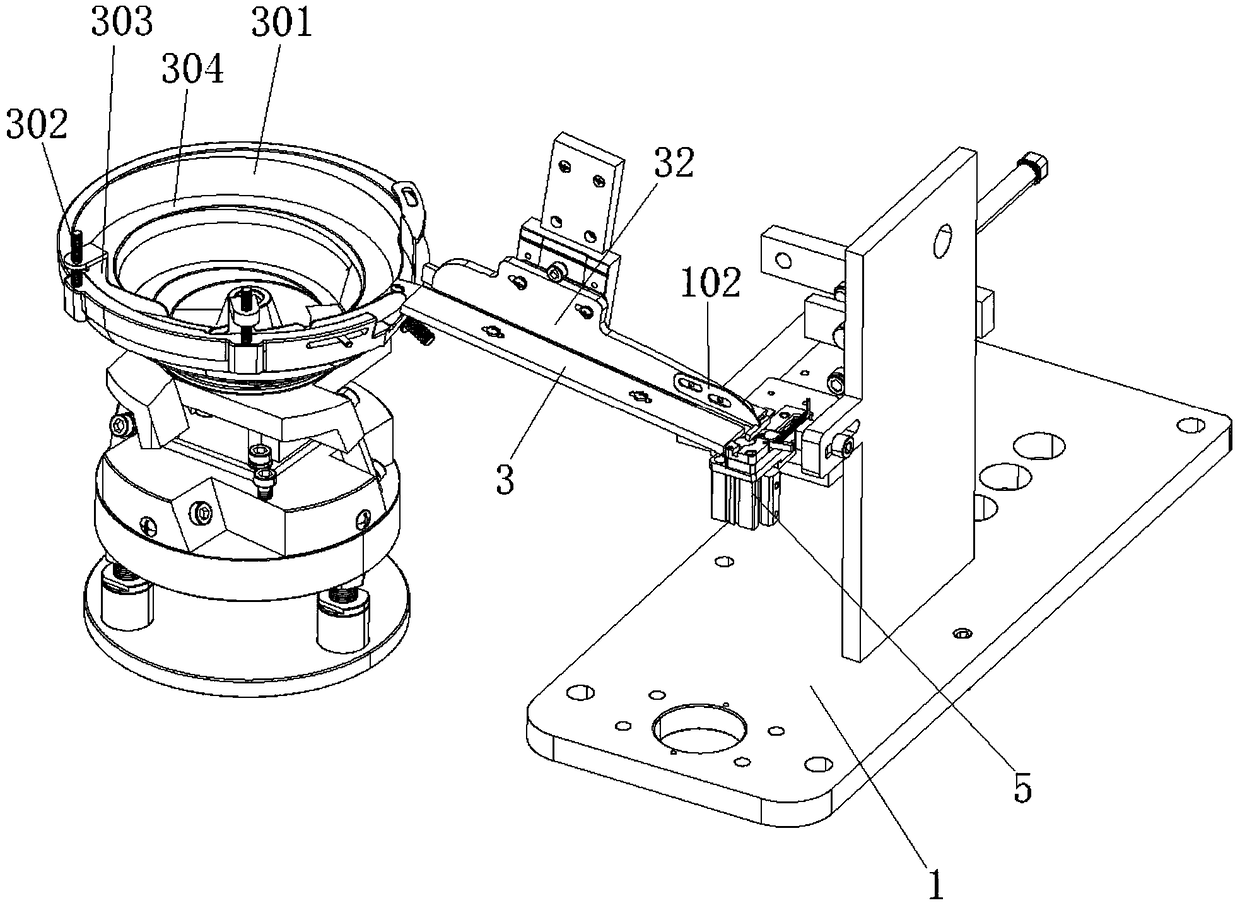

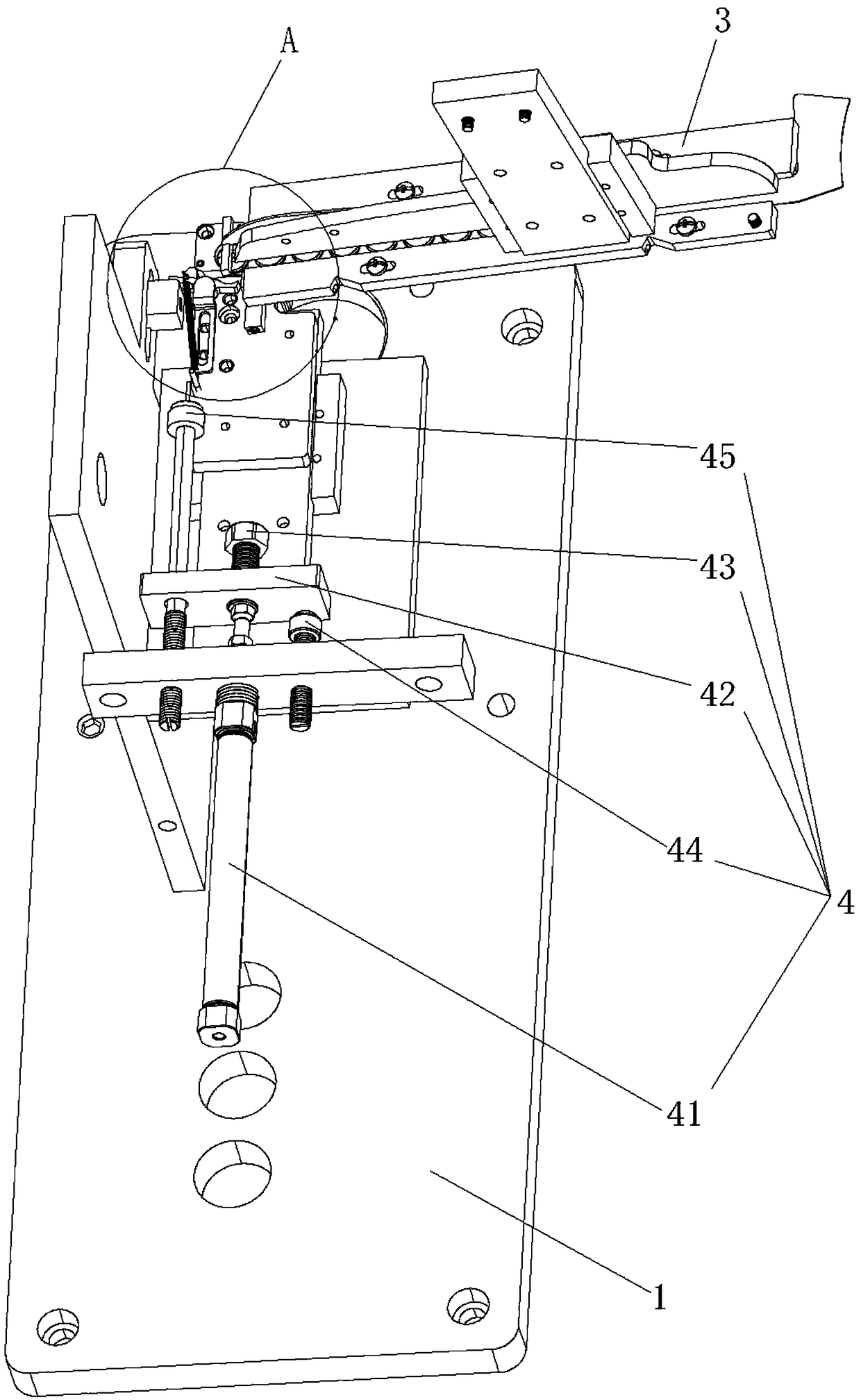

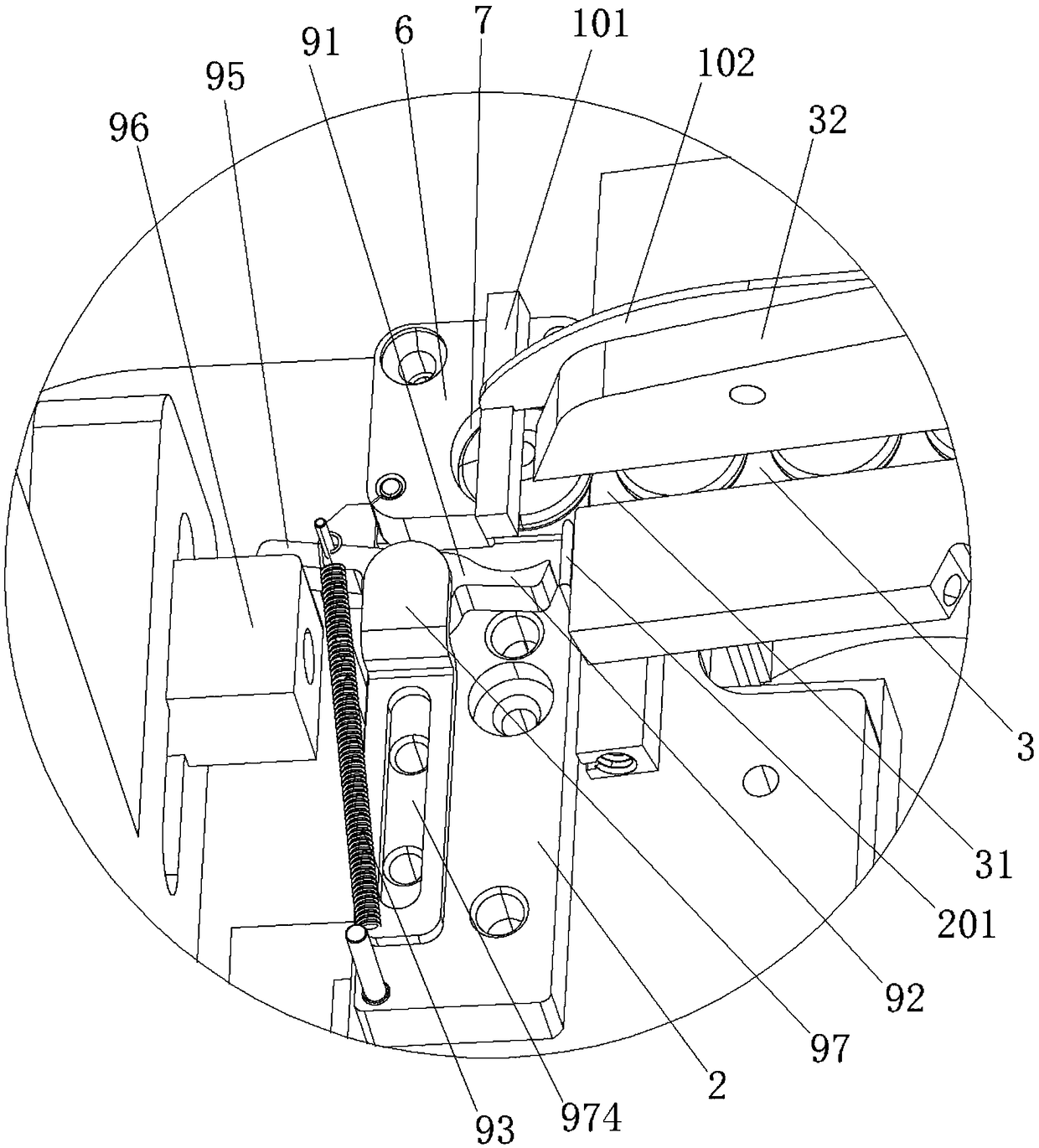

Automatic feeding apparatus for button sewing machine

PendingCN108914395AOutstanding and Beneficial Technical EffectsSmooth feedingSewing apparatusReciprocating motionEngineering

The invention belongs to the field of button sewing machines, in particular to a novel automatic feeding apparatus for a button sewing machine. The apparatus comprises a frame, a feeding seat, a material loading track, a driving seat pushing mechanism and a lifting cylinder. The driving seat pushing mechanism drives the feeding seat to perform reciprocating motion. A positioning part is installedon the feeding seat. A positioning groove is formed in the positioning part. A workpiece anti-flying press strip is arranged in the positioning groove of the positioning part. A feeding gap is arranged in the positioning groove. The side surface of the feeding gap is equipped with a workpiece side buckle-clamping mechanism. The lifting cylinder is mounted below the positioning part. A position rodof the lifting cylinder corresponds to the center of the positioning groove. The novel automatic feeding apparatus for the button sewing machine has the following advantages: the apparatus is simplein structure and stable in feeding operation and can suitable for all kinds of differently-sized buttons; and the apparatus is also convenient to adjust.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

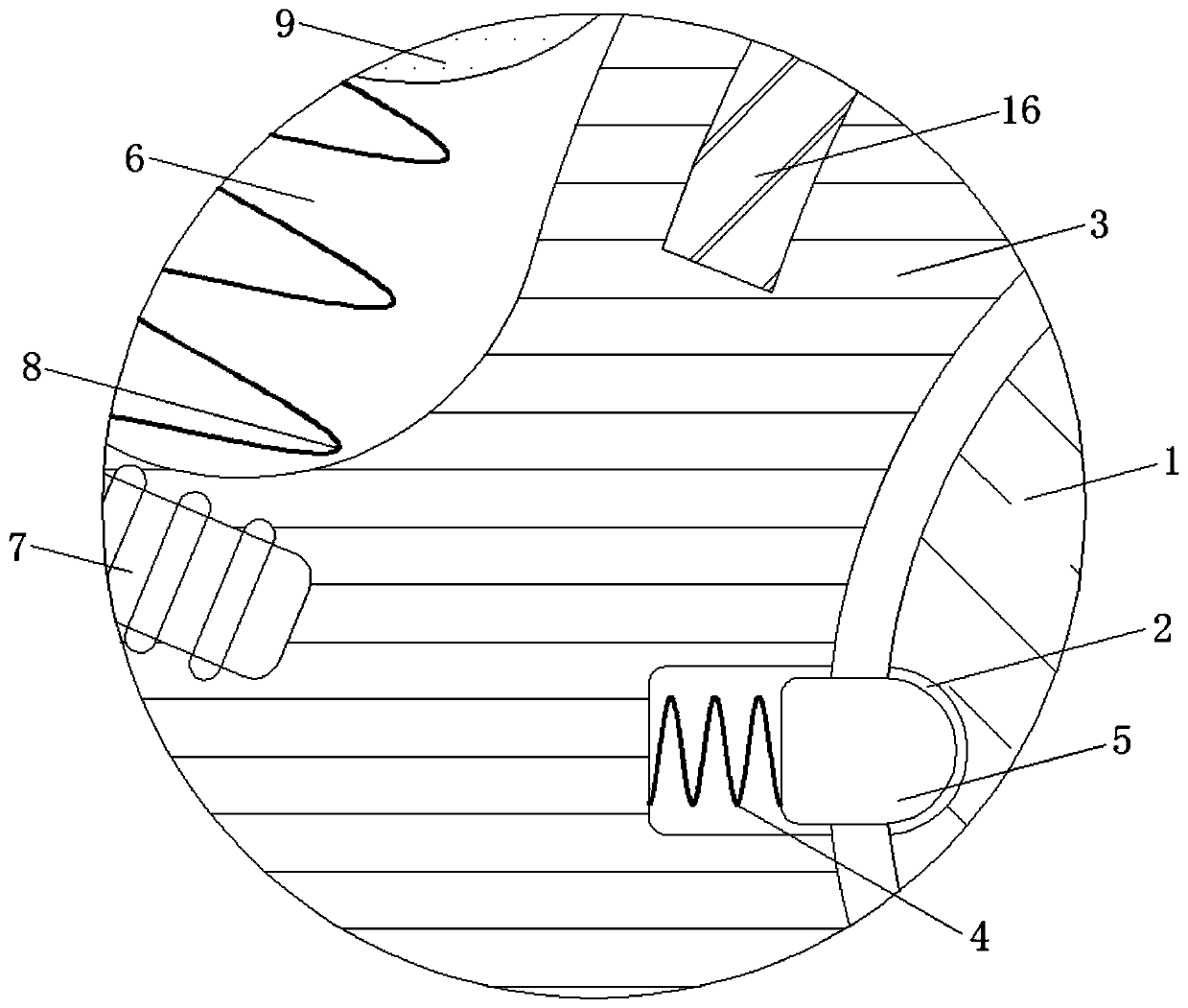

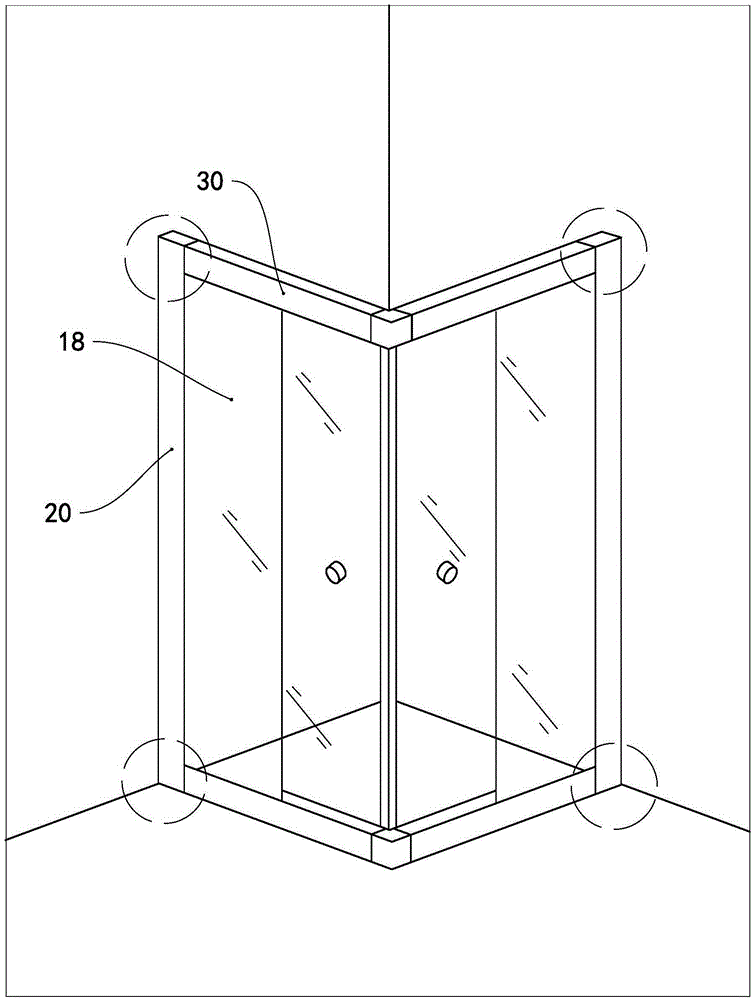

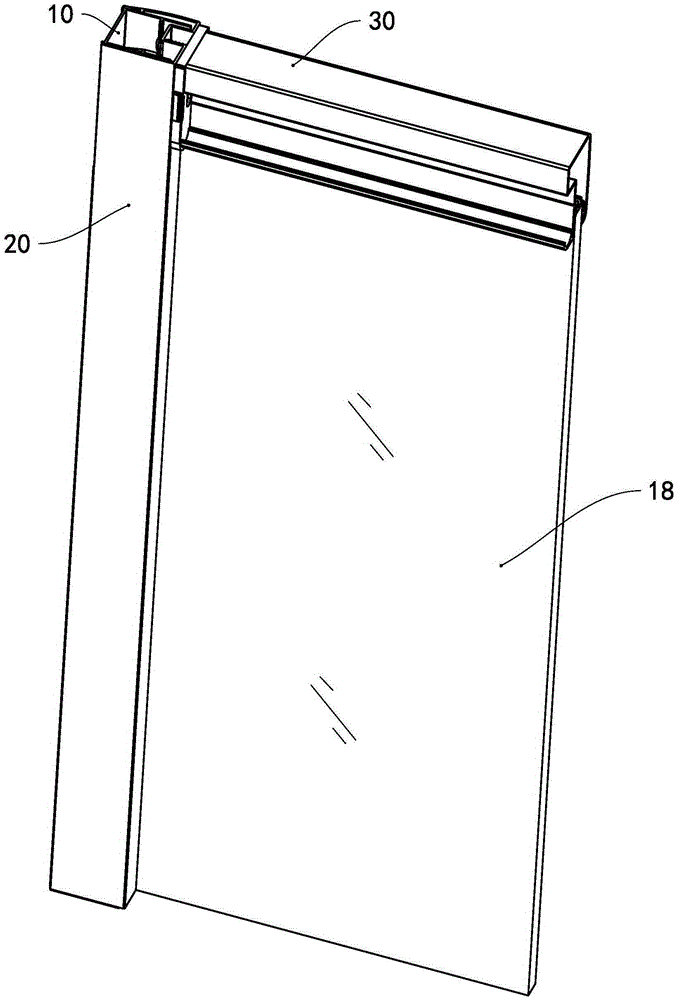

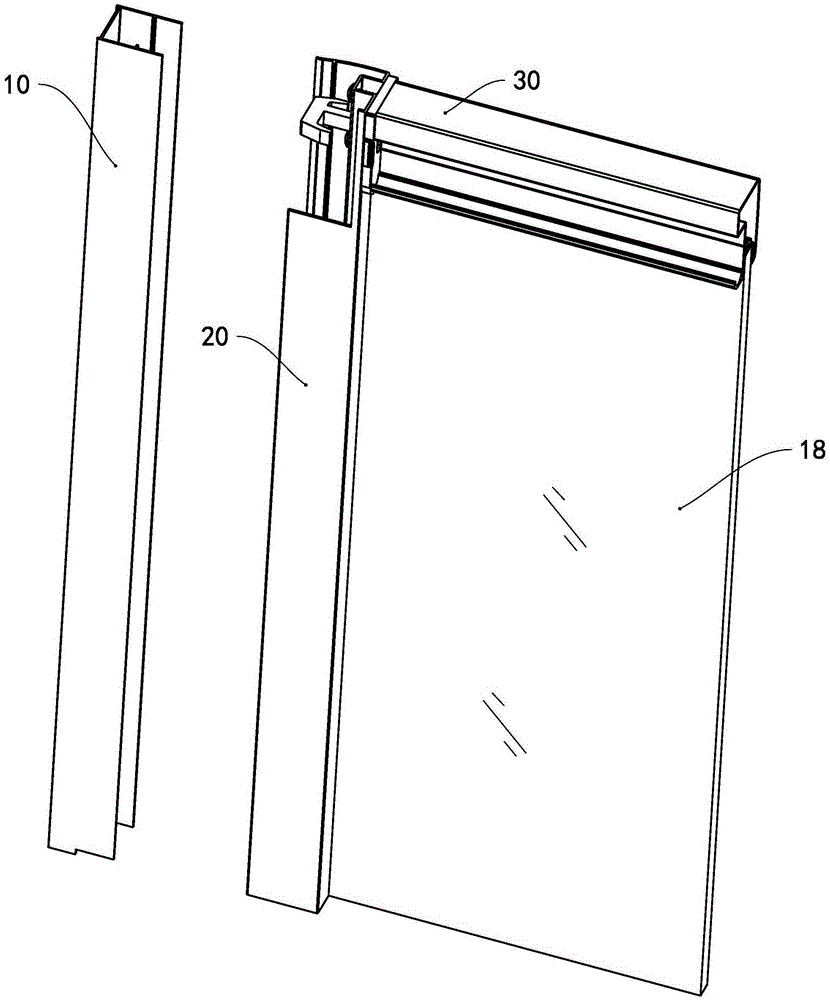

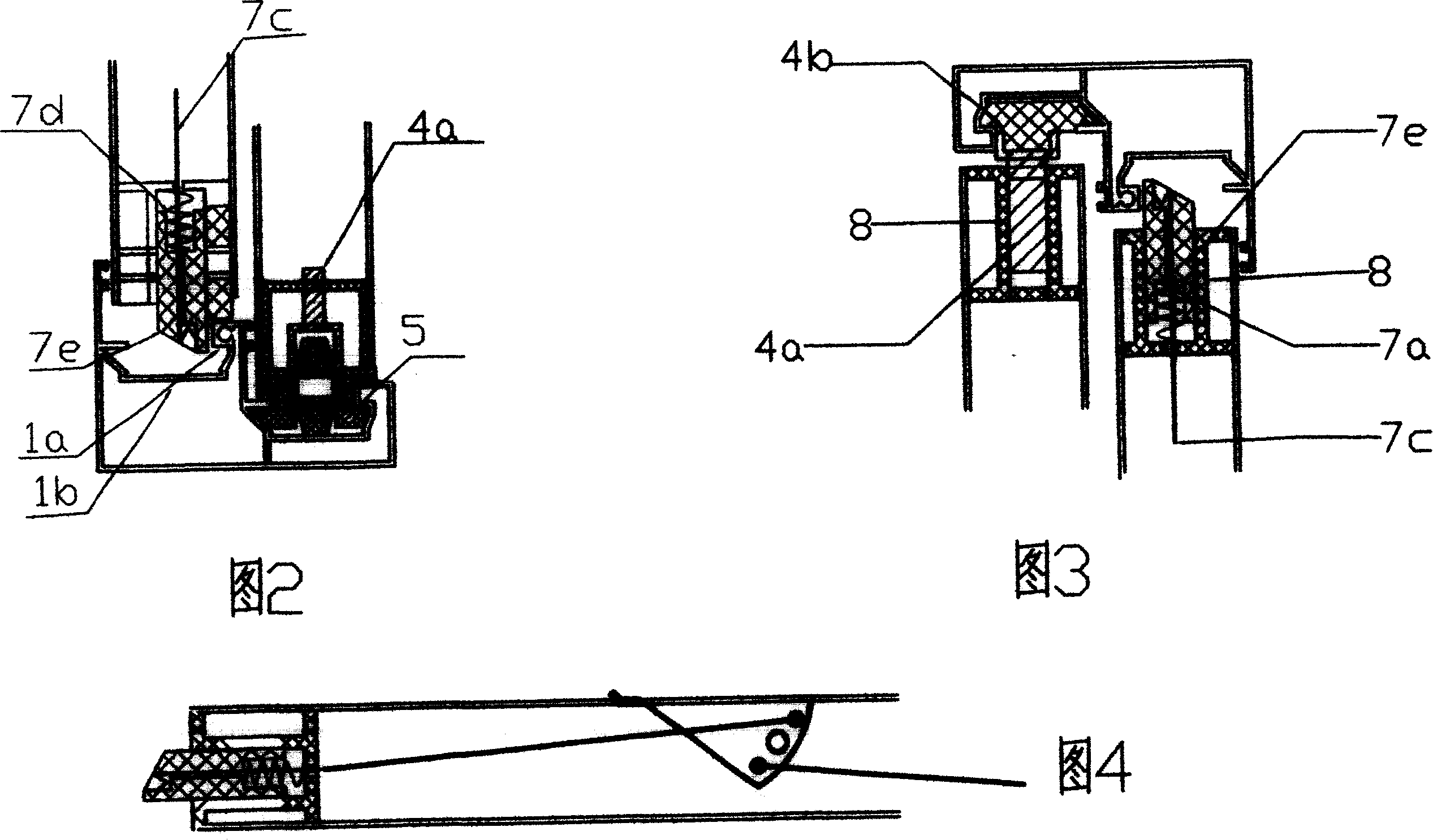

Shower room door assembly and shower room door

ActiveCN105492714AAchieve regulationMovement restrictionsWindow/door framesBase framesPhysicsMechanical engineering

The invention relates to the field of bathroom appliance and provides a shower room door assembly and a shower room door. The shower room door comprises a fixing frame, an adjusting frame and a horizontal frame. The fixing frame, the adjusting frame and the horizontal frame are connected to each other through an adjusting assembly, wherein the adjusting assembly comprises a fixing base which is fixed at one end part of the horizontal frame; the fixing base is provided with a first through hole; a spring locking piece is installed on the fixing base and can move with respective to the fixing base in a length direction vertical to the adjusting frame and in the length direction vertical to the horizontal frame; the middle part of the spring locking piece is provided with a second through hole; the area of the second through hole is larger than that of the first through hole, and the first through hole is covered by the first through hole; the adjusting assembly also comprises a connecting strip; the connecting strip is provided with a gear rack which passes through the first through hole and the second through hole, and the side edge of the second through hole is inserted in the rack root. The shower room door is provided with above shower room door assembly, and the adjusting frame is provided with a rotary axis door.

Owner:FOSHAN IDEAL

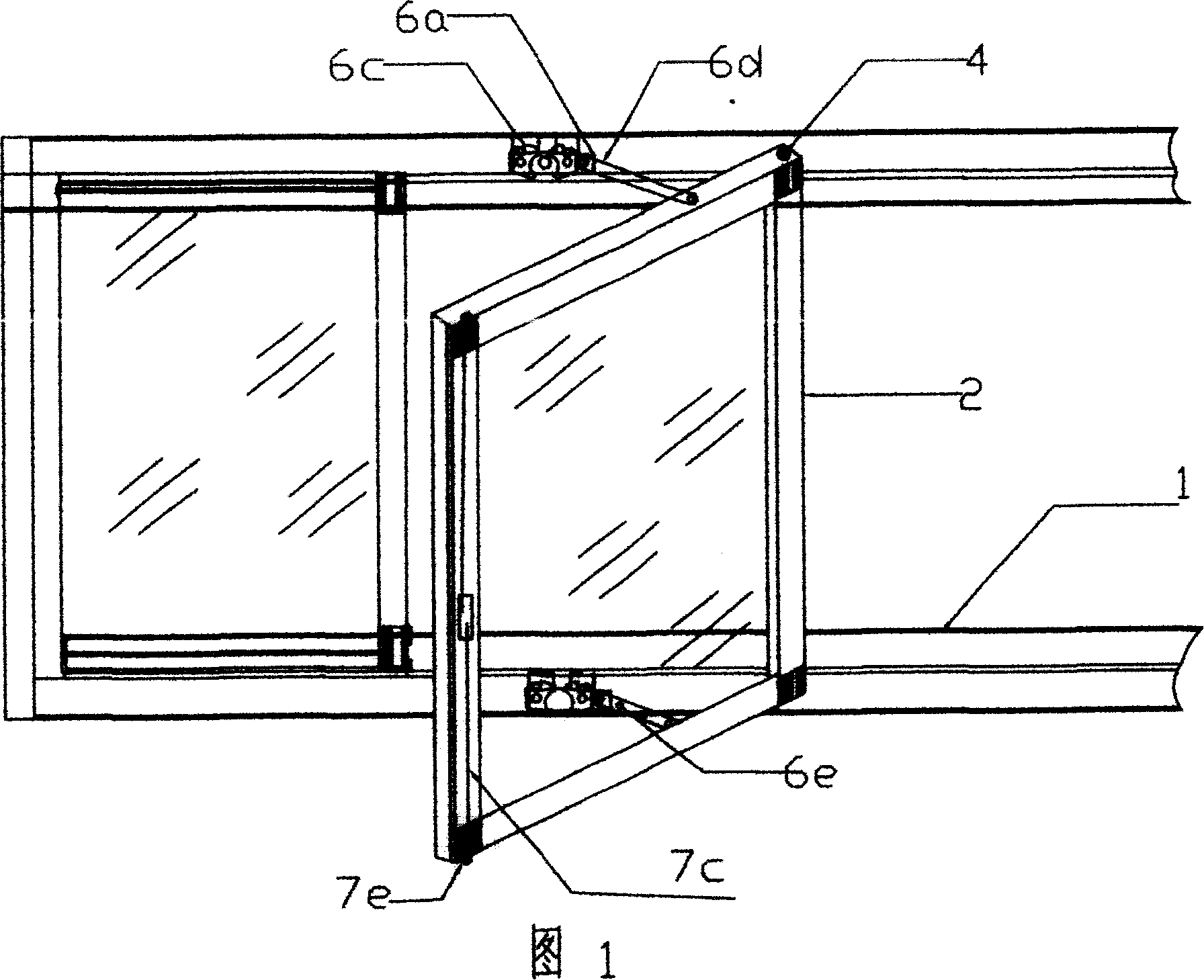

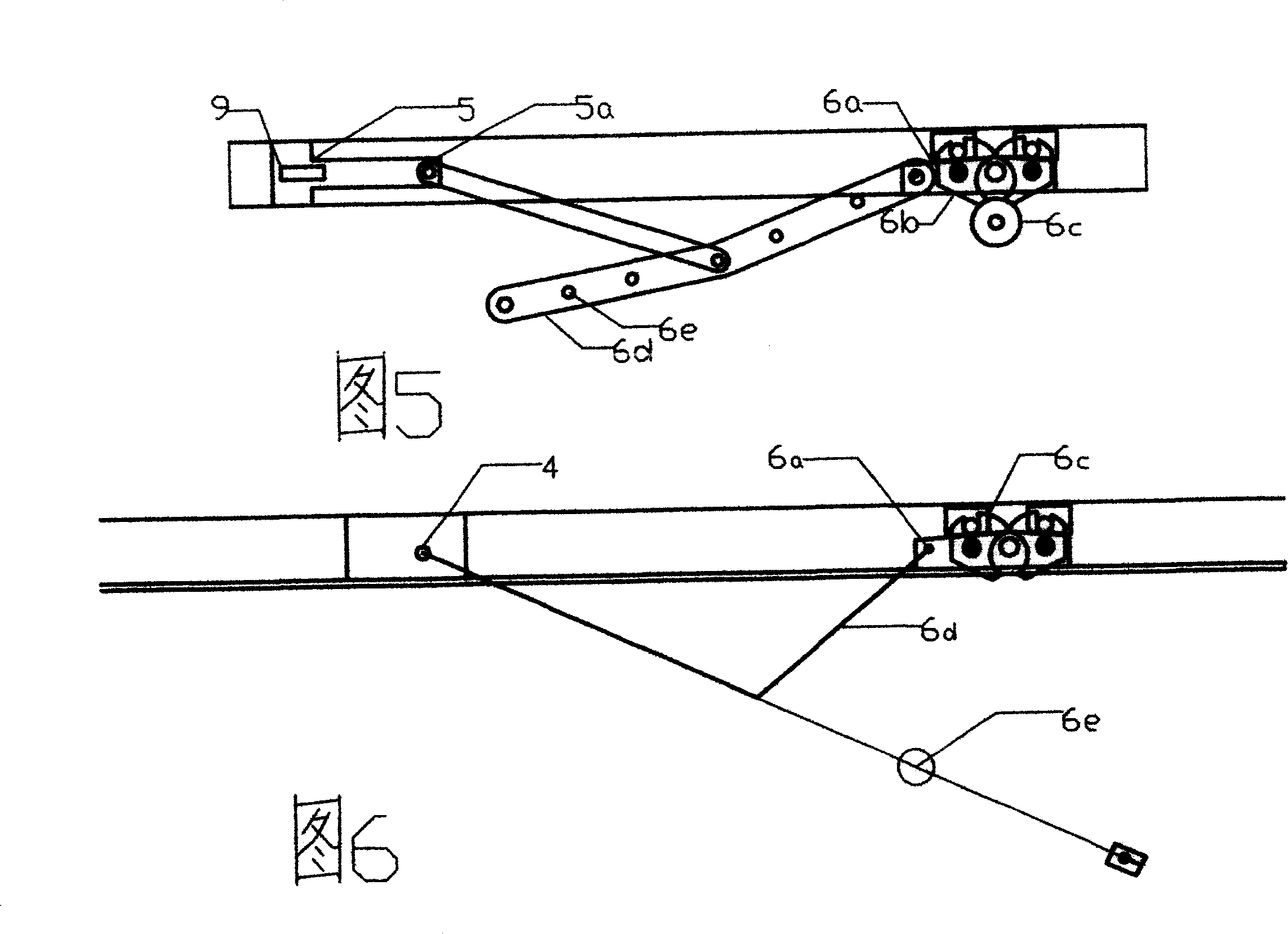

Easy pulling casement multifunctional window

InactiveCN101131064AMovement restrictionsEasy to operatePin hingesWing arrangementsEngineeringMultiple function

The present invention discloses one kind of simple multifunctional sliding-side hanging window for building. The multifunctional window features the upper and lower window frames with fixed slide way, sliding-shifting shaft, roller seat and crab pincers seat; the window sash with lower roller seat, lower shaft sleeve holder, roller and stopper; and the supporting rod with two hinged ends for opening window sash in 0-180 deg. The multifunctional window with automatic locking mechanism can fix the window sash in different opening angle and may be opened and closed easily. The present invention discloses also one window sash fastening and regulating structure.

Owner:以体明 +1

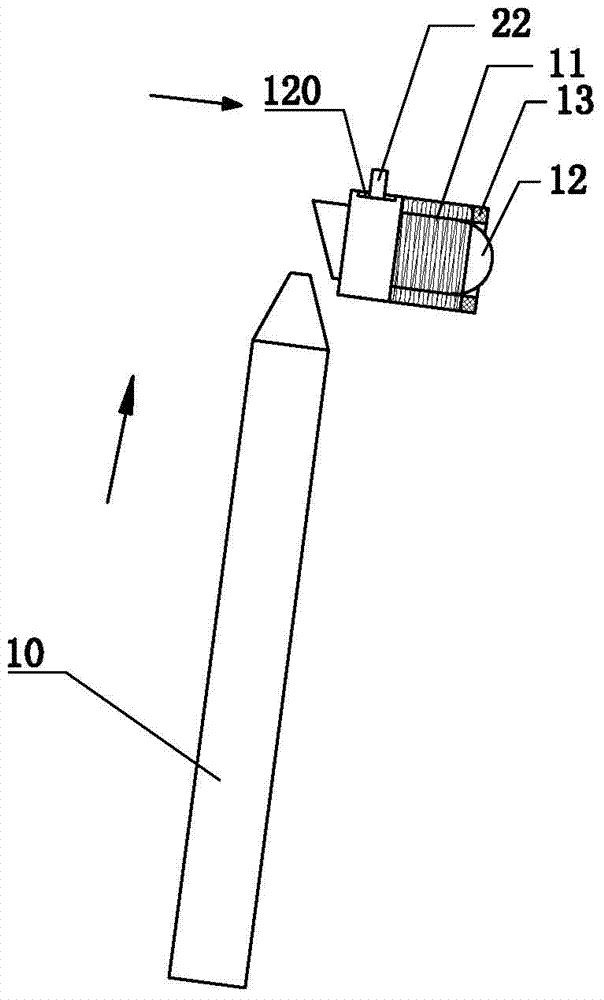

Novel building pile driver

PendingCN108035350AReduce the use of manpowerImprove efficiencyBulkheads/pilesEngineeringThreaded rod

The invention discloses a novel building pile driver which comprises an enclosure. A motor case is fixedly installed at the rear side of the enclosure. A servo motor is fixedly installed inside the motor case. One end of a rotating shaft of the servo motor is connected with a spindle in a transmission mode through a coupling. A driving gear is fixedly installed at one end of the spindle. A first gear and a second gear are arranged at the two sides of the driving gear correspondingly. One side of the first gear is fixedly connected with a first arc-shaped gear through a first connecting rod, and one side of the second gear is fixedly connected with a second arc-shaped gear through a second connecting rod. A rack is arranged at one side of the first arc-shaped gear. A threaded rod is weldedto the bottom end of the rack. An impact plate is arranged at one end of the threaded rod. According to the novel building pile driver, the servo motor, the spindle and the driving gear are arranged to be matched with the first gear and the first arc-shaped gear as well as the second gear and the second arc-shaped gear, and therefore the impact plate can be driven to move up and down back and forth so that pile bodies can be driven, and manpower is saved.

Owner:绍兴市柯桥区蓝天软件有限公司

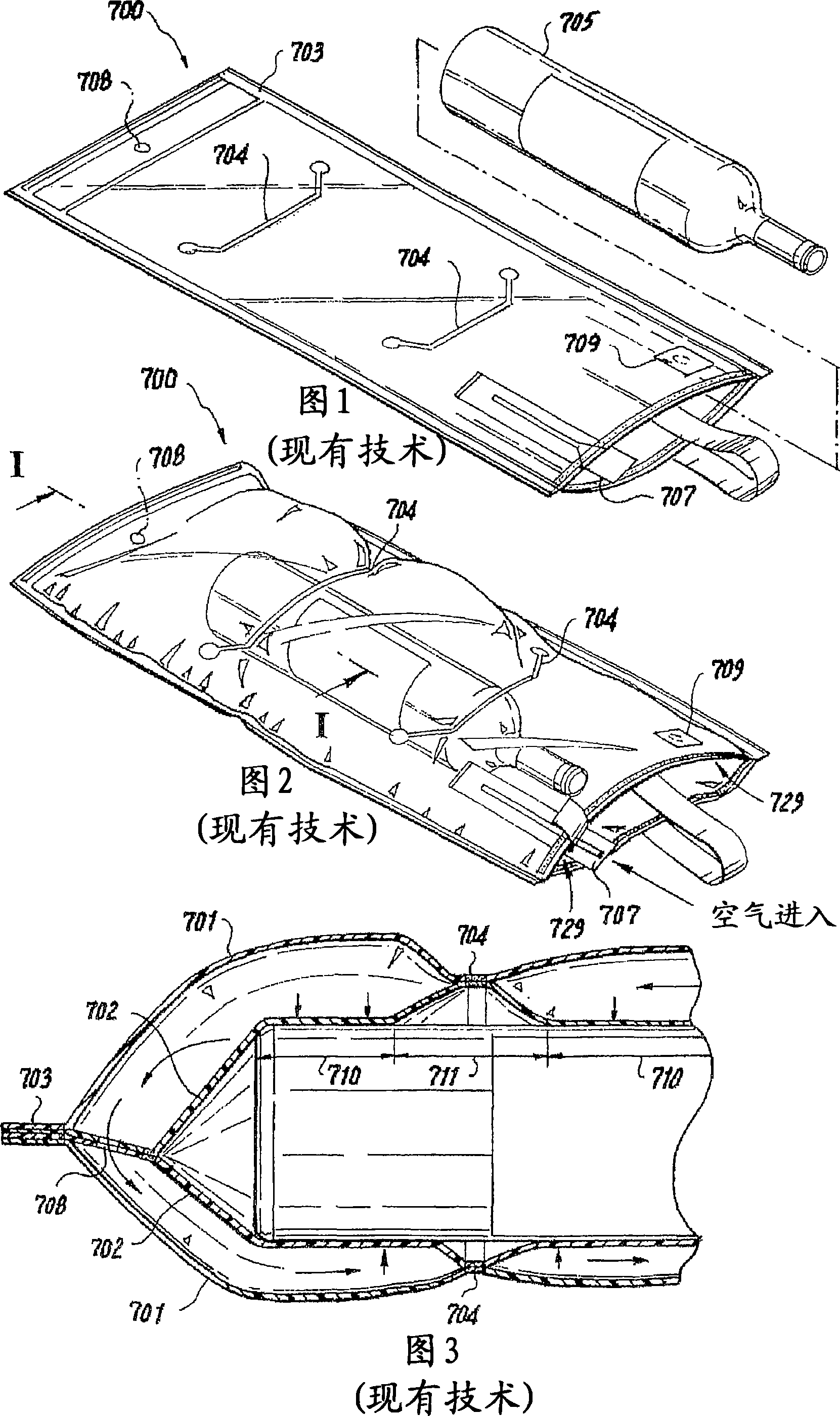

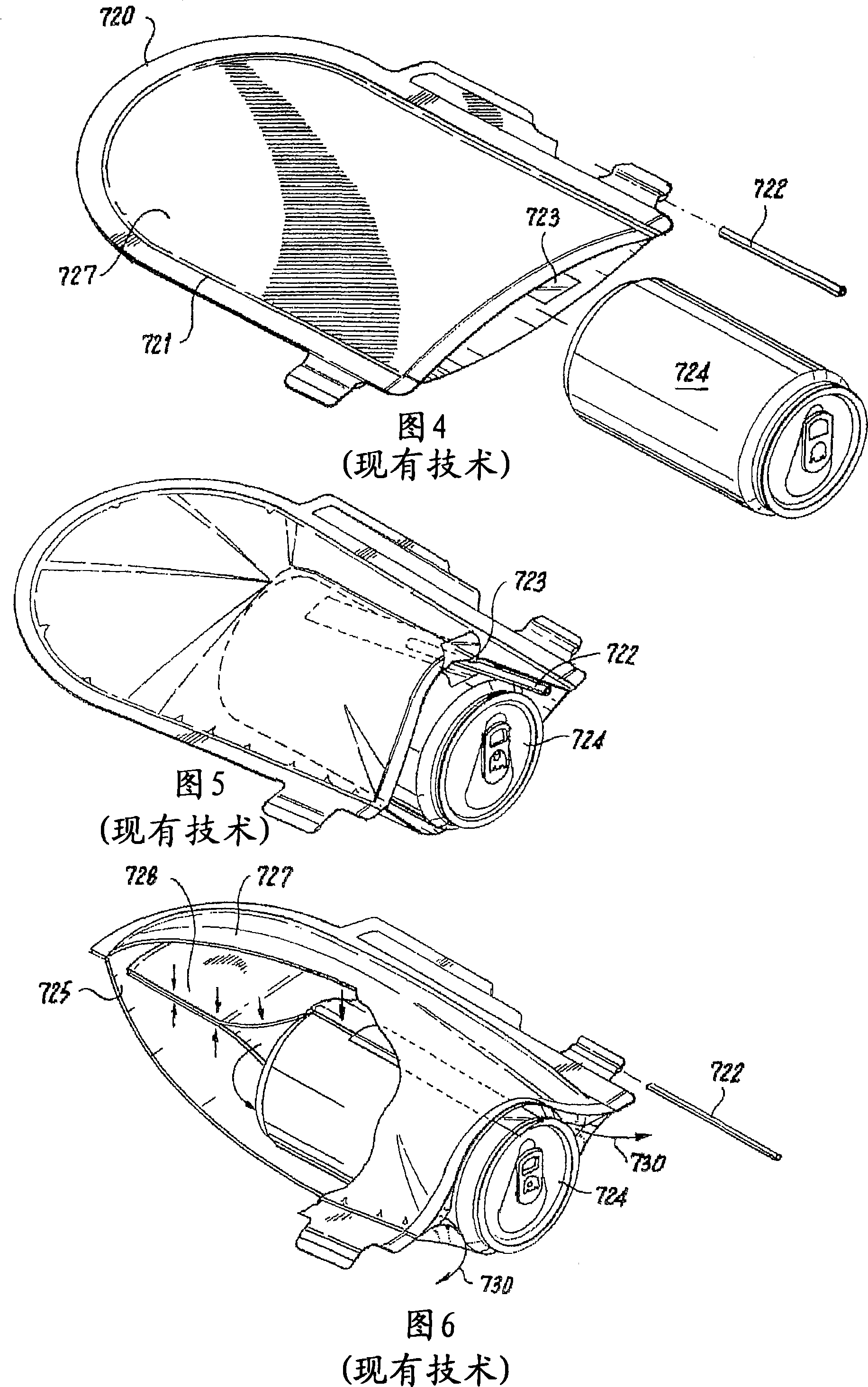

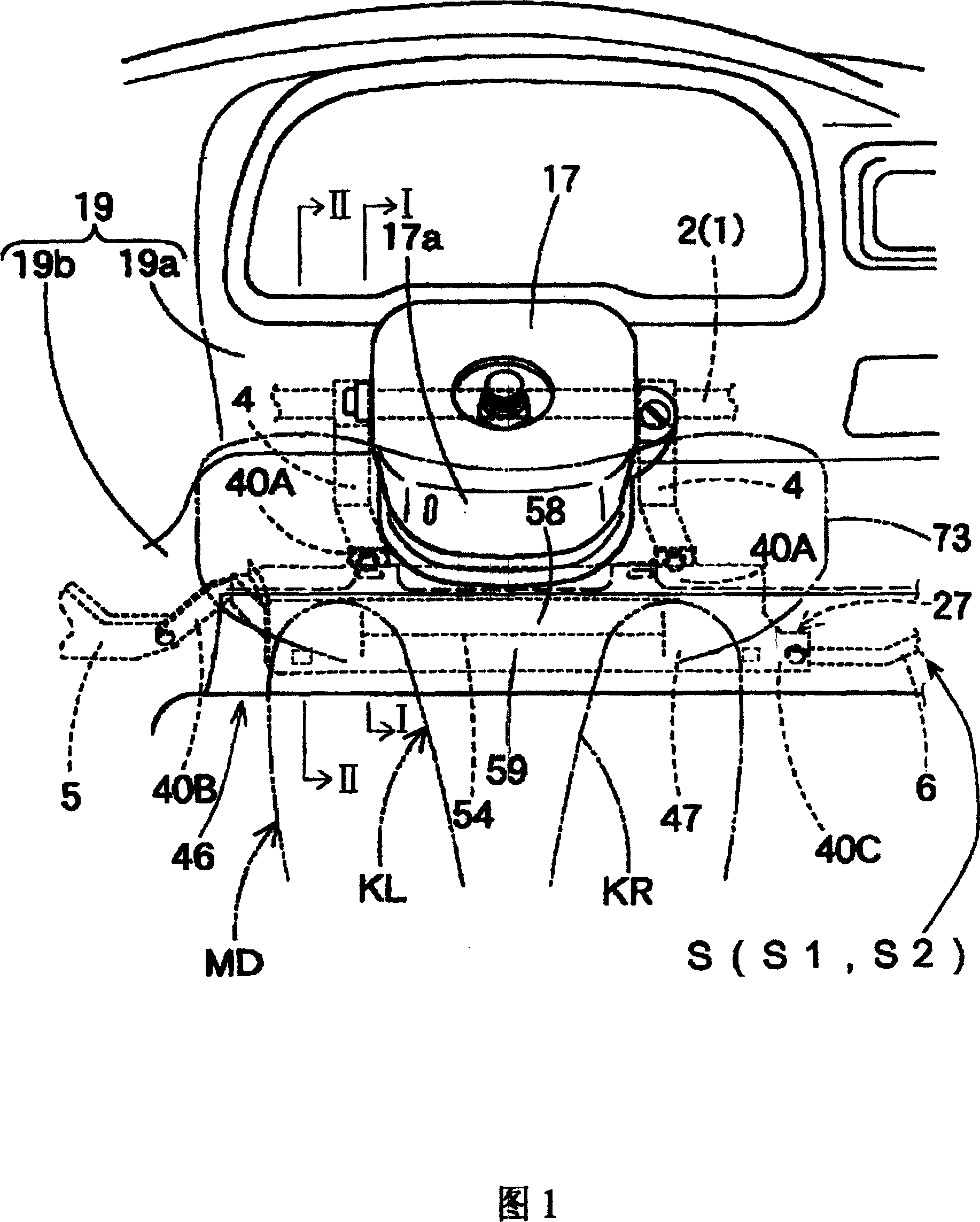

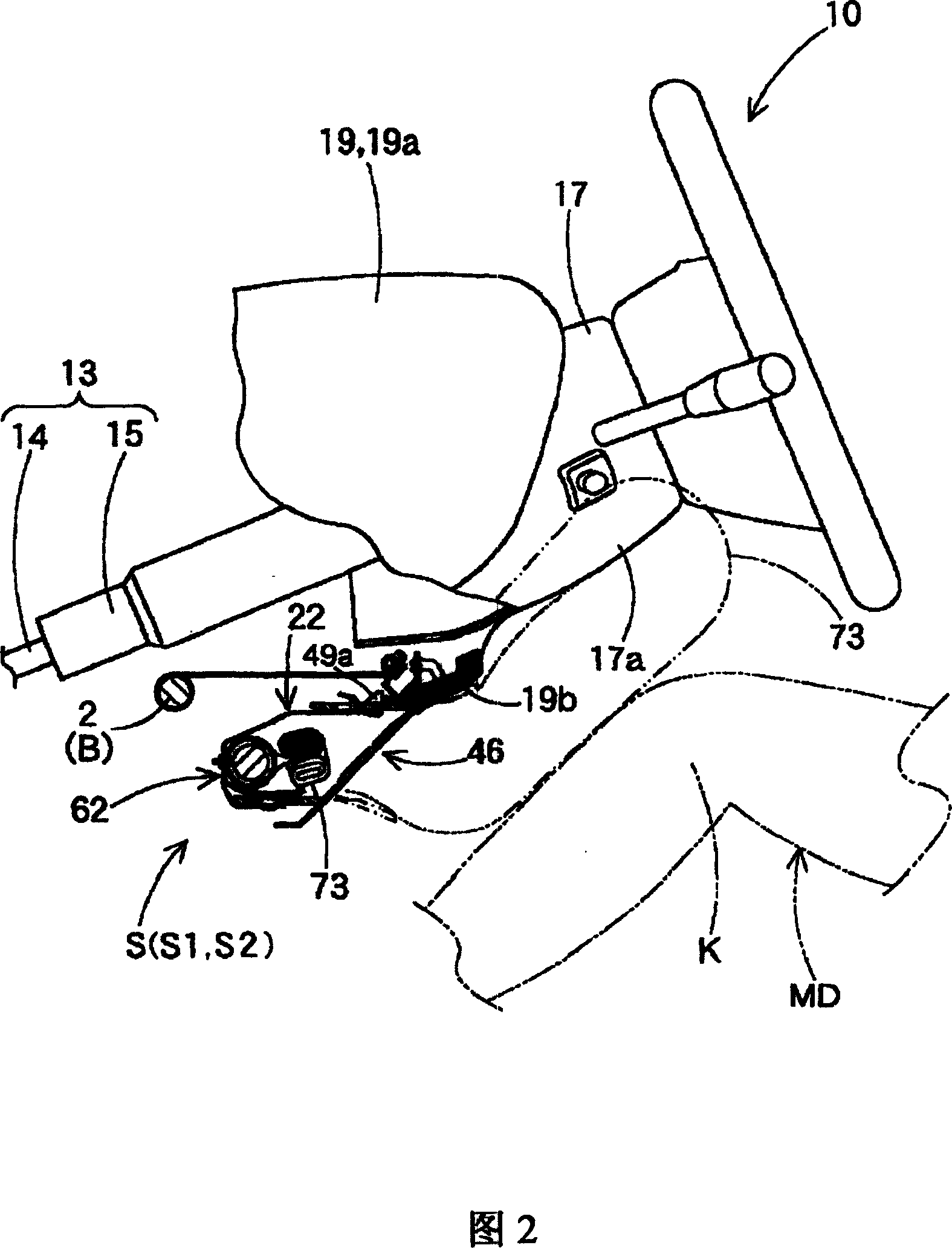

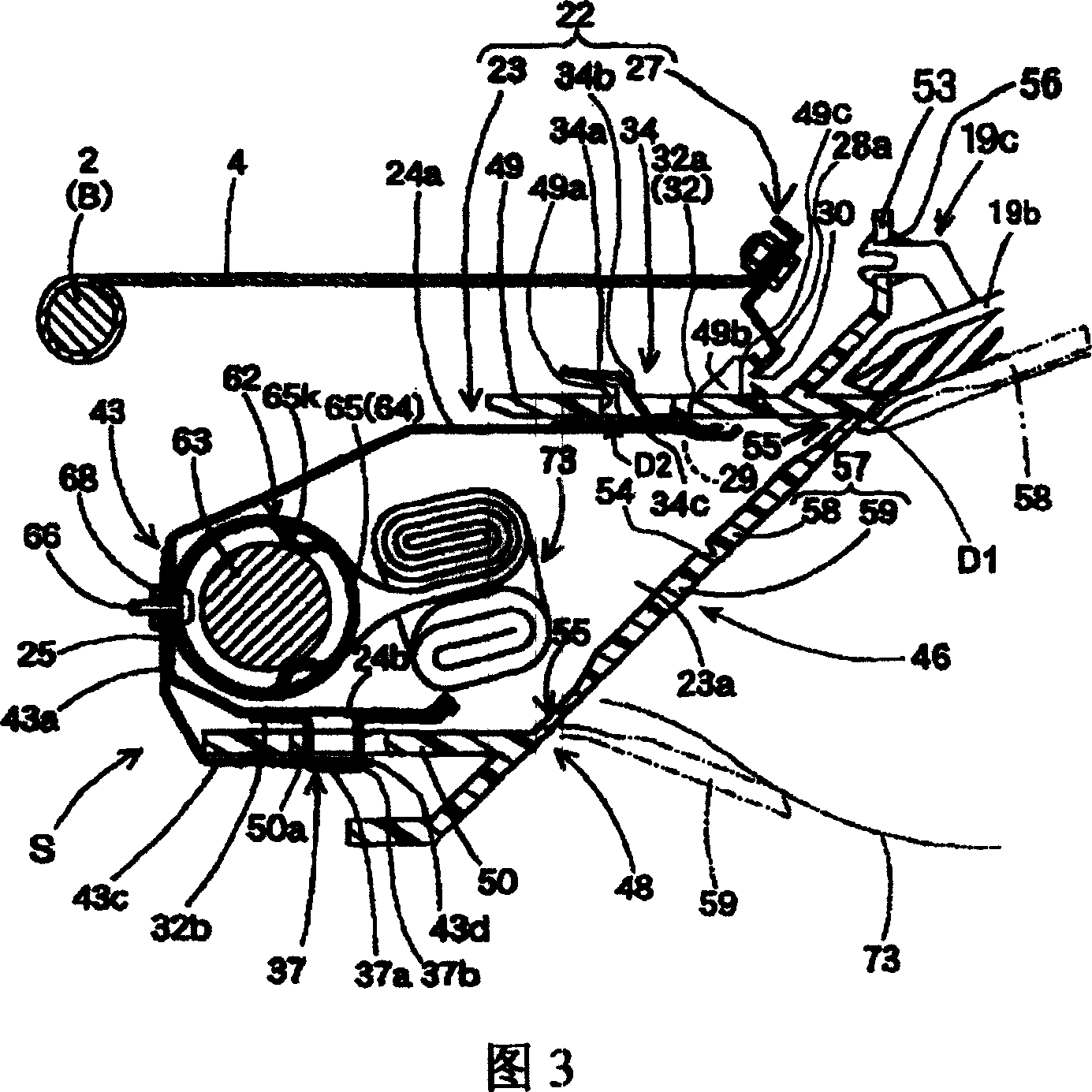

Knee protection air bag apparatus

InactiveCN101028808AExcellent designMovement restrictionsPedestrian/occupant safety arrangementLeft directionAerospace engineering

The present invention provides a knee protection air bag apparatus. In the knee protection air bag apparatus, the air bag cover is assembled to a case which stores therein an air bag and an inflator and also includes an opening formed in the vehicle backward direction portion thereof such that the air bag cover is movable with respect to the case in the vehicle back-and-forth direction, in the vehicle vertical direction and in the vehicle right and left direction and, at the same time, the air bag cover is mounted on its adjoining vehicle interior part (a lower panel). A projecting streak provided on the air bag cover regulates the movement of the air bag cover in the vehicle backward direction with respect to the case, whereby the expanding and developing power of the air bag can be properly transmitted to a breaking portion formed in the lid portion of the air bag cover.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com