Automatic feeding apparatus for button sewing machine

An automatic feeding and buttoning machine technology, applied in the field of buttoning machines, can solve problems such as damage, unstable feeding, poor adjustment ability, etc., and achieve the effect of preventing mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

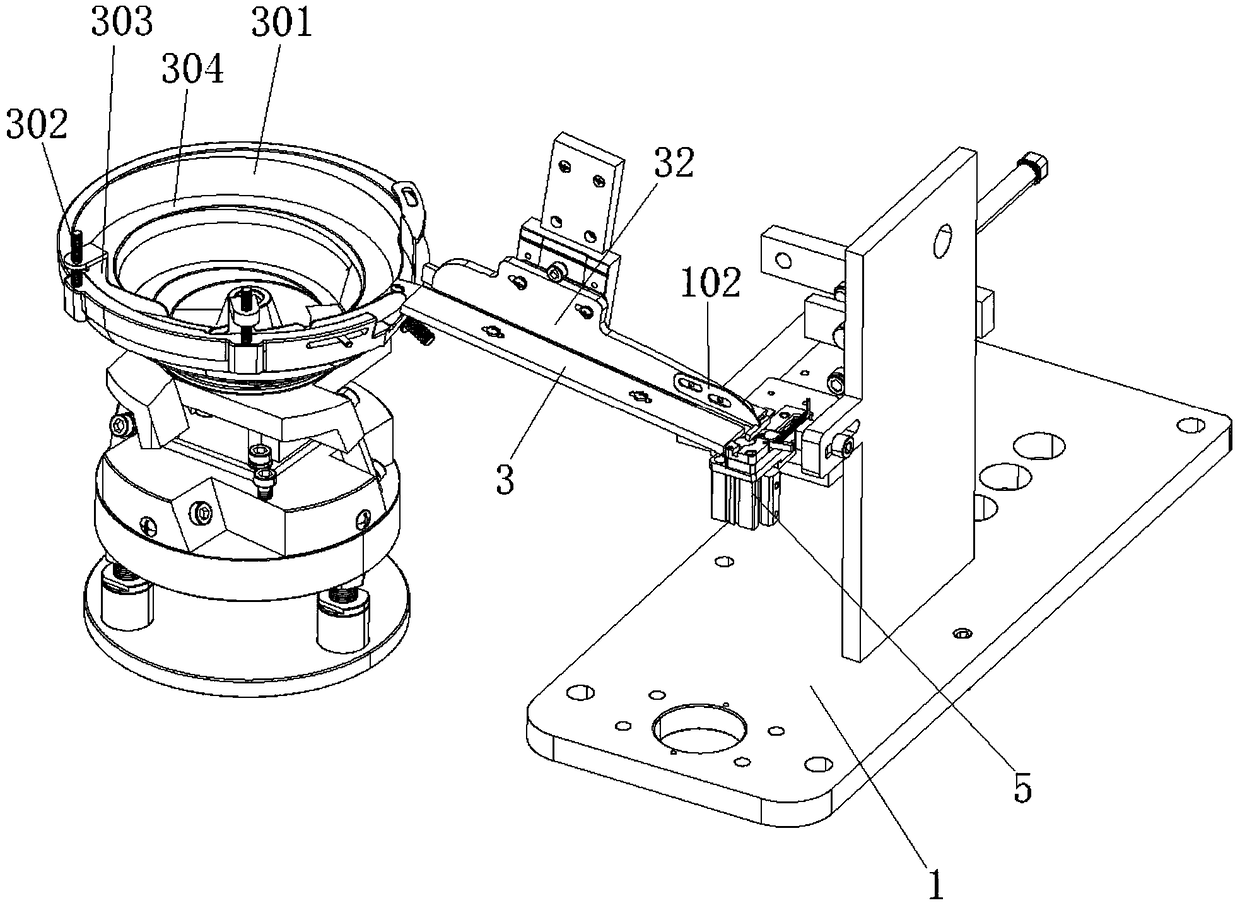

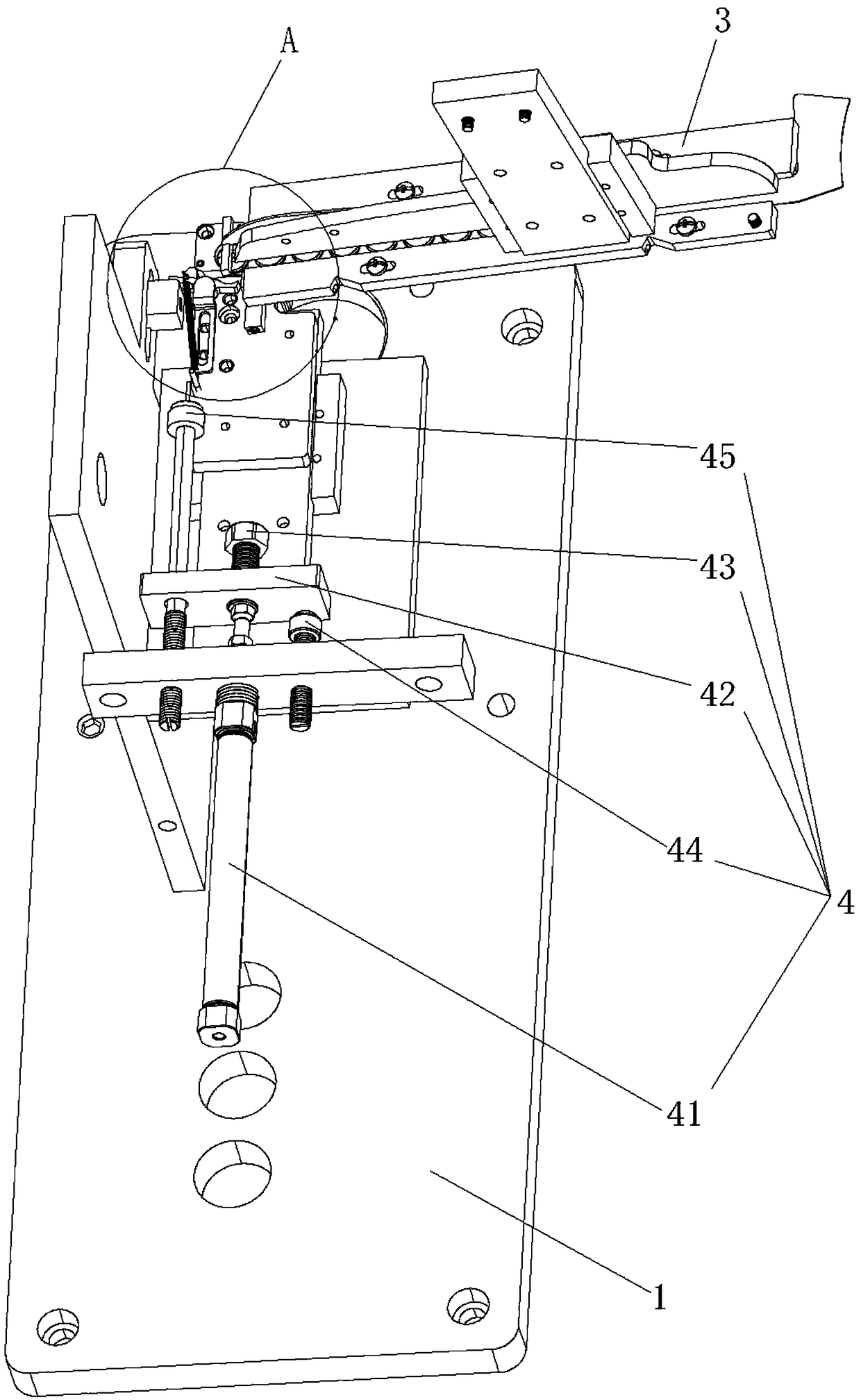

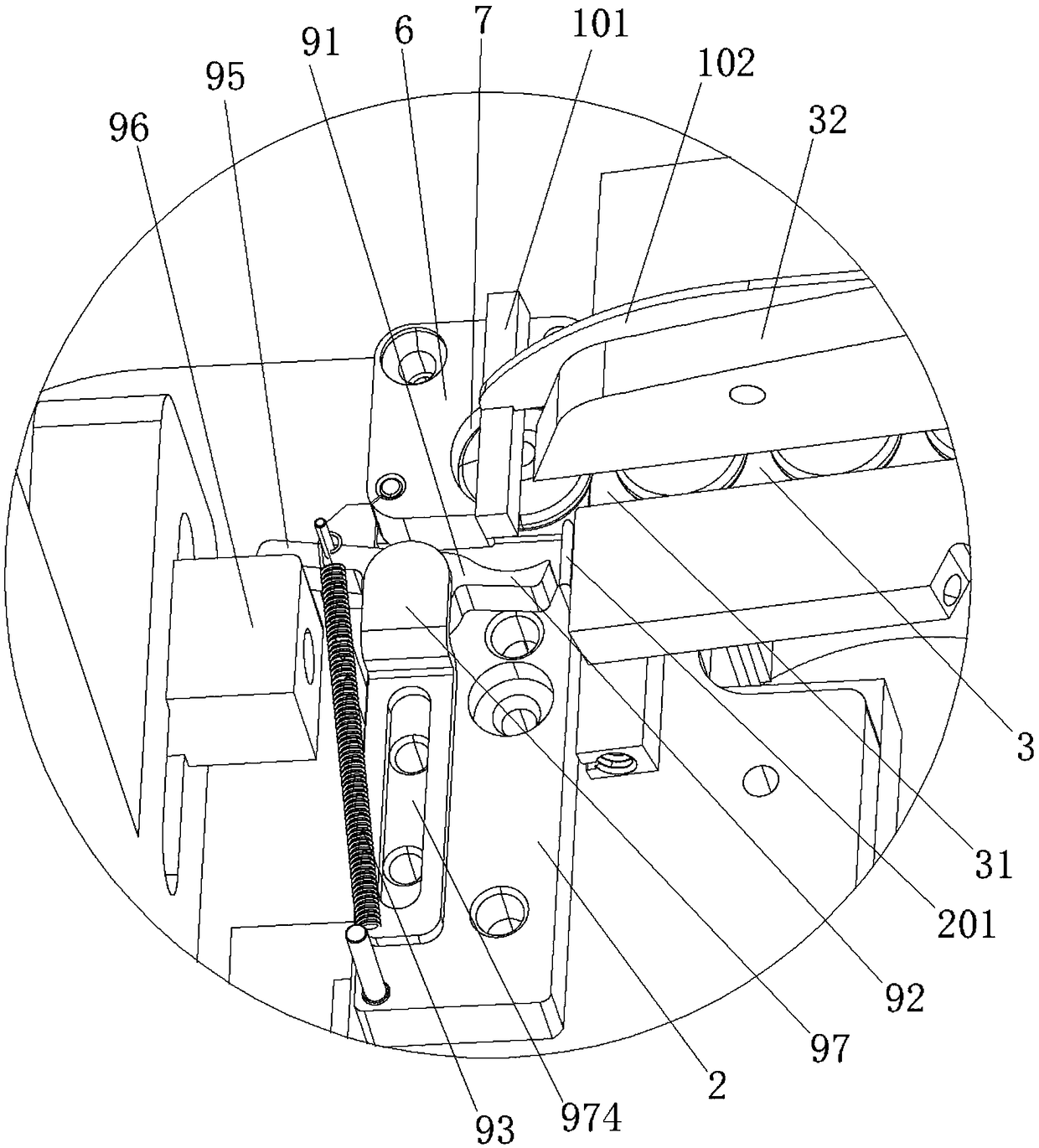

[0048] An automatic feeding device for a button sewing machine, comprising a frame 1, a feeding seat 2, a feeding track 3, a feeding seat pushing mechanism 4 for driving the feeding seat to reciprocate, and an upper cylinder 5, and the feeding seat 2 is provided with The positioning part 6 is formed with a positioning groove 7 on the positioning part 6, and the positioning groove 7 of the positioning part is provided with a workpiece anti-flying pressure strip 101, and the positioning groove 7 is provided with a feeding gap 8, and the side of the feeding gap is provided with The workpiece side clamping mechanism, the workpiece anti-flying pressure strip gives the workpiece pressure from top to bottom, and the workpiece side clamping mechanism gives the workpiece a radial pressing force, so that the workpiece is tightly attached to the side wall of the positioning groove 7, and the upper The top cylinder 5 is arranged below the positioning member, and the piston rod of the top c...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, the difference is that the workpiece longitudinal stabilization mechanism is an air blowing device arranged above the positioning groove, and the air blowing device blows air downwards to give the workpiece a downward force to prevent the workpiece from beat.

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 1, the difference is that the workpiece longitudinal stabilization mechanism is a pressing plate arranged on the feeding seat, and the entire pressing plate covers the feeding seat. At this time, the depth of the positioning groove in the positioning member is basically the same as The thickness of the workpiece is the same, so that the effect of longitudinal stability can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com