Pneumatic centering clamping and overturning mechanism for axle housing welding

A technology of flipping mechanism and clamping mechanism, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inability to adjust the outward expansion of clamping components, different sizes, inconvenient loading and unloading or clamping bridges Shell and other problems, to achieve the effect of convenient manual push, convenient storage or installation, and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

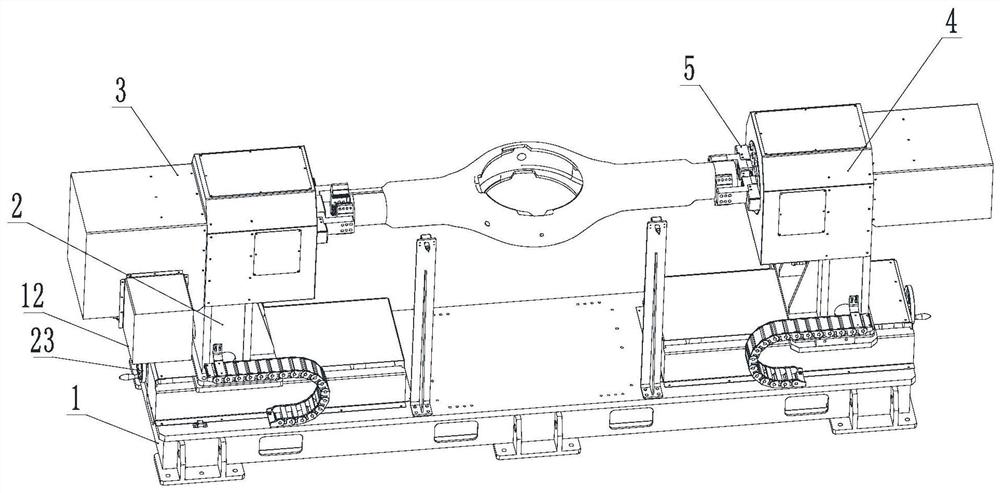

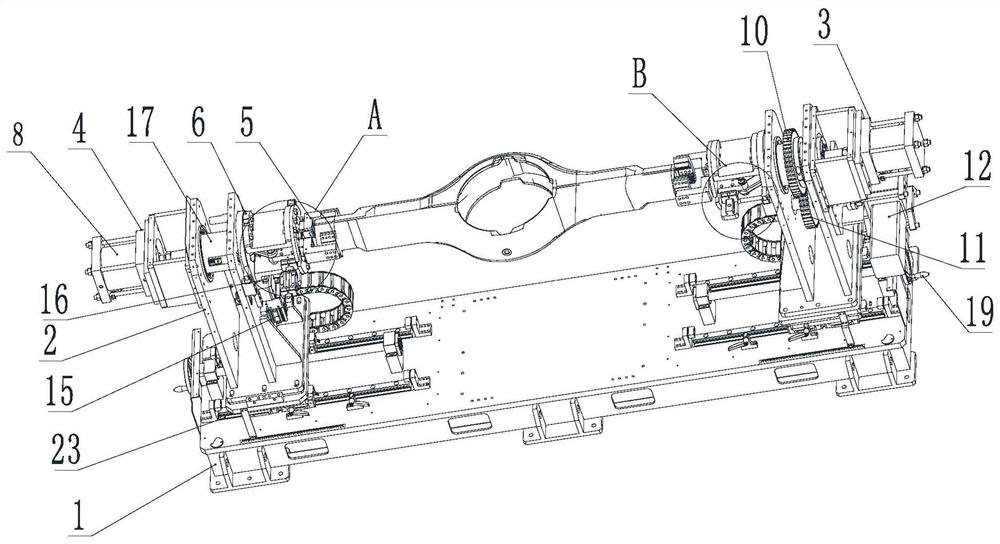

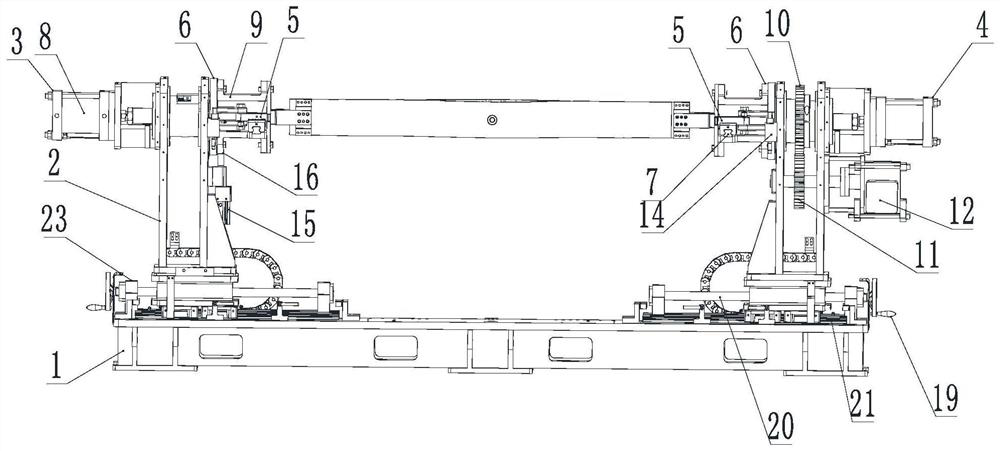

[0029] Such as figure 1 with figure 2 As shown, a pneumatic centering clamping and turning mechanism for axle housing welding, including a base 1, a support frame 2 is provided at both ends of the base 1, and a driving end clamping mechanism 3 is provided on one of the support frames 2 , the other support frame 2 is provided with a driven end clamping mechanism 4 that matches the driving end clamping mechanism 3; both the driving end clamping mechanism 3 and the driven end clamping mechanism 4 include The clamping device 5 active end clamping mechanism 3 that shell is used also comprises the overturning device 6 that overturns clamping device 5 usefulness, and clamping device 5 is connected with overturning device 6, and overturning device 6 is connected with support frame 2; Side is provided with slide rail 7, and slide rail 7 is slidably connected with clamping device 5, is all provided with the driving cylinder 8 that pushes clamping device 5 to slide on slide rail 7 on t...

Embodiment 2

[0032] This embodiment is carried out on the basis of embodiment 1, as Figure 2-4As shown, the active end clamping mechanism 3 also includes an overturning device 6, and the overturning device 6 includes an overturning frame 9 for the horizontal axis overturning clamping device 5. The overturning frame 9 is rotatably connected with the support frame 2, and an active Wheel 11 and driven wheel 10, also be provided with the driving device 12 that drives driving wheel 11 rotation usefulness on support frame 2 side, drive device 12 is connected with support frame 2, driven wheel 10 is connected with overturning device 6; And the secondary gear mechanism realizes clamping and drives the axle housing to rotate at the same time, realizing 360° no dead angle welding of the axle housing; when rotating, the driving device 12 can use a motor or a rotatable cylinder, and the driving device 12 drives the driving wheel 11 to rotate, and the driving device 12 can drive the driving wheel 11 to...

Embodiment 3

[0034] This embodiment is carried out on the basis of embodiment 2, such as Image 6 As shown, a block 13 is provided on the overturning frame 9, and the block 13 is connected with the overturning frame 9. On the support frame 2, a limit block 14 for matching the block 13 is provided, and the limit block 14 is provided with two , and the two limit blocks 14 are respectively horizontally and symmetrically arranged on both sides of the overturning frame 9, and the horizontally symmetrical limiting blocks 14 are arranged on both sides of the overturning frame 9. 9 Flip back and forth by 180°, and then flip the axle housing clamped by the clamping device 5 by 180°, and weld the other side of the axle housing to replace manual flipping and reduce the work intensity of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com