Component which conducts high-pressure medium

A technology for structural elements and high-pressure media, applied in pump elements, engine elements, components of pumping devices for elastic fluids, etc., can solve problems such as aggravation of the processing process, and achieve the effect of increasing temperature stability and reducing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

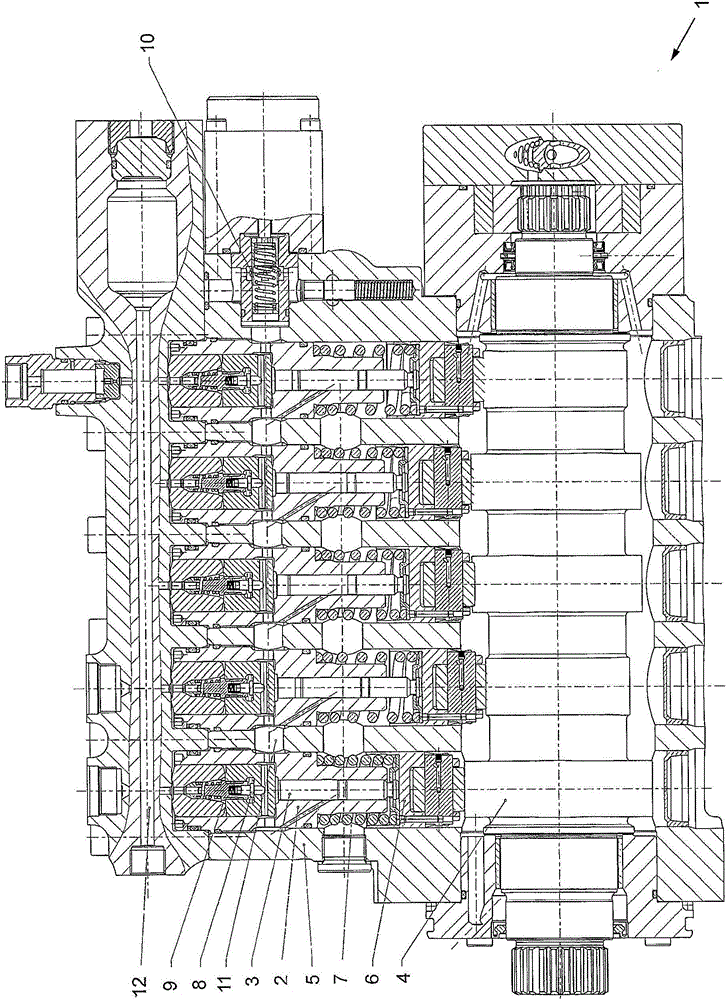

[0023] figure 1 The basic structure of a high-pressure pump 1 for a common rail injection system is shown, which has five pump elements consisting of a pump cylinder 2 and a pump piston 3 . A camshaft 4 driven by an internal combustion engine is mounted in a pump housing 5 and moves a pump piston 3 up and down in a pump cylinder 2 via a roller tappet 6 . The contact between roller tappet 6 and cam is maintained by compression spring 7 . During the downward stroke of the pump piston 3 , via the suction valve 8 , the fuel quantity determined by the metering unit 10 is suctioned out of the pump suction chamber 11 extending circularly around the pump element in the longitudinal direction of the pump housing and It is then pressed into the rail 12 via the pressure valve 9 during the upward stroke.

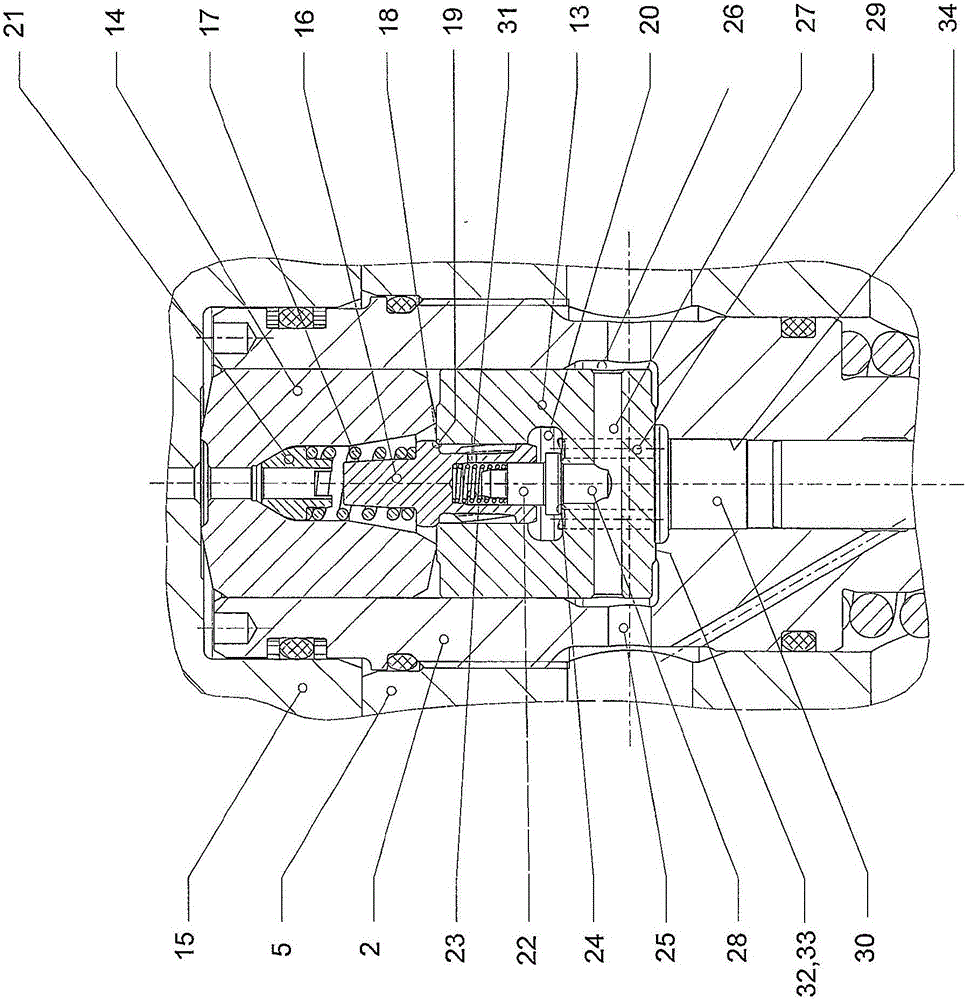

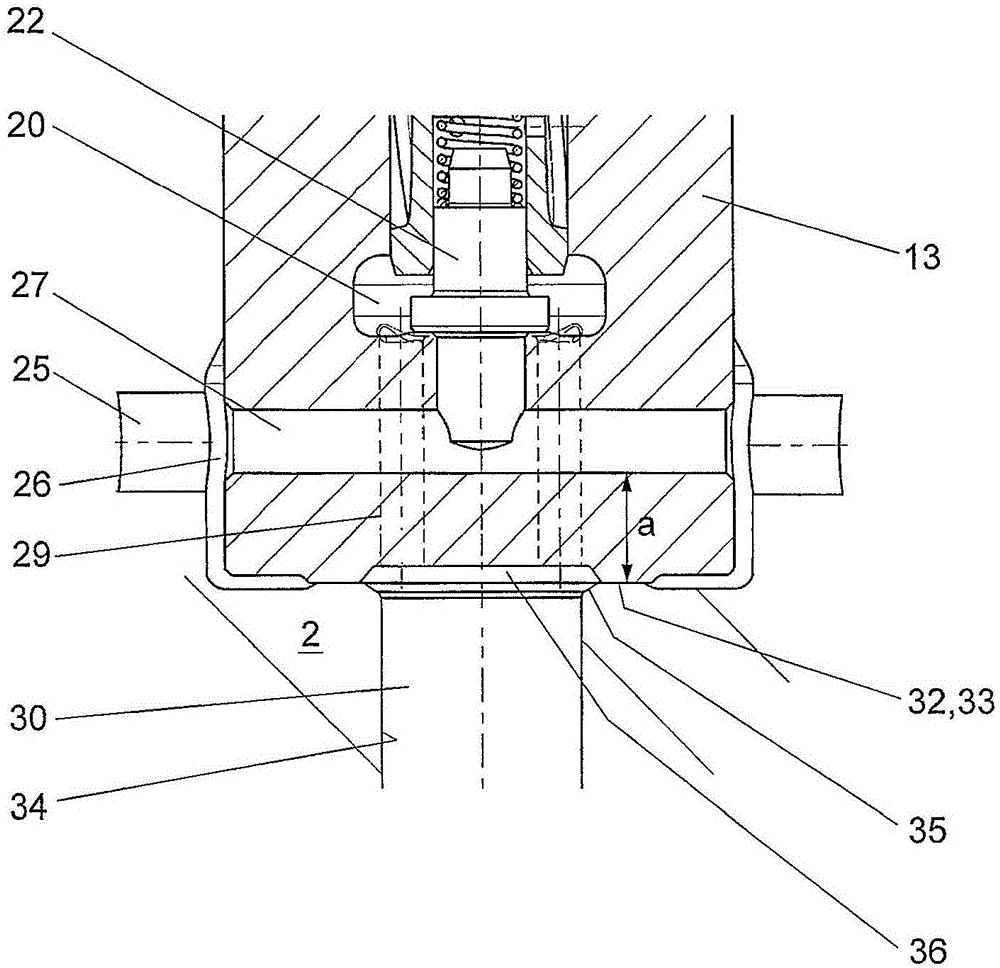

[0024] exist figure 2 A cross-section of a valve unit according to the prior art is shown in . Arranged in the upper region of the pump cylinder 2 is a valve carrier 13 and a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com