Piston-cylinder unit

A piston cylinder and assembly technology, which is applied to the direction of piston, piston ring, cylindrical piston, etc., can solve problems such as wear and stopper noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

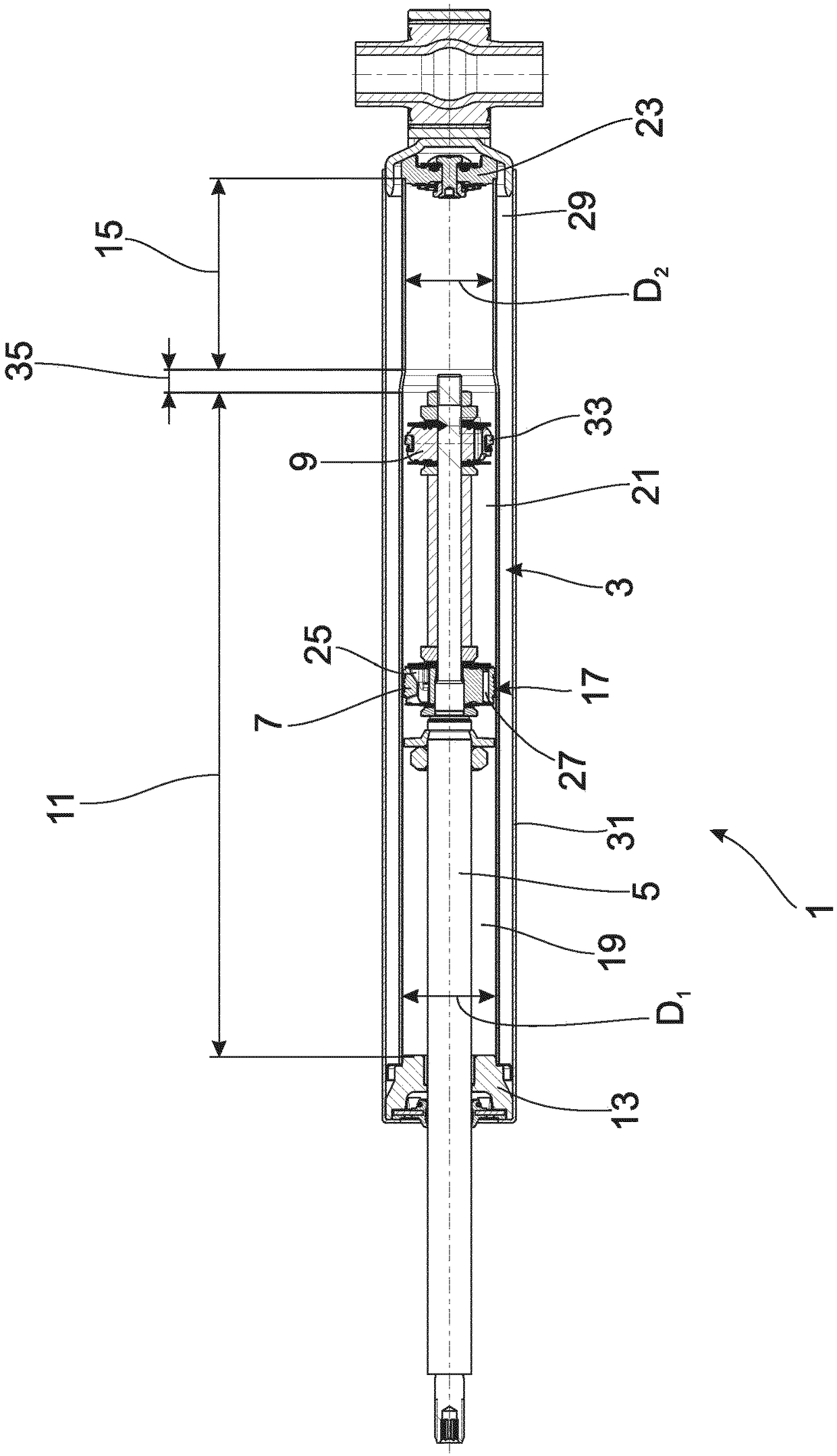

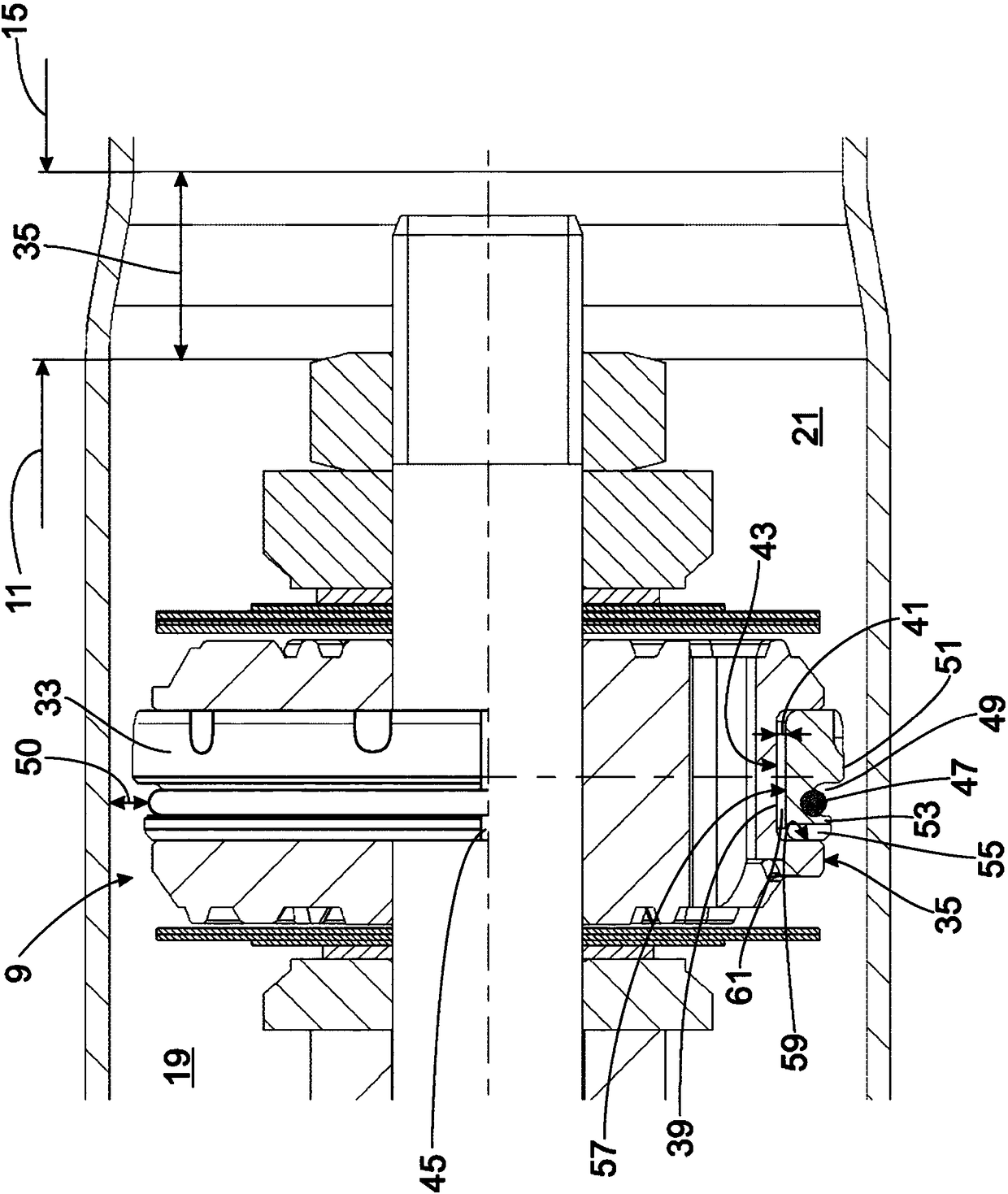

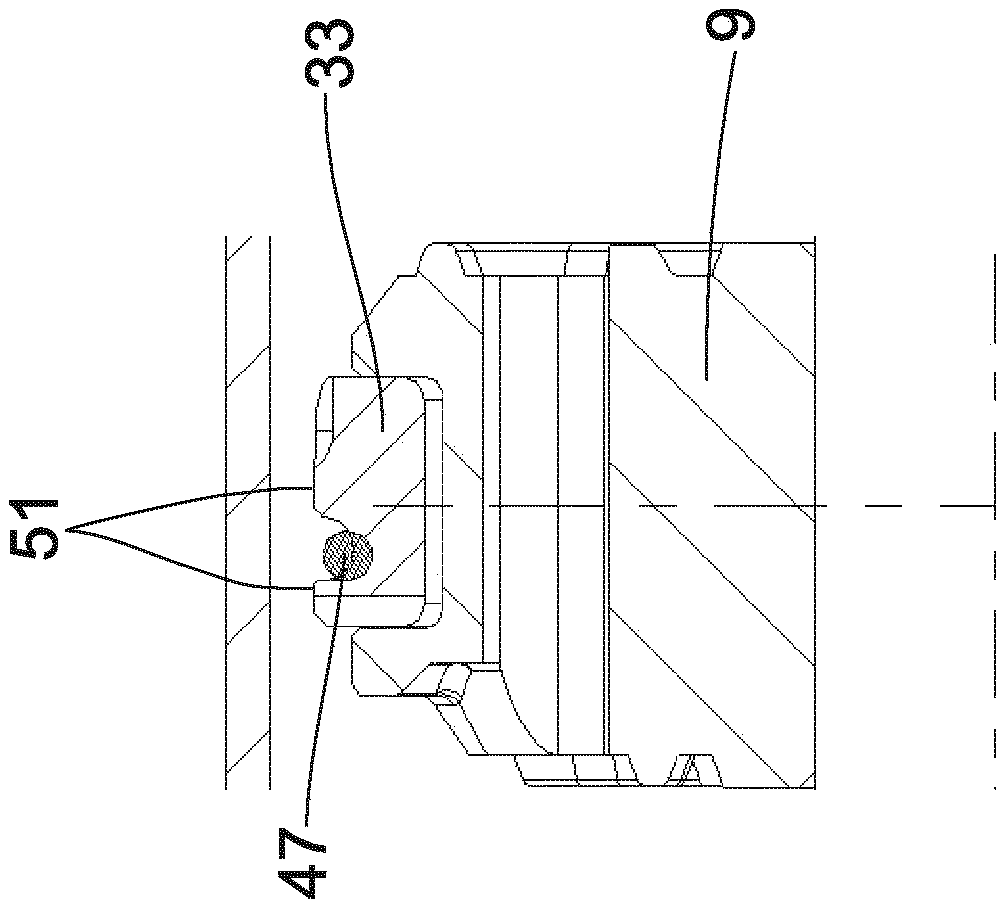

[0024] figure 1 is a possible implementation of the piston-cylinder assembly 1 according to the invention. A piston rod 5 is mounted axially displaceable on the cylinder 3 , on which piston rod a first piston 7 and a second piston 9 arranged at an axial distance therefrom are arranged. Usually, the arrangement of the two pistons 7 , 9 is fixed, but the invention can also be implemented with one or both pistons 7 , 9 displaceably mounted in the region of the piston rod 5 .

[0025] Said cylinder 3 comprises a first longitudinal section 11 having a first diameter D1. In this exemplary embodiment, the first longitudinal section 11 is closed at the end by a piston rod guide 13 . Adjacent at the opposite end is a second longitudinal section 15 having a second diameter D2 , wherein the second diameter D2 is smaller than the first diameter D1 .

[0026] The two pistons 7, 9 also have different nominal diameters. The first piston 7 is adapted to the larger diameter D1 of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com