Eye drop packaging bottle

A technology for packaging bottles and eye drops, which can be used in pharmaceutical packaging, packaging, packaged food, etc., and can solve problems such as poor control of the force, accidental eye damage, and eye drops overflowing the eyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

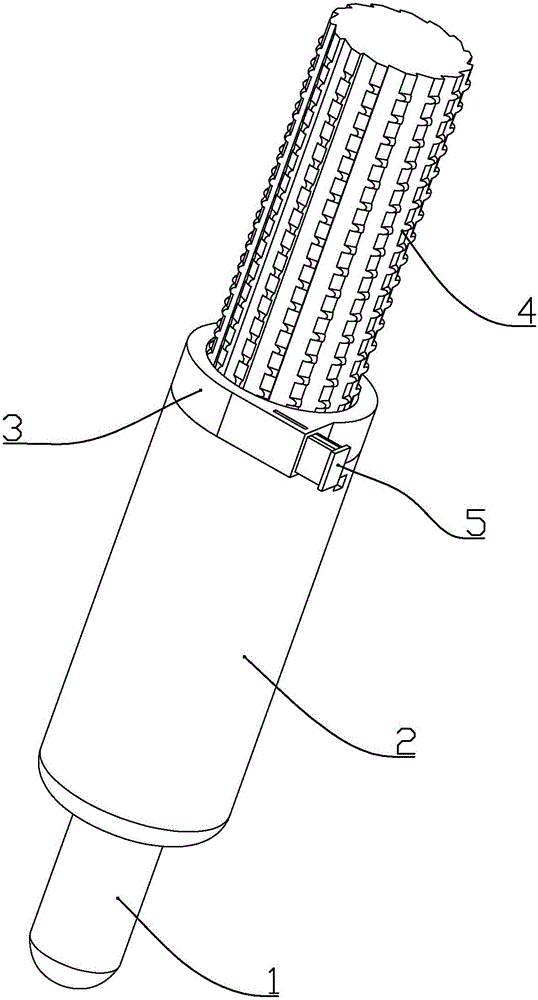

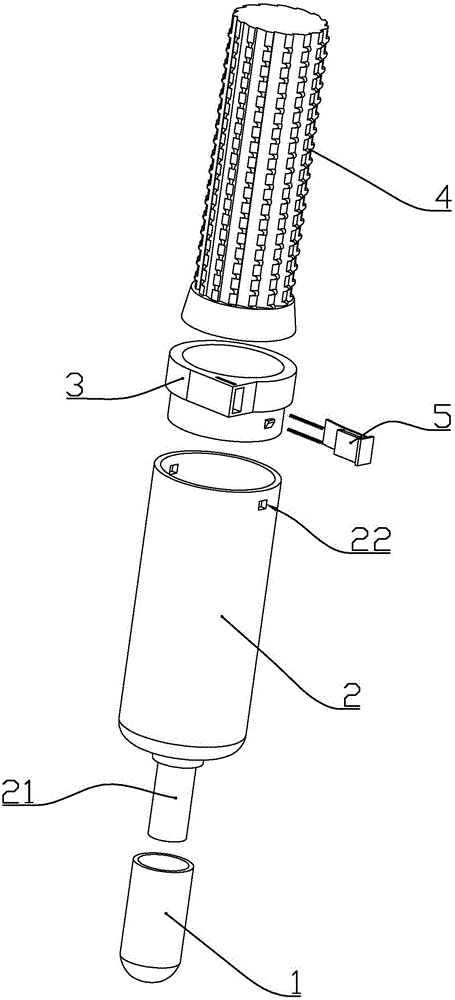

[0022] according to Figure 1 to Figure 7 As shown, a kind of eye drops packaging bottle described in the present embodiment is characterized in that: it comprises a cylindrical bottle body 2, a drip tube 21 is formed on the front end of the bottle body, and a bottle cap 1 is provided on the outer cover of the drip tube;

[0023] The rear end of the bottle body is open, and a piston assembly 4 is slidably connected in the bottle body;

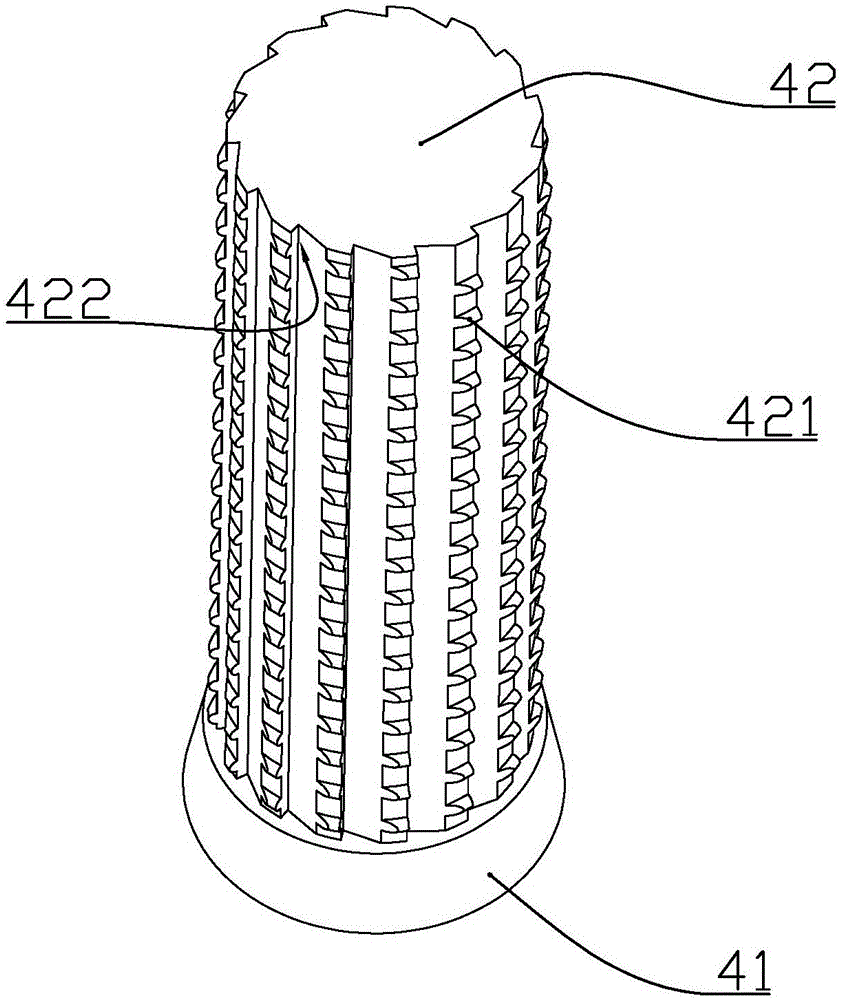

[0024] The piston assembly includes a piston body 41 slidably connected to the inner wall of the bottle, and a cylindrical piston rod 42 connected to the rear end of the piston body;

[0025] The outer wall of the piston rod is formed with an external thread 421; the piston rod is formed with a one-way pushing groove 422 along the length direction; the rear end of the bottle body is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com