Device for driving a pair of counter-rotating propellers by means of an epicyclic gear train

A technology of reverse rotation and propeller, applied in the direction of transmission, engine components, engine functions, etc. to drive multiple propellers, it can solve the problem of damaged teeth, etc., and achieve the effect of reducing size and cantilever, reducing internal force and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

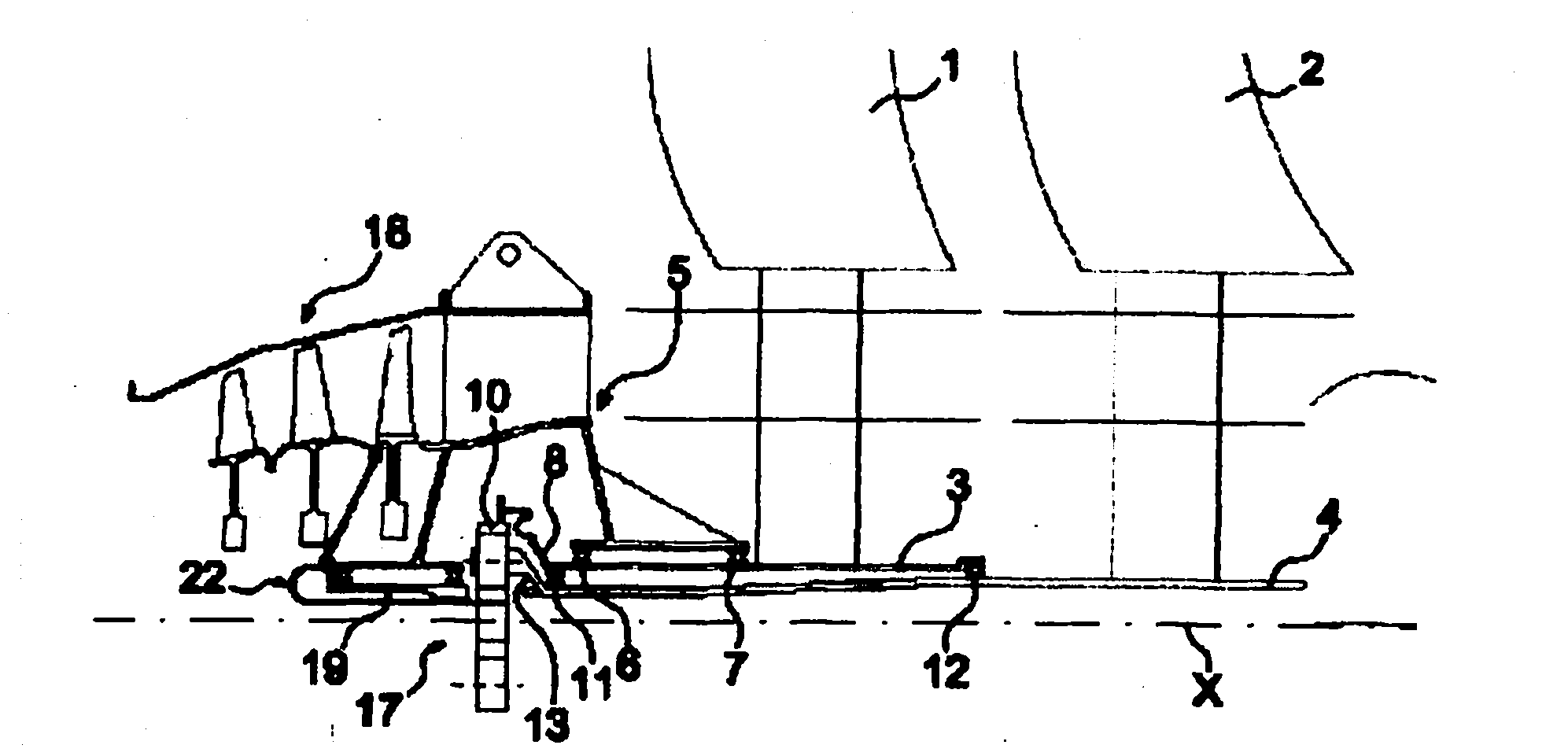

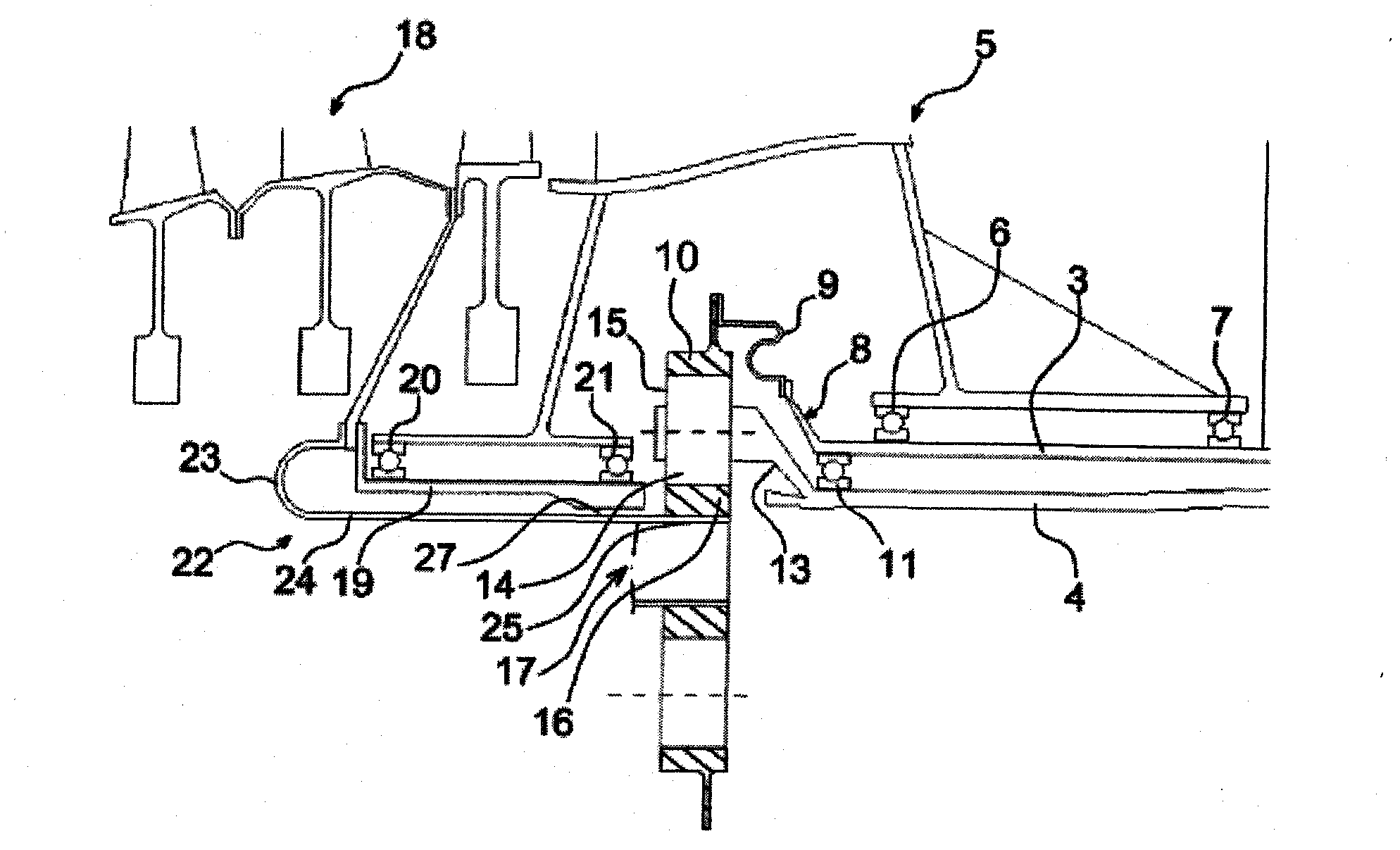

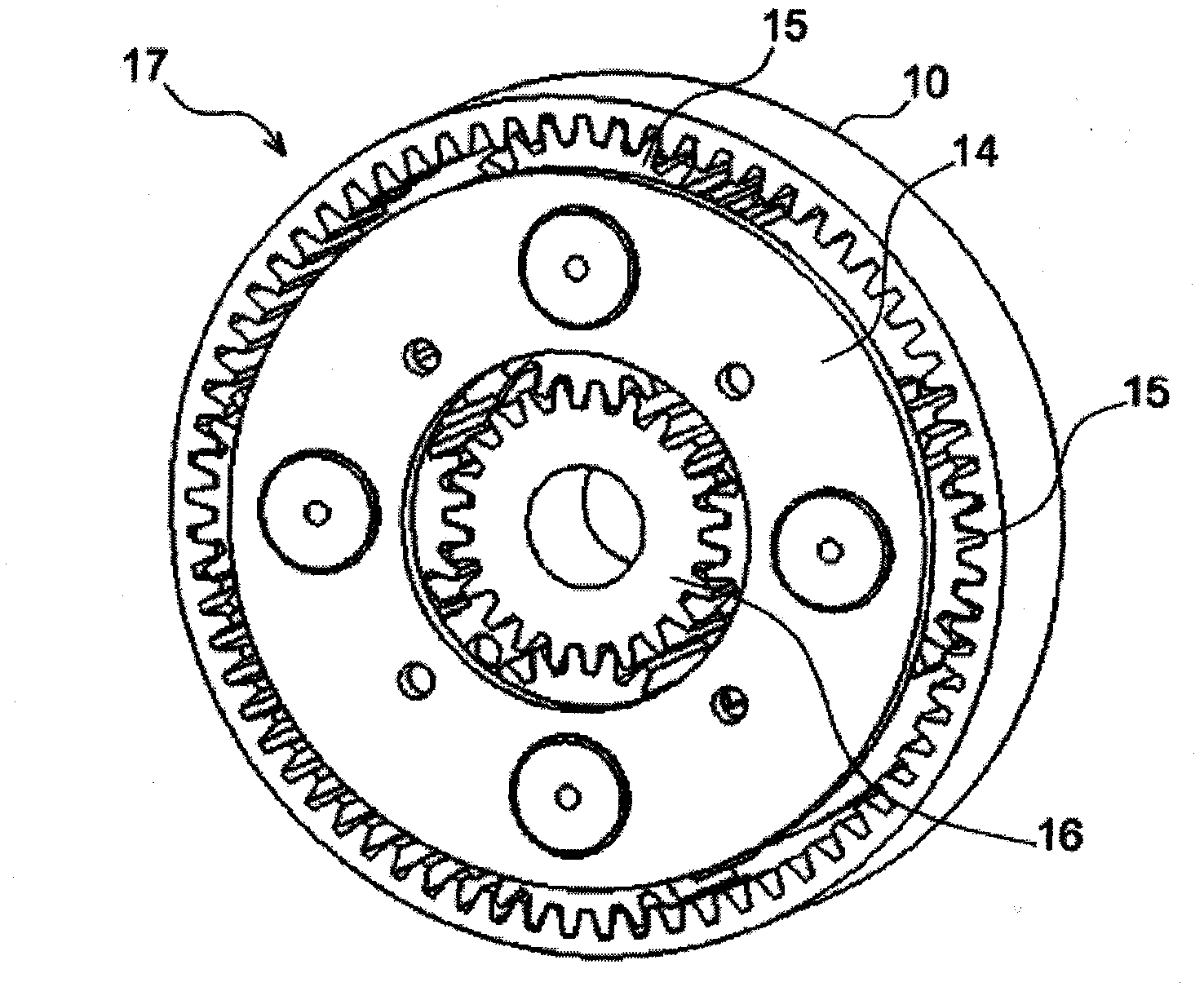

[0015] Referring to FIGS. 1 and 2 , the engine of the invention forms a unit comprising two propellers 1 , 2 each arranged to rotate about the same axis X. As shown in FIG. The upstream propeller 1 is mounted on the first hollow shaft 3 and the downstream propeller 2 is mounted on the second hollow shaft 4 . A first hollow shaft 3 is supported on a static housing 5 by means of a pair of bearings 6 and 7, beyond which the first hollow shaft 3 extends into a conical sleeve 8 with corrugations 9 and ends upwards There is a ring gear 10 with teeth formed on the inner surface. The second hollow shaft 4 is supported by the first hollow shaft 3 through two bearings 11 and 12, and the second hollow shaft 4 extends into a second conical sleeve 13 contained in the first conical Inside the sleeve 8 and connected to the pinion carrier 14 . The pinion carrier 14 has satellite gears 15 distributed around a circle meshing on the outer surface of the ring gear 10 and on the inner surface wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com