Lens barrel

A technology of lens barrel and rotating frame, applied in instruments, installation, optics, etc., can solve the problems of easy change in distance and creeping teeth between gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

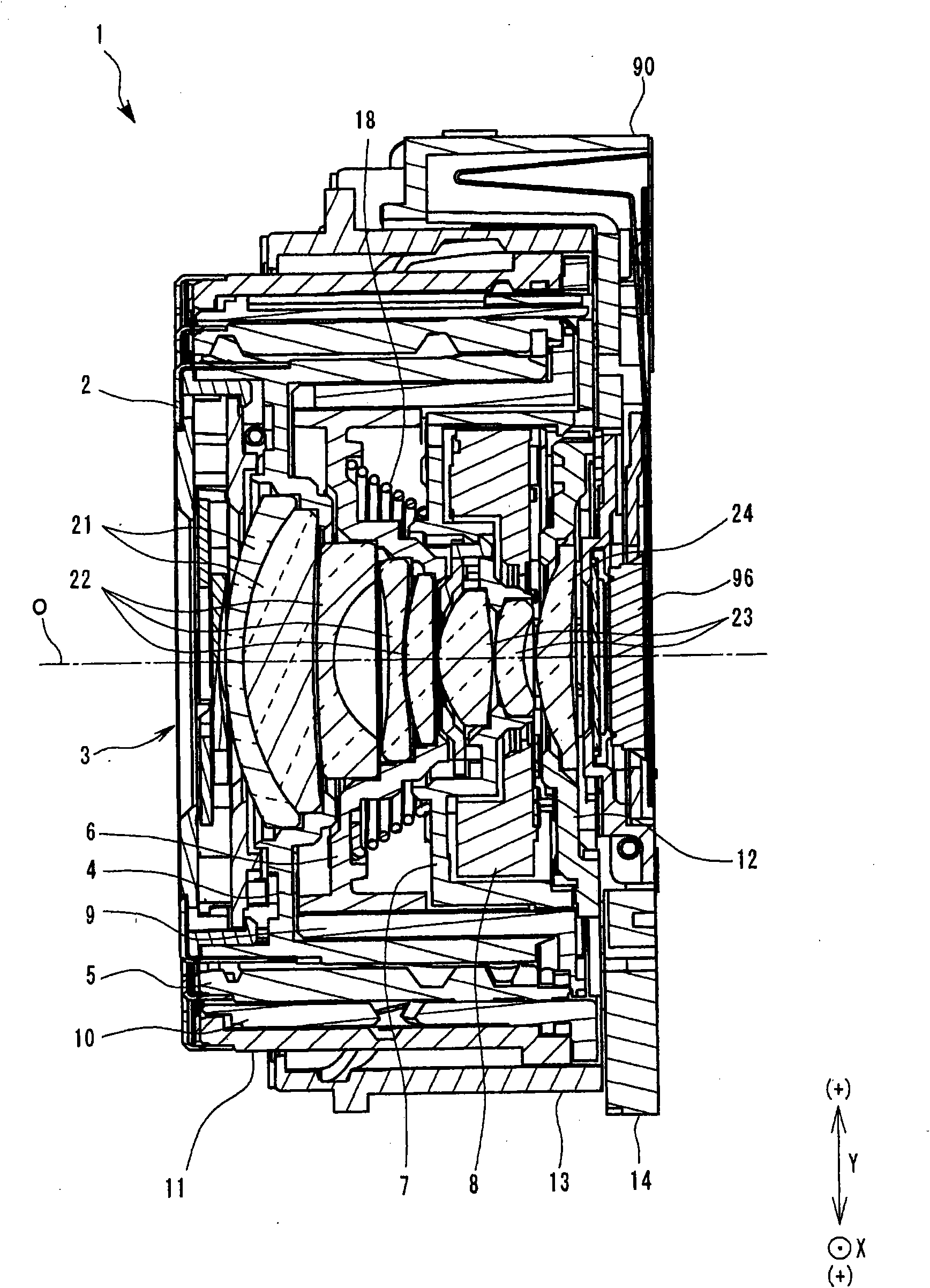

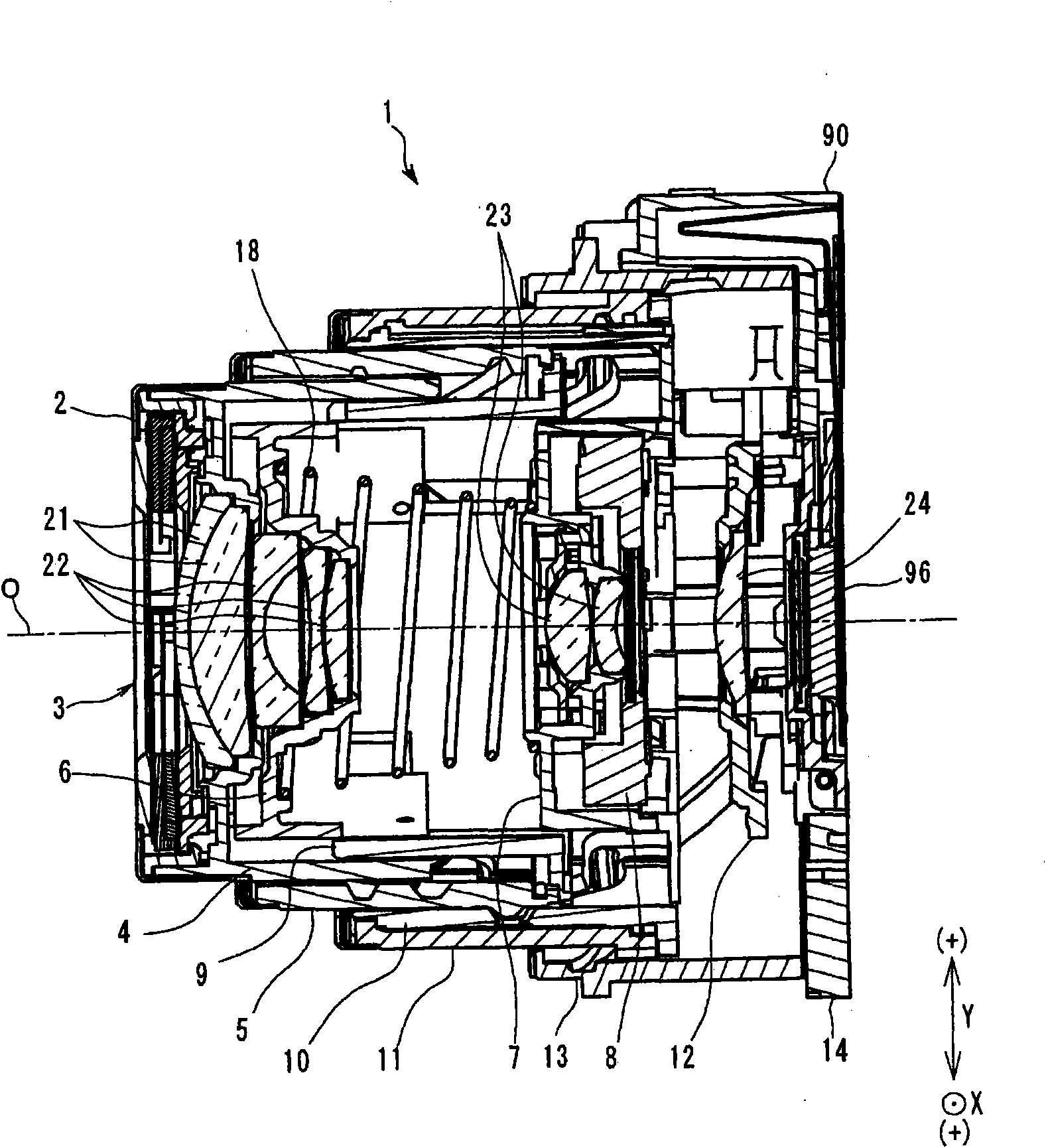

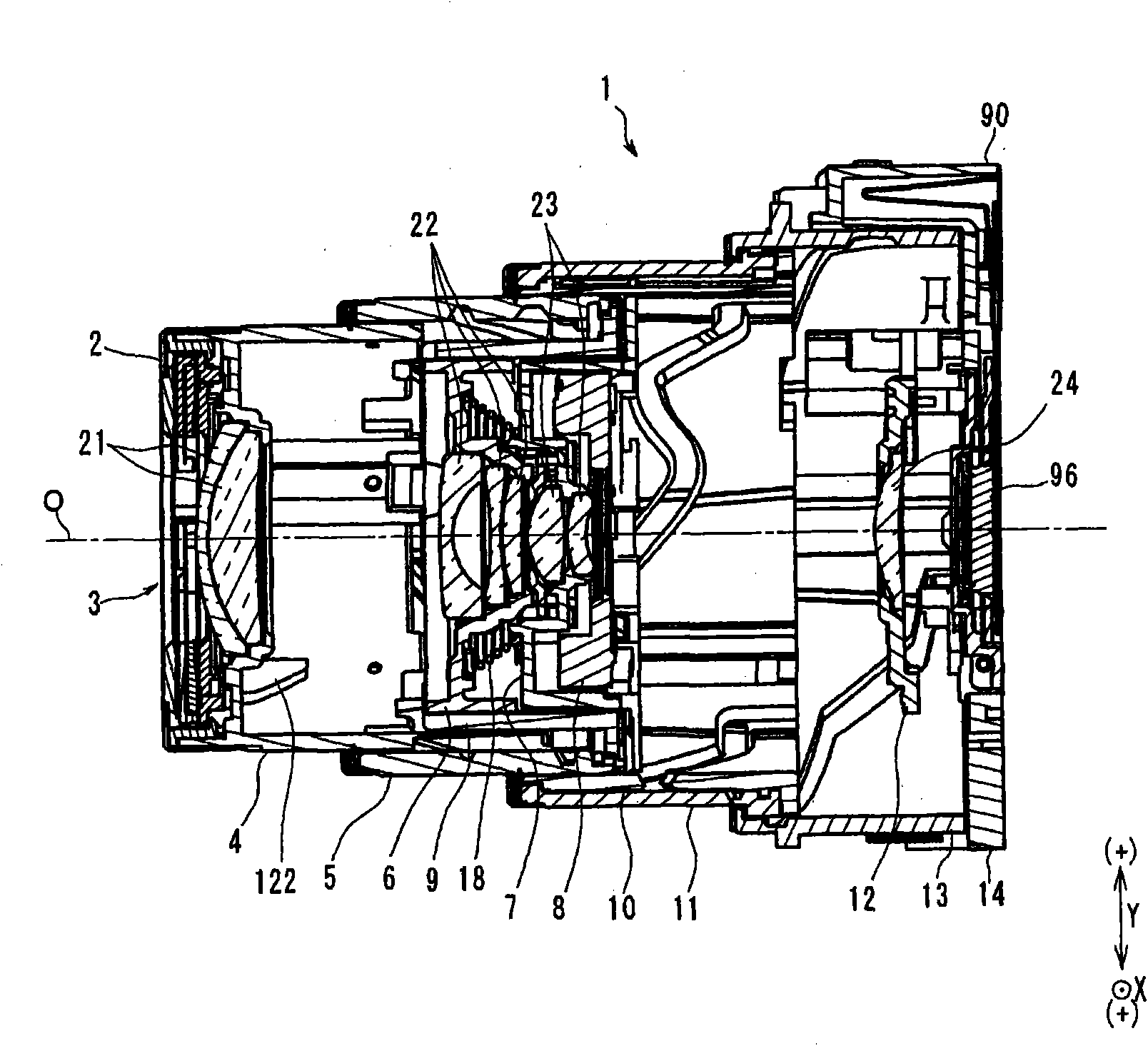

[0024] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. In addition, in each drawing used in the following description, in order to make each constituent element a recognizable size on the drawing, the scale is different for each constituent element, and the present invention is not limited to those shown in these drawings. The number of constituent elements, the shape of the constituent elements, the size ratio of the constituent elements, and the relative positional relationship of each constituent element are described.

[0025] Such as Figure 1 to Figure 3 As shown, the lens barrel 1 of the present embodiment is a device for holding a photographic optical system consisting of a first group lens 21 having a positive refractive power, a second group lens 22 having a negative refractive power, and a lens group having a negative refractive power. The four-group structure composed of the third group lens 23 with pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com