Mobile crushing device for graphite for manufacturing negative electrode materials for lithium batteries

A technology for pulverizing device and negative electrode material, applied in the field of graphite pulverizing device for mobile lithium battery negative electrode material, can solve the problems of increased construction cost, no commercial products, difficult graphite processing, etc., and achieves the effect of saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

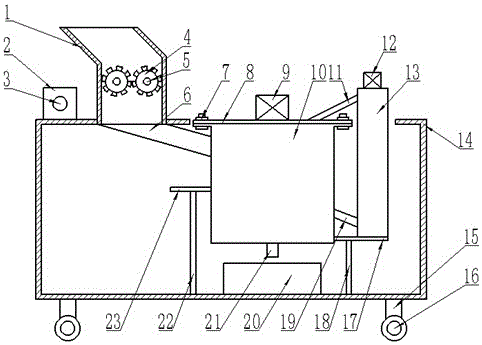

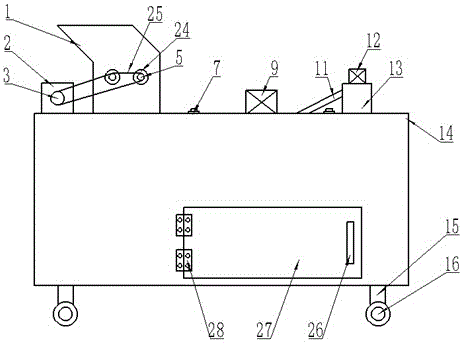

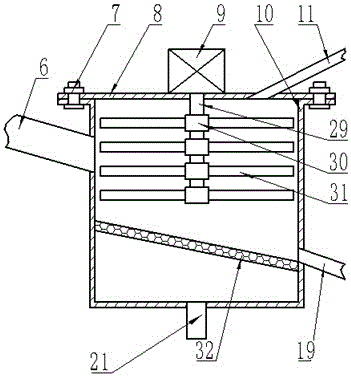

[0020] See Figure 1-4 , A mobile lithium battery negative electrode material graphite crushing device, including a primary feeding and crushing device and a secondary crushing and receiving device; the primary feeding and crushing device includes a feeding box 1, a first motor 2, a transmission shaft 3, a crushing rotary Wheel 4, rotating shaft 5, first guide tube 6, carrier box 14, wheel bracket 15, wheel 16, bearing seat 24, transmission belt 25, handle 26, cabinet door 27 and hinge 28; the carrier box 14 is welded to carry four The wheel support 15; the wheel support 15 is welded to the lower end surface of the carrier box 14; the wheels 16 are fixedly arranged on the wheel support 15, and the whole device is made mobile by moving the wheels 16; the feeding box 1 is welded to In the upper left side of the loading box 14; the bearing seat 24 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com