Multi-feed stirring equipment for animal husbandry

A feed mixing and animal husbandry technology, applied in feed, mixer accessories, mixers with rotary mixing devices, etc., can solve the problems of time-consuming, manual manual loading and unloading, and unbalanced livestock nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

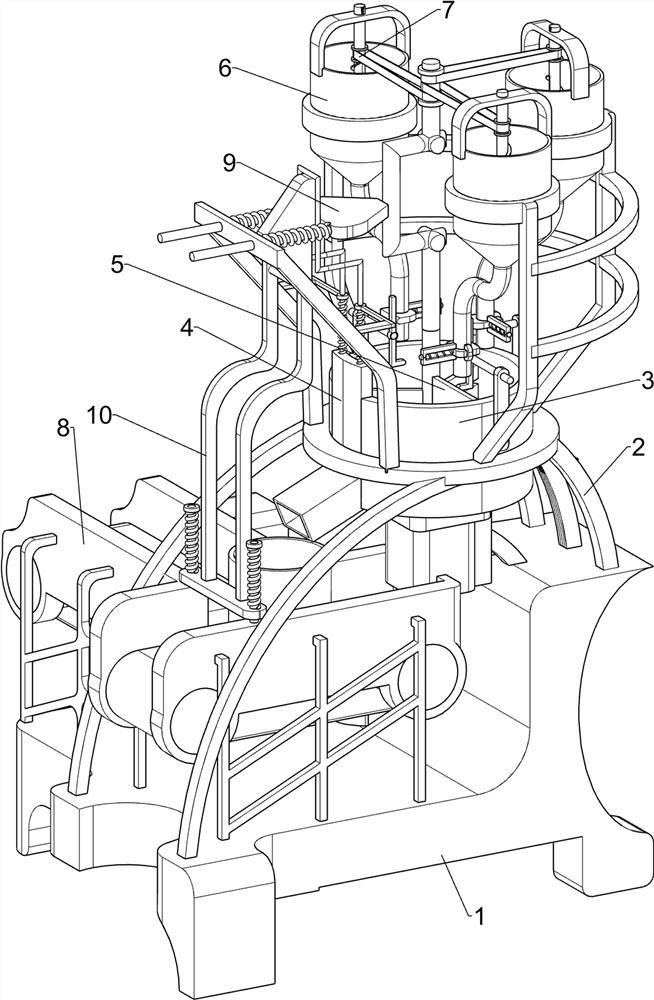

[0073] A variety of feed mixing equipment for animal husbandry, such as figure 1 As shown, it includes base plate 1, support 2, mixing barrel 3, baffle plate 4, stirring mechanism 5 and interval blanking mechanism 6, base plate 1 upper front side is provided with support 2, and support 2 is provided with stirring barrel 3, and stirring barrel 3 The left sliding type is provided with a baffle plate 4, a stirring mechanism 5 is provided between the bottom plate 1 and the mixing bucket 3, and an interval feeding mechanism 6 is provided between the bracket 2 and the mixing bucket 3.

[0074] When people need to stir the feed, they can use this variety of feed mixing equipment for animal husbandry. People put three different types of feed in the interval feeding mechanism 6, then start the stirring mechanism 5, and the movement of the stirring mechanism 5 drives The feeding mechanism 6 moves at intervals, so that the three feeds fall into the mixing tank 3, and the stirring mechani...

Embodiment 2

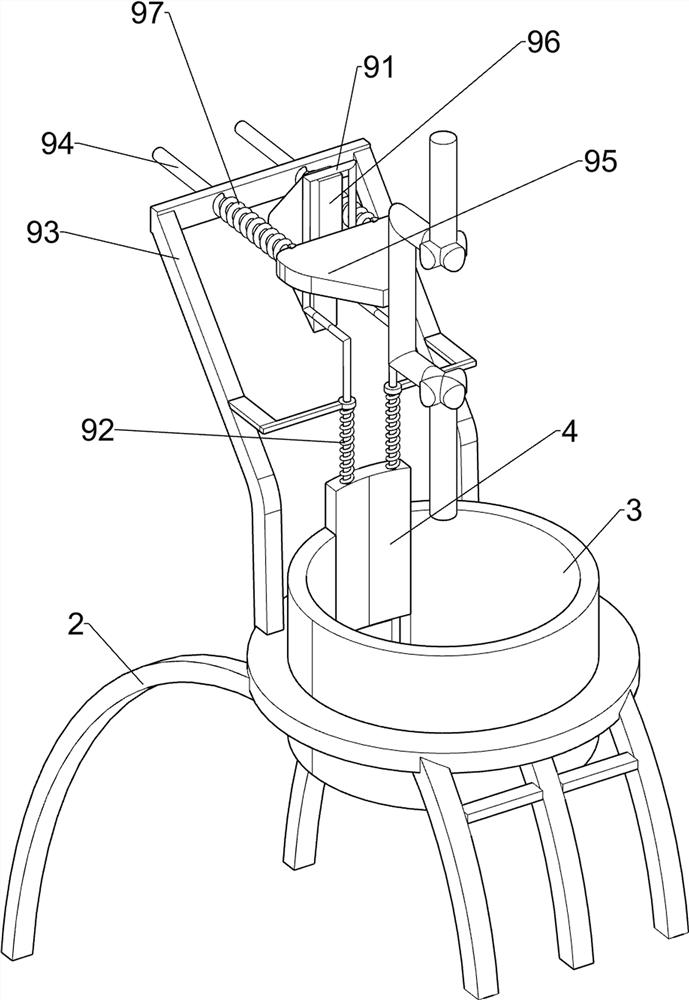

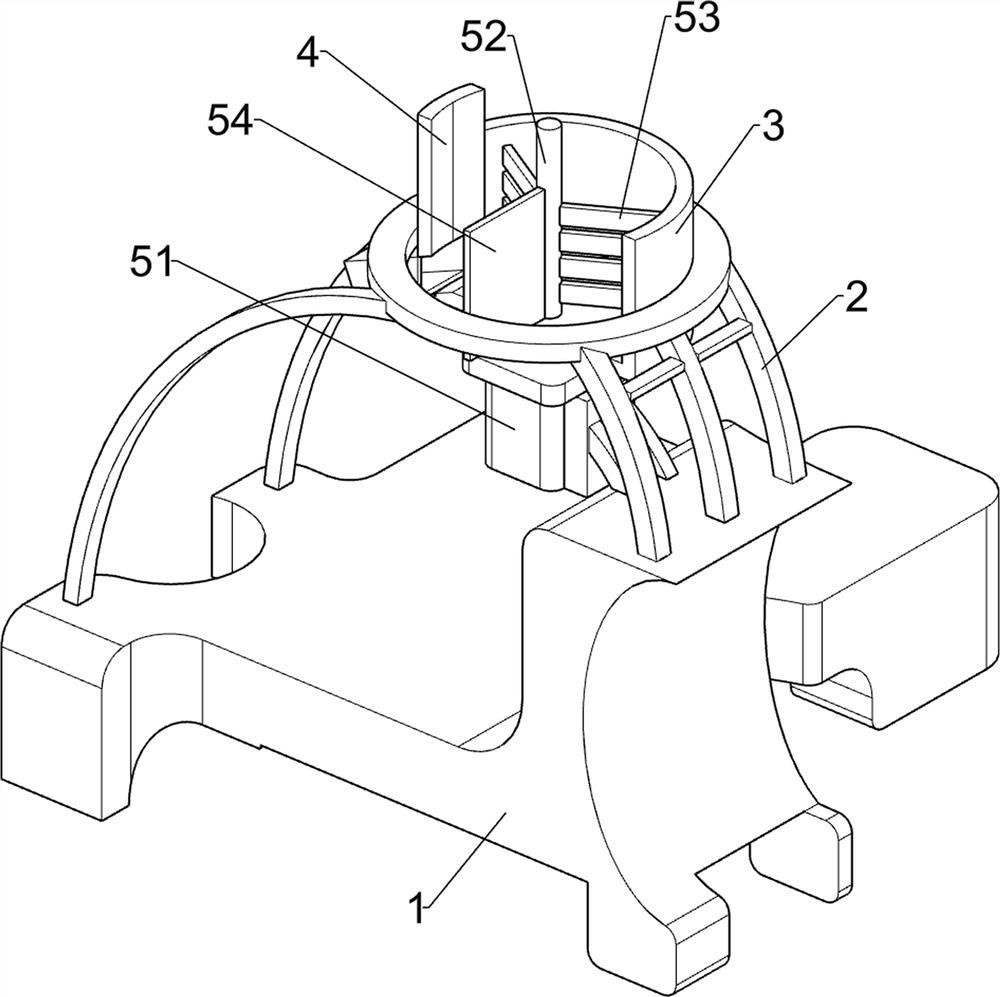

[0076] On the basis of Example 1, such as figure 2 and image 3 As shown, the stirring mechanism 5 includes a first servo motor 51, a first rotating shaft 52, a stirring plate 53 and a scraper 54. The first servo motor 51 is installed on the right side of the upper front part of the bottom plate 1, and the rotary device on the mixing bucket 3 There is a first rotating shaft 52, which is connected with the output shaft of the first servo motor 51, the left and right sides of the first rotating shaft 52 are provided with stirring plates 53, and the front side of the first rotating shaft 52 is provided with a scraper 54.

[0077] When the three different types of feed are placed in the interval feeding mechanism 6, people start the first servo motor 51, and the output shaft of the first servo motor 51 rotates to drive the first rotating shaft 52 to rotate, thereby driving the stirring plate 53 and the scraper 54 rotates, and the scraper 54 rotates to drive the 6 parts of the in...

Embodiment 3

[0081] On the basis of Example 2, such as Figure 4-7 As shown, anti-clogging mechanism 7 is also included, and anti-clogging mechanism 7 includes special-shaped rod 71, the third fixed block 72, threaded rotating shaft 73 and transmission belt 74, is connected with special-shaped rod 71 on the first rotating shaft 52, storage barrel 62 The third fixed block 72 is connected on the top, and the third fixed block 72 is rotatably connected with a threaded rotating shaft 73. Between the threaded rotating shaft 73 and the special-shaped rod 71, there are three transmission belts 74.

[0082] The first rotating shaft 52 rotates and drives the special-shaped bar 71 to rotate, thereby making the transmission belt 74 rotate, and then the threaded rotating shaft 73 rotates, and then the feed in the storage barrel 62 is stirred, preventing the feed from blocking the feed pipe 63.

[0083] Also include delivery mechanism 8, delivery mechanism 8 includes installation outer frame 81, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com